Helm HELMPAK User manual

HelmPak Press Control

1

Users Guide

Helm Instrument Co. • 361 West Dussel Drive • Maumee, Ohio USA • 419-893-4356

HELMPAK™

Press Control

HelmPak Press Control

2

Users Guide

HelmPak Press Control

3

Users Guide

SECTION 1:

INTRODUCTION........................................................................................................................................... 4

THE HELM-PAK SYSTEM............................................................................................................................. 4

WARNINGS.................................................................................................................................................... 5

SECTION 2:

WHAT IS CLUTCH / BRAKE SOFTWARE?.................................................................................................. 6

POSITION MONITORING............................................................................................................................. 6

PROGRAMMABLE LIMIT SWITCH AND DIE MONITORING BASICS...................................................... 6

SECTION 3:

BASIC OPERATION .................................................................................................................................... 12

MODE OF OPERATION ............................................................................................................................ 13

SHUT DOWN SYSTEM................................................................................................................................ 13

SECTION 4:

SCREEN NAVIGATION............................................................................................................................... 14

LOGIN.......................................................................................................................................................... 15

COUNTERS.................................................................................................................................................. 15

MOTOR CONTROL ..................................................................................................................................... 16

TONNAGE MAIN......................................................................................................................................... 17

TONNAGE ALARMS.................................................................................................................................... 18

SECTION 5:

SYSTEM SETUP ......................................................................................................................................... 19

TONNAGE CALIBRATION ......................................................................................................................... 20

SHUTHEIGHT SETUP ............................................................................................................................... 21

MOTOR SETUP .......................................................................................................................................... 22

ROBOT SETUP ........................................................................................................................................... 23

SECTION 6:

RECIPE SETUP AND DOWNLOAD .......................................................................................................... 24

ACTIVE JOB SETUP .................................................................................................................................. 29

APPENDIX A:

ALARM EXPLANATIONS ........................................................................................................................... 34

LIMITED WARRANTY ........................................................................................................... 43

HelmPak Press Control

4

Users Guide

HelmPak Press Control

5

Users Guide

SECTION 1:

INTRODUCTION

You have just purchased the most advanced press control system available. HELM

INSTRUMENT COMPANY, INC. manufactures a complete line of press control solutions

for use on metal stamping, forging, compaction and assembly presses.

At HELM, quality is inherent not only in the design of our products but in the attitudes of

our employees as well. We’re working together to give you the best. After all, that’s what

our business is all about - providing innovative instrumentation to help make your

manufacturing processes more productive and your operations more efficient.

THE HELM-PAK SYSTEM

Helm-Pak consists of an operator interface type enclosure containing the, run buttons,

press control processors, magnetics and Human Machine Interface (HMI). These

components are laid out for the maximum operator efficiency.

The control enclosure(s) contain Allen-Bradley SLC PLC’s, operating pushbuttons,

selector switches and the operator Interface.

The dual rack configurations provide the redundant control of the clutch and brake

system. Both controllers monitor all clutch/brake I/O and exchange information about

machine status. They are linked by hardwired I/O so if one controller detects a condition

different from that detected by the other, the control logic is designed to declare a fault

and turn off all outputs to press valves. The other controller is designed to follow suit.

Compliance:

The package uses two redundant processors with application software for self testing and

verification to meet the safety requirements of ANSI B11.1, OSHA 1910.217 and

CAN/CSA Z142-M90 press safety regulations for mechanical stamping presses.

HelmPak Press Control

6

Users Guide

REPLACING MODULES

Do not remove modules under power.

The module location in a specific rack is critical to proper operation of the Helm-Pak press control. If a

module is replaced, ensure that the proper module is inserted into the proper slot in the rack. If it is not

the ladder programming will not recognize the module and the Helm-Pak control will become unstable

and unsafe to operate.

TURNING SYSTEM ON

SAFETY FIRST Check all light curtains, barriers, safety shields and

personnel safety devices to ensure that they are present and functioning

properly. If they are not, do not proceed with starting the press. Authorized

personnel should make any repairs that are required before starting the press.

Alwa

y

s wear e

y

e and ear

p

rotection when o

p

eratin

g

a stam

p

in

g

p

ress.

