AER 89030 Owner's manual

Heating and Hot Water Solutions

AERCO International, Inc. • 100 Oritani Drive • Blauvelt, NY 10913

USA: T: (845) 580-8000 • Toll Free: (800) 526-0288 • AERCO.com

Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST

© 2022 AERCO

Condensate Neutralizer Tank Kit

Part Description

P/N:

Condensate Neutralization

Tank, 18 Liter (4.8 gal), with

x2 Unions and x2 Nipples

89030

Replacement Neutralization

Media (40 lbs.) for BMK,

INN, Recon, MFC (nat. gas

only), Modulex, and KC

89031

Replacement Neutralization

Media (25 lbs.) for AM

Series Boilers/Heaters

62801022

Condensate Neutralization Tank

For Neutralizing Condensate Waste from Gas

Burning Boilers & Water Heaters

Technical Instruction Document

Applies to the following AERCO models:

Benchmark Series

Innovation Series

Recon Series

MFC Series (natural gas only)

Modulex Series

AM Series (Maintenance only. For tank installation see O&M manual GF-146)

KC1000 Models

TID-0074_0H •8/22/2022

Disclaimer

The information contained in this manual is subject to change without notice

from AERCO International, Inc. AERCO makes no warranty of any kind with

respect to this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular application. AERCO International is

not liable for errors appearing in this manual, not for incidental or

consequential damages occurring in connection with the furnishing,

performance, or use of these materials.

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 2of 14

INTRODUCTION

The Condensate Neutralization Tank is used for neutralizing condensate from condensing boilers

that use natural gas or propane as fuel. Waste condensate, produced by the burning of these

fuels, is potentially harmful to the environment and can corrode unprotected piping systems. The

kit is used to neutralize the acidic PH of the condensate to ensure the harmful effects are

minimized.

Features and Benefits:

•Prevents acidic condensate from corroding pipes and sewer systems.

•Environmentally friendly.

•Fast and easy installation.

•Kit materials are made from corrosion resistant materials.

•For use on all types of Natural Gas and Propane appliances.

•Initial charge of neutralizer agent is included.

•Includes: baffles designed to channel flow thoroughly for complete neutralization, integral

bypass to prevent condensate backflow into appliance, NPT connections with unions for fast

and versatile installation.

INSTALLATION INSTRUCTIONS

NOTE: Check with your local water authority for regulations regarding discharge of treated

condensate into a drain or sewer system.

W A R N I N G !

RISK OF DAMAGE TO APPLIANCE!

Follow these instructions carefully to avoid damage to equipment and appliances.

The Condensate Neutralization Tank can be installed using either of the following methods:

•Neutralization tank is installed such that the inlet and discharge of the tank are at a lower

elevation than the AERCO condensate trap outlet. This can be achieved by:

a) Installing the Neutralization Tank in a pit (see Figure 2).

b) Elevating the AERCO boiler/water heater(s) and the AERCO condensate trap(s) (see

Figure 3).

•A condensate pump is used to lift the condensate from the appliance to the Neutralization

Tank (Figure 4).

Do not allow exhaust flue gases to vent through the Neutralization Tank. Flue gas leakage can

cause injury or death from carbon monoxide. Ensure the AERCO condensate trap is properly

installed with the boiler/water heater, upstream of the Neutralization Tank. See the boiler/water

heater installation manual for condensate trap installation instructions.

Connection to the appliance and Neutralization Tank must be installed to ensure that no

condensate backflow into the appliance can occur.

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 3of 14

TABLE 1: Condensate Neutralizer Tank Contents (P/N 89030)

Qty.

Description

1

18 liter (4.8 U.S. gallon) tank (1” FNPT inlet/outlet connections) and lid made from

polypropylene construction; comes filled with neutralization media (P/N 89031).

2

1” NPT PVC unions

2

1” NPT PVC close nipples

Each Neutralization Tank will neutralize condensate from appliances up to 6,400,000 BTU/hr

input. Table 1 lists the parts included in the Condensate Neutralization Kit (P/N 89030).

