Aeropro A240 Owner's manual

AEROPRO CZ

,

Produc

er

of

Light Sport Aircraft

Mladá 835, 687 25 Hluk, Czech Republic

Pilot Operating Handbook

and

Flight Training Supplement

AEROPRO

A2

4

0

Light Sport Aircraft

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

0

-

2

Aircraft Type:

A2

4

0

Serial Number:

____

_

____

Registration:

N

_________

Date of Issue:

September 1, 2016

version 1.0

This aircraft was manufactured in accordance with Light Sport Aircraft airworthiness standards

and does

not conform to standard category airworthiness requirements.

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

0

-

3

RECORD OF REVISIONS

Any revisions or amendments to the present manual shall be issued in the form of bulletins with attached

new pages. It is in the interests of every user to enter such re

vision into the table of revisions and to

replace the existing page by the new one. The revised or corrected text shall be indicated by a vertical line

on left page margin and the page shall bear revision number and date of its issue.

Rev. No.

Pages Affec

ted

Date of Issue

Bulletin Number

New Page Inserted On, Signature

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

0

-

4

TABLE OF CONTENTS:

RECORD

OF

REVISIONS

................................

................................

..............

..

0

-

3

0.

GENERAL INFORMATION

................................

................................

.....

0

-

7

0.1

I

NTRODUCTION

................................

................................

.......................

0

-

7

0.2

C

ERTIFICATION

B

ASIS

................................

................................

.............

0

-

7

0.3

M

ANUFACTURER

................................

................................

....................

0

-

7

0.4

W

ARN

ING

,

C

AUTION AND

N

OTE

................................

..............................

0

-

7

1.

AIRPLANE AND SYSTEMS

DESCRIPTION

....................

....................

.

1

-

8

1.1

E

NGINE

...............................................................................

....................

1

-

9

1.2

P

ROPELLER

................................

................................

.............................

1

-

9

1.3

F

UEL AND FUEL CAPACIT

Y

................................

................................

......

1

-

9

1.4

O

IL

................................

................................

................................

........

1

-

11

1.5

O

PERATING WEIGHTS

&

LOADING

(

OC

CUPANTS

,

BAGGA

GE

,

FUEL

).........

1

-

11

1.6

C

OCKPIT OVERVIEW

................................................................

...............

1

-

12

1.7

A

IRCRAFT

E

LECTRICAL

S

YSTEM

................................

...........................

1

-

17

1.8

Electric Backup Fuel Pump..

…………………………………………………….

1

-

1

7

1.9 Additional Equipment........................................................................... 1

-

17

2.

OPERATING LIMITATION

S

................................

................................

.

2

-

18

2.1

S

TALL SPEED AT MAXIMU

M TAKE

-

OFF WEIGHT

(VS

AND

VSO)

............

2

-

18

2.2

F

LAPS EXTENDED SPEED

RANGE

(VSO

TO

VFE)

................................

...

2

-

18

2.3

M

AXIMUM MANEUVERING S

PEED

(VA)

................................

................

2

-

19

2.4

N

EVER EXCEED SPEED

(VNE)

................................

...............................

2

-

19

2.5

C

ROSSWIND AND WIND LI

MITATION

................................

......................

2

-

19

2.6

S

ERVICE CEILING

................................

................................

..................

2

-

19

2.7

L

OAD FACTORS

................................

................................

.....................

2

-

19

2.8

P

ROHIBITED MANEUVERS

................................

................................

......

2

-

19

2.9

O

THER

L

IMITATIONS

................................

................................

.............

2

-

20

3.

WEIGHT AND BALANCE I

NFORMATION

................................

........

3

-

21

3.1

I

NSTALLED EQUIPMENT L

IST

................................

................................

.

3

-

21

3.2

C

ENTER OF GRAVITY

(CG)

RANGE AND DETERMINAT

ION

......................

3

-

21

3.2

.1

Weight and balance determination for flight

...............................

3

-

21

3.2.2

Detailed calculation of CG position

…………………………...…. 3

-

21

4.

PERFORMANCE

................................

................................

......................

4

-

24

4.1

T

AKE

-

OFF AND LANDING DIST

ANCES

................................

.....................

4

-

24

4.2

R

ATE OF CLIMB

................................

................................

.....................

4

-

24

4.3

C

RUISE SPEEDS

................................

................................

.....................

4

-

24

4.4

RPM

................................

................................

................................

.....

4

-

24

4.5

F

UEL CONSUMPTION

................................

................................

.............

4

-

25

4.6

O

THER PERFORMANCE DAT

A

................................

................................

4

-

25

5.

NORMAL PROCEDURES

................................

................................

.......

5

-

26

5.1

P

REFLIGHT INSPECTION

................................

................................

.........

5

-

26

5.1.1

Daily preparation

................................

................................

........

5

-

26

5.1.2

Preflight Inspection

................................

................................

......

5

-

28

5.2

E

NGINE STARTING

................................

................................

.................

5

-

28

5.2.1

Use of External Power Supply

................................

