Sefa LP 130 V3 User manual

User guide

Manuel utilisateur

Guía del usuario

Benutzerhandbuch

ENGLISH

FRANÇAIS

ESPAÑOL

DEUTSCH

LP 130 V3

HEAT TRANSFER TECHNOLOGIES

www.sefa.fr 3

EnglishFrançaisEspañolDeutsch

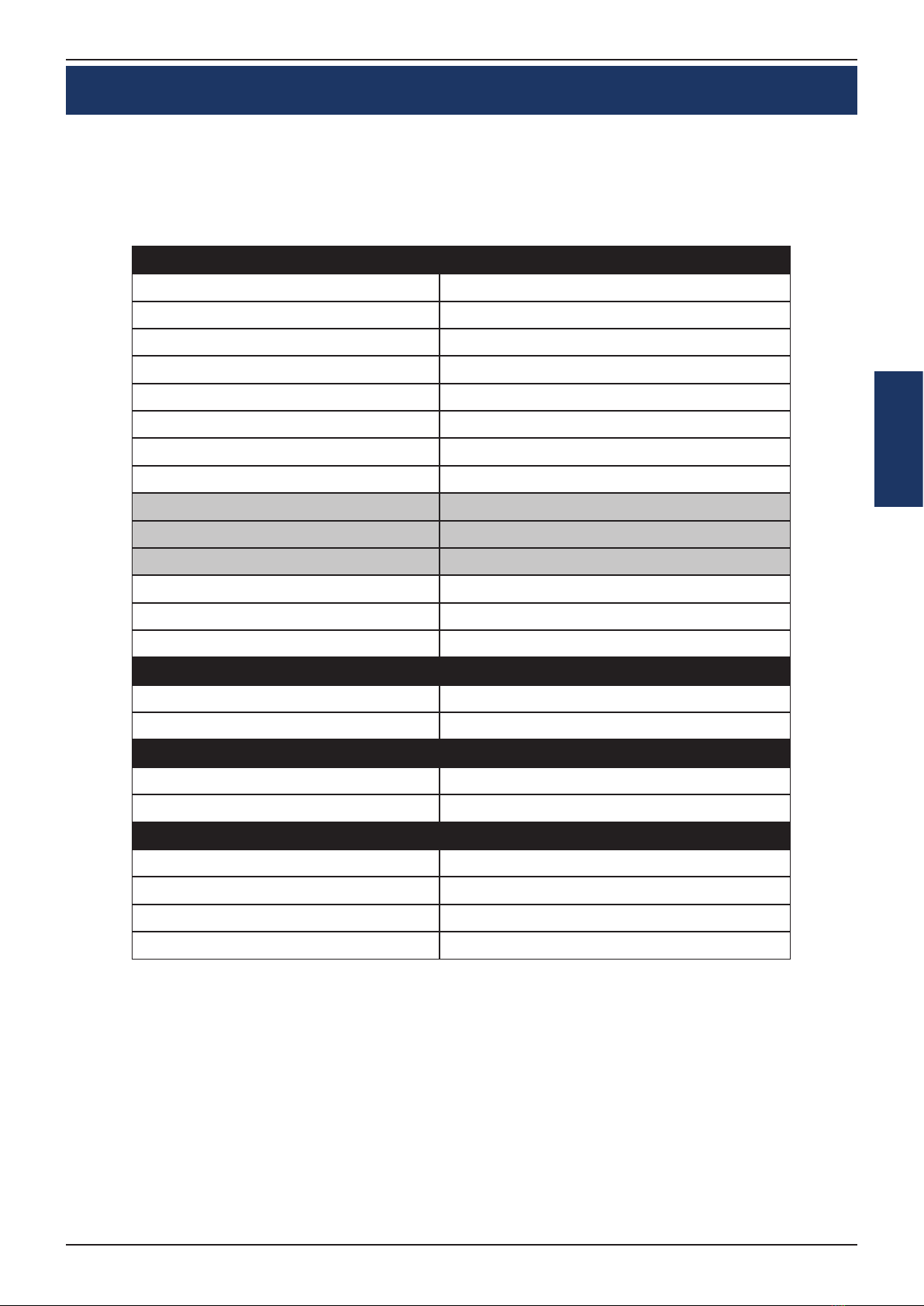

INDEX

INDEX

INDEX������������������������������������������������������������������������������������������������������������������������������������������������������������������� 3

WARRANTY TERMS ������������������������������������������������������������������������������������������������������������������������������������4

TECHNICAL DATA����������������������������������������������������������������������������������������������������������������������������������������� 5

OVERVIEW��������������������������������������������������������������������������������������������������������������������������������������������������������6

SAFETY ����������������������������������������������������������������������������������������������������������������������������������������������������������������7

OPERATION������������������������������������������������������������������������������������������������������������������������������������������������������8

SMART TOUCH ® CONTROL SCREEN ����������������������������������������������������������������������������������������� 11

SERVICING�������������������������������������������������������������������������������������������������������������������������������������������������������15

TROUBLESHOOTING TIPS ������������������������������������������������������������������������������������������������������������������� 16

CONDITIONS DE GARANTIE���������������������������������������������������������������������������������������������������������������18

CARACTERISTIQUES �������������������������������������������������������������������������������������������������������������������������������� 19

GENERALITES����������������������������������������������������������������������������������������������������������������������������������������������20

SECURIT����������������������������������������������������������������������������������������������������������������������������������������������������������21

UTILISATION ��������������������������������������������������������������������������������������������������������������������������������������������������22