The neutralizer tank can be used for multiple appliance installation with a combined BTU/hr. input

not exceeding 6,400,000. See Tables 2 and 3 for selection guideline for all AERCO gas fired

products.

TABLE 2: Neutralizer Tank Application Chart (BMK, INN, MLX EXT)

AERCO Equipment

BTU/Hr. Input

Kit Qty Required

Eight (8) BMK750

6,000,000

1

Six (6) BMK1000

6,000,000

1

Four (4) BMK1500

6,000,000

1

Three (3) BMK2000

6,000,000

1

Two (2) BMK2500

5,000,000

1

Four (4) BMK2500

10,000,000

2*

Two (2) BMK3000

6,000,000

1

Four (4) BMK3000

12,000,000

2*

One (1) BMK6000

6,000,000

1

Eight (8) INN800

6,400,000

1

Six (6) INN1060

6,360,000

1

Four (4) INN1350

5,400,000

1

Eight (8) MLX EXT 802

6,416,000

1

Six (6) MLX EXT 962

5,772,000

1

Five (5) MLX EXT 1123

5,615,000

1

Four (4) MLX EXT 1530

6,120,000

1

Three (3) MLX EXT 1912

5,736,000

1

Two (2) MLX EXT 2295

4,590,000

1

Two (2) MLX EXT 2677

5,354,000

1

Four (4) MLX EXT 2677

10,708,000

2*

Two (2) MLX EXT 3060

6,120,000

1

Four (4) MLX EXT 3060

12,240,000

2*

* Use one (1) neutralizer tank for each pair of BMK 3.0/BMK 3000. Do not install

multiple neutralizer tanks in series.

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 4of 14

TABLE 3: Neutralizer Tank Application Chart (MFC Series)

AERCO Equipment

BTU/Hr. Input

Kit Qty Required

Two (2) MFC 3000

6,000,000

1

One (1) MFC 4000

4,000,000

1

One (1) MFC 5000

5,000,000

1

One (1) MFC 6000

6,000,000

1

One (1) MFC 8000

8,000,000

2**

One (1) MFC 10000

10,000,000

2**

** Neutralizertanks are tobe installed inparallel. Do not installmultiple neutralizer tanks in series.

Figure 1: Condensate Neutralization Tank (P/N 89030) Dimensions

The inlet connection (6.5") is higher than the outlet connection (6.3"). Set the neutralization tank

on a secure and level base. Connections to the appliance and neutralization kit must be installed

to ensure that no condensate backflow can occur. Connect appliance condensate drain to the

inlet using corrosion resistant piping. Do not route the condensate line through any area that is

exposed to freezing temperatures. If traffic poses a risk, install some protection to prevent

movement and/or damage. Mount as per installation diagram. Ensure that no air pockets will

remainor form in the pipingand that the condensate willflow freelyfrom theappliance condensate

drain into the tank and then to the drain. Access to the discharge is necessary for proper

maintenance in order to check the effectiveness of the neutralizing media, using pH test strips.

If there is no gravity drain available or if the boiler/water heater cannot be elevated to be higher

than the Neutralization Tank, install a condensate removal pump designed for use on condensing

boilers and furnaces (Figure 4).

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 5of 14

The condensate pump must be equipped with an over flow switch to prevent the appliance from

running should a failure occur. The over flow switch must be wired to the Remote Interlock of the

AERCO boiler/water heater I/O Box for KC1000, Innovation, and Benchmark units (see Figure 8);

or, for Modulex units, on Pins 3 and 4 of Connector I on Modulex E8 controller (see Figure 9).

NOTE:

For Modulex boilers, an over flow switch may only be utilized in Indoor/Outdoor Reset and

Constant Set Point modes of operation.

It cannot be utilized in 0 to 10 Volt Remote Set Point mode and when a BMS II is used.