.....................

5

-

29

5.2.2

Engine Starting

................................

................................

............

5

-

29

5.3

T

AXIING

................................

................................

................................

5

-

29

5.3.1

Prior to taxiing

................................

................................

.............

5

-

29

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

0

-

5

5.3.2

Taxiing

…………………………………………………………………

5

-

29

5.3.3

Engine warm

-

up, power check

.....................

................................

5

-

3

0

5.4

N

ORMAL TAKE

-

OFF

................................

................................

...............

5

-

30

5.4.1

Prior to tak

e

-

Off

................................

................................

...........

5

-

30

5.4.2

Take

-

off

................................

................................

........................

5

-

31

5.5

B

EST ANGLE OF CLIMB S

PEED

(VX)

................................

......................

5

-

31

5.5.1

Climbing

................................

................................

.......................

5

-

31

5.6

B

EST RATE OF CLIMB SP

EED

(V

Y

)

................................

.........................

5

-

32

5.6.1

Climbing

................................

................................

.......................

5

-

32

5.7

C

RUISE

................................

................................

................................

..

5

-

32

5.7.1

Cruise Flight

................................

................................

................

5

-

32

5.8

A

PPROACH

................................

................................

............................

5

-

32

5.8.1

Descent

................................

................................

.........................

5

-

32

5.8.2

Downwind

................................

................................

....................

5

-

32

5.9

N

ORMAL LANDING

................................

................................

................

5

-

33

5.9.1

On base leg

................................

................................

..................

5

-

33

5.9.2

On final

................................

................................

........................

5

-

33

5.9.3

Landing

................................

................................

........................

5

-

33

5.9.4

After landing

................................

................................

................

5

-

33

5.9.5

Engine stopping

................................

................................

...........

5

-

33

5.9.6

Post

-

flight check

................................

................................

..........

5

-

34

5.10

S

HORT FIELD TAKE

-

OFF AND LANDING PROC

EDURES

.............................

5

-

34

5.11

A

BORTED LANDING PROCE

DURES

................................

.........................

5

-

34

5.12

I

NFORMATION ON STALLS

,

SPINS AND ANY OTHER

USEFUL PILOT INFORMA

TION

....

5

-

34

5.12.1

Rain

................................

................................

..............................

5

-

34

6.

EMERGENCY PR

OCEDURES

................................

...............................

6

-

35

6.1

I

NTRODUCTION

................................

................................

.....................

6

-

35

6.2

E

NGINE

F

AILURE AND

E

MERGENCY LANDINGS

................................

.....

6

-

35

6.2.1

Engine failure during take

-

off Run

................................

..............

6

-

35

6.2.2

E

ngine failure during take

-

off

................................

......................

6

-

35

6.2.3

In

-

flight engine failure

................................

................................

.

6

-

35

6.2.4

Additional information for engine failure and emergency landing procedures....

6

-

36

6.2.5

Carburetor icing

................................

................................

..........

6

-

36

6.3

I

N

-

F

LIGHT

E

NGINE

S

TARTING

................................

...............................

6

-

37

6.4

F

IRES

................................

................................

................................

....

6

-

37

6.4.1

Engine fire on the ground

................................

............................

6

-

37

6.4.2

Engine fire during t

ake

-

off

................................

...........................

6

-

37

6.4.3

Engine fire in

-

flight

................................

................................

......

6

-

38

6.4.4

Cockpit or electrical fire

................................

..............................

6

-

38

6.5

G

LIDING

................................

................................

................................

6

-

38

6.6

P

RECAUTIONARY

L

ANDING

................................

................................

...

6

-

38

6.7

B

LOWN

-

O

UT

T

IRE

L

ANDING

................................

................................

.

6

-

39

6.8

D

AMAGED

L

ANDING

G

EAR

L

ANDING

................................

....................

6

-

39

6.9

V

IBRATIONS OR OTHER E

NGINE PROBLEMS

................................

...........

6

-

39

6.10

I

NADVERTENT ICING EN

COUNTER

................................

.........................

6

-

39

6.11

E

XTREME TURBULENCE EN

COUNTER

................................

....................

6

-

40

6.12

E

LECTRICAL SYSTEM MAL

FUNCTIONS

................................

...................

6

-

40

6.12.1

Charging

indicator is illuminated

................................

................

6

-

40

6.13

I

NADVERTENT

R

ESCUE

S

YSTEM

S

TALL AND SPIN RECOVE

RY

...............

6

-

40

6.13.1

The following general procedure should be followed should a stall occur:

6

-

40

6.13.2

The following general procedure should

be followed should a spin occur:

6

-

40

6.14

RESCUE SYSTEM …………………………………………………...6

-

4

0

6.14.1

Operation of Rescue System………………………………………

.

….6

-

4

0

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

0

-

6

7.

AIRCRAFT GROUND HAND

LING AND SERVICING

......................

7

-

41

7.1

S

ERVICING FUEL

,

OIL

,

COOLANT

................................

............................

