Aero-motive 14111 User manual

Other Aero-motive Car Spares manuals

Aero-motive

Aero-motive 13209 User manual

Aero-motive

Aero-motive 11203 User manual

Aero-motive

Aero-motive 11209 User manual

Aero-motive

Aero-motive 11107 User manual

Aero-motive

Aero-motive 11105 User manual

Aero-motive

Aero-motive 14115 User manual

Aero-motive

Aero-motive 11801 User manual

Aero-motive

Aero-motive 17147 User manual

Aero-motive

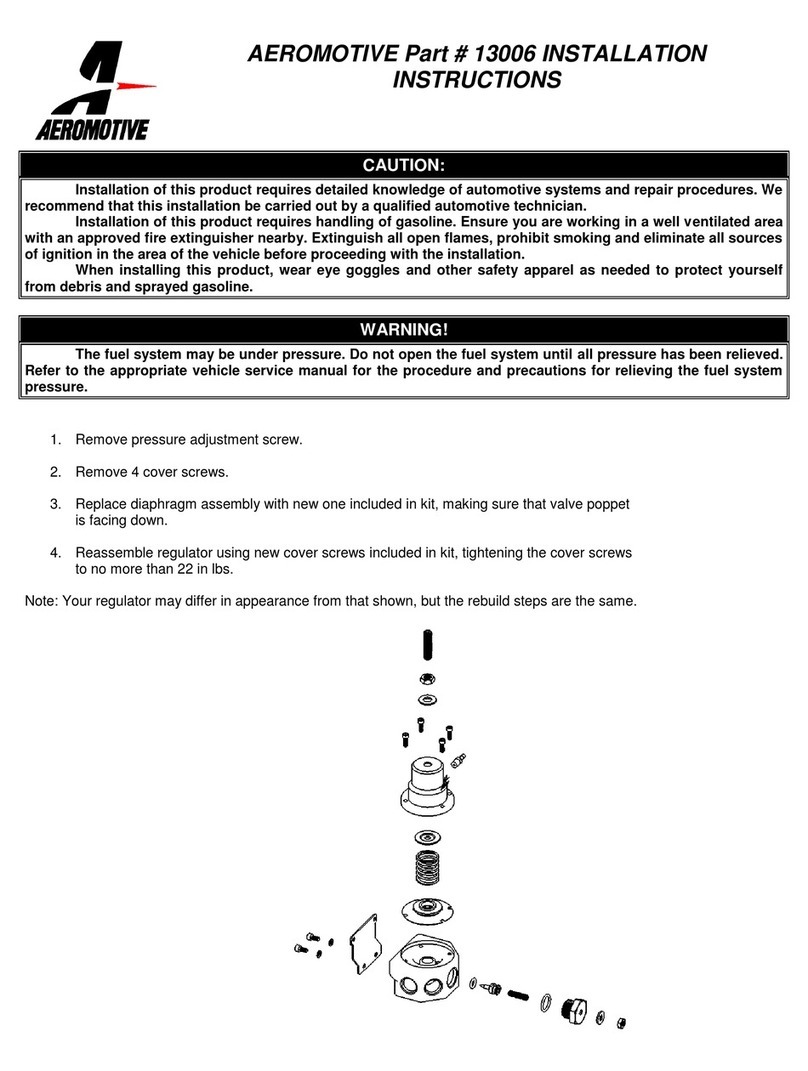

Aero-motive 13006 User manual

Aero-motive

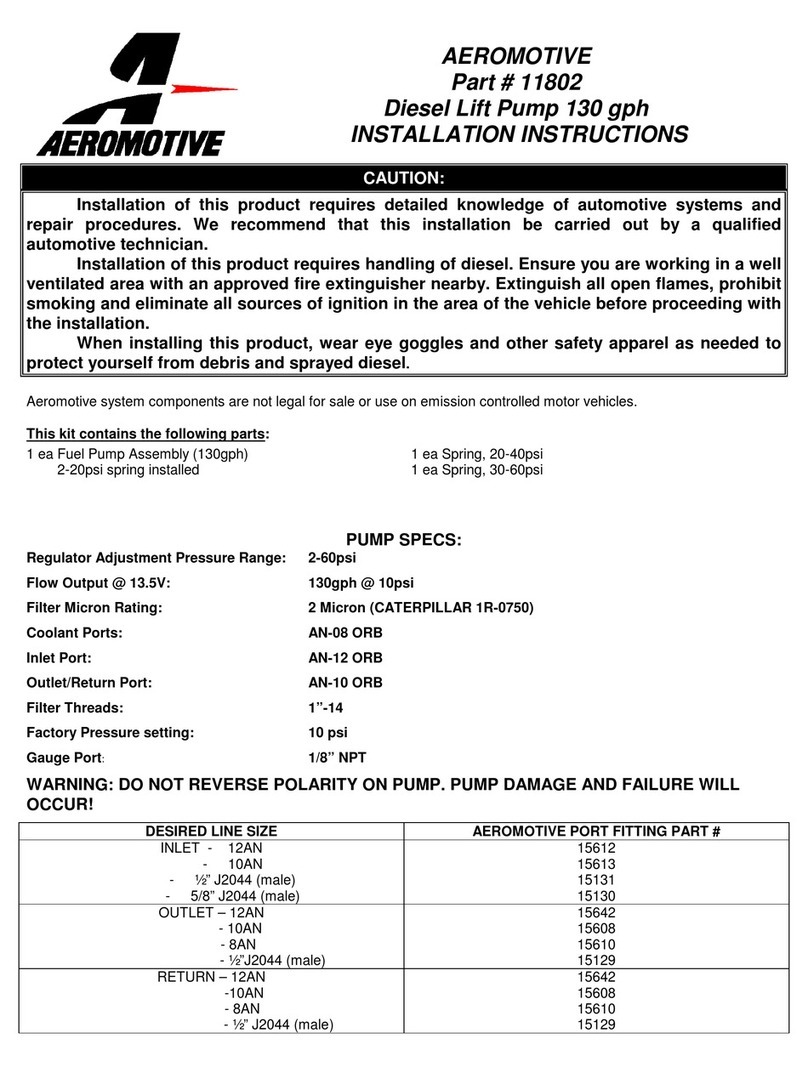

Aero-motive 11802 User manual

Popular Car Spares manuals by other brands

Hellwig