To utilize an overflow switch, set the Modulex boiler to Standby mode ( ). To set the boiler

to Standby mode, close the swing-down front panel door of the E8 and turn the wheel counter-

clockwise until the Standby symbol ( ) is displayed. With pins 3 and 4 closed, the Standby

symbol, and others in the display, will be blinking. This indicates that the boiler is enabled.

When the connection is broken between pins 3 and 4, the Standby symbol, and others in the

display, will stop blinking indicating that the boiler is disabled. Closing/breaking pins 3 and 4

not only start/stops the boiler but also start/stops other pumps (boiler water pumps) wired to

the Modulex boiler.

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 6of 14

Figure 2: Multiple Boiler Units with Tank (P/N 89030) Placed in a Pit

Minimum Pit Depth

BOILER MODEL

DIM. A (MIN. PIT DEPTH)

BMK1500/2000

1-1/4"

BMK2500/3000

1"

BMK 4000/5000N

2"

Use Figure 2 and the above table for installations where a boiler pad no thicker than 4" is desired.

For models not shown in this table: the condensate neutralizer can be installed on the floor while

the boiler is installed on a 4 inch pad.

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 7of 14

Figure 3: Elevated Multiple Boiler Units with Tank (P/N 89030)

NOTE: The condensate neutralizer tank inlet and outlet ports must be lower than the boiler

condensate outlet.

Minimum Boiler Pad Height

BOILER MODEL

DIM. A (MIN. BOILER PAD HEIGHT)

BMK1500/2000

5-1/4”

BMK2500/3000

5”

BMK 4000/5000N

6”

Use Figure 3 and the above table for installations where a pit cannot be constructed for the

condensate neutralizer tank. For models not shown in this table: the condensate neutralizer can

be installed on the floor using a 4 inch pad.

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 8of 14

Figure 4: Multiple Boiler Units with Tank and Condensate Pump (P/N 89030)

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 9of 14

Figure 5: MFC 3000: Dual Boiler Units with Condensate Neutralizer Tank (P/N 89030)

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 10 of 14

Figure 6: MFC-4000 –6000: Single Boiler Unit with Condensate Tank (P/N 89030)

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 11 of 14

Figure 7: MFC8000 –10000: Single Boiler Unit with Two Condensate Tanks (P/N 89030)

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 12 of 14

mA OUT

RS-485

COMM. +

-

+

-

ANALOG IN

SENSOR COMMON

OUTDOOR SENSOR IN REMOTE INTL'K IN

B.M.S. (PWM) IN

SHIELD

+

-

+

-

(AIR) AUX SENSOR IN

NOT USED

EXHAUST SWITCH IN

DELAYED INTL'K IN

FAULT RELAY

120 VAC, 5A, RES

AUX RELAY

120 VAC, 5A, RES

G

RELAY CONTACTS:

120 VAC, 30 VDC

5 AMPS RESISTIVE

DANGER

120 VAC USED

IN THIS BOX

NOT USED NOT USED

NC

COM

NO

NC

COM

NO

NOT USED

0 –10V

AGND

Figure 8: BMK, KC, and INN I/O Box Wiring for Overflow Switch Relay Connection

(REMOTE INTL’K IN)

Figure 9: Modulex E8 Controller Wiring for Overflow Switch Relay Connection

(Pins 3 & 4 of Connector I)

Pins

4 - 3

Overflow Switch

Relay Connections

Modulex Connector I

NOTE:

Remove the jumper between

the two “REMOTE INTL”K IN”

terminals before connecting

the Overflow Switch Relay.

Overflow Switch

Relay Connections

REMOTE INTL’K IN

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 13 of 14

OPERATION

The appliance condensate will flow through the neutralizing media, raising the condensate pH to

a level that will help prevent corrosion of the domestic drain and the public sewer system.

