Aeromix Class I TORNADO User manual

Class I TORNADO®Aspirating Aerator

Installation,

Operation, and

Maintenance Manual

© 2009, AEROMIX Systems, Inc.

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 1 of 30

Welcome to the AEROMIX family. You have purchased quality aeration

equipment designed to provide years of trou le free service.

Enclosed are many important items:

•Registration/Referral Bonuses: Allows you to earn money y referring

customers to AEROMIX.

•Extended Warranty: Allows you to extend the standard one (1) year warranty

an additional year for a total of two (2) years.

•Brochures: Provide rief description of all AEROMIX aeration products.

•Instruction Manual: Explains equipment operation and routine maintenance.

•Recommended Maintenance: Kits you should have on hand to maximize

equipment life.

Read the instruction manual, purchase the extended warranty, purchase the

maintenance kits, and earn money for every customer you refer to AEROMIX.

Register as a new customer y filling out and faxing ack the enclosed

registration form and get a great free gift sent to you.

Call our Customer Service Department at (800) 879-3677 anytime with questions

on how to keep your AEROMIX aerators performing perfectly all the time.

Sincerely,

Customer Service Department

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 2 of 30

Extended Warranty

A draft copy of the standard AEROMIX warranty is enclosed. This warranty

provides you with excellent protection against defects in workmanship and

materials which may occur during the first year. The exact terms and conditions

are printed on the warranty statement.

You can now extend this warranty coverage to protect original equipment for an

additional one (1) year (total of two (2) years of warranty coverage). Extended

warranties cannot e purchased past 60 days of shipment.

Extending the warranty enefits you y:

•Assuring you and the aeration equipment are protected against material

and workmanship defects that may occur in the future.

•Potentially saves parts expenses.

Extending the warranty is simple. Call our Customer Service Department at

(800) 879-3677 for more information.

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 3 of 30

Warranty No:

Warranty

AEROMIX Systems, Incorporated proudly warrants all products manufactured by

it to be free of defects in material or workmanship for a period of eighteen

months from shipment, or twelve months from date of installation, whichever

occurs first. We will repair or replace any item which fails within the warranty

period when it is returned freight prepaid to our plant in Minneapolis, MN, USA

or to an authorized local repair center. This warranty is subject to the

conditions set forth below. Equipment or accessories not manufactured by

AEROMIX Systems, Incorporated, but supplied by us, such as; motors, control

panels, etc., carry the full warranty supplied by the manufacturer of that

equipment. The Purchaser assumes Original Buyer responsibility. Any

warranty claim for that equipment must be made directly to the original

manufacturer.

This warranty is subject to the following conditions:

1. Purchaser understands, agrees and accepts this warranty. Such acceptance shall be indicated by all

applicable parties signing and returning a copy of this document to AEROMIX. Warranty period begins as

stated above but is not activated or valid until all material is paid for in full to AEROMIX and the signed original

has been returned to AEROMIX. AEROMIX will then return a copy of the official, activated warranty statement

to all signing parties.

2. This warranty is made for the benefit of Purchaser (municipality or end user) and when applicable to the

Purchaser’s agent (contractor) only. This warranty is non-transferable and non-assignable.

3. Any repaired or replacement item supplied under this warranty shall be warranted as provided herein only for

the remainder of the warranty period applicable to the original purchase.

4. This warranty expressly excludes defects or damage caused by Acts of God such as, but not limited to; falling

objects, external forces, explosion, fire, riot, civic commotion, acts of war, or vandalism. It also excludes;

mishandling by Purchaser, excess wear, excessive corrosion, fatigue, abuse, or failure caused by lack of

maintenance, or caused by freight damage, improper storage, contact with foreign objects, use in highly

corrosive, highly abrasive or high temperature solutions, excess foam, or use in solutions with high levels of

large suspended solids.

5. AEROMIX shall have the absolute discretion to either repair or replace the failed item. The work so performed

shall be done using AEROMIX practices and materials. AEROMIX, herewith reserves the right to approve

and/or negotiate any contract for any such work not performed by AEROMIX.

6. IT IS UNDERSTOOD AND AGREED THAT AEROMIX’S LIABILITY HEREIN, WHETHER IN CONTRACT, IN

TORT, UNDER ANY WARRANTY, IN NEGLIGENCE OR OTHERWISE, SHALL NOT EXCEED THE COSTS

OF THE PURCHASE PRICE PAID TO AEROMIX AND UNDER NO CIRCUMSTANCES SHALL AEROMIX,

BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, LIQUIDATED, CONSEQUENTIAL, OR OTHER

TYPES OF DAMAGES INCLUDING ON-SITE LABOR. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR APPLICATION.