HelmPak Press Control

7

Users Guide

SECTION 2:

CLUTCH / BRAKE SOFTWARE

The HelmPak Clutch/Brake Control System is a bundle of hardware, software, and

engineering documents designed to control the clutch and/or brake mechanism on a

mechanical stamping press that has a part-revolution friction clutch and/or brake. This

system uses two processors for clutch/brake control.

The clutch/brake control system is designed to signal brake wear by monitoring the brake

monitor cam (BCAM). Should it see the BCAM closed after a normal cycle stop has been

initiated and before the press comes to a top stop, it is designed to protect against press

restart. System

I/O modules in both Clutch/Brake chassis are identical for clutch/brake control. If the

processor in one chassis detects a condition different from that detected by the other, its

control logic is designed to declare a fault and turn off all outputs to press valves. The

other processor is designed to follow suit. Dual processors control outputs to

clutch/brake valve. Chapter 1

Clutch/Brake Modes:

The operator can select the mode of control system operation with the selector switch

located on a control panel.

Mode Operation

Inch Jog the press through successive parts of the cycle by pressing and

releasing the pair of INCH buttons. If INCH buttons are held, the press

will stop at the top of its stroke, if inch stop on top is enabled in the setup

menu.

Single-stroke Run the press through one complete cycle by holding both RUN buttons

until completion of the down stroke.

Continuous Run the press in a single on demand manner until stopped by a stop-on-

top command or until a fault is detected. The method to start the press is

a factory configured option where operator presses the CONTINUOUS

SETUP button and press both RUN buttons in all active stations within

five seconds.

POSITION MONITORING

•The Helm-Pak Press control is configured with dual resolvers to monitor the position

of the press electronically. The control system monitors the rotational position of the

press.

HelmPak Press Control

8

Users Guide

PROGRAMMABLE LIMIT SWITCH OPERATION

PLS software is a group of engineered press-control products for PLC processors. This

software controls the operation-of:

•Programmable Limit Switch (PLS) for crankshaft synchronization

WHAT IS A PROGRAMMABLE LIMIT SWITCH?

The Programmable Limit Switch is ladder logic for a PLC -based control system that

times or sequences outputs according to precise and repeatable positions of a

crankshaft. Crankshaft positions are monitored by a resolver. You can use PLS to

integrate auxiliary press machinery such as lifters, grippers, blow-off valves, and inter-

press automation into your stamping press control system.

HOW A PLS CHANNEL WORKS

You preset the rotational position (preset angle) at which you want the PLS output to turn

ON. You select how you want the PLS output to turn off: based on a preset angle or a

preset time. If the PLS is to only occur intermittently, based on a number of strokes, then

Intermittent angle or intermittent timer mode is necessary. You will then select the

number of strokes, time duration, or OFF angle based on the desired mode of operation

HelmPak Press Control

9

Users Guide

APPLY DM SENSORS TO A STAMPING PROCESS IN A VARIETY OF WAYS.

STOCK

MATERIAL

STRAIGHTNER

END OF

MATERIAL

ELECTRONIC

FEED

BUCKLE

DETECT

LIGHT

CURTAIN

PROGRESSION

LUBRICATOR

PART

BLOW OFF

SLC PROCESSOR

LIGHT

CURTAIN

PARTS

BIN

RESOLVER

PART-EJECTION

LIGHT

SHORT

FEED

Typical PLS / DM / Load Monitoring Application

FOR EXAMPLE:

SENSORS TO DETECT MOVEMENT OF A PART

part in position

part ejected

feed

coil

misfeed

SENSORS TO DETECT STATIC CONDITIONS

lube

end of feed

die clamps

air pressure

DESCRIPTION OF MODES

The purpose of DM channels is to verify that predictable conditions in your press

operation take place. When the software detects a fault condition, it sets a selected

output response. You select the type of mode for each channel from the following:

Static

Cyclic

Intermittent Cycle

In Position

Intermittent In Position

Use the following table to help you select the types of channel modes

required for your application.

HelmPak Press Control

10

Users Guide

Mode: Signal must be seen as follows, or function sets an output action:

static continuously

cyclic Thru a preset angular window once every cycle.