ÉCRAN DE CONTROLE SMART TOUCH ®���������������������������������������������������������������������������������25

MAINTENANCE������������������������������������������������������������������������������������������������������������������������������������������� 29

CONSEILS D’INTERVENTION RAPIDES�������������������������������������������������������������������������������������� 30

CONDICIONES DE GARANTÍA�����������������������������������������������������������������������������������������������������������32

CARACTERÍSTICAS ������������������������������������������������������������������������������������������������������������������������������������33

ASPECTOS GENERALES �����������������������������������������������������������������������������������������������������������������������34

SEGURIDAD���������������������������������������������������������������������������������������������������������������������������������������������������35

UTILIZACIÓN������������������������������������������������������������������������������������������������������������������������������������������������� 36

PANTALLA DE CONTROL SMART TOUCH ®��������������������������������������������������������������������������� 39

MANTENIMIENTO�������������������������������������������������������������������������������������������������������������������������������������43

CONSEJOS DE INTERVENCIÓN RÁPIDA ����������������������������������������������������������������������������������44

GARANTIEBESTIMMUNGEN��������������������������������������������������������������������������������������������������������������46

TECHNISCHE DATEN������������������������������������������������������������������������������������������������������������������������������ 47

ALLGEMEINES���������������������������������������������������������������������������������������������������������������������������������������������48

SICHERHEIT ��������������������������������������������������������������������������������������������������������������������������������������������������49

VERWENDUNG ������������������������������������������������������������������������������������������������������������������������������������������50

SMART TOUCH ® BEDIENDISPLAY�����������������������������������������������������������������������������������������������53

WARTUNG�������������������������������������������������������������������������������������������������������������������������������������������������������57

RATSCHLÄGE FÜR SCHNELLE EINGRIFFE������������������������������������������������������������������������������58

SPARE PARTS����������������������������������������������������������������������������������������������������������������������������������������������� 59

WIRING DIAGRAM������������������������������������������������������������������������������������������������������������������������������������60

PNEUMATIC DIAGRAM �������������������������������������������������������������������������������������������������������������������������� 61

MAINTENANCE LOG ������������������������������������������������������������������������������������������������������������������������������� 62

2021-03-25

4 www.sefa.fr

English

WARRANTY TERMS

The warranty period shall come into effect on the day on which the equipment is

brought into service at the user’s premises, as attested on the returned warranty certif-

icate and the delivery note, and shall run for two years, based on a standard equipment

operating schedule of 8 hours per day, i.e. 3,000 hours.

The warranty is strictly limited to our equipment, and covers faulty materials and work-

manship,

which the purchaser shall be required to substantiate.

Our liability shall be limited to making good or replacing free of charge parts that are

acknowledged by us to be defective, and no claims for damages for any reason may be

made against us.

Parts replaced under warranty shall:

- Remain our property

- Be invoiced on consignment

A credit note will be issued upon return of the faulty parts.

Returns must be made NO LATER THAN ONE MONTH after the work is performed un-

der warranty.

THIS WARRANTY DOES NOT COVER :

Commercially sourced consumables such as:

- Fuses, LEDs, seals, hoses, nozzles, filters, etc.

- Material and equipment not manufactured wholly by us, which are covered by the

warranty of the manufacturer thereof.

THIS WARRANTY DOES NOT EXTEND TO :

Replacements or repairs arising from fair wear and tear of the appliances or machines,

damage or accidents arising from negligence, lack of supervision or maintenance, im-

proper use or alterations made without our written consent.

Defects arising from material provided by the purchaser or mandatory design require-

ments issued by the purchaser.

Repairs made necessary by damage or accidents arising during carriage.

Normal maintenance and adjustment procedures required during use of the machine,

as set out in the maintenance instructions, such as:

- adjustment of intermediate components

- tightening of pipes, hoses, etc.

Any traces of detergent oil in the air system of pneumatic machines

shall invalidate the aforementioned warranty terms.

Quote the machine reference and serial number when making technical enquiries

or ordering spare parts.

User guide - SEFA LP 130 V3

www.sefa.fr 5

English

TECHNICAL DATA

Technical data

Weight in working order 15 kg

Height 472 mm

Depth 544 mm

Width 246 mm

Platen size 130x130 mm

Power supply 220/240 V single phase + ground 50/60 Hz

Power consumption 400 W

Amp rating 5 A

Power supply (US version) 110/120 V single phase + ground 50/60 Hz

Power consumption (US version) 600 W

Amp rating (US version) 6 A

Air supply 4 - 8 bars

Pressing 2 - 7,5 bars (membrane : 8 bars)

Membrane inflation (Air Pro) 0,5 bars

Electronic temperature controller

Accuracy +/- 1%

Setting range 0 °C - 220 °C

Electronic timer

Accuracy +/- 1%

Setting range 0 s - 59 min 59 sec

Operating conditions

Noise level < 70 dB (A)

Ambient operating temperature 10 °C - 35 °C

Humidity < 90%

Maximum pressing force 940 daN

Non-contractual document : we reserve the right to alter our product specifications in

line with advances in technology.