7. All claims made under this warranty must be made to AEROMIX within thirty (30) days after Purchaser shall

have reasonably discovered the subject defect. AEROMIX, must be given a reasonable opportunity to inspect

any material claimed to be defective. Upon determination by AEROMIX, that a claimed failure is covered

under this warranty, and should AEROMIX choose to have the Purchaser handle the repair locally, the

Purchaser shall obtain two (2) competitive bids for the work involved. AEROMIX, shall have the right to obtain

additional bids at its sole cost. If AEROMIX elects to have any repair performed pursuant to any such bid,

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 4 of 30

Rugged Solutions in Water and Wastewater

AERATION

TORNADO® Aerator

HURRICANE® Aerator

TWISTER® Aerator

TYPHOON® Aerator

ZEPHYR® IAF System

CYCLONE® Diffuser

RIPTIDE™ Mixer

MONSOON® Aerator

AEROMIX offers a complete line of aerators, mixers,

diffusers and aeration systems for improving the

quality of water and wastewater. Our aerators

and aeration equipment are used worldwide for

municipal and industrial wastewater treatment and

lake rejuvenation. Let our technical experts assist

you in proper sizing, layout, and operation of your

next aeration or mixing system.

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 5 of 30

AE

R

R

AT I

O

N

AEROMIX Aeration Products:

Rugged Solutions inWater and Wastewater

AEROMIX is a world leader in water and wastewater treatment equipment. With decades of proven reliability

and unique installations in 75 countries, AEROMIX equipment is depended upon by prominent organizations

across the globe, including the U.S. Army Corps of Engineers, Contrack International, Haliburton, Coca-Cola,

and numerous others. AEROMIX offers full lines of treatment systems, aeration equipment and solar powered

equipment. Please visit www.aeromix.com to learn more about AEROMIX Systems.

Rental units available. Covered by United States Patent Nos. 5,160,667 - 4,741,870 - 5,868,091 - 7,048,260B2 - 5,183,596 - 6,634,626B2 - 5,762,833 -

D324,279. © 2010, AEROMIX Systems, Inc.

AEROMIX Systems, Inc.

7135 Madison Ave. West

Minneapolis, MN 55427 U.S.A.

Ph: 800-879-3677, 763-746-8400

Fax: 763-746-8408

e-mail: aeromix@aeromix.com

web: www.aeromix.com

To learn more about the AEROMIX aeration solution best suited for your application, call 800-879-3677 or visit www.aeromix.com

TORNADO®Aerator

• Self-Aspirating and Blower Assisted models available

• Available from 2 to 100HP (1.5 to 75 kW)

• All stainless steel construction, grease lubricated

bearings, and solid shaft vibration-free design

• Ideal for activated sludge basins, sludge holding

tanks, oxidation ditches, lagoons, ice control, and

post aeration applications

HURRICANE®Aerator

• Submersible Aspirating Aerator/Mixer

• Available from 5 to 100HP (3.75 to 75 kW)

• Customized air diffuser lengths for most efficient

aeration and mixing

• Effective in aerobic digesters, sludge holding tanks,

ow equalization tanks, sequencing batch reactors,

and post aeration

ZEPHYR®IAF System

• Induced Air Flotation (IAF) System

• Available from 1 to 10HP (.75 to 7.5 kW)

• Stainless steel construction

• Separates and removes fats, oils, and otable solids

• Applied at pulp and paper mills, petrochemical,

meat, vegetable and oil processing facilities

CYCLONE®Diffuser

• Coarse Bubble Diffusers

• Unique bubble shearing action for high oxygen

transfer efficiency

• Stainless steel construction

• Perfect for activated sludge basins, aerobic

digesters, aerated grit chambers, sludge storage

tanks, basin channels, and post-aeration basins

TWISTER®Aerator

• Low Speed Surface Aerator

• Available from 2 to 150HP (1.5 to 112 kW)

• Intense air-to-water mixing for high oxygen transfer

• Wear resistant and durable construction

• Ideal for highly loaded basins, oxidation ditches,

leachate treatment and activated sludge applications

TYPHOON®Aerator

• Floating High Speed Aerator

• Available from 2 to 200HP (1.5 to 150 kW)

• High pumping rates with a low trajectory for intense air-

to-water mixing and excellent oxygen transfer rates

• Minimal maintenance required

• Perfect for high rate aeration applications in basins and

lagoons

RIPTIDE®Mixer

• Direct Drive Surface Mixer

• Available from 2 to 30HP (1.5 to 22.5 kW)

• Directional mixing just below the surface for high basin

mixing efficiency

• Weedless design propeller

• Used in industrial applications for wastewater treatment

MONSOON®Aerator

• Floating Paddlewheel Aerator

• Available from 2 to 40HP (1.5 to 30 kW)

• High oxygen transfer and strong horizontal mixing

• 100% stainless steel construction for the ultimate

corrosion resistance

• Effective in lagoons, oxidation ditches, and equalization

basins

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 6 of 30

Packaged Plants

Compact Water Treatment

BREEZE® VOC Removal System

Field Erect Plant

TREATMENT SYSTEMS

Rugged Solutions in Water and Wastewater

AEROMIX offers factory pre-fabricated packaged

wastewater treatment plants, compact water

treatment systems, and air strippers. Our treatment

systems are used worldwide to provide potable

water for thousands of people at hotels and resorts,

shopping centers, ofce buildings, municipalities,

and industrial and military facilities. Let our

technical experts assist you in selecting the water

or wastewater treatment system that matches your

exact needs and requirements.