Hellwig 5812 installation instructions

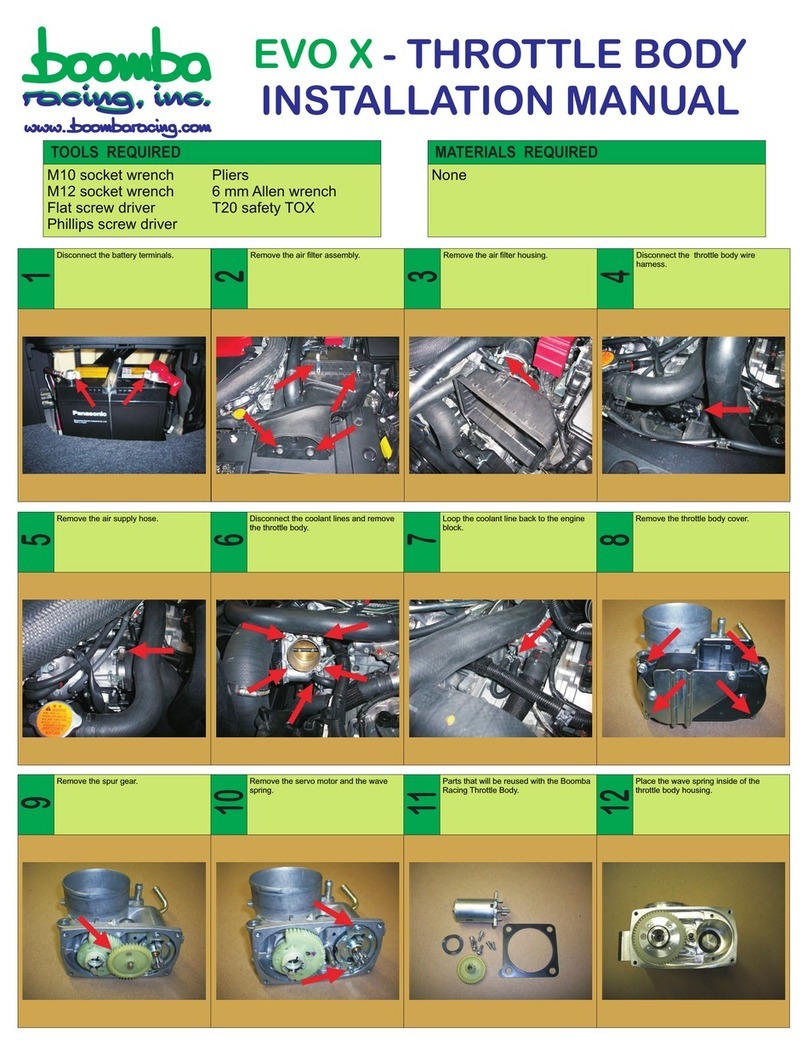

Boomba Racing

Boomba Racing EVO X installation manual

Xtracer

Xtracer 1152 manual

Go Rhino

Go Rhino DOMINATOR SERIES Assembly/installation instructions

Go Rhino

Go Rhino DOMINATOR 2 SERIES Assembly/installation instructions

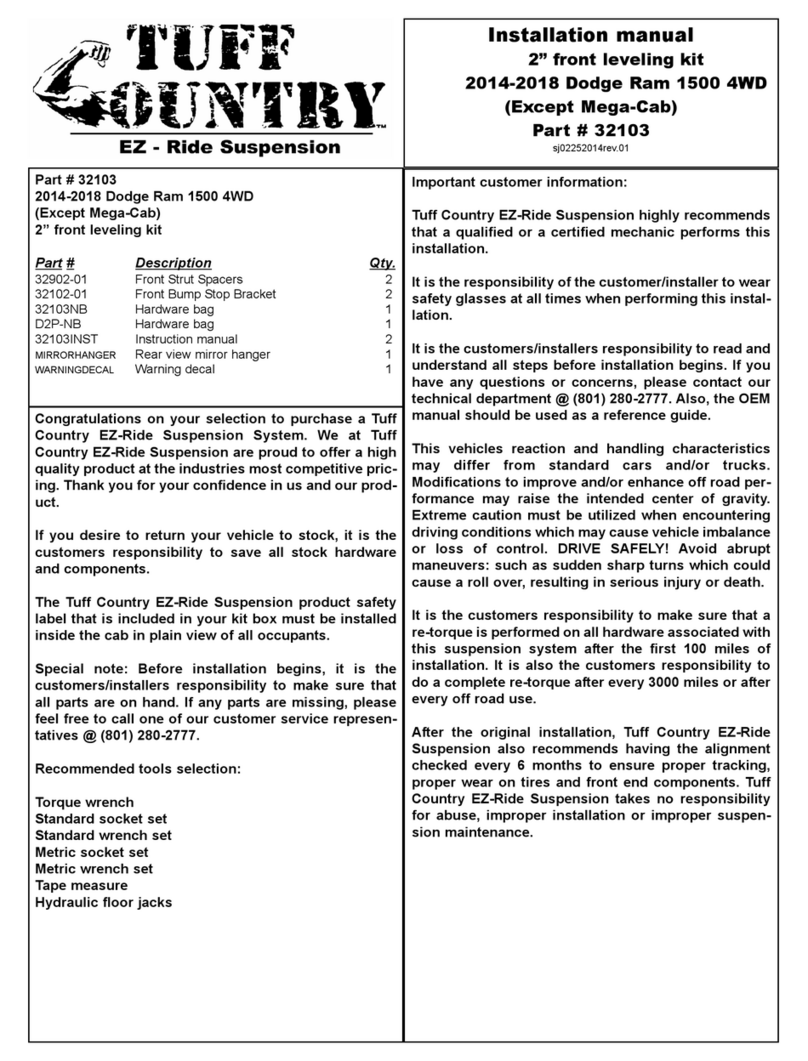