2021-03-25

6 www.sefa.fr

English

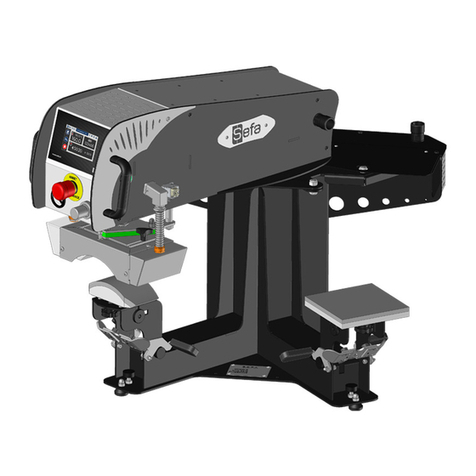

OVERVIEW

This heat press has been designed to operate at high output without risk to operator

safety in accordance with article L 233-5 of the French labour code. It has been de-

signed for use by a single operator positioned in front of the machine.

Air supply

connection

Heat platen height

adjustment handle

Knurled locknut

Heat platen and

safety guard

Cold platen with

silicone foam

Emergency stop

button

Pressure

controller

Pressure

gauge

Touch screen

controller

Foot pedal

User guide - SEFA LP 130 V3

www.sefa.fr 7

English

SAFETY

Please read the Operating Manual carefully before operating the press.

The press should be operated by a qualified person who is aware of the potential dan-

gers arising from improper use of the equipment. The factory-installed pneumatic,

electrical and mechanical settings programmed by our technicians and the safety fea-

tures must not be altered under any circumstances. SEFA accepts no liability for pro-

blems that may be caused by the machine if such alterations are made.

Personal Protective Equipment (PPE) must be worn (e.g. gloves and

safety glasses).

Do not touch hot parts of the machine during use. Do not place hands

between the platens when the machine is switched on. Make sure the

operator is not exposed to risks of burns, electrocution or other ha-

zards when handling the machine.

Check the machine each day before use. Make sure there is nobody in

the vicinity of the machine before starting work. If the machine mal-

functions, cut the power supply and look for the cause of the problem

(see the Servicing section of this manual).

No changes must be made to the safety covers and safety systems.

They must be refitted if they are removed for servicing work.

They must be kept in place and in good condition during normal use.

Presses are fitted with safety systems to protect the operator from pinch-point hazards.

The main safety components are:

- Front-mounted button that switches the machine off when pressed.

- Two contact switches are located on top of the upper heat platen.

This system helps safeguard the operator against pinch points and crushing

hazards.

If the system detects an obstacle, it raises the heat platen, immediately shuts off the

swing function and puts the press into safe mode.

To restore the machine to operating mode, press the red area on the «Alarm» page,

position the arm over one of the lower platens and depress the pedal.

Test the emergency shut-off and the safety guard daily. After an emmergency sttop,

make sure there are no other unresolved problems preventing use before restoring

the machine to normal operating mode. Turn the red button to release the emergency

stop. The machine will be reset automatically.

Technical parts documents are supplied with the machine. Please read them before

starting to use your SEFA machine.

a� International symbols

b� Important safety precautions

c� Safety features

THIS MACHINE IS DESIGNED FOR USE BY A SINGLE QUALIFIED OPERATOR

OFF

HOT SURFACE

ON

DANGER, WARNING ELECTROCUTION

HAZARD

2021-03-25

8 www.sefa.fr

English

DO NOT CARRY THE MACHINE BY THE PLATES

TO BE PERFORMED BY QUALIFIED PERSONNEL

OPERATION

Cut the packing straps and undo the cover and dome

retaining screws.

Remove the cover and then the dome from the case.

Remove the plastic bag from the machine.

Remove the anchor bolts securing the machine to the pallet.

Carry the machine and attach it to a stable, level table.

Fit and secure the lower platens in place if they are not already installed.

Switch on the compressed air supply to the machine. The com-

pressor must deliver at least 4 bars of compressed air pressure.

Fit a padlockable pneumatic shut-off valve. Plug in the ma-

chine using the power lead provided. Press the switch at the

back of the arm to «1» and make sure that the emergency stop

button at the front is not engaged.

Press the main switch at the back of the machine to turn the

power on.

The control panel page will be displayed on the touch screen.

This machine must be used by qualified personnel. Switching

on the machine turns on the temperature control, electronic

board and electrical power supplies.

a� Setting up the machine

b� Switching on

User guide - SEFA LP 130 V3

www.sefa.fr 9

English

The height of the heat platen can be adjusted according to the thickness of the im-

printable substrate. The maximum gap setting between the heat platen and the cold

platen is 20 mm in the working position.

1. Loosen the locknut as shown in Figure 1.

2. Turn the adjustment wheel as shown in Figure 2 to adjust the height of

the platen.

3. Turn clockwise to lower the platen or anti-clockwise to raise it.

4. Tighten the locknut to apply the setting.

c� Setting the height of the heat platen

Figure 1 Figure 2

Knurled locknut

Adjustment wheelKnurled locknut

2021-03-25

10 www.sefa.fr

English

1. Place the work item on the lower platen.

2. Position the transfer sheet correctly.

3. Depress the cycle start pedal. The heat platen will lower and start the

press timer.