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 7 of 30

TREATMENT

S

Y

Y

S

TEM

S

To learn more about the AEROMIX treatment system best suited for your application, call 800-879-3677 or visit www.aeromix.com

AEROMIX Treatment System Products:

Rugged Solutions inWater and Wastewater

AEROMIX is a world leader in water and wastewater treatment equipment. With decades of proven reliability

and unique installations in 75 countries, AEROMIX equipment are depended upon by prominent organizations

across the globe, including the U.S. Army Corps of Engineers, Contrack International, Haliburton, Coca-Cola,

and numerous others. AEROMIX offers full lines of treatment systems, aeration equipment and solar-powered

equipment. Please visit www.aeromix.com to learn more about AEROMIX Systems.

Rental units available. Covered by United States Patent Nos. 6,547,855B1. © 2010, AEROMIX Systems, Inc.

AEROMIX Systems, Inc.

7135 Madison Ave. West

Minneapolis, MN 55427 U.S.A.

Ph: 800-879-3677, 763-746-8400

Fax: 763-746-8408

e-mail: aeromix@aeromix.com

web: www.aeromix.com

Packaged Plants

• Biological wastewater treatment system for

domestic waste

• Capable of producing up to 150,000 gallons per

day of potable water

• High degree of treatment - 99% removal of

BODs

• Compact and self-contained

• Installed above or below grade

• Applications include suburban subdivisions,

mobile home parks, motels, housing

developments, hotels and resort areas,

recreational facilities, highway rest areas, power

stations, apartment complexes, and military

posts

Compact Water Treatment

• Water treatment plants for the production of

potable water from well or surface water

• Flows from 1,000 to 1,000,000 gallons per day of

potable water

• Able to supply drinking water for populations

from 100 to 25,000 people

• Pre-fabricated, skid-mounted, or containerized

water treatment

• Treatment can include chemical addition,

coagulation, media ltration, membrane

separation, and disinfection depending on raw

water quality

• Perfect for industrial applications, hotels and

resorts, rural water supply, and military bases

BREEZE® VOC Removal System

• VOC Removal and Air Stripping System

• Maximum water ow of 200 gallons per minute

• Capable of removing nearly 100% of all volatile

organic compounds (VOC) and other gases

dissolved in water

• Compact, low maintenance, low cost alternative

to lters, packed towers, and mechanical

aerators

• Fine or coarse bubble diffusers are used to resist

fouling caused by iron, calcium, and biological

activity

• Can be operated with the assistance of an

induced draft or postiive displacement blower

Field Erect Plant

• Biological wastewater treatment system for

domestic waste

• Capable of producing 150,000 to 2,000,000

gallons per day of potable water

• High degree of treatment - 99% removal of BODs

• Permanent or temporary installations

• Easy to install and low maintenance

• Flexible design permits process selection for

each unique application

• Factory eld painting by AEROMIX (optional)

• Ideal for growing municipalities, residential

subdivisions, mobile home developments, small

cities or towns, and industrial waste applications

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 8 of 30

LumenAER™

Solar-Powered Circulator

SunAER™Diffused Air System

SolarAER™Surface Aerator

AuraAER™Floating Fountain

PhotonAER™

Submersible Aspirator

ECO-AERATION

Rugged Solutions in Water and Wastewater

AEROMIX is Your Solar Solution in Aeration and

Circulation.SM AEROMIX offers a comprehensive

line of water quality management products that

are completely powered by solar energy. AEROMIX

Eco Aeration products are used in ponds, lakes

and reservoirs, for algae and odor control,

reducing chemical consumption, improved mixing,

aeration, digesting bottom sludge, ice control, and

sh kill prevention.

Let our technical experts assist you in the proper

sizing, layout and operation of your next solar

powered aeration or circulation system.

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 9 of 30

E

E

E

E

C

C

C

C

O

O

O

O

-

A

A

E

E

R

A

A

A

T

T

T

I

O

N

To learn more about the AEROMIX eco-aeration solutions best for your application, call 800-879-3677 or visit www.aeromix.com

AEROMIX Eco-Aeration Products:

Rugged Solutions inWater and Wastewater

AEROMIX is a world leader in water and wastewater treatment equipment. With decades of proven reliability

and unique installations in 75 countries, AEROMIX systems are depended upon by prominent organizations

across the globe, including the U.S. Army Corps of Engineers, Contrack International, Haliburton, Coca-Cola,

and numerous others. AEROMIX offers full lines of treatment systems, aeration equipment and solar-powered

equipment. Please visit www.aeromix.com to learn more about AEROMIX Systems.

Rental units available. Covered by United States Patent Nos. 4,741,870 - 6,439,853B2 - 7,121,536B2 - 5,931,382 - D322,118.

© 2010, AEROMIX Systems, Inc.

AEROMIX Systems, Inc.

7135 Madison Ave. West

Minneapolis, MN 55427 U.S.A.