Tuff Country

Tuff Country 32103 installation manual

ADD

ADD 2003 – Current Chevy 1500/2500 ADD Lite installation instructions

ADD

ADD 2007-2014 Jeep JK venom installation instructions

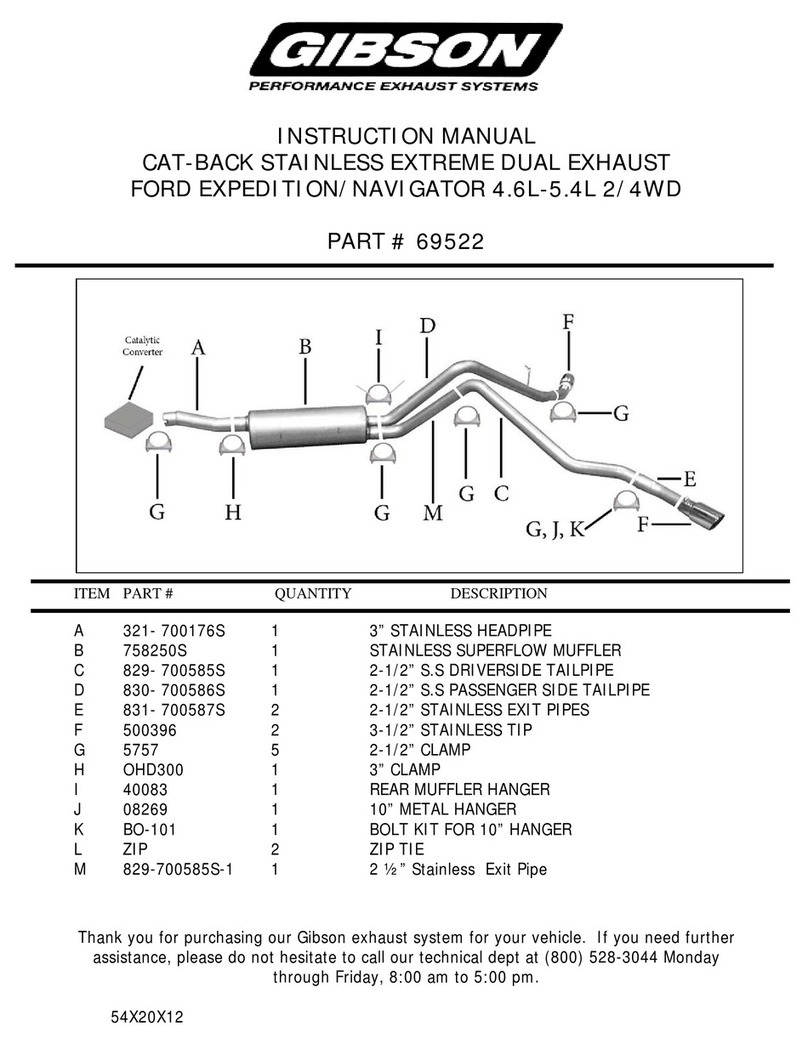

Gibson

Gibson 69522 instruction manual

Airaid

Airaid 400-279 installation instructions