Intermittent cyclic Thru a preset angular window after a preset number of press cycles

in position thru a preset angular window (with part in place)

intermittent in position Thru a preset angular window with part in place after a preset number of press

cycles.

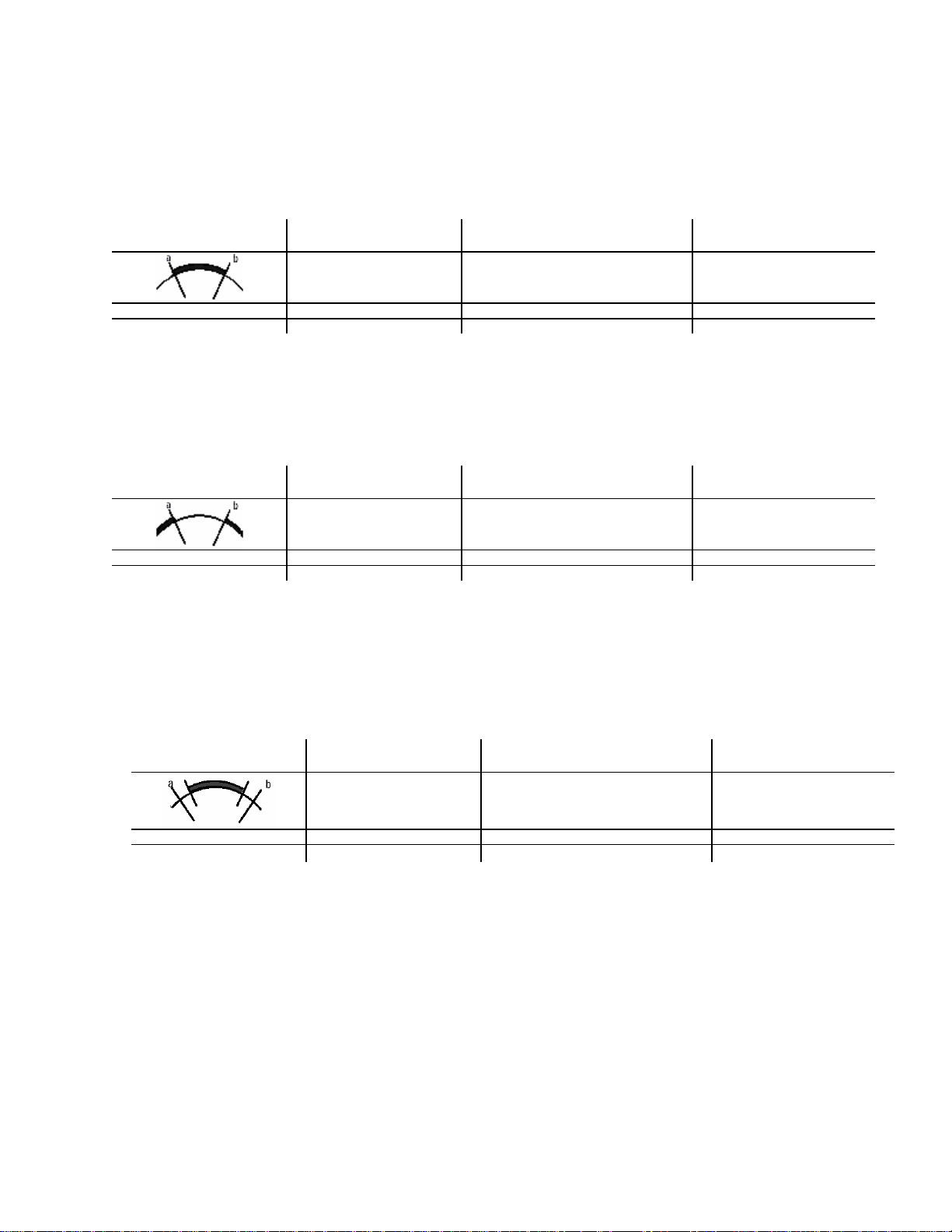

DEFINITION OF DIE MONITORING WINDOW

Window Input signals for Cyclic (CYC) and In-position (POS) modes are synchronized

with the rotation of the crankshaft, and must be detected within a zone of crankshaft

rotation. We call this zone a window. For example, a part-detect signal could be expected

within a window of 80-110º to indicate that a part was inside a die before it was hit by a

stroke.