Ph: 800-879-3677, 763-746-8400

Fax: 763-746-8408

e-mail: aeromix@aeromix.com

web: www.aeromix.com

SolarAER™Surface Aerator

• Surface Aerator

• Operates 24/7

• Horizontal water movement increases dissolved oxygen

levels over a wide area

• Ideal for use in lakes and ponds

• Operates year round in any climate

LumenAER™ Circulator

• Solar-Powered Floating Circulator

• Operates 24/7

• Rapid oxygenation and distribution removes or reduces

odors, excess algae, excessive nutrient concentrations

and digesting bottom sludge

• Applied in lakes, estuaries, stormwater detention ponds,

polishing ponds, drinking water reservoirs, and more

AuraAER™Fountain

• Solar-Powered Floating Fountain

• Operates 24/7

• Aerates to control algae formations, add oxygen, reduce,

and prevent sh kill

• Ideal for lakes, residential and commercial ponds,

shallow ponds, and water sh ponds

SunAER™Diffused Air System

• Solar-Powered Diffused Air System

• 1 to 4 diffuser models available

• Vertical water circulation for total pond treatment

• Uses air bubbles to add oxygen, eliminate stratication,

and promote aerobic decomposition of bottom muck,

dead plants, and other waste materials from small water

bodies

PhotonAER™Submersible Aerator

• Solar-Powered Submersible Aerator

• Operates 24/7

• Fine bubble discharge destraties and provides

horizontal water circulation

• Ideal for shallow water bodies, only requiring a 2 foot (.6

meter) depth.

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 10 of 30

TABLE OF CONTENTS

Safety Precautions 1

Section 1: Features 2

Section 2: Operating Principle 3

Section 3: Unpacking 4

Section 4: Mounting the Aerator 4

Section 5: TORNADO® Aerator Accessories 5

5.1: Mounting Accessories 5

5.2: Float Accessories 6-8

Section 6: Float Mooring Options 9

6.1: Mooring to Shore 9

6.2: Proper Way to Clip Wire Rope 10

6.3: Mooring with Anchors 11

Section 7: Mooring Accessories 12

Section 8: Wiring the Aerator 12

8.1: Recommended Electrical Accessories 12

8.2: Cable Selection 13

8.3: Electrical Accessories 13

Section 9: Start Up 14

9.1: Training 14

9.2: Propeller Rotation 14

9.3: Amp Draw 15

9.4: Observation of Operation 15

Section 10: Aligning the Coupling 15

Section 11: Maintenance Schedule 16

Section 12: Troubleshooting 17

Section 13: Disassembly & Maintenance 18

13.1: Removing the Propeller 18

13.2: Removing the Draft Tube 18

Section 14: Service Policy 19

Class I TORNADO® Drawings

Start-Up Sheet

APPENDICES A – C

Propeller & Motor Seal Module Instructions

Electrical Cable Selection

U-Bolt Clip Instructions

TORNADO Parts Kits

APPENDIX D

Equipment Data Sheets

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 11 of 30

SAFETY PRECAUTIONS

ANY EQUIPMENT THAT INVOLVES WATER, ELECTRICITY AND

MOVING PARTS IS POTENTIALLY DANGEROUS!

Owners and equipment operators are responsible to ensure that

everyone follows local safety rules and the rules listed in this

manual. AEROMIX is not responsible for injury or property

damage caused by unsafe equipment operation.

1. Read this manual before operating the equipment.

2. Always keep yourself and others away from the propeller when

the aerator is operating in or out of water.

3. Never let anyone swim in a pond which has an aerator operating.

4. When installing an aerator make sure the propeller is clear of any

submerged items such as mooring or electrical cable.

5. Make sure the electrical circuits are locked out (disconnected)

whenever equipment is being handled or serviced.

6. If the aerator is used for de-icing, make sure signs are posted in

accordance with state or local laws advising of thin ice and open

water.

7. NEVER climb on float or mounting assemblies while the equipment

is operating.

8. See additional safety precautions regarding the coupling flanges in

APPENDIX A.

9. All wiring should be done by a qualified electrician in accordance

with local electrical codes.

-1 -

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 12 of 30

SECTION 1: FEATURES

1. All wetted parts are stainless steel, including the propeller.

2. The CLASS I model is available from 2-10 horsepower (1.5 - 7.5kW) in 60 Hz and 2 -

7.5 horsepower (1.5 – 5.6kW) in 50 Hertz. Similar models available from 15-40

horsepower (11- 30kW), and 50 - 100 horsepower (37.5 - 75kW).

3. The aerator operates with no splashing or spraying. All mixing and oxygen transfer

takes place under the water's surface.