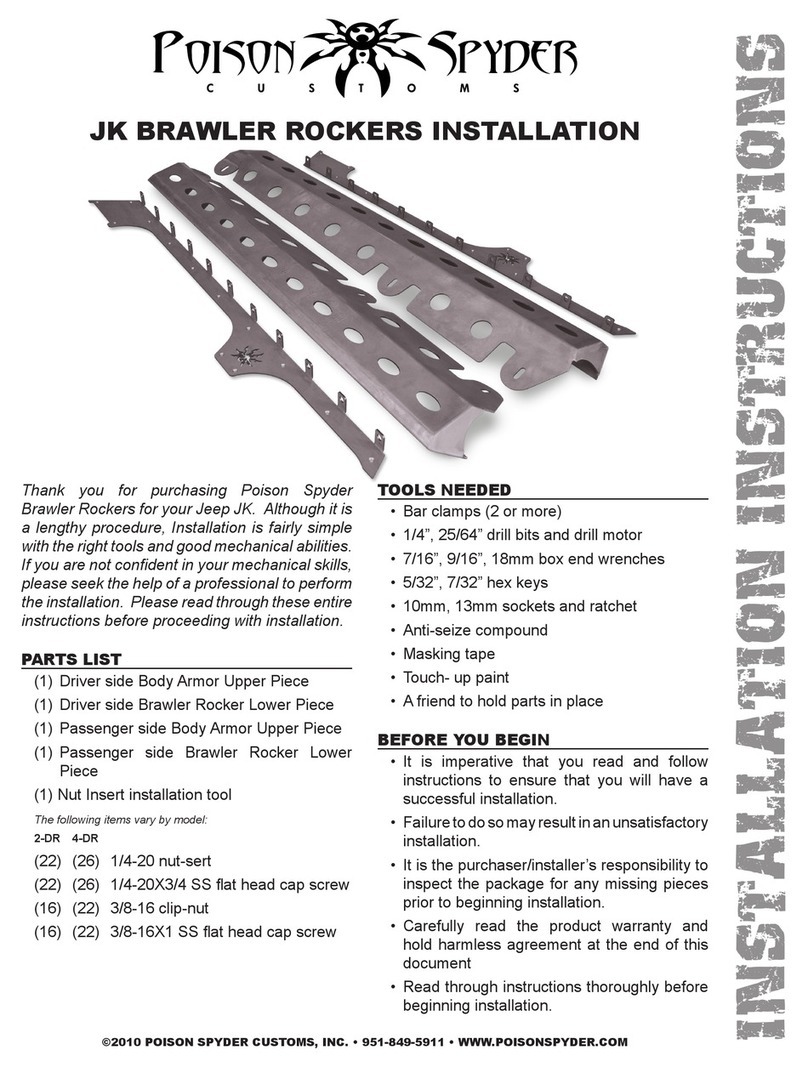

Poison Spyder

Poison Spyder JK BRAWLER ROCKERS Installation instructions manual

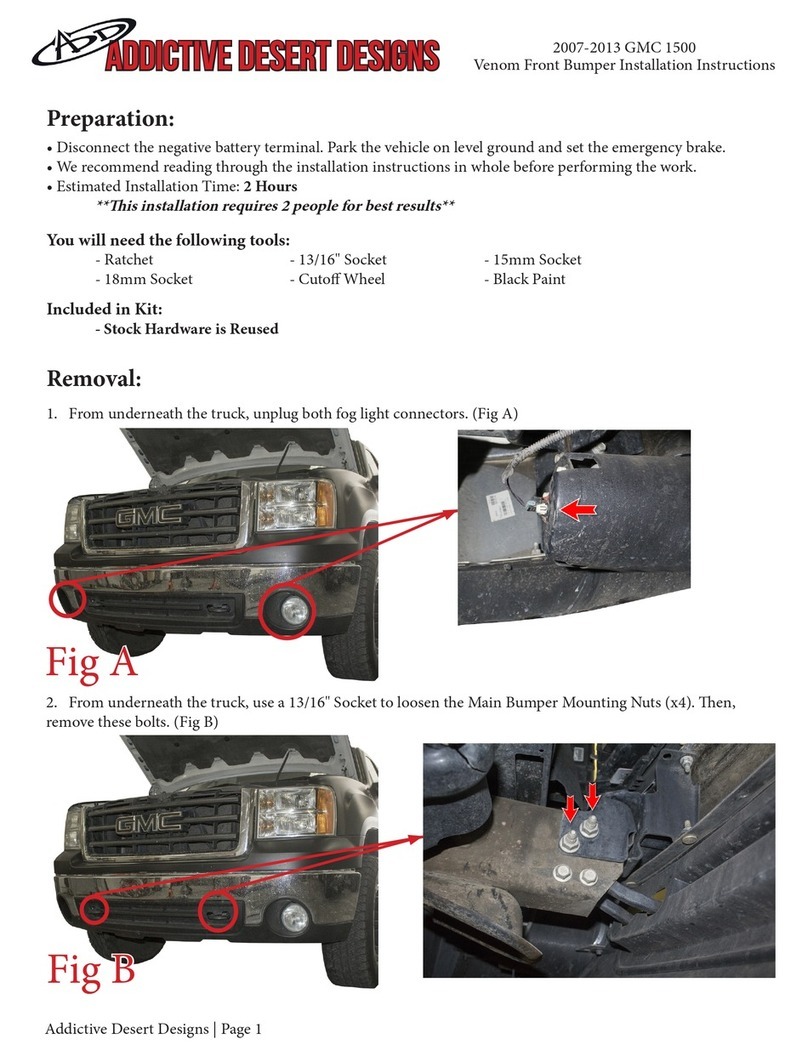

ADD

ADD 2007-2013 GMC 1500 installation instructions

aFe Power

aFe Power 54-12208 instruction manual

USA Standard Gear