When the software detects input signals that are different from those described here, the

software generates a fault signal. We graphically define these (window) inputs as follows:

DEFINITION OF DIE MONITORING WINDOW

Cyclic (CYC) N.O. Use this mode to verify that a pulse from the sensor (OFF-ON-OFF)

occurred within the window once each stroke. For example, use it to detect that a part

moved past a monitor.

Transition Diagram For These

Expected Transitions Input is NOT ALLOWED

When Sensor: Which Results in a

Fault Signal Sent After:

Sensor turns ON then OFF

within window 1. stays ON beyond window window goes OFF

2. turns ON outside window sensor turns ON

3. remains OFF for the cycle next window goes ON

Cyclic (CYC) N.C. Use this mode to verify that a pulse from the sensor (ON-OFF-ON)

occurred within the window once each stroke. For example, use it to detect that a part

moved past a monitor.

Transition Diagram For These

Expected Transitions Input is NOT ALLOWED

When Sensor: Which Results in a

Fault Signal Sent After:

Sensor turns OFF then ON

within window 1. stays OFF beyond window window goes OFF

2. turns OFF outside window sensor turns OFF

3. remains ON for the cycle next window goes OFF

HelmPak Press Control

11

Users Guide

In-position (POS) N.O. Use this mode to verify that the sensor signal remained ON

within the entire window once each stroke. The signal must cycle OFF outside the

window. Use it to detect if an ejector and other automation parts are retracted to home

position.

Transition Diagram For These

Expected Transitions Input is NOT ALLOWED

When the Sensor Signal: Which Results in a

Fault signal Sent After:

Sensor turns ON before,

and OFF after window 1. turns OFF before window goes OFF sensor turns OFF

2. does not turn OFF outside window next window goes ON

3. remains OFF for the cycle next window goes OFF

In-position (POS) N.C. Use this mode to verify that the sensor signal remained OFF

within the entire window once each stroke. The signal must cycle ON outside the window.

Use it to detect if an ejector and other automation parts are retracted to home position.

Transition Diagram For These

Expected Transitions Input is NOT ALLOWED

When the Sensor Signal: Which Results in a

Fault signal Sent After:

Sensor turns OFF before,

and ON after window 1. turns ON before window goes ON sensor turns ON

2. does not turn ON outside window next window goes OFF

3. remains ON for the cycle next window goes ON

DEFINITION OF DIE MONITORING WINDOW

Intermittent Cyclic (ICYC) Use this mode to verify that a pulse from the sensor (OFF-

ON-OFF) occurred within the window once after a preset number of press cycles.

Transition Diagram For These

Expected Transitions Input is NOT ALLOWED

When Sensor: Which Results in a

Fault Signal Sent After:

Sensor turns ON then OFF

within window 1. stays ON beyond window window goes OFF

2. turns ON outside window sensor turns ON

3. remains OFF for the cycle next window goes ON

DEFINITION OF DIE MONITORING WINDOW

Static Mode (STC) Use this mode to detect that an event occurred independent of the

press stroke. When a static-mode input turns Off, the programmed output is turned On.

For example, use it to detect end of stock.

HelmPak Press Control

12

Users Guide

OUTPUT RESPONSES FOR DIE MONITORING CHANNELS

When the software detects a channel fault, it displays the channel number and type of

fault on the Operator Interface screen. The software also sets a fault response that you

select from the following:

Warning (displays alarm banner on the active screen)

Top Stop

E-Stop

Output bypassed (no fault response)

HelmPak Press Control

13

Users Guide

SECTION 3:

BASIC OPERATING INSTRUCTIONS

•Turn power on

•Set CONTROL POWER to ON

•Press CONTROL POWER RESET, to reset the safety relay

•Start the Oil/Coolant pumps, button will turn green when all pumps running

•Set the press MODE selector switch to INCH mode

•Set the Main Motor selector switch to FORWARD

•Press Main Motor Start

•Verify that the current job/recipe matches the part being produced

•Set the press MODE selector switch: Inch, single, or Continuous

The Main Menu screen is the initial startup screen.