7

-

41

7.1.1

Servicing fuel

................................

................................

..............

7

-

44

7.1.2

Servicing oil

................................

................................

.................

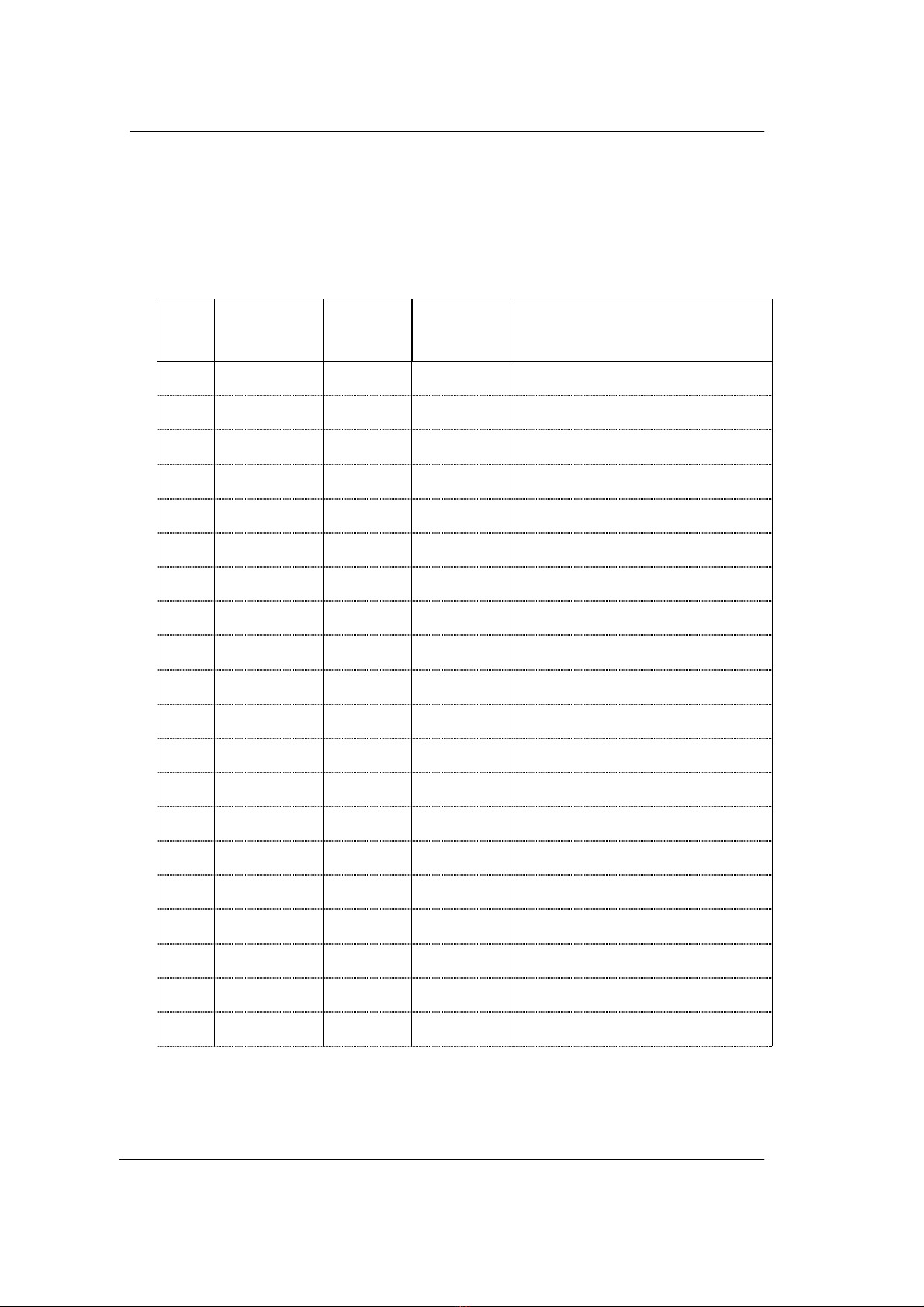

7

-

41

7.1.3

Servicing coolant

................................

................................

.........

7

-

41

7.2

L

ANDING GEAR TIRE DIM

ENSION AND

PRESSURE

................................

...

7

-

42

7.3

T

OWING AND TIE

-

DOWN INSTRUCTIONS

................................

................

7

-

42

7.3.1

Aircraft towing instructions

................................

.........................

7

-

45

7.3.2

Aircraft tie

-

down instructions

................................

......................

7

-

42

7.4

P

ARKING BRAKE OPERA

TION

..................

...............................

..................

7

-

42

8.

REQUIRED PLACARDS AN

D MARKINGS

................................

.........

7

-

43

8.1

A

IRSPEED INDICATOR RA

NGE MARKINGS

................................

..............

7

-

43

8.2

O

PER

ATING LIMITATION ON

INSTRUMENT PANEL

................................

..

7

-

44

8.3

P

ASSENGER WARNING

................................

................................

...........