USA Standard Gear Spartan Locker installation manual

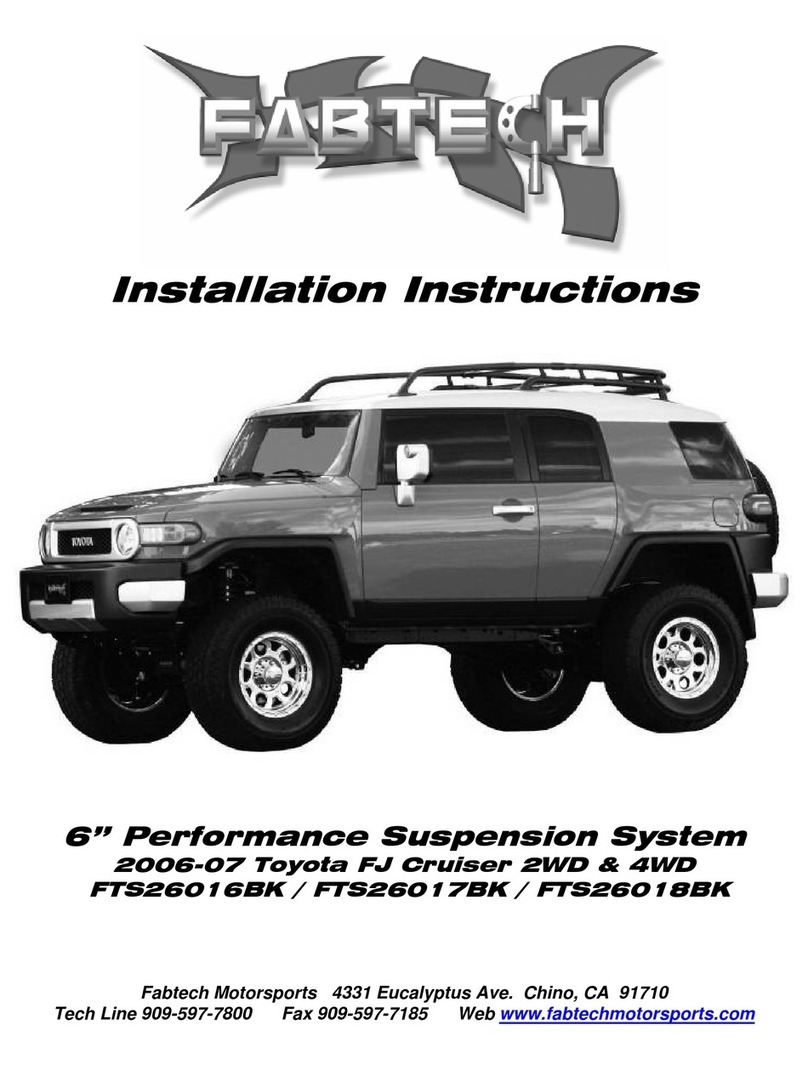

Fabtech

Fabtech FTS26016BK installation instructions

Go Rhino

Go Rhino DOMINATOR D2 SERIES installation instructions

Torklift

Torklift C2207/FMTPJ07LDCHSB Important owner-operator installation instructions

Grammer

Grammer COMPACTO Comfort S manual