Fault conditions are indicated on the top of the screen in the alarm banner. Clear any

faults by pressing the FAULT RESET button on the operator station.

Press is ready to start – Refer to Mode of Operation

♦To EMERGENCY STOP the press push E-STOP

♦To stop the press in a non-emergency press TOP STOP

HelmPak Press Control

14

Users Guide

MODE OF OPERATION

Off Disable operation of clutch/brake control.

Inch Press and release both RUN buttons on side of

Operator Interface enclosure to inch slide. Hold

RUN buttons in and press will make one

complete cycle, stopping at the top of the cycle,

if inch stop on top is enabled

Single Stroke Press and hold RUN buttons for entire down

stroke of press, past 180. Press will stop at the

top of the cycle.

Continuous Run In this application Continuous is being used to

operate the press in a Single-On-Demand mode.

Press CONTINUOUS SETUP button. Press

both RUN buttons within 5 seconds of pressing

the CONTINUOUS SETUP button. Hold the

RUN buttons for the entire down stoke of the

first cycle. Release the RUN buttons on the

upstroke of the first cycle. The press should

now be operating in Single-On-Demand mode.

The press will stop at the top of the press stoke,

waiting for the robot to leave and initiate another

stroke. The press will wait at top for an amount

of time determined in the Job Recipe.

SHUT DOWN SYSTEM

To shut down the Helm-Pak:

•Stop the press

•Shut off Main Motor

•Shut Control Power off.

•Turn panel power off.

HelmPak Press Control

15

Users Guide

SECTION 4:

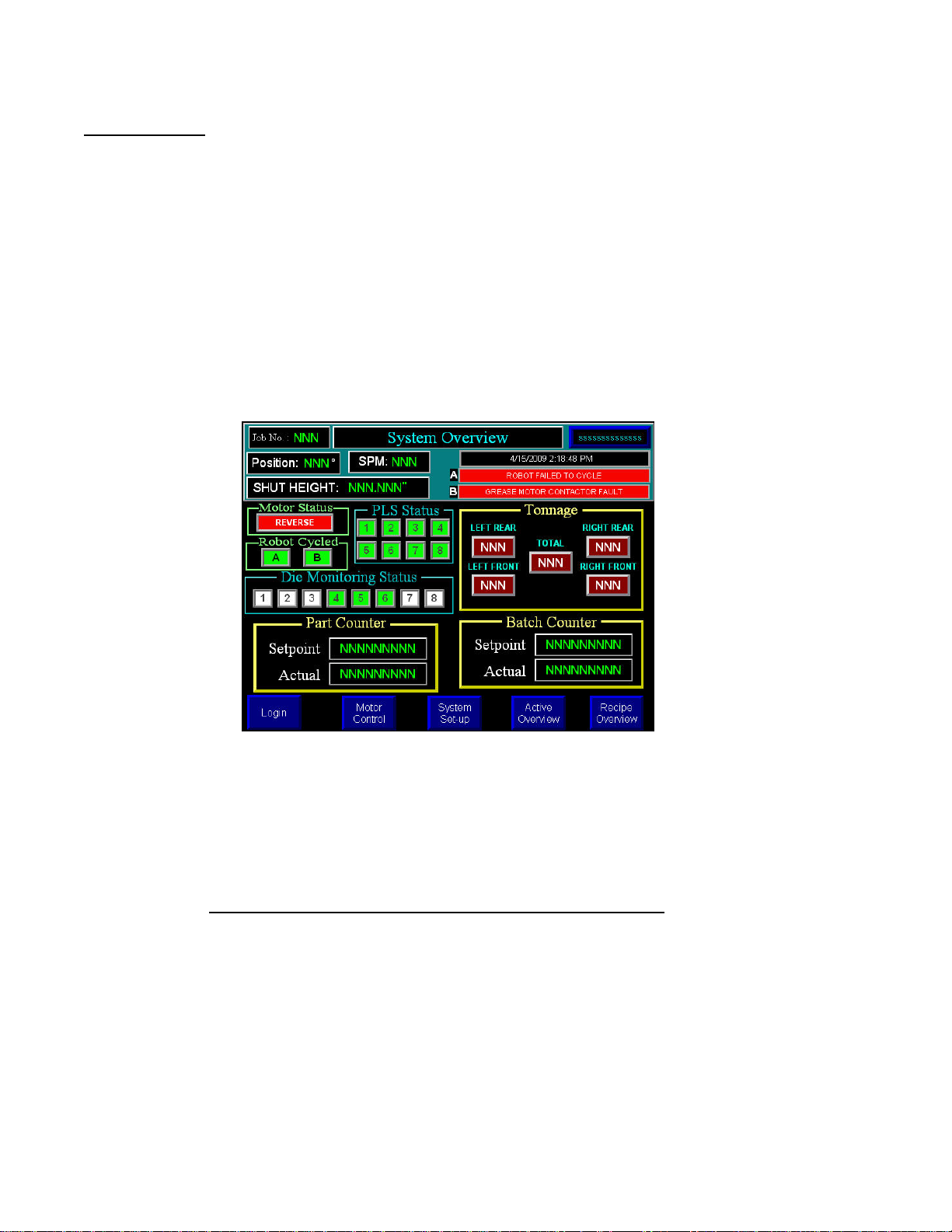

SCREEN NAVIGATION

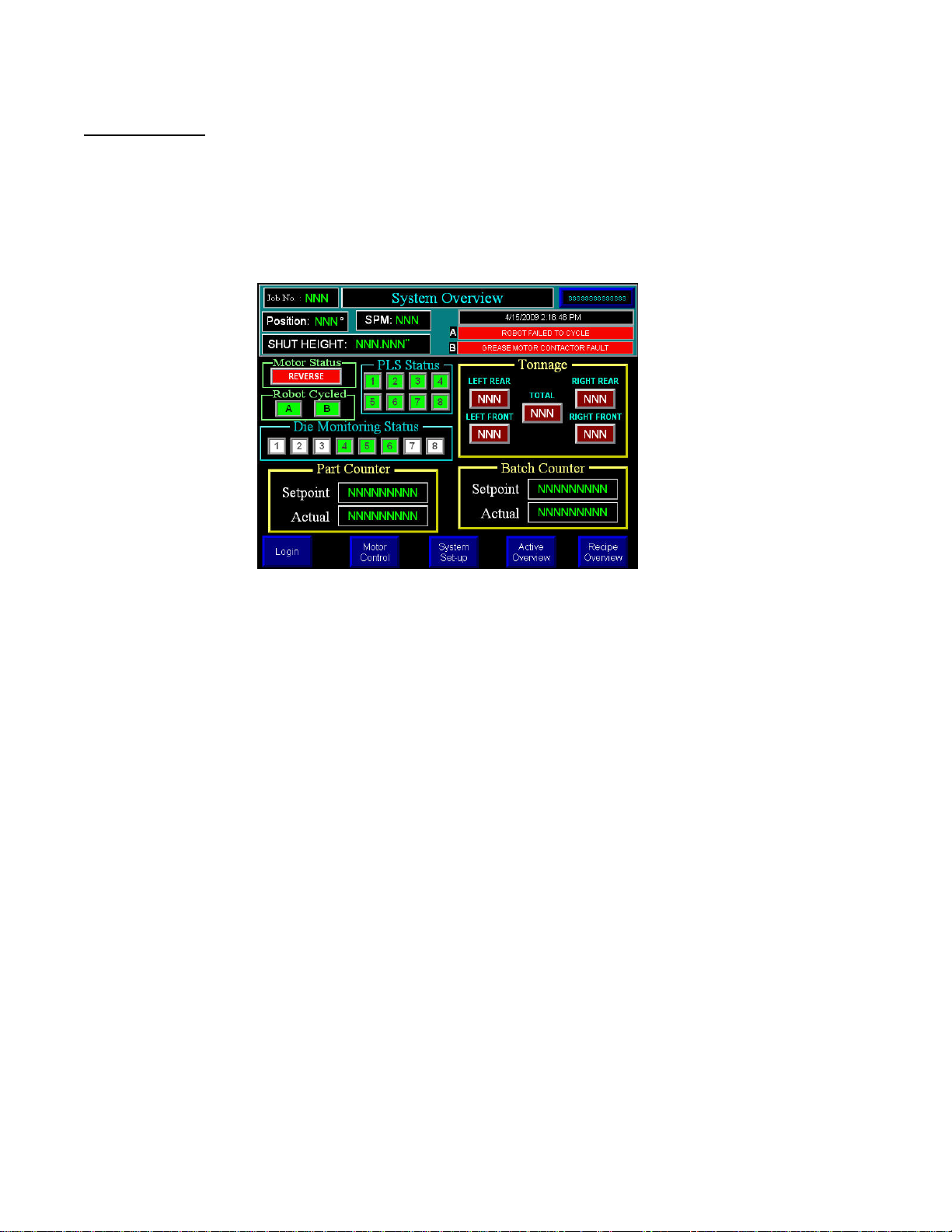

MAIN MENU

The MAIN SCREEN provides a display of pertinent information about the current run, including the

FAULT description when a machine stop occurs.

If recipe is incorporated into your system, the current job number is displayed. If shutheight monitoring is

installed, the current shutheight is displayed.

Entering a Preset

Most of the screens allow you to set a preset by touching the field for entry area on the screen. A data

entry field will pop up and you will use the numeric or alphanumeric keys to enter the value. Use the

ENTER key to store the value.

All Setup screens require a user to be logged in with sufficient privileges; this is done through the Login

Screen. Users can logout manually from the login screen or they will be automatically logged out after 30

minutes of no activity on the HMI.

By pressing on the various sections of the main menu, the user will be directed to that specific screen.

For example Tonnage will take the user to the main tonnage screen, Counters to counters screen, etc.