4. The heat platen will lift open when the timer has finished.

5. Remove the work item from the workstation and get the next one ready.

6. Repeat from step one above.

Pressing the pedal or the on-screen Stop button during a cycle will stop the cycle.

d� Operating cycle

User guide - SEFA LP 130 V3

www.sefa.fr 11

English

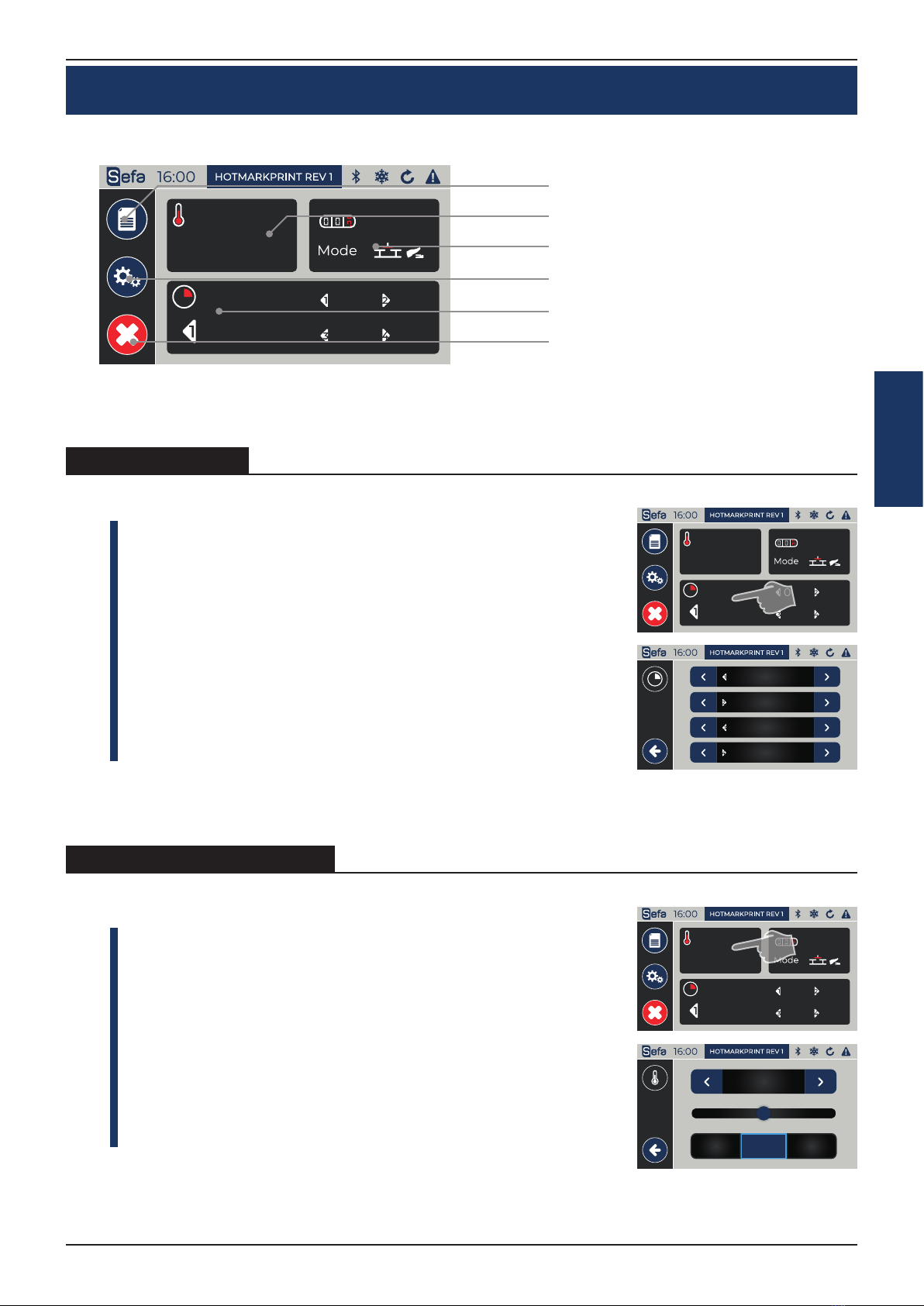

SMART TOUCH ® CONTROL SCREEN

25°C

0:10

0:10

0:05 0:15

0:20

190°C TEXTILE

001502

Recipes (d)

Temperature - current & setpoint (b)

Counter & mode (c)

Settings (e)

Pressing time & next pressing times (a)

Stop cycle

25°C

0:10

0:10

0:05 0:15

0:20

190°C TEXTILE 001502

25°C

0:10

0:10

0:05 0:15

0:20

190°C TEXTILE 001502

Press here to set the machine’s pressing time.

Use the left and right arrow keys to increase and decrease the

setting.

You can also have 4 consecutive pressing times (cf. “settings

(e)”) on single-platen presses and up to 4 times for dual-

platen presses.

You can also change this setting by pressing the time display

and entering the required time from the touch pad (4 cha-

racters must be entered).

Once you have entered the required time, press the “confirm”

key in the bottom right corner of the screen.

Press the “temperature” menu (b).

You can select the temperature you require in the same way

as for the pressing time, using the arrow keys on the left and

right of the temperature display. You can also click on the rea-

ding and manually select a temperature. When typing in a

temperature below 100°C, enter a “0” first (e.g. 090°C).

You can also slide the blue cursor left and right with your fin-

ger to lower and raise the temperature respectively, and then

adjust it using the arrows. Select the profile you wish to press

(Textile, Rigid or DTG).

