Aeropro N851NP Instruction Manual

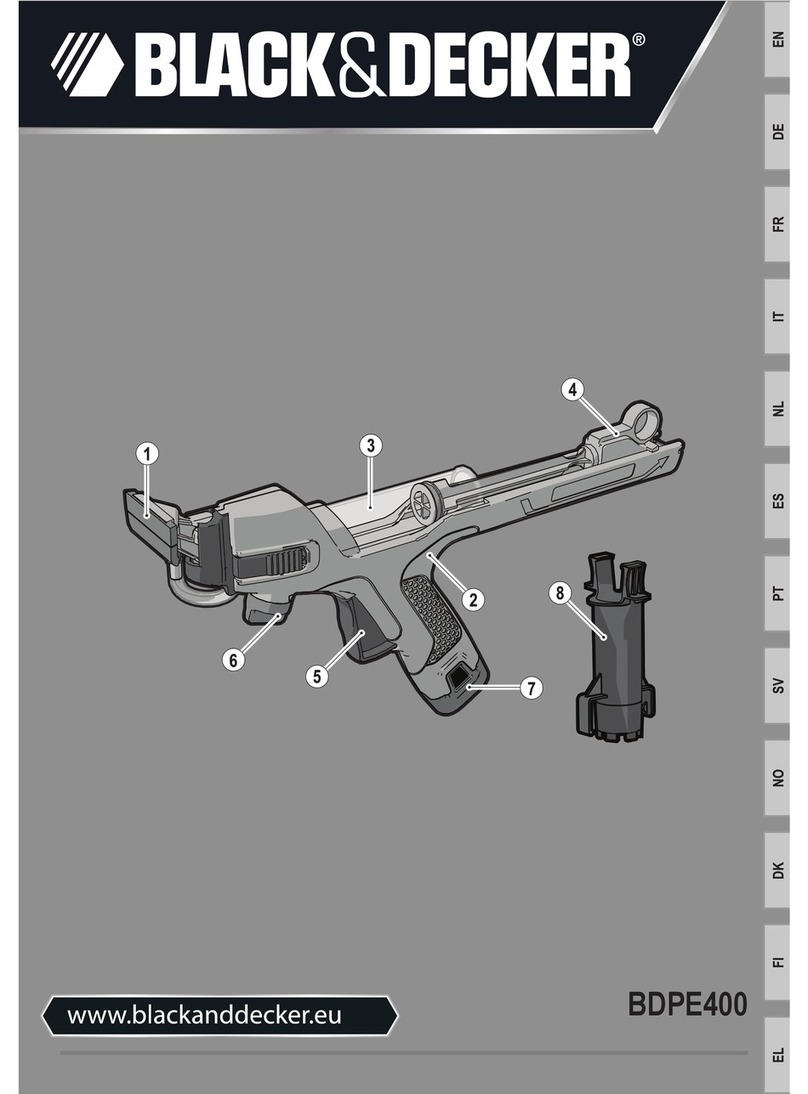

Fig 1.

Operating Instruction and safety manual

WIDE CROWN STAPLER –Model No. N851NP

Contain:

◎Technical Data

◎Important Safety Rules

◎Operating Instruction

◎Maintenance

◎Troubleshooting

◎Parts List

※Technical Data

Type:

N851NP

Max. working pressure

8.3bar(120psi)

Capacity

50pcs

Operation pressure

4.8-7.5bar(70-110PSI)

Staple length

25-50mm(1’’-2’’)

Air inlet

1/4”

Fastener size

16Ga (1.60×1.40mm)

Dimension

362×340×80mm

Weight

2.1kg

※Important Safety Rules

1. KEEP CHILDREN AWAY. All children should be kept away from the work area. Don’t let them

handle the tool.

2. USE SAFETY GLASS AND EAR PROTECTION: Air tool operators and others in work area

should always wear safety glass to prevent the injury from fastenersand flying debris when

loading and unloading this tool. Maybe the noise would harm your hearing, wear the ear

IMPORTANT:

Upon receipt of the product, read and follow all safety rules,

operating instructions before first use it. And retain this manualfor

future reference.