7

-

44

8.4

“N

O INTENTIONAL SPINS

”

................................

................................

......

7

-

44

8.5

M

ISCELLANEOUS PLACARD

S AND MARKINGS

................................

........

7

-

44

9.

SUPPLEMENTARY INFORM

ATION

................................

...................

8

-

45

9.1

F

LIGHT FAMILIARIZATIO

N PROCEDURES

................................

................

8

-

45

9.2

P

ILOT OPERATING ADVIS

ORIES

................................

..............................

8

-

45

9.3

F

URTHER

I

NFORMATION

................................

................................

.......

8

-

45

10. APPENDIX

10.1 Airplane weight and balance statement………………………………..10

-

1

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

0

-

7

0.

General information

0.1

Introduction

This handbook is provided with your aircraft to allow you to attain as much knowledge about the aircraft

and its opera

tion as possible. This manual is following

ASTM F2746

-

09 Standard Specification for Pilot’s

Operating Handbook (POH) for Light Sport Airplane

. Read this manual thoroughly before your first flight

and make sure you understand all the information contained w

ithin. This aircraft is equipped with a non

-

certified engine that meets the ASTM F

-

2339 engine standard. Flying this aircraft must always be done

with the possibility of a safe landing due to loss of engine power.

Pay attention to the fact that you as the

pilot are fully responsible for the safety of your passengers and

persons or property on the ground.

0.2

Certification basis

This aircraft was manufactured in accordance with Light Sport Aircraft airworthiness standards and does

not conform to standard categ

ory airworthiness requirements.

0.3

Manufacturer

A

eropro

CZ

Mladá 835

687 25 Hluk

Czech Republic

0.4

Warnings, cautions and notes:

In this handbook the following is used to highlight especially important information:

WARNING

Information which could prevent

personnel injury or loss of life

CAUTION

Information which could prevent damage to equipment

NOTE

Information of special importance to pilots

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

8

1.

Airplane and systems description

The

Aeropro

A2

4

0

is an

S

-

LSA

aircraft

designed as a high

-

wing mono

plane. A two

-

spar wing is equipped

with

external airfoil

flaperons. Fuselage is an open truss structure welded of

chromoly

steel tubes. Tail

unit is formed of a lattice

-

work tube frame. The

A2

4

0

is equipped with t

ricycle

-

gear with a steerable

nosewheel

.

Wing area including flaperon

s

…………………

………

……………..

122.53 sq. ft

Chord length (inc

luding flaperon)………………

……….

……………

4.265 ft

Win

g loading...........................................................................

10.1 lbs/sq. ft

Power loading........

............................

..............................

........

12.35 lbs/HP

Aspect

-

ratio

.......................................

......................................

6.74

:1

Propeller

clearance..........................

..

........................

...

...

.........

1

1

.5

inches

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

9

1.1

Engine

The

A2

4

0

is powered by the Rotax 912ULS

100

-

hp

engine. It is a four

-

cylinder, four

-

stroke, horizontally

-

opposed, center

-

camshaft engine with overhead valves. Engine cooling is of a combined type; cylinder

heads ar

e water

-

cooled while cylinders are air

-

cooled. The engine has dry

-

sump lubrication. The ignition

system is a dual, electronic and capacitor flywheel magneto type. The engine is equipped with an electric

starter, AC generator and a mechanical fuel deliver

y pump. The propeller is driven by an integrated

reduction gearbox with mechanical damping.

Engine manufacturer

.....................................

.

..

Rotax GmbH., Austria

Engine model.........................

.............................

Rotax 912ULS

Ma

x. power

-

take

-

off............

...... 100 hp

-

continuous......

....

.

..

94 hp

Max. engine speed (MSL)

-

take

-

off................

5800 RPM (max. 5 min)

-

continuous.....

..

...

.

5500 RPM

Max. cylinder head temperature.......

..............................

....

....

280

F

Min. o

il temperature………………………………………

….

…

..

..

12

2

F for full

-

throttle operation

Normal ope

rating temperature……………………………

….

...

…

190

–

230

F

M

ax. oil temperature....................................................

.

...

.....

.

..

300

F

M

inimum oil pressure……………...................…

............

....

.

..

…

12 psi min oil pressure below 3,500 rpm

M

aximum oil pressu

re (cold start only)…………………

…..

..

.

.

..

103 psi

N

ormal oil pressure range..........................

.............

.........

...

.

..

29

–

73 psi

Oi

l consumption

…………………………………………

…

….

...

max 0.06 quarts/hour

Fuel pressure

-

minimum...............

...........................

.

....

.18 bar (2.2 psi)

-

maximum.............

..............................

..

.

.4

bar (5.8

psi)

Pr

opeller gearbox reduction ratio....

..............................

.

.

.....

...

.

2.43 : 1

For more details see

Operator’s Manual f

or all versions of

Rotax 912

supplied with the engi

ne.

WARNING

This aircraft is equipped with a non

-

certified engine that

meets

the

ASTM F

-

2339

engine standard.