99 : 99

99 : 99

99 : 99

99 : 99

TEXTILE RIGID DTG

190°C

a� Pressing time

b� Temperature settings

2021-03-25

12 www.sefa.fr

English

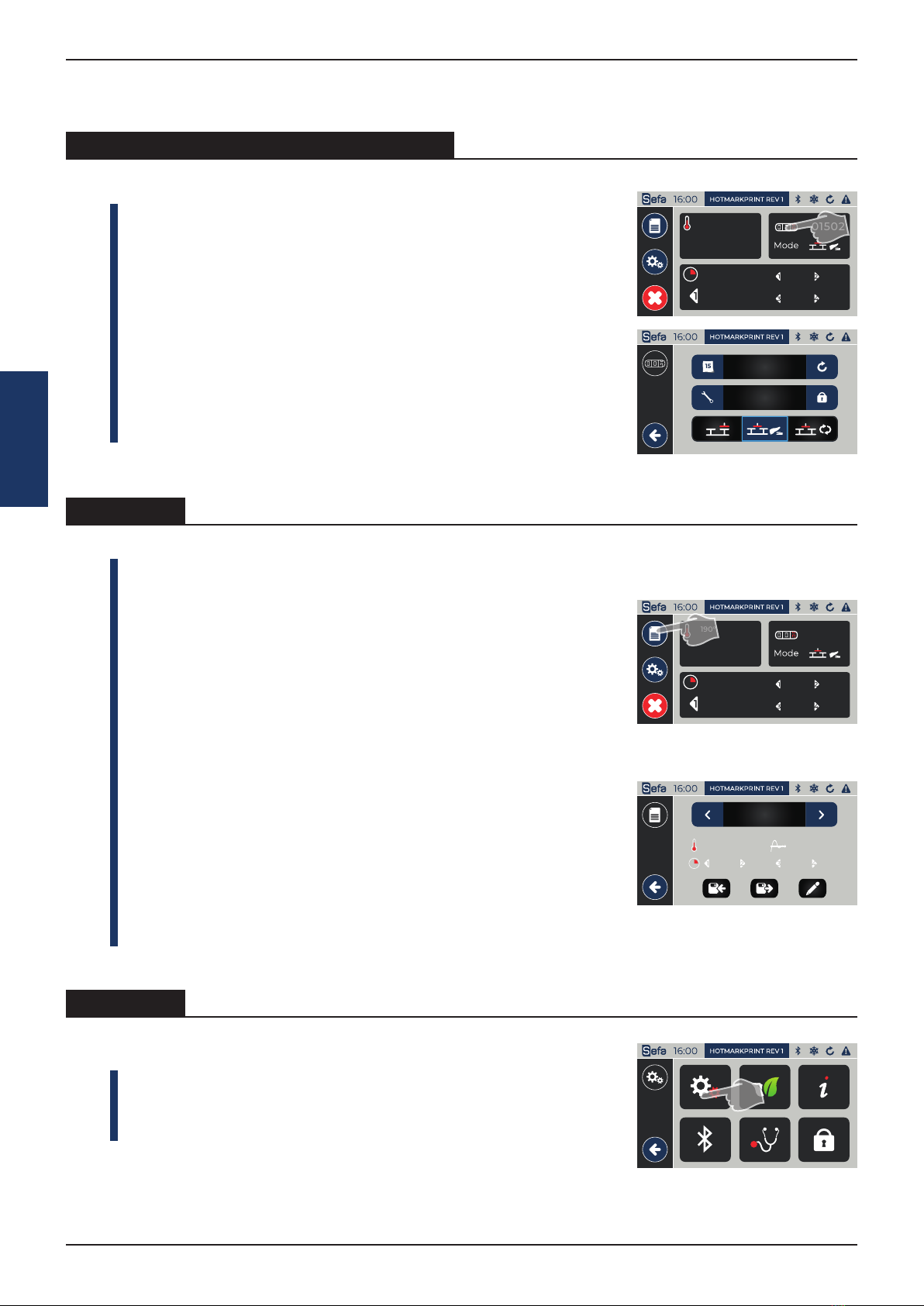

c� Item counter / Operating mode

d� Recipes

e� Settings

25°C

0:10

0:10

0:05 0:15

0:20

190°C TEXTILE 001502

25°C

0:10

0:10

0:05 0:15

0:20

190°C TEXTILE 001502

This menu shows how many items the machine has printed.

When you click on this icon, two counters are displayed. See

the table below.

You can also select the operating mode on Duplex models:

single-platen, dual-platen actuated by button/pedal for each

press stroke, and dual-platen auto mode.

The first counter shows the partial count and can be reset to

zero by pressing the arrow to its right.

The second counter shows the total number of items printed

since the machine was installed. This count is permanent and

cannot be reset.

Pressing the “Recipes” icon (d) brings up the menu shown

opposite.

Use the left and right arrows to select one of the 10 pre-confi-

gured recipes. To use (load) a recipe, press the floppy disk icon

with the arrow pointing to the right. Once selected, press the

arrow in the bottom left corner to return to the main menu.

To create or alter a recipe, you must first set the time and

temperature from the main screen and then select a memo-

ry slot (1 to 10) from the recipe (d) screen. To rename a recipe,

press the pencil icon. Give your recipe a name and press the

arrow in the bottom right corner to confirm. To finish, press

the floppy disk icon with the arrow pointing to the left to save

your choice/setting.

An asterisk(*) at the start of the name of the current recipe on

the indication bar means that the current settings are not the

same as the original settings for this recipe, and the settings

that are currently being applied have not been saved to the

recipe.

Press icon (e) in the main menu to go to the machine set-

tings. There are 6 available options.

The gear wheel button lets you change the machine’s tech-

nical aspects.