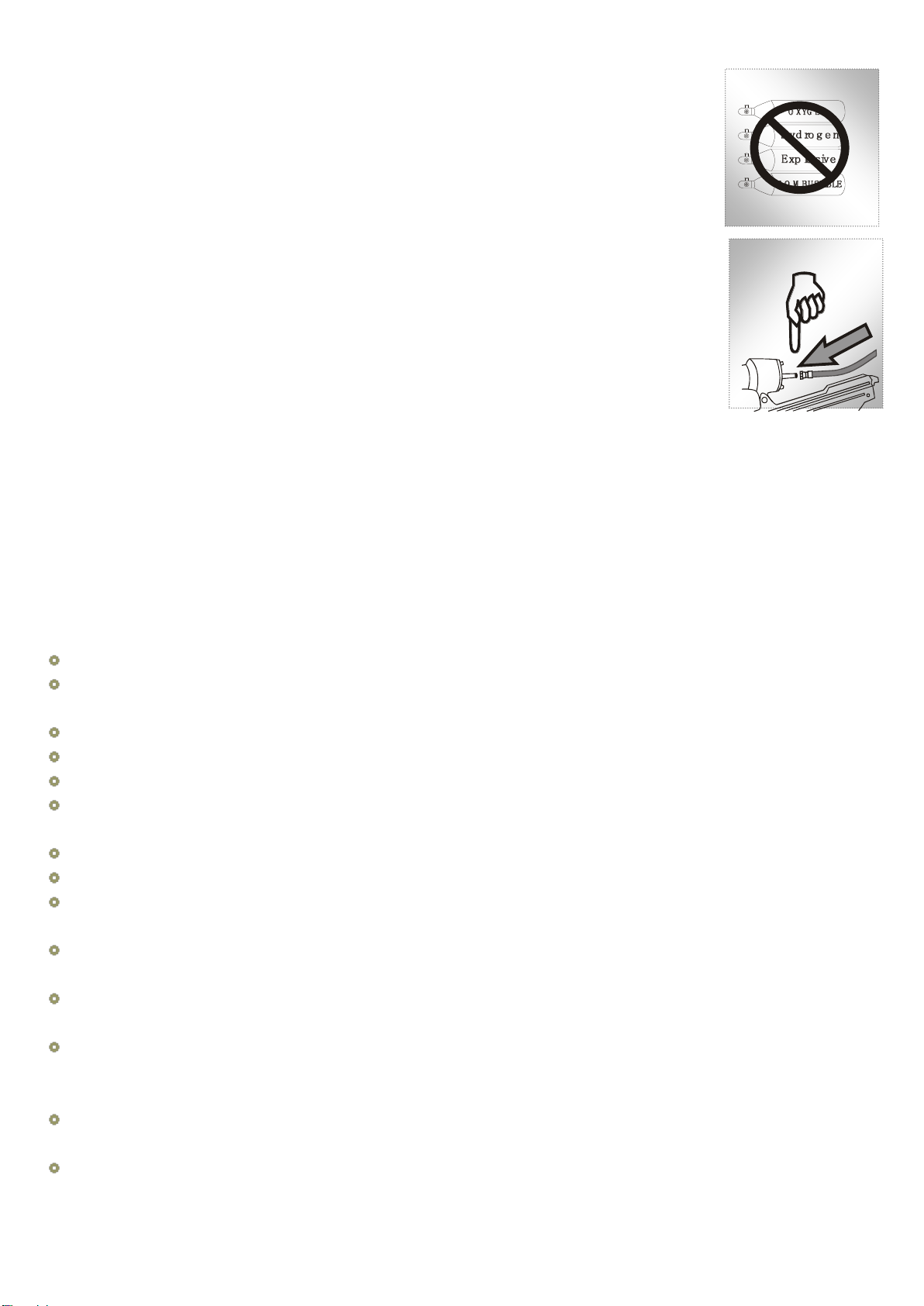

Fig 2.

Fig 3

protection to safeguard. (See fig 1.)

3. NEVER USE OXYGEN, COMBUSTIBLE OR ANY OTHER BOTTLE GAS as a power source

or would cause explosion and serious personal injury. (See fig 2.)

4. DO NOT CONNECT TOOL TO COMPRESSED AIR which pressure exceeds 120psi.

5. DO NOT PLACE OVER-LONG AIR HOSE in working area in case of the operator’s

unexpected tripping .Make sure all connections are tight

6. CARRING TOOL ONLY BY THE HANDLE do not keep the trigger pull on safety yoke

mechanism to avoid unintentional firing of fastener.

7. KEEP THE TOOL POINTED AWAY FROM YOURSELF and others at all time and keep hands,

any body parts away rear area to Safety guard against possible injury.

8. DISCONNECT TOOL FROM AIR SUPPLY BEFORE LOADING fasteners to prevent a

fastener from being fired during connection. (See fig3.)