Flying this aircraft must always be done with the possibility of a safe landing due

to loss of engine power. The pilot is fully responsible for consequences of such

failure.

1.2

Propeller

The

standard

propeller is manu

factured by

Woodcomp

in the

Czech Republic

.

The propeller is a

3

-

blade,

ground

-

adjustable prop.

Propeller

is 68" diameter.

For additional propeller information see

Operators Manual and Technical description

supplied with the

propeller.

1.3

Fuel and fuel cap

acity

Fuel tank capacity

-

wing tanks

(two)............................

.

....

10.6 U.S. gallons each

-

central connecting tank

(header tank)

...........................

1.

3

U.S. gallons

Max. fuel quantity

..............................................

...............

22.

5

U.S. gallons

Usable fuel quantity.........................

...............................

.

2

2

.

0

U.S. gallons

Unusable fuel quantity

......................................................

0.

5

U.S. gallons

Fuel specifications…

……....

..

p

remium unleaded auto fuel (Standard Spec. for Automotive

Spark

-

Ignition Engine, Fuel

, ASTM D 4814) or AVGAS 100 LL

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

10

Due to the higher lead content in AVGAS, the wear of the valve seats, deposits in th

e combustion

chamber and lead sediments in the lubrication system will increase. Therefore, use AVGAS only if you

encounter problems with vapor lock or if other fuel types are not available.

For additional information concerning fuel specification consult

the

Operator’s Manual for all versions

of Rotax 912

supplied with the engine.

The fuel system consists of two 10.6 U.S. gallon

s wing tanks, a 1.

1

U.S. gallons

central header tank

behind the left seat, a fuel drain valve positioned below the header tank,

three fuel valves, one fuel filter,

an engine driven fuel pump

,

a backup electric fuel pump (not shown in the diagram below),

and the

connecting fuel lines.

The fuel is gravity

-

fed from the right

-

hand and/or left

-

hand wing tank, through the wing tank fu

el values,

into the central header tank. The fuel is then further directed from the central tank through the fuel filter

and the electric fuel boost pump through the main fuel valve and to the mechanical fuel pump on the

engine which then delivers the fuel

to the carburetors.

The amount of fuel in each tank is indicated by a visual sight tube which is a part of each tank. Minimum

fuel quantity in the central tank is indicated by a red warning light on the instrument panel. The remaining

fuel (0.9 U.S. gall

on), is enough for approximately 10 minutes of flight. The low fuel warning light can be

tested at any time by pushing the control button next to the light on the instrument panel. If the red light

does not light up when the control button is pushed and he

ld, consider the bulb to be blown out and so do

not rely on the minimum fuel quantity warning light:

-

In this case, make a more conservative estimate for

fuel on board, regularly check the fuel quantity in wing tanks and land as soon as you are not confid

ent of

the fuel quantity in the wing tanks.

Although it is normal to leave both wing tank fuel values open, occasionally, one tank will drain faster than

the other. Should this situation occur, manipulate the fuel tank valves to ensure continuous flow of

fuel to

the engine is maintained.

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

11

The fuel drain valve outlet is located behind and below the left seat on the outside of the fuselage; to

check for water and dirt, push the neck of the drain pipe gently upwards, into the fuselage and

subsequently a fuel

sample can be taken.

For refuelling information see section

7.1

1.4

Oil

Oil tank capacity………………………………………………….

3.2 quarts

Maximum oil quantity…………………………………………….

2.6 quarts

Minimum o

il quantity…………………………………………….

2

.1 quarts

Oil specification:

Use semi

-

synthetic 10w40 motorcycle type oil of a registered brand name. Caution

:

When selecting the

most suitable lubricants refer to the additional information in the Rotax Service Information SI

-

18

-

1997.

Normally the recomme

nded oil is Aeroshell Sport 4 (a 10w40 semi

-

synthetic oil)

.

—

Use only oil with API classification "

SF

" or "

SG

"!

—

Due to the high stresses in the reduction gears, oils with gear additives such as high

performance motor cycle oils are required

—

Because of the

incorporated friction clutch, oils with friction modifier additives are

unsuitable as this could result in a slipping clutch during normal operation.

—

Heavy duty 4

-

stroke motor cycle oils meet all the requirements. These oils are normally

not mineral oils

but

are

semi

-

or full synthetic oils.

—

Oils primarily for Diesel engines are

insufficient

due to

high temperature properties

and additives which favor clutch slipping, generally therefore are unsuitable.

CAUTION

:

If the engine is mainly run on AVGAS

mor

e frequent

oil changes will be required. See Rotax

Service Information SI

-

18

-

1997.

For additional information concerning oil system consult

Operator’s Manual for all versions of Rotax

912

supplied with the engine.

The maximum and minimum oil level is indi

cated by two marks on the dipstick in the oil tank.

1.5

Operating weights and loading (occupants, baggage, fuel, ballast)

Empt

y weight (wit

h typical options).......................................

6

5

5

lbs

Max. take

-

off weight..............................

...............................

