7ENGLISH

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listedbelowmayresultinelectricshock,reand/or

seriousinjury.

Save all warnings and instruc-

tions for future reference.

The term "power tool" in the warnings refers to your

mains-operated(corded)powertoolorbattery-operated

(cordless) power tool.

Jig saw safety warnings

1.

Hold the power tool by insulated gripping sur-

faces, when performing an operation where the

cutting accessory may contact hidden wiring or

its own cord. Cutting accessory contacting a "live"

wire may make exposed metal parts of the power tool

"live" and could give the operator an electric shock.

2.

Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holdingtheworkpiecebyhandoragainstyourbody

leavesitunstableandmayleadtolossofcontrol.

3.

Always use safety glasses or goggles. Ordinary

eye or sun glasses are NOT safety glasses.

4. Avoid cutting nails. Inspect workpiece for any

nails and remove them before operation.

5. Do not cut oversize workpiece.

6. Check for the proper clearance beyond the

workpiece before cutting so that the blade will

not strike the oor, workbench, etc.

7. Hold the tool rmly.

8. Make sure the blade is not contacting the

workpiece before the switch is turned on.

9. Keep hands away from moving parts.

10. Do not leave the tool running. Operate the tool

only when hand-held.

11. Always switch off and wait for the blade to

come to a complete stop before removing the

blade from the workpiece.

12. Do not touch the blade or the workpiece imme-

diately after operation; they may be extremely

hot and could burn your skin.

13. Do not operate the tool at no-load

unnecessarily.

14.

Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation and

skin contact. Follow material supplier safety data.

15. Always use the correct dust mask/respirator

for the material and application you are work-

ing with.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

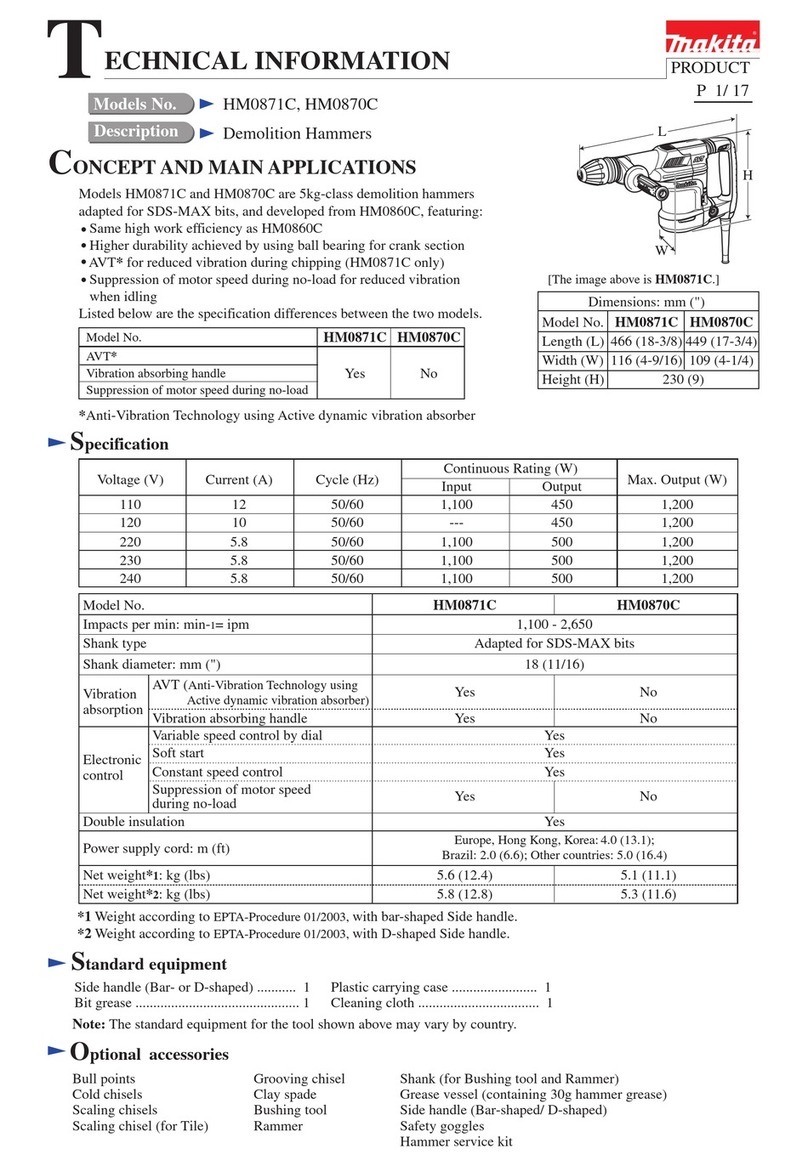

FUNCTIONAL DESCRIPTION

CAUTION:

• Alwaysbesurethatthetoolisswitchedoffand

unpluggedbeforeadjustingorcheckingfunction

on the tool.

Selecting the cutting action

►Fig.1: 1. Cutting action changing lever

Thistoolcanbeoperatedwithanorbitalorastraight

line(upanddown)cuttingaction.Theorbitalcutting

actionthruststhebladeforwardonthecuttingstroke

and greatly increases cutting speed.

Tochangethecuttingaction,justturnthecuttingaction

changing lever to the desired cutting action position.

Refertothetabletoselecttheappropriatecuttingaction.

Position Cutting action Applications

For cutting mild steel,

stainless steel and plastics.

For clean cuts in wood

and plywood.

Small orbit

cutting action

For cutting mild steel,

aluminum and hard wood.

For cutting wood and

plywood.

For fast cutting in

aluminum and mild steel.

Large orbit

cutting action

For fast cutting in

wood and plywood.

0Straight line

cutting action

Medium orbit

cutting action

Switch action

►Fig.2: 1. Switch trigger 2.Lockbutton

CAUTION:

• Before plugging in the tool, always check to see

that the switch trigger actuates properly and

returns to the "OFF" position when released.

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

For continuous operation, pull the switch trigger and

thenpushinthelockbutton.

To stop the tool from the locked position, pull the switch

trigger fully, then release it.

Speed adjusting dial

For 4350CT, 4350FCT

►Fig.3: 1.Speedadjustingdial

Thetoolspeedcanbeinnitelyadjustedbetween800

and2,800strokesperminutebyturningtheadjusting

dial.Higherspeedisobtainedwhenthedialisturnedin

thedirectionofnumber5;lowerspeedisobtainedwhen

itisturnedinthedirectionofnumber1.

Refertothetabletoselecttheproperspeedforthe

workpiecetobecut.However,theappropriatespeed

may differ with the type or thickness of the workpiece. In

general, higher speeds will allow you to cut workpieces

fasterbuttheservicelifeofthebladewillbereduced.