9. DO NOT KEEP THE TIRGGER OR SAFETY DEPRESSED during loading fasteners or the

unintentional firing of a fastener would cause personal injury.

10. DO NOT KEEP THE TIRGGER OR SAFETY DEPRESSED during loading fasteners or the

unintentional firing of a fastener would cause personal injury.

11. DISCONNECT TOOL FROM AIR SUPPLY HOSE and close the compressor before performing maintenance, alter the

accessories or during non-operation.

12. DO NOT DRIVE FASTENER ON SCAFFOLDINGS,LADDERS and on such similarly construction, not working on

airtight case, and vehicles.

13. DO NOT DRIVE FASTENER ON TOP OF NAILED FASTENER, or the fastener can ricochet causing personal injury.

14. NEVER USE A TOOL that is leaking air, had missing or damaged parts or requires repair and make sure all the screws

and securely tightened.

15. ONLY USE PARTS AND ACCESSORIES recommend by manufacturer.

※ADDITIONAL SAFETY INSTRUCTIONS FOR PNEUMATIC POWER TOOLS

Air under pressure can cause severe injury.

Always shut off air supply, drain hose of air pressure and disconnect tool from air supply whenever not in use, before

changing accessories or where making repairs.

Never direct air at yourself or anyone else.

Whipping hoses can cause severe injury. Always check for damaged or loose hoses and fittings.

Cold air should be directed away from the hands.

Whenever universal twist couplings(claw couplings) are used, lock pins shall be installed and whip check safety

cables shall be used to safeguard against possible hose-to-tool and hose-to-hose connection failure.

Do not exceed the maximum air pressure stated on the tool.

Never carry an air tool by the hose.

Only fasteners listed in the specifications may be used in the fastener driving tool. The fastener driving tool and the

fasteners specified in the specifications are to be considered as one unit safety system.

Quick action couplings shall be used for connection to the compressed air system and the non-sealable nipple must

be fitted at the tool in such a way that no compressed air remains in the tool after disconnection.

Oxygen or combustible gases shall not be used as an energy source for compressed air operated fastener driving

tools.

Fastener driving tools shall only be connected to an air supply where the maximum allowable pressure of the tool

cannot be exceeded by more than 10%; in the case of higher pressure ,a pressure reducing valve which includes a

downstream safety valve shall be built into the compressed air supply.

Only the main energy and the lubricants listed in the operating instructions may be used for the maintenance of

fastener driving tools. Only spare parts specified by the manufacturer or his authorised representative shall be used.

Repairs shall be carried out only by the manufacturer's authorized agents or by other experts, having due regard to

the information given in the operating instructions.

Stands for mounting the fastener driving tools to a support, for example to a work table, shall be designed and

constructed by the stand manufacturer in such a way that the fastener driving tools can be safely fixed for the

intended use, thus for example avoiding damage, distortion and displacement.

Check prior to each operation that the safety and triggering mechanism is functioning properly and that all nuts and

bolts are right.

Do not carry out any alterations to the fastener driving tool.

Do not disassemble or make inoperative any parts of the fastener driving tool such as the safety yoke.

Do not perform any ¡°emergency repairs¡±without proper tools and equipment.

The fastener driving tool should be serviced properly and at regular intervals in accordance with the manufacturer¡¯s

instructions.

Avoid weakening or damaging the tool, for example by:

-punching or engraving;

-modification not authorized by the manufacturer;

-guiding against templates made of hard material such as steel;

-dropping or pushing across the floor;

-using the tool as a hammer;

-applying excessive force of any kind.

Never point any fastener driving tool at yourself or at any other person or animal.

Hold the fastener driving tool during the work operation in such a way that no injuries can be caused to the head or to

the body in the event of possible recoil consequent upon a disruption in the compressed air supply or hard areas

within the workplace.

Never actuate the fastener driving tool into free space.

This will avoid any hazard caused by free flying fasteners and excessive strain of the tool.

The tool shall be disconnected from the compressed air system for the purpose of transportation, especially where

ladders are used or where an unusual physical posture is adopted whilst moving .

Carry the fastener driving tool at the workplace using only the handle, and never with the trigger actuated.

Take conditions at the workplace into account. Fasteners can penetrate thin work pieces or slip off corners and edges

of workplaces, and thus put people at risk.

For personal safety, use protective equipment such as hearing and eye protection.

Fastener driving tools are operated by actuating the trigger using finger pressure.