001502

141003

195°C

02:00 02:00 02:00 02:00

RIGID

1: HOTMARKPRINT REV

User guide - SEFA LP 130 V3

www.sefa.fr 13

English

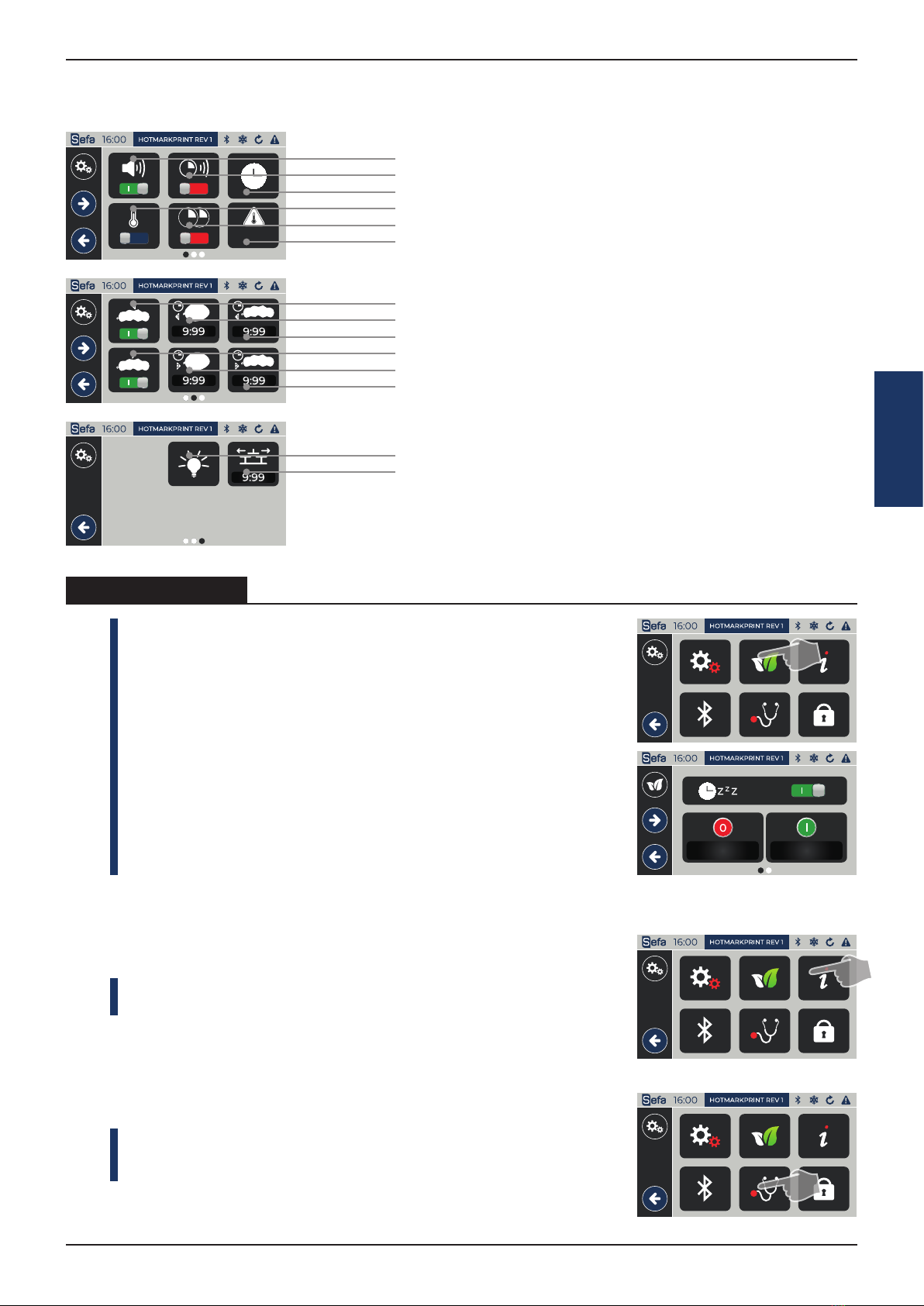

f� Other settings

The green leaf icon is used to set energy-saving mode.

The operator can use two energy-saving modes :

- Hibernate

Hibernate start time

Heating restart time

- Sleep

Sleep temperature (40°C (104°F) to 140°C

(284°F))

Idle time before sleep mode

The board will only switch to eco mode if it is on the home

screen. If the user leaves the press on another screen, the

screen is presumed to be in the process of being altered. Sim-

ply touch the screen or start a cycle to exit energy-saving mo-

des that are currently running.

The “i” at the top right provides key information about the sof-

tware version and SEFA contact details.

The diagnostic button brings up the machine status so you

can see if there are currently any malfunctions. If there are,

contact your distributor.

°C

0

0-30<Δ<+30

Switch the sound on or off. Warning sounds will still be emitted if needed.

Switch the left platen membrane on or off (Duplex Air Pro).

Choose between Celsius or Fahrenheit.

Switch the right platen membrane on or off (Duplex Air Pro).

Switch the 2-second end-of-cycle notification signal on or off.

Left membrane inflation time before platen down (Duplex Air Pro).

Screen backlight setting.

Choose 1 (OFF), 2 or 4 different timers.

Right membrane inflation time before platen down (Duplex Air Pro).

Internal clock setting (date and time).

Left membrane deflation time before platen up (Duplex Air Pro).

Duplex Pro/Air Pro: dwell time before platen switch (Auto mode).

Operating temperature range setting.

Right membrane deflation time before platen up (Duplex Air Pro).