MAINTENANCE

Monitor the level of the neutralization media in the tank periodically. The pH can be checked after

the condensate has exited the tank or by removing the lid and taking a sample from the last

chamber before the outlet. Check the pH level every three months forthe first year. Use a suitable

pH test strip paper or an electronic pH meter for precise measurement. The frequency of checking

the pH levelcanbe reduced toevery sixmonthsorevery yeardependingon thereadingsobtained

compared to local water authority requirements. The neutralizing media should be replaced when

the pH level drops below the minimum level of the local water authority. For replacement media

contact your local AERCO sales representative.

•Replacement neutralization media for KC, BMK, INN, Recon, MFC, and Modulex series

models is P/N 89031.

•Replacement neutralization media for AM Series models is P/N 62801022.

At delivery, the replacement media comes in two clear plastic bags; a smaller one inside the

bigger (Figure 10). The larger bag consists of larger pieces of neutralization material, while the

smaller bag consists ofsmaller pelletsof neutralization material. Replenish thetank with the larger

material, then sprinkle the smaller pellets on top.

Figure 10: Condensate Neutralization Tank Replacement Media (In Bags)

LIMITED WARRANTY

The unit is warranted against defects in materials and workmanship for one year.

Bag Inside

Containing

Smaller Pieces

of Media

Inside

Bag Containing

Larger Pieces

of Media

Condensate Neutralization Tank User Instructions

TID-0074_0H •8/22/2022 Technical Support •(800) 526-0288 •Mon-Fri, 8 am - 5 pm EST Page 14 of 14

Change Log:

Date

Description

Changed By

11/13/2019

Rev F:

DIR 19-71 –Updated overall format; Updated Figure 3.

Linley Thobourne

8/22/2022

Rev G:

Added BMK 4000 & 5000N to tables.