4. Units can be operated alone or in groups to create a circular flow pattern.

- 2 -

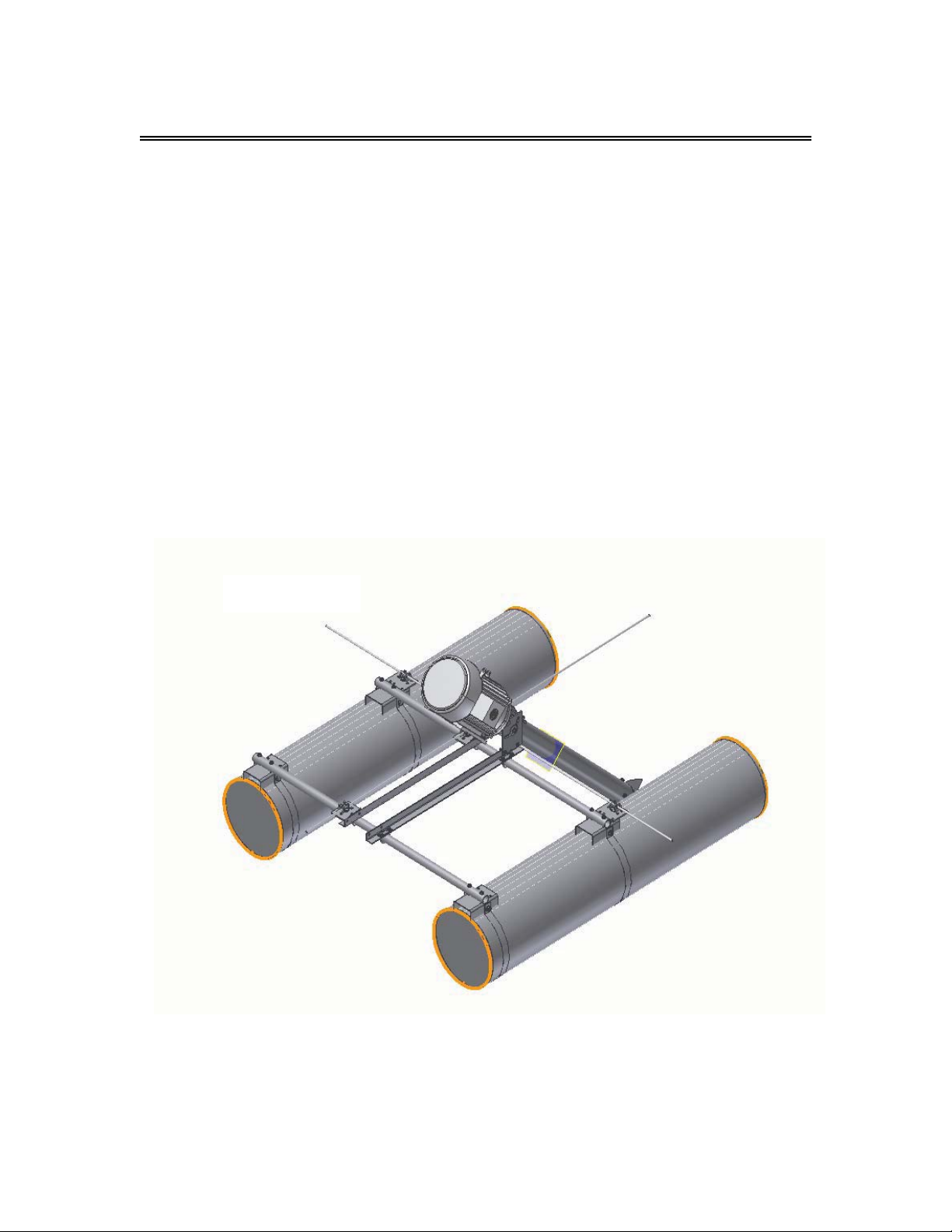

FIGURE 1:

Construction features of the Class I TORNADO®aerator

Stainless Steel

Propeller

Grease zerks (easy to

reach)

Standard

Coupling

Flanges

Standard TEFC

Motor

Large open Propeller Hub

for more air flow

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 13 of 30

SECTION 2: OPERATING PRINCIPLE

FIGURE 2 illustrates an aerator in operation. Water moving past the propeller creates

a low pressure zone at the propeller hub. This draws air through the draft tube air inlet

hole down to the propeller. Action of the propeller mixes the air stream with the water

resulting in tiny bubbles. The air and water mixture is forced away from the propeller

both horizontally and vertically effectively mixing and oxygenating the water.

- 3 -

FIGURE 2:

Aerator in operation

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 14 of 30

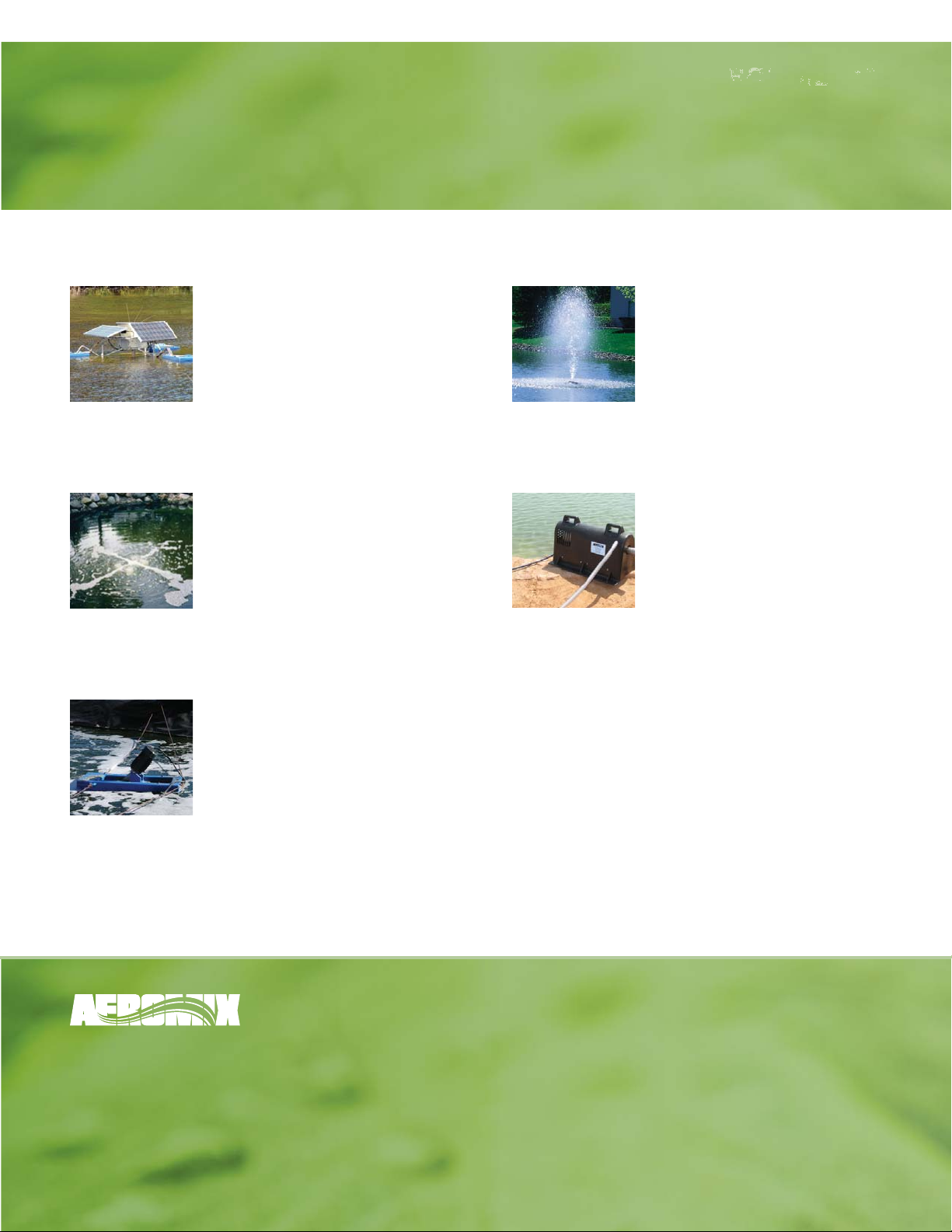

SECTION 3: UNPACKING

All AEROMIX TORNADO®aerators are inspected and tested at our factory prior to

shipment to assure that each aerator meets our quality standards. Be sure to inspect

the aerator for dents, scratches or any other damage that may have been caused in

shipping. Turn the propeller by hand to make sure it rotates freely without binding.

Minor binding resulting from bumps in shipping and handling can usually be remedied by

a thoughtful adjustment of the four propeller-end bolts attaching the draft tube to the

bearing support tube. These bolts require a 9/16 inch wrench and are easily accessed

(See FIGURE 16). The four similar bolts on the motor end of the draft tube do not

need adjustment. Simply tighten and loosen opposing pairs of the bolts in tandem to

again make the machined "collar" of the

propeller concentric within the draft tube. It

may require some experimenting with

adjustments to these two pair of bolts, but the

binding will be quickly and easily remedied.

(Note: Re-apply Loktite to the bolts whenever

removing and reinstalling them.) Uncorrectable

binding may be caused by a bent shaft, often the

result of the aerator being dropped onto its

propeller during shipping and handling. Check all

the aerator bolts for tightness. Report any

damage to the freight carrier, equipment

distributor and AEROMIX.