1235 lbs

Max. landing weight...............................................................

1235 lbs

Max. fuel weight………………………………………………….

135 lbs

Max. baggage

weight in baggage compartm

ent…………….

50

lbs

Maximum num

ber of p

ersons on board………………….......

2

Minimum crew weight……………………………………………

121 lbs

WARNING

Make sure that above

-

mentioned weight limits are strictly followed.

Structural failures which result from

overloading of the aircraft may

be dramatic and catastrophic.

The additional stress placed on the structural parts by overloading can accelerate the occurrence of metal

fatigue failures. Also

,

flight characteristics might change significantly when aircraft is

overloaded. Take

-

off

and landing distance is significantly longer for overloaded aircraft. Overloading of the

aircraft is one of the

causes of accidents.

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

12

1.6

Cockpit overview

LAYOUT OF CONTROLS AND INSTRUMENTS

(see following pages for details conc

erning Figures 1

-

9)

Fig.1

a

irspeed indicator

1. control stick

19. area for GPS or iPad installation

Fig.2

e

ngine start up

2. rudder pedals

20. air vents

Fig.3

m

ain fuel valve

3. flaperon control knob

21.

EIS engine instrumentation

Fig.4 EIS en

gine instrument

4. elevator trim control knob

22.

intercom

Fig.5

c

entral control panel

5. main fuel valve

23. ELT panel controller

Fig.6

f

laps, trim

6.

boost pump switch

24

. Rotax fuel pressure gauge

Fig.7 s

witches and

circuit breakers

7.

keye

d igntion switch

2

5.

cigarette lighter type power socket

Fig.8

c

ontrol lights

8. magneto on/off switches

26.

circuit breaker for power socket

Fig.9

d

oor lock mechanism

9. airspeed indicator

27.

mapbox

10.

altimeter/VSI

28.

throttle

11. tran

sponder

29.

carb heat knob

12. radio

30.

cockpit heat knob

13. EFIS/attitude indicator (optional)

31.

oil cooler flap knob

1

4. annunciator test button

32

brake lever

15. low fuel level warning light

33.

choke lever

16. low voltage war

ning light

34.

switches

17. EIS warning light

35.

circuit breakers

18.

compass

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

13

List of typical installed instruments and other equipment including options:

Type

Serial No.

a

irspeed indicator

ASI 150 M

-

3

a

ltimeter

and vertical speed indicator

MGL ALT

-

3 electronic

s

lip

i

ndicator

(in EFIS)

m

agnetic compass

CM

-

13

f

uel pressure

BDT1/31/B

ELT

ELT345

r

adio

-

intercom

ATR833

-

OLED

and PM1000II

t

ransponder with encode

r

Funkwerk Avionics TRT800H

-

OLED

EFIS or

a

ttitude indicator (optional)

Figure 1

-

Airspeed Indicator marking

Figure 2

-

Ignition and master switch

Ignition OFF

Ignition ON

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

14

Figure 3

-

Main Fuel Valve open and closed position

Figure 4

-

EIS Model 4000 for Rotax 912

-

series engines

Display panel description (shown is EIS page 1

-

defau

lt display page)

tachometer

-

engine RPM

OAT

-

outside air temperature

H

2O

–

coolant t

emperature

oil temperature

aircraft hourmeter

EGT

-

exhaust gas temperature (hottest EGT)

oil pressure

Indicator unit alert li

mits max limit

Engine rotation speed (rpm)

..........................

5

6

00 ................. 5800

EGT/Exhaust gas temperature (ºF)

..............

16

5

0 .................. 1850

H2O

/c

oolant

temperature (ºF)

.....................

2

28

................... 2

4

8

Oil temperature, (ºF)

................................

.....

260 ..................

. 300

Oil pressure, max (psi)

................................

.

8

4

................... 100

Oil pressure, min (psi)

................................

..

28 .................. 12 (minimum)

Oil pressure, normal (psi)....

......

..

..

. 29

-

72

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

15

T

he

EIS

system not only alerts you when reaching an actual system lim

it, it also has the

capability to provide alerts when reaching a Warning Limit that is just short of the actual non

-

permissible limit

.

When one or more Warning Limits are exceeded

–

the corresponding value blinks on the EIS

display, the alarm lamp on the i

nstrument panel blinks

.

When

the pilot presses the “Next/Ack”

button on the EIS,

the

Alarm Lamp goes steady until the out of tolerance condition is corrected.

When the actual limit is reached, the EIS reacts in the same manner as a new fault, except the

alarm lamp blinks at longer intervals. The pilot must press Next/Ack again to turn both the

blinking alarm light and EIS display to steady.