2021-03-25

14 www.sefa.fr

English

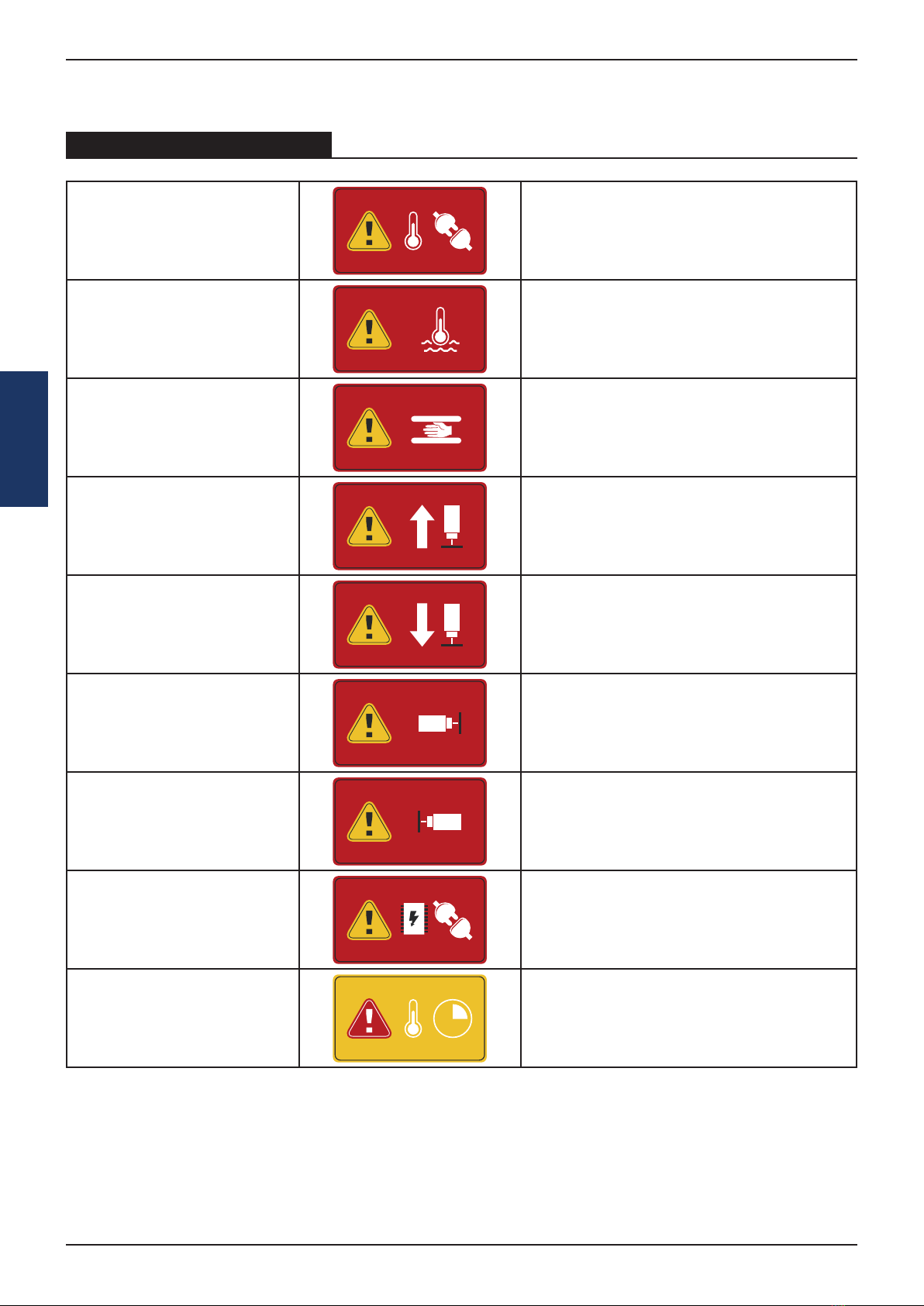

g� List of alarms / events

Press the red/orange area to clear the fault.

Alarm 01: Probe PT100 Probe signal lost (sensor or cable). The

heating control is instantly disabled.

Alarm 02: Overheating. Tem-

perature above 220°C

Temperature reading above 230°C. The

heating control is instantly disabled.

Alarm 03: Platen safety sys-

tem triggered

Detection is immediate. The heating

control and pressing operation are ins-

tantly disabled.

Alarm 06: Upper pressing

sensor not reached

Signal not detected after 5 seconds.

Caused by faulty sensor, lack of com-

pressed air supply, jamming (mechanical,

etc).

Alarm 07: Lower pressing

sensor not reached

Signal not detected after 5 seconds.

Caused by faulty sensor, lack of com-

pressed air supply, jamming (mechanical,

etc).

Alarm 08: Right rotation sen-

sor not reached

Signal not detected after 5 seconds.

Caused by faulty sensor, lack of com-

pressed air supply, jamming (mechanical,

etc).

Alarm 09: Left rotation sen-

sor not reached

Signal not detected after 5 seconds.

Caused by faulty sensor, lack of com-

pressed air supply, jamming (mechanical,

etc).

Alarm 10: Communication

error

Communication lost between power

board and screen board.

Contact your stockist.

Alarm 13: Temperature not

reached.

Blocks first cycle start request. Permits

cycle start at second request (forced start

despite setpoint not being reached).

User guide - SEFA LP 130 V3

www.sefa.fr 15

English

SERVICING

TO BE PERFORMED BY QUALIFIED PERSONNEL

THE MACHINE MUST BE SWITCHED OFF AND LOCKED AND TAGGED PRIOR TO

SERVICING (ELECTRIC AND PNEUMATIC POWER SOURCES DISCONNECTED)

The following tools should be available at hand:

- Phillips and flat-blade screwdrivers

- Set of open-ended spanners and box spanners

- Set of Allen keys

- Multimeter

- Silicone foam pads

Check that the platen is cold.

Make sure the surface of the platen is clean.