HelmPak Press Control

16

Users Guide

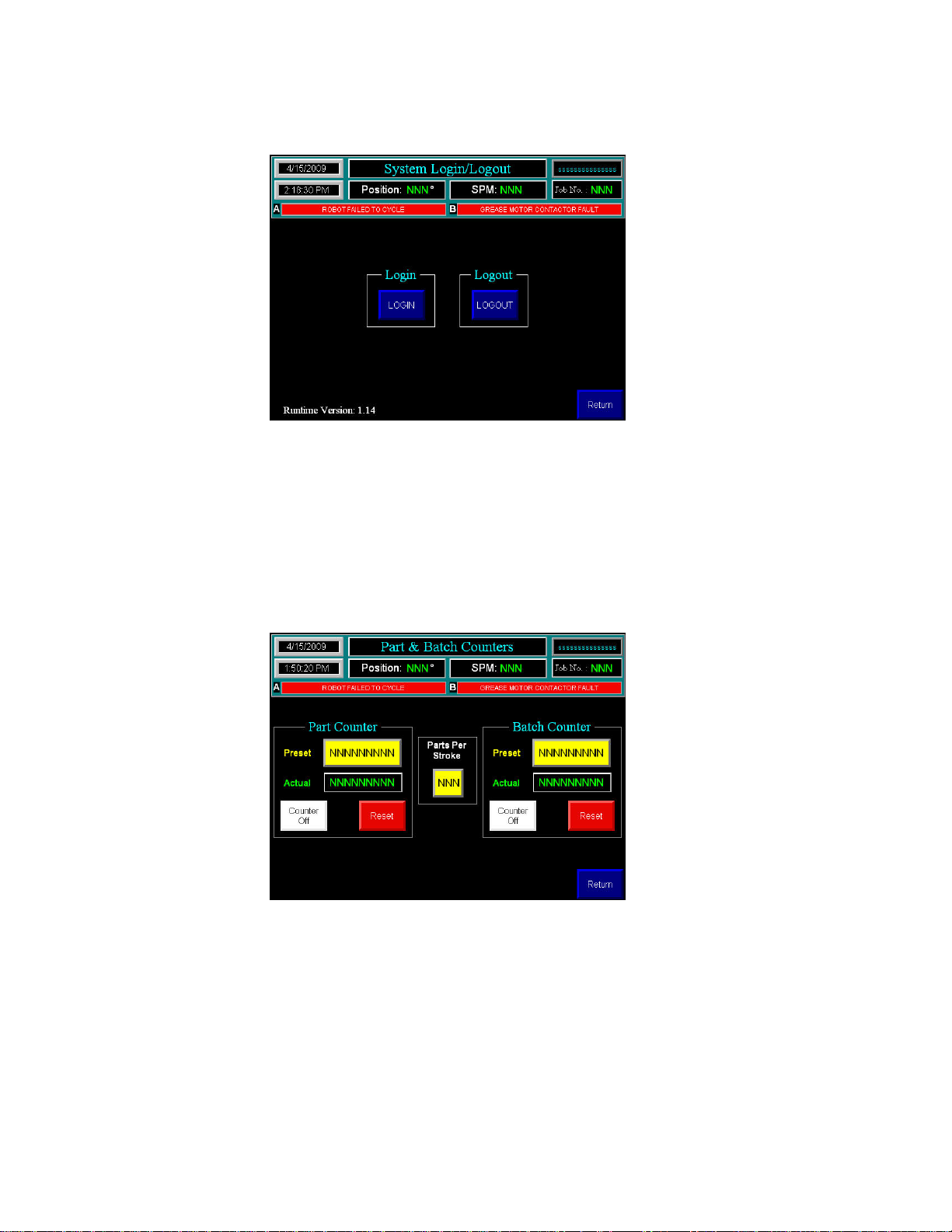

Login

Runtime Version – displays the current version of the HMI Application

Login – will bring up a user/password message, which will allow for value entry.

Logout – will log a user out and return the system to the “Default” user.

A user will automatically be logged out if there is no screen activity for 30 minutes.

Counters

Parts Per Stroke – Identifies the number of parts each counter will be incremented by per press stroke

Counter: Preset – the value at which the count will continue to accumulate

Actual – the current value of the counter

Counter On/Off – enables the counter

Reset – Resets the Actual value

HelmPak Press Control

17

Users Guide

Motor Control

This screen allows the user to Start and Stop the Filter Motor, as well as displaying the current status of

the motor.

HelmPak Press Control

18

Users Guide

Tonnage Main

The 4 channels of Tonnage are all displayed individually, along with corresponding trending displays, and

the Total Tonnage.

The Monitor Parts/Peak Push Button Determines the mode of the Tonnage Module

Peak Mode – capacity alarms are active, trend alarms are inactive

Monitor Mode – both capacity and trend alarms are active

The Reverse Load Off/On Push Button Determines the mode of the Tonnage Module

Off – The module monitors standard load/force.

On – The module monitors the measurement of negative load/force being exerted on

machine following the break-through of material, also referred to as snap through.

HelmPak Press Control

19

Users Guide

Tonnage Alarms

High Capacity – displays the current High Capacity Alarm Setpoint.

These values are set for each channel and are typically established as press

capacity alarms. Each channel is typically set based on the formula:

Press Capacity divided by number of strain gage channels.

This value can be set lower that press capacity on each channel, but no

higher than 195% of scale factor.

High / Low Trend % - Displays the current Trend Percentage for the running tonnage

These values, set independently on each channel, are based on a percent of

allowable change from a sampled tonnage. This value can range from 1% to 99%. A

setting of 0% disables the trend alarms.

HelmPak Press Control

20

Users Guide

SECTION 5:

System Setup

On the main System Setup screen, the user has 5 entry options, 4 page buttons, and an exit to

configuration screen button. The Exit to Configuration screen button exits out of the current running

application, to the built in HMI interface.

Resolver Setup

This is used to calibrate the resolver input module during initial installation.

Move the crank position to 0 degrees and press Zero Resolver.

Calibrate the resolver input module in both PLC A & PLC B processors.

DM Inch Bypass

This buttons will allow Die Monitoring Inch Bypass to be enabled or disabled ( Enabled by Default)

Inch Stop On Top

This buttons will allow Inch Stop On Top to be enabled or disabled (disabled by Default)

Top Stop Setup

Run the press at maximum speed.

Enter the arbitrary number into the minimum angle. (350)

Run a Single stroke.

Add or subtract the top stop angle value to get an accurate top stop and enter that value into the top stop

angle. For instance if the press stops at 30°, Subtract 30 from the top stop and enter that value of

350(350-30=320). Enter 320 into the minimum angle.

Brake Monitor Setup

Shows the brake stop time in milliseconds and brake fault preset time, which is the amount of time in

milliseconds allowed before the system alarms on a brake fault time fault.

Table of contents