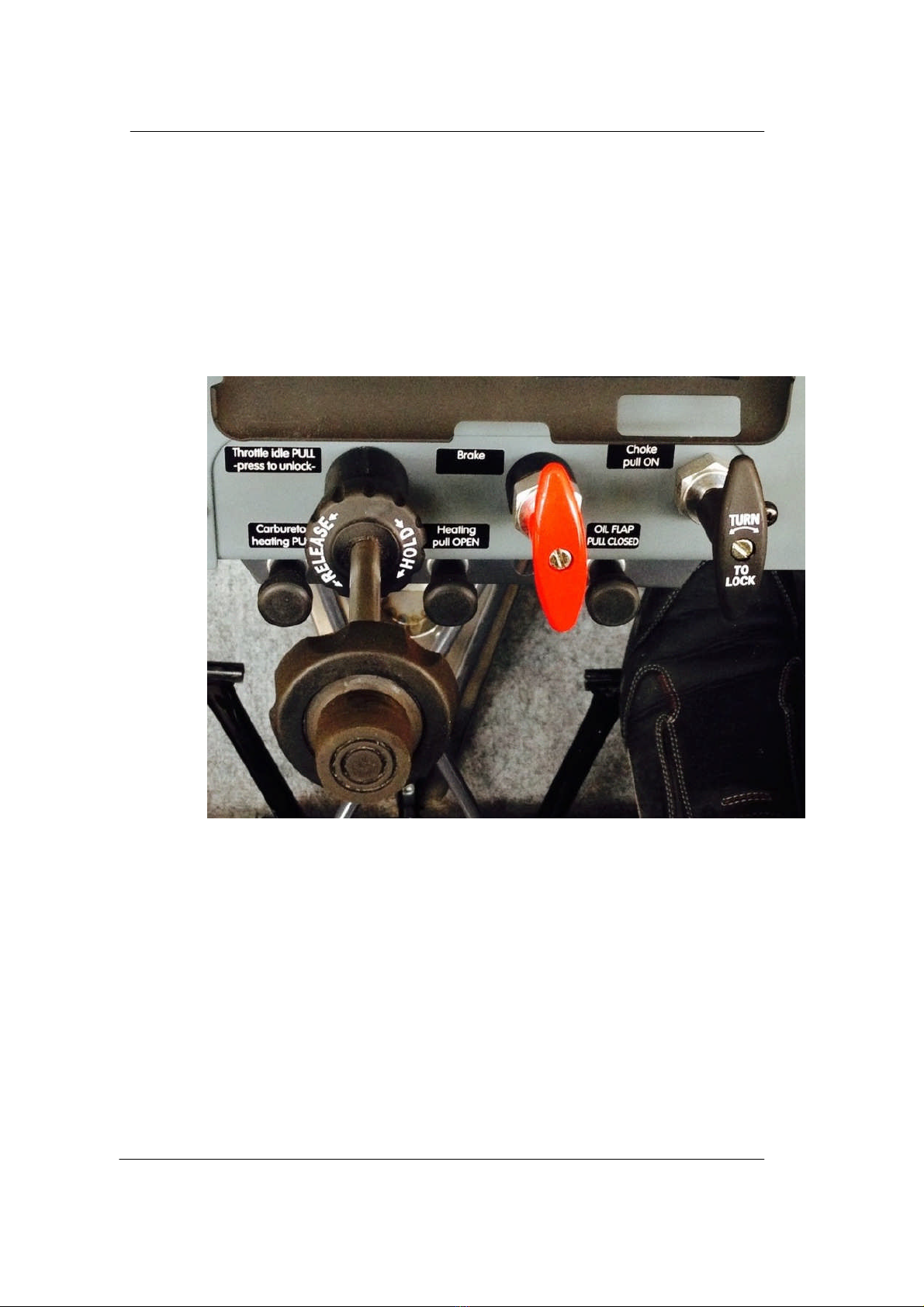

Figure 5

–

c

entral panel

Note: Rotate throttle lever

knob

for fine power settings (clockwise to increase power,

counterclockwise to reduce

power), for larger changes push/pull throttle when the button is pressed and held

.

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

16

Figure 6

–

Flaps and trim

Figure 7

–

Switches and fuses panel

(older panel shown...)

Figure 8

–

Control lights and fuel reserve bulb check

button

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

1

-

17

Figure 9

–

Door locking mechanism

The battery (Powersafe SBS8, 12v, 7 ah) is located behind the right

-

hand pilot’s seat. Nominal voltage in

aircraft system is 13.5 to 14.2 V. The engine is equipped with an integrated AC generator with external

rectifier

-

regulator (12 V, 20A DC).

1.7

Aircraft lighting equipment

The A220 features the Whelen LED wingtip lights. This system consists of a white rearward

-

facing LED

lights and a flashing LED strobe light on the side of both wingtips, a green forward

-

faci

ng LED light on the

right wingtip and a red forward

-

facing light on the left wingtip. There is also a landing light fitted to the

lower nose cowling which also acts as a taxi light. Power for the light system is taken from the aircraft's

main power supply.

NOTE:

The A240 is NOT approved for night flight, and the exterior aircraft lighting does not comply with all

the FAR requirements for night flight.

1.8

Electric fuel pump

The

A2

4

0

is equipped with an electric fuel pump with an on/off switch and "on" indicato

r light on the

instrument panel. The electric fuel pump serves as a booster or backup to the engine

-

driven mechanical

fuel pump.