In addition, fastener driving tool is fitted with a safety yoke which enables the driving operation to be carried out only after

the safety yoke of the tool is pressed against a work piece, These tools are marked with an inverted triangle (▽)behind the

serial number and are not permitted for use without an effective safety yoke. A safety yoke is not required on fastener

driving tools which accelerate the heaviest usable fasteners to a free flight velocity below an admissible risk of injury.

Those fastener driving tools are not marked with an inverted triangle.

※Operating instruction

Description

Model N851NP drives Ga.16 finish nails from 25mm to 50mm length. Large cast aluminum body provide more power to

easily drive nails in to hard wood. Quick and easy pushing follower for fast loading. Comfort grip rubber handle for

improved control and comfort even during extended use. Fasteners system can shoot frequently. Narrow nose is ideal

for door and window trims, exterior trims, and cabinet work, finish paneling, decorative trims, furniture making and etc.

Air supply

1. Use clean, Dry and Regulated compressed air at 4.8-7.5bar (70-110psi). Never exceed maximum permissive

operating pressure 8.3bar (120psi).

2. Never exceed maximum and minimum pressure. Too low or too high pressure would cause noise, fast-worn or

misfiring.

3. When connecting air supply always keep hands and body from discharge area of tool.

4. A filter-regulator-lubrication is required and should be located as close to tool as possible.(see fig.4)

5. Keep air filter clean. Adirty filter will reduce the air pressure to the tool causing a reduction in power and efficiency.

6. For better performance, install a quick connector in your tool and quick coupler on the hose if possible.

7. Be sure all connections in air supply system are sealed to prevent air loss.

Loading fastener and operation

WARNING: Always disconnect the tool from the compressed air before loading. When loading the tool always point

the tool away from yourself and others. Make sure that you are not holding the tool with trigger depressed while loading the

tool.

1. Insert a strip of fasteners into magazine Keeping it point down.

2. Release the latch and pusher, slid the pusher against the nails.

3. Connect the tool to the air supply. Make sure the air pressure is in the correct range denoted in the Technical Data.

4. Then test the driving depth in a sample piece of wood before using. If the fasteners are being driven too far or not far

enough, adjust the regulator to provide less air pressure or more air pressure.

5. Never operate tool unless safety nose is contact with workpiece. Do not operate tool without fasteners or damage to

tool may result.

6. Never fire fasteners into air because fasteners may injury operator or others and damage to tool may result.

※Maintenance

WARNING: Disconnect the tool from the air compressor before adjusting, clearing jams, servicing, relocating and

during non operation.

·Regular lubrication, if your tool without using the in-liner automatic oilier, place 2 or 6 drops of pneumatic tool oil into

the air inlet before each work day or after 2 hours of continuous use depending on the characteristic of workpiece or type of

fasteners.

·Check and change all worn or damaged o-rings, seals, etc. Tight all the screws and caps in case personal injury.

·Inspect trigger and safety mechanism to assure safe system is complete and functional: no loose and missing parts,

no building or sticking parts.

·Keep magazine and nose of tool clean and free of any dirt lint or abrasive particles.

※Troubleshooting

The following form lists the common operating system with problem and solutions. Please read the form carefully and

follow it.

WARNING: If any of the following symptoms appears during your operating, stop using the tool immediately, or

serious personal injury could result. Only a qualified persons or an authorized service center can perform repairs or

replacement of tool.

Disconnect tool from air supply before attempting repair or adjustment. When replacing O-rings or Cylinder, lubricate with

air tool oil before assembly.

SYMPTOM

PROBLEM

SOLUTIONS

Air leak near top of tool or

in trigger area

1.O-ring in trigger valve are damage.

2.Trigger valve head are damage.

3.Trigger valve stem ,seal or O-ring are

damaged.

1.Check and replace O-ring.

2.Check and replace.

3.Check and replace trigger valve stem,

seal or O-ring

Air leak near bottom of tool.

1. Loose screws.

2. Worn or damaged O-rings or

bumper.

1.Tighten screws.

2.Check and replace O-rings or bumper.

Air leak between body and

cylinder cap.

1. Loose screws.

2. Worn or damaged O-rings or seals.

1.Tighten screw.

2.Check and replace O-rings or bumper.

Blade driving fastener too

deep.

1. Worn bumper.

2. Air pressure is too high.

1.Replace bumper.

2.Adjust the air pressure.

Tool does not operate well:

can not drive fastener or

operate sluggishly.