Lisa Weiss

© AERCO International, Inc., 2022

Table of contents

Popular Boiler Supplies manuals by other brands

Grant

Grant SpiraVac WPVKIT5POD Installation & user's instructions

Immergas

Immergas 3.018911 quick start guide

Immergas

Immergas Victrix Superior KW X Warnings and instruction sheet

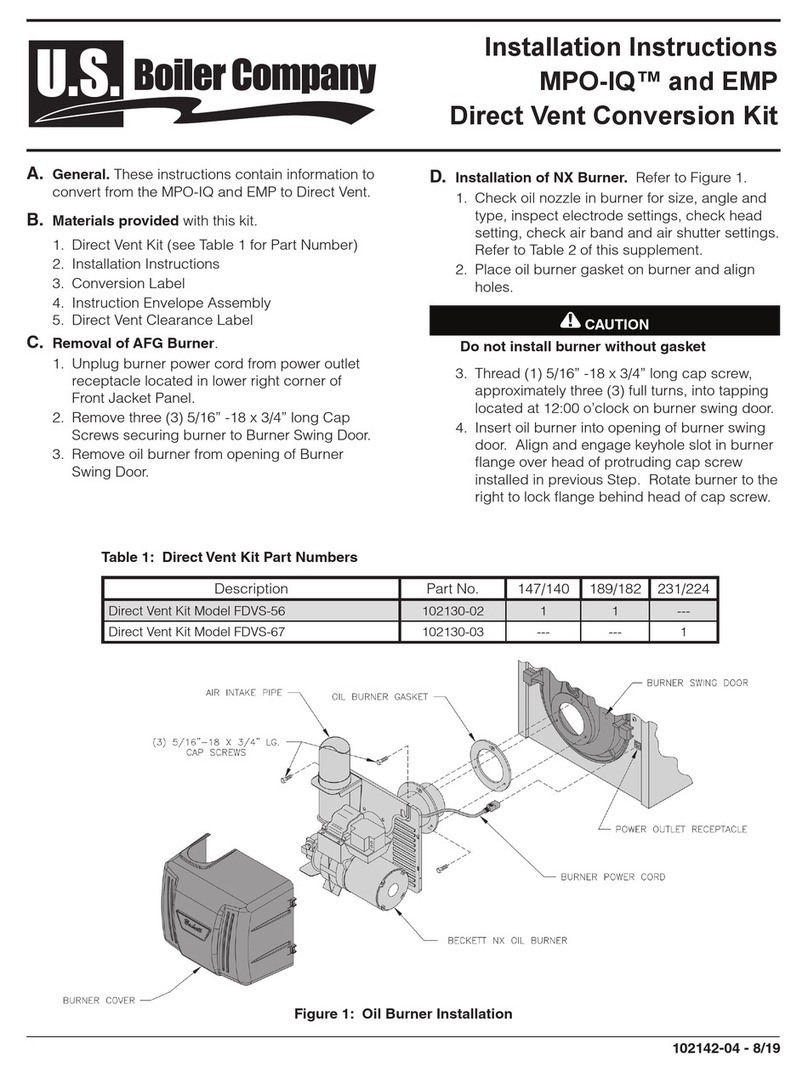

U.S. Boiler Company

U.S. Boiler Company FDVS-56 installation instructions

Xylem

Xylem McDonnell & Miller 51 Series instruction manual

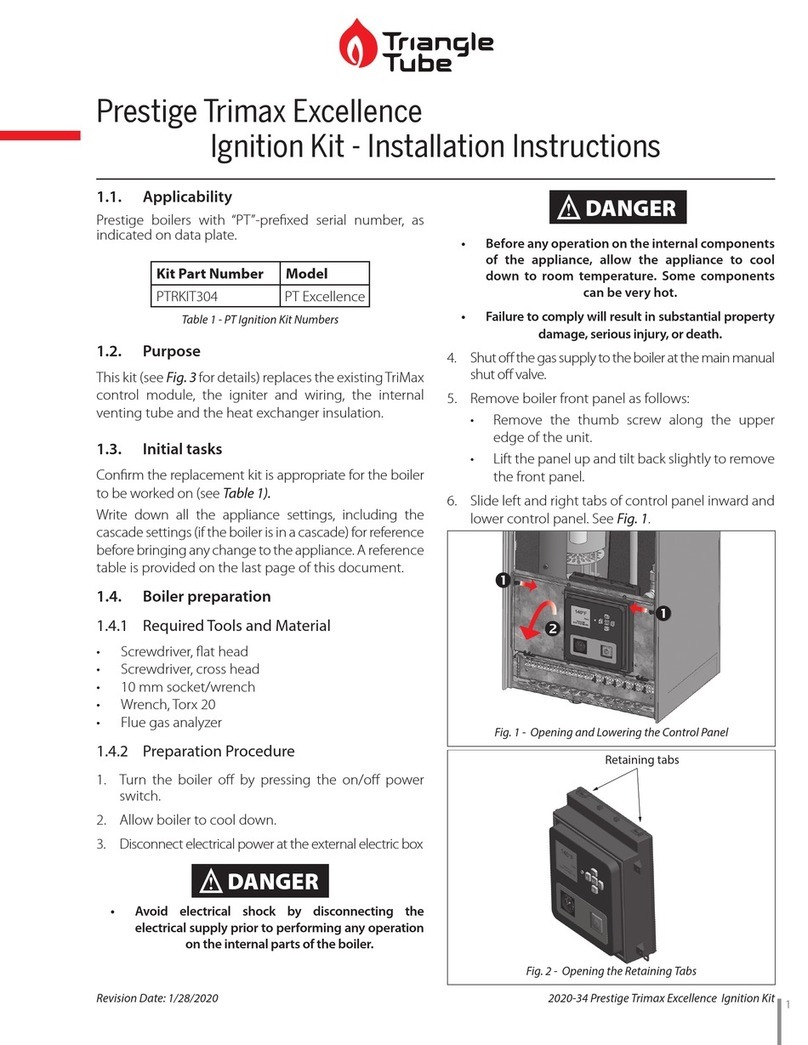

TriangleTube

TriangleTube PTRKIT304 installation instructions