The electric fuel pump should be used at any time when the sudden failure of the

engine

-

driven mechanical fuel pump and a los

s of fuel pressure could cause a loss of engine

power and compromise safety. Normally this will mean utilizing the electric fuel pump during

takeoff, during climb

-

out to a safe minimum altitude, during any low

-

altitude operations, and

during landing.

1.9

Add

itional equipment

reserved

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

2

-

18

2.

Operating limitations

Airspeed indicator system calibration:

As requested by ASTM F

-

2245

-

04

§9.1

all flight speeds are presented as calibrated airspeeds in miles

per hours (MPH). As the calibrated airspeed cannot be usually de

termined by a simple reading of the

aircraft airspeed indicator, corresponding Indicated airspeeds in miles per hours (MPH) are also

presented in this document. All airspeed values in this handbook assume no instrument error.

2.1

Stall speed at maximum take

-

o

ff weight (V

S

and V

SO

)

Aircraft configuration

Stall speed

–

angle of bank 0°

MPH

(Indicated Air speed)

MPH

(Calibrated Air speed)

Flaps down (V

so

)

4

1

45

Flaps up (V

s

)

.

49

.

50

WARNING

The stall speed mentioned above are with wings level. Once any

angle of bank

(e.g. turn) is encountered the stall spe

ed is significantly increasing.

e

xample: angle of bank

60° …….

V

S

= 73 MPH

The more bank

–

the higher the stall speed. This simple rule is especially important when a turn at

maximum permitted angle

of bank (60°) is performed. Do not start the turn until you have sufficient

airspeed reserve

–

recommended entry speed is 92 MPH. Full throttle is also essential to have sufficient

thrust reserve as the drag is

increasing during a steep turn.

2.2

Flaps extend

ed speed range (V

SO

to V

FE

)

MPH

(Indicated Air Speed)

MPH (Calibrated Air Speed)

Lower limit

41

45

Upper limit

93

90

MPH

(Indicated Air

speed)

MPH

(Calibrated Air

speed)

40

44

46

48

57

59

69

69

81

79

92

89

104

99

115

109

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

2

-

19

2.3

Maximum maneuvering speed (V

A

)

MPH

(Indicated Air Speed)

MPH

(Calibrated Air Speed)

Max. maneuvering speed (V

A

)

109

104

2.4

Never

exceed speed (V

NE

)

MPH

(Indicated Air Speed)

MPH (Calibrated Air Speed)

Never exceed speed

(V

NE

)

143

134

2.5

Crosswind and wind limitation

Maximum permitted wind speed components for take

-

off and landing:

m

ax. headwind ………………….……………..............

28 mph

(25 knots)

c

rosswind……………………………………………

.

.

….

17 mph (15 knots)

tail wind………………………………………………

..

….

7 mph (6 knots)

Crosswind take

-

offs and landings require training and experience, the higher crosswind component, the

better your skill must be. Do not fly with

out proper experience when the wind speed is approaching the

limit.

Avoid take

-

offs with a tail wind when possible

–

the total take

-

off distance is significantly longer and longer

ground distance is required to gain altitude.

When landing with a tail win

d the aircraft ground speed is higher resulting in longer landing distance.

2.6

Service ceiling

Service ceiling

................................

................................

..

14,760 ft (standard day)

WARNING

Oxygen mask and/or other equipment

as

required to reach

maximum

ceiling, consult respective re

gulations.

2.7

Load factors

Flaps up:

Maximum positive

load factor

(measured at CG)

………..……

+4 Gs

Maximum negative

load factor

(measured at CG)

……………

-

2 Gs

Flaps down:

Maximum positive

load factor

(measured at CG)

…………….. +

2 Gs

Maximum negative

load factor

(m

easured at CG)

…………….

0 Gs

2.8

Prohibited maneuvers

WARNING

Aerobatics and intentional spins are prohibited.

Maximum angle of bank

: 60°

Aeropro CZ

-

A2

4

0

-

Pilot Operating Handbook and Flight Training Supplement

Sept

ember 20, 2017

2

-

20

2.9

Other Limitations

WARNING

No s

moking

.

WARNING

Flights with rear

cockpit cover

removed are prohibited

.

WARNING

Flights at ambient temperature between 14

F and 32

F are permitted only

under no icing conditions and when the carburetor

heating is activated.

WARNING

IFR flights and flying in clouds is prohibited.

Night Flights are prohibited

.

Flight into know icing conditions is prohibited

.

This aircraft is not certified for operation in IMC (Instrument meteorological conditions). Alw

ays stay clear

of clouds and have visual contact with the ground. Follow the airspace classification regarding distance

from clouds. Always evaluate weather during your flight and try to get weather information from your

destination using radio whenever po

ssible. When weather is deteriorating make a diversion or turn back

before the low cloud base and/or low visibility are critical. The aircraft is not certified to be flown at night.

Table of contents

Other Aeropro Aircraft manuals