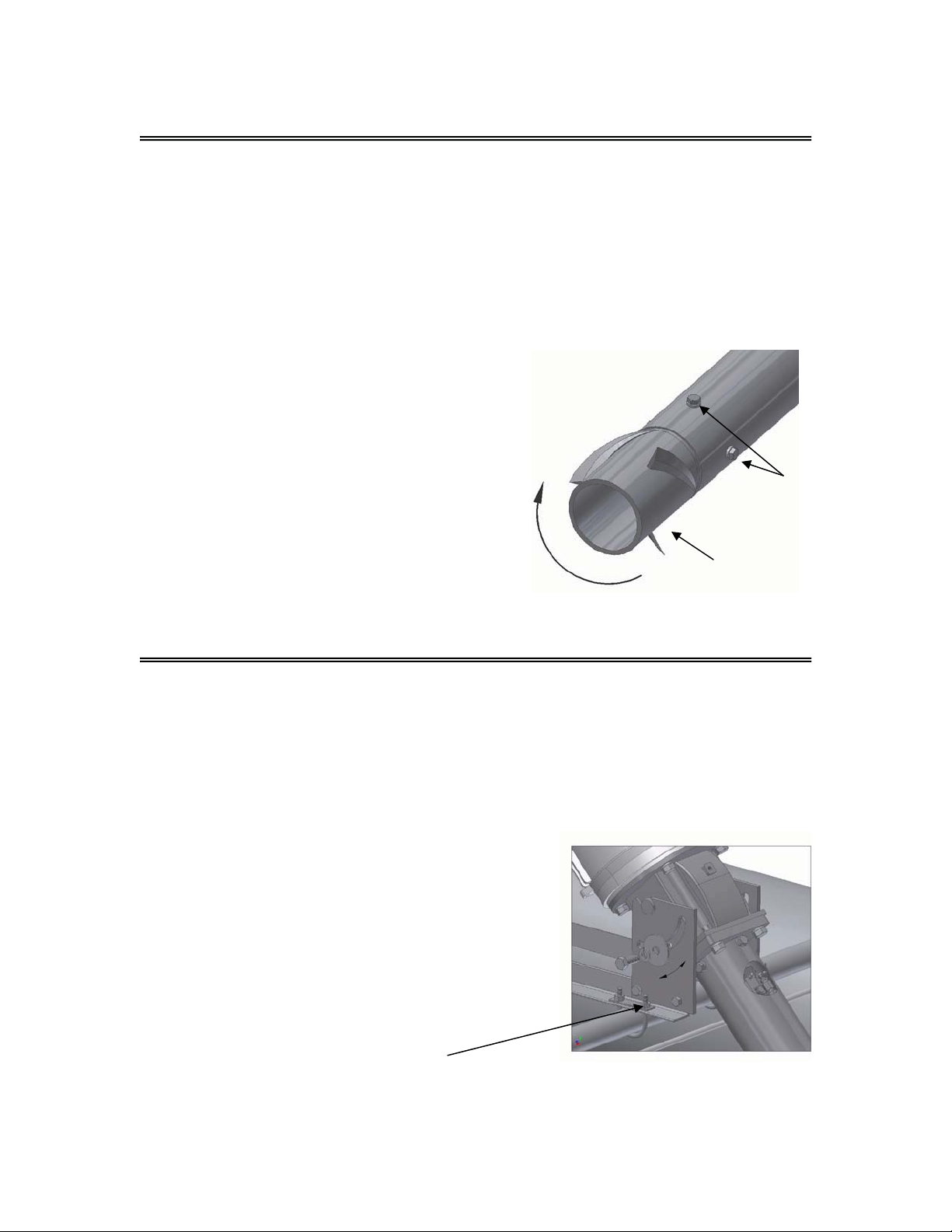

SECTION 4: MOUNTING THE AERATOR

All AEROMIX mounting accessories require mounting cradles as illustrated in FIGURE 4

below. Mounting the aerator simply consists of lowering the unit so the motor mount

pins set in the mounting cradle slot. A bolt, lockwasher, and flatwasher is tightened into

the semicircular slots on each side of the aerator. The semicircular slot allows the

aerator to be mounted in nearly any position from vertical to horizontal. Mounting

cradles are included in float or with mount kits.

Recommended tilt angle for general wastewater

applications is 45º from the horizontal. In some

applications, larger or smaller angles may be called

for to optimize the air aspiration rate and mixing

profile. Smaller angles maximize horizontal mixing

but reduce bubble hang time – larger angles mix

more deeply but reduce slightly the amount of air

aspirated. When angles smaller than 35° are used

to mount the aerator, vortex/cavitation shields may

be needed.

- 4 -

Mounting

Cradle

FIGURE 4:

Mounting the Aerator

FIGURE 3:

Unpacking &

Inspection

Verify propeller

turns freely

Draft Tube Bolts

(for adjustment if

needed)

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 15 of 30

FIGURE 5:

TORNADO Float Mount

SECTION 5: TORNADO AERATOR ACCESSORIES

AEROMIX offers a number of optional items including mounting accessories, mooring

accessories and electrical accessories. Unless ordered with the aerator, these

accessories are normally not included. The following drawings are general

arrangements and are not a detailed representation of offered accessories. For exact

drawings and parts lists, refer to the attachments to this manual, and the manual for the

float systems.

5.1: MOUNTING ACCESSORIES

The float mount and fixed mount (wall or bridge) are the two basic methods for

mounting the TORNADO aerator. The float mount (FIGURE 5) is best suited for large

basins, basins with sloped sides and basins with fluctuating water levels. It can be

easily moved to different locations.

FIGURE 6 shows a typical wall mount which is custom designed and built to wall and

water level dimensions supplied by the customer. These fixed mounts can be further

customized to allow swiveling the aerator and its mounting cradles through a full 180º

sweep, allowing fine-tuning of the direction of the mixing energy.

(Not shown, but also available, are mounting brackets that adapt our TORNADO aerator

to the float systems of other aerator

manufacturers.)

-5-

FIGURE 6:

TORNADO Wall Mount

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 16 of 30

5.2: FLOAT ACCESSORIES

Vortex Shield: Excessive vortexing (see Troubleshooting section) will not normally

occur with the TORNADO aerator when operated under ordinary conditions and when

tipped into the water at a 45º angle. In situations where vortexing does occur, an

optional vortex shield (FIGURE 7) is available.

Swing Arms: Swing arms (FIGURE 8) are needed whenever water levels fluctuate

beyond the limits of the mooring cable. Floats with swing arms can only be moored

perpendicular to the cable. Aerator thrust should be directed toward points of

attachment (cable or wall) so that arms are in tension, not compression.

- 6-

FIGURE 8:

Float with optional

swing arms

FIGURE 7:

TORNADO

with optional

vortex shield.

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 17 of 30

Front Low Water Level Legs: Typically used in combination with swing arms, low

water level legs (FIGURE 9A, B, C and 10A, B and C) allow a pond to be completely

emptied with the TORNADO aerator and floats moored into place. The legs hold the

propeller off the basin floor when there is no water in the basin.