1. Inadequate air supply.

2. Inadequate lubrication.

3. Worn or damaged O-rings or seals.

4.Exhaust port in cylinder head is

blocked.

1.Verify adequate air supply.

2.Place 2 or 6 drops of oil into air inlet.

3.Check and replace O-rings or seal.

4.Replace damaged internal parts.

Tool skips fasteners.

1.Worn bumper or damaged spring.

2.Dirt in front plate.

3.Dirt or damage prevents fasteners

from moving freely in magazine.

4.Worn or dry O-ring on piston or lack

of

lubrication.

5.Cylinder cover seal leaking.

1.Repalce bumper or pusher spring.

2.Clean drive channel on front plate.

3.Magazine needs to be cleaned.

4.O-ring need to be replaced.

And lubricate.

5.Replace Sealing washer.

Tool jams

1.Incorrect or damaged fasteners.

2.Damaged or worn driver guide.

3.Magazine or nose screw loose.

4.Magazine is dirty.

1.Change and use correct fastener.

2.Check and replace the driver.

3.Tighten the magazine.

4.Clean the magazine.

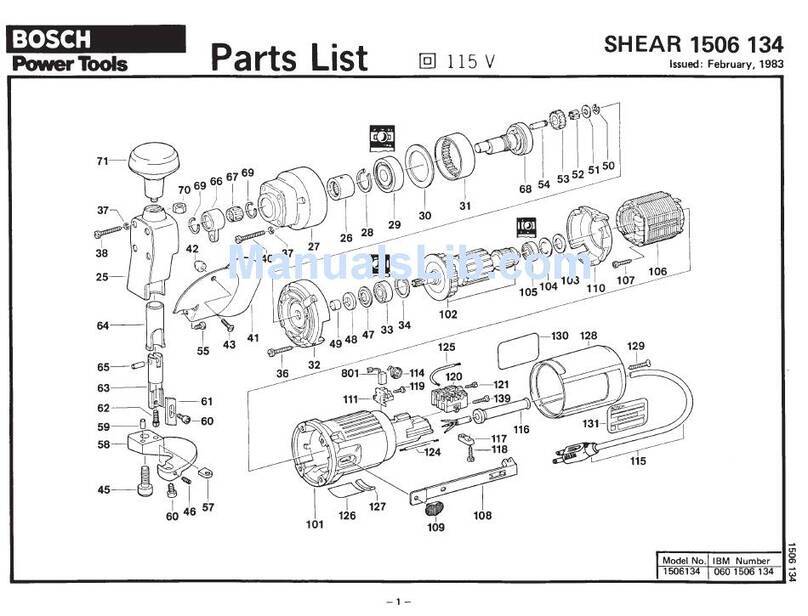

N851NP Explosive View and Parts list

Issue date:

Version no.:

No.

Figure number

Description

Qty.

No.

Figure number

Description

Qty.

No.

Figure number

Description

Qty.

No.

Figure number

Description

Qty.

accessories

Note:If you need spare parts of this model, pls feel free to contact us or the distributor where you bought this tool. Tks!

Hex bolt

Bearing

O-ring 9X1.8

Exhaust cap

Hex bolt

Spring washer

Cylinder cap

Compressed spring seat

Compressed spring

O-ring 38.7x2.65

Valve

O-ring 48.7X2.65

Cylinder seal ring

Lining ring

O-ring 57.5x3

O-ring 41.7x3

O-ring 46.2x3.55

Cylinder

O-ring 35.5x3.55

Piston-Driver

Bumper

Cylinder washer

Gun body

Oriented washer

O-ring 1.7x2

Oriented seat

Trigger pin

Safety spring

Safety assembly

Trigger

Pin 3x16

Safety stand

Switch seal ring

Valve seat

O-ring 16x1.6

O-ring 6.1x1.8

O-ring 6.4x2

Valve case

Switch spring

O-ring 2.5x1.5

Switch Lever

O-ring 18x2.65

Switch seat

Trigger handle spring

Hex bolt

Spring washer

Plate

Nose

Hex bolt

Hex bolt

Safety cover

Fixed plate

Hex bolt

Limit bolt

Spring roller

Pusher

Hex bolt

Magazine

Hex bolt

Stand

Plate

Stand bumper

Stand pin

Fixed seat

Rubber handle Grip

End cap washer

End cap

Hex bolt

Air coupler

oiler

wrench M5

wrench M6

Table of contents

Other Aeropro Power Tools manuals