Low Water Level Legs:

Front and Rear

-7-

FIGURE 9A, 9B, 9C:

Low Water Level Legs

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 18 of 30

-8-

FIGURE 10A, 10B, 10C:

Low Water Level Legs

Front and Rear

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 19 of 30

SECTION 6: FLOAT MOORING OPTIONS

A float mooring system is more flexible for positioning aerators than most other

mounting systems. The most common ways of mooring floats are mooring to posts on

shore or mooring to anchors. Optional mooring kits are available to enable the

attachment of the mooring lines to the float system (see Section 7.)

6.1: MOORING TO SHORE

The TORNADO floats are normally equipped to be moored either perpendicular (mooring

option A in FIGURE 11) or parallel (mooring option B in FIGURE 11) to the mooring

cable. Special modifications may be possible to allow the floats to be mounted at

different angles to shore. Size the mooring cable by number of aerators per span and

their motor horsepower by using the chart in Appendix C.Appendix C also provides

the maximum cable length and maximum unsupported distance for different cable sizes.

-9 -

FIGURE 11:

Moorin

g

to cable s

p

ans

OPTION BOPTION A

Aeromix Class 1 Tornado Aspirating Aerator - Installation Operation Maintenance - Vendor Manual

Q-Pulse Id: VM483

Active: 11/11/2015

Page 20 of 30

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

i4Technology

i4Technology GRAD A-1000 PRO + manual

Dalen

Dalen Rustic Raised Bed Garden 5357 Assembly instructions

Lucky Duck

Lucky Duck Super Swimmer HD 10516-0 quick start guide

Pioneer Athletics

Pioneer Athletics BRITE STRIPER 1600PS Instruction manual and parts listing and parts listing

Ransomes

Ransomes MP653 Safety, operation & maintenance manual

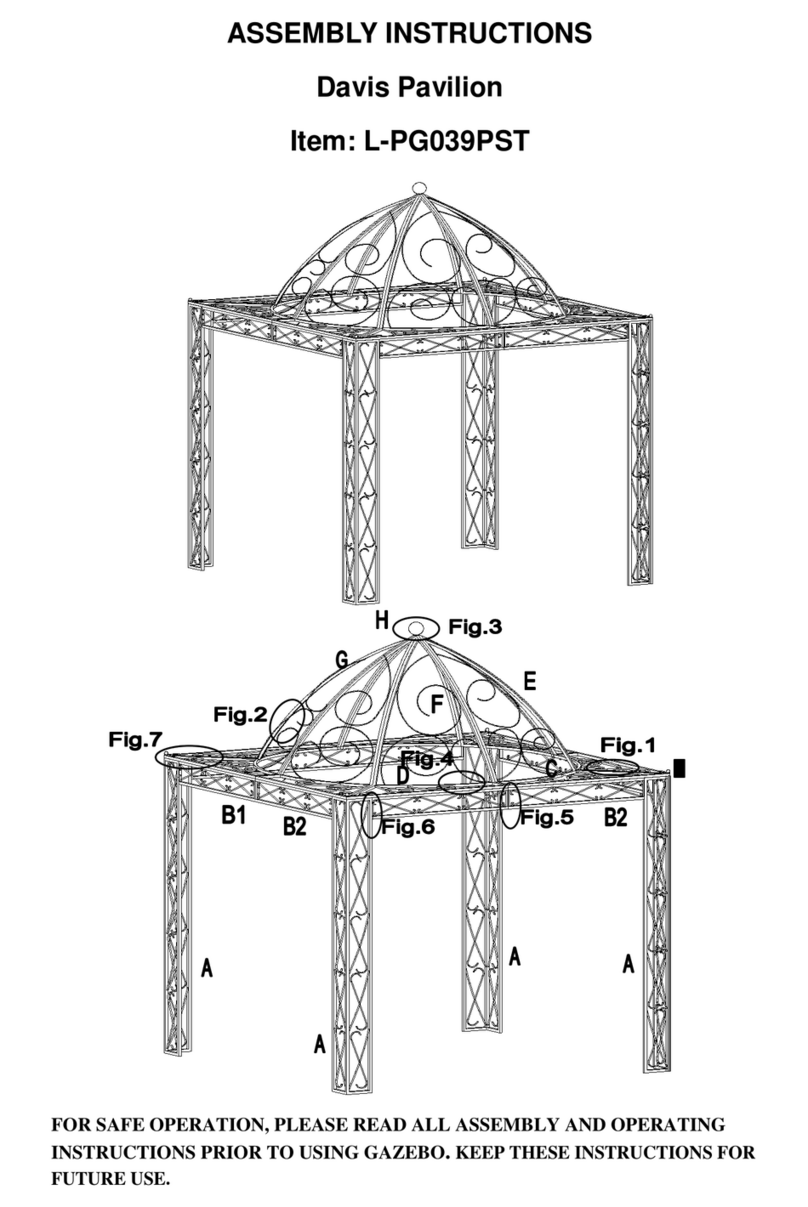

Sunjoy

Sunjoy Davis Pavilion Assembly instructions