The surface can be cleaned using soapy water. Suitable personal protective

equipment must be worn.

Use RTV-1 glue to stick the foam pad to the aluminium platen (NB: read the

instructions for use on the packet).

The pad and the platen must be clean and dry before they are stuck together.

Apply a thin layer of glue evenly over the platen and then stick the pad

immediately into place, making sure there are no air bubbles trapped between

the platen and the pad (e.g. a notched tile adhesive comb).

Leave to set overnight at room temperature with a slight pressure applied and

the platen cold.

- For other parts, contact your stockist to determine whether they need to be renewed

or repaired.

SEFA heat presses are practically maintenance-free. Follow the preventive mainte-

nance instructions below to ensure trouble-free operation:

Do not heat items that could perish or score the silicone pad or damage the heat

platen’s teflon coating.

Clean the machine at regular intervals, with the platen cold, using a clean cloth and

soapy water and wearing suitable personal protective equipment.

Keep the heat platen in the raised position when it is hot but not in use.

DAILY CARE:

Clean the foam pad and the heat platen’s coating (when cold) with a dry cloth

or a cloth with grease remover.

Inspect the air inlet filter on the left side of the swing arm; drain the filter if it is

heavily condensated.

MONTHLY CARE:

Check that the hinged joints are lubricated.

According to use:

Replace the foam pad every 6 months.

a� Replacing worn parts

b� Maintenance

2021-03-25

16 www.sefa.fr

English

TROUBLESHOOTING TIPS

The machine must be switched off and locked and tagged prior to any ser-

vice repair work (electric and pneumatic power switched off).

The heat platen can cause burns. Check that the platen temperature rea-

ding on the display panel is below 25° C before handling.

Problem Possible causes Solution

The machine does not

switch on

The plug is not connected

The switch has not been pressed

The emergency stop is activated

Faulty display panel

Check the mains electricity and

that the machine is plugged in.

Press the main On/Off switch to 1.

Turn the red button to release the

emergency stop

Check whether the cables are da-

maged (potential short circuit)

The platen does not heat

up

Faulty heating element

Problem with the automated system

Temperature setting too low

Check the connections and the

condition of the wires.

Contact your retailer to have the

heat platen removed.

Check the on-screen messages

and contact your stockist

See section 5 to change this setting

The platen overheats Problem with the probe or the tempe-

rature control

Check the on-screen messages

and contact your stockist

The timer is not counting

down

Disabled or faulty cylinder-mounted

sensor

Problem with the automated system

Check its position. Check the

connections. Replace if necessary.

Check the on-screen messages

and refer to the manual or contact

your stockist.

The platen does not lower Leaking cylinder

The solenoid control valve or the pro-

portional controller are faulty

Compressed air pressure too low

Check the seals and all the connec-

tions. Cut the ends of the pipes.

Contact your retailer.

Check the valve couplings. Contact

your retailer about a possible repla-

cement.

Check that the supply pressure is

working.

The platen does not lift

up

Faulty solenoid control valve

Leaking cylinder

Check the valve couplings. Contact

your retailer about a possible repla-

cement.

Check the seals and all the connec-

tions. Contact your retailer.

The platen stays down

after pressing

Lack of compressed air Check the compressed air system

Manuel utilisateur - SEFA LP 130 V3

www.sefa.fr 17

Français

2021-03-25

18 www.sefa.fr

Français

CONDITIONS DE GARANTIE

La période de garantie débute le jour de la mise en service du matériel chez l’utilisateur,

matérialisée par le retour du bon de garantie et le bon de livraison, pour une durée de

deux ans pour une utilisation courante de 8 heures par jour, soit 3000 heures.

La garantie est strictement limitée à nos matériels, contre les défauts de matière et

d’exécution.

A charge pour l’acheteur de prouver les dits défauts.

Notre responsabilité est limitée à l’obligation de rectifier ou de remplacer gratuitement

les pièces reconnues défectueuses par nous, sans qu’il ne puisse nous être réclamé au-

cune indemnité pour quelque cause que ce soit.

Les pièces remplacées au titre de la garantie :

- Restent notre propriété,

- Font l’objet d’une facturation de dépôt

Un avoir d’annulation est déclenché dès le retour des pièces défectueuses.

Le retour devra survenir UN MOIS MAXIMUM après l’intervention.

LA GARANTIE NE COUVRE PAS :

Les fournitures consommables du commerce telles que :

- Fusibles, LED, joint, flexibles, buses, filtres...

- Les fournitures n’étant pas notre fabrication pure, subissent la garantie de leur fabri-

cant.

LA GARANTIE NE S’APPLIQUE PAS :

Aux remplacements, ni aux réparations qui résulteraient de l’usure normale des appa-

reils et machines, des détériorations ou accidents provenant de négligences, défaut de

surveillance ou d’entretien, d’utilisation défectueuse ou de modifications sans notre

accord écrit.

En cas de vice provenant de matière fournie par l’acheteur, ni d’une conception im-

posée par celui-ci.

Aux réparations qui résulteraient des détériorations ou accidents survenues lors du

transport.

Aux opérations d’entretien et de réglages inhérentes à l’utilisation de la machine, et

indiquées dans la notice d’entretien, telles que :

- réglages d’intermédiaires

- resserrage de tuyauterie, etc. …

Pour les machines pneumatiques, toutes traces d’huile détergen-

te dans le circuit pneumatique inhibent les conditions de garanties

précédemment citées.

Pour tout renseignement technique ou commande de pièces détachées,

donner la référence de la machine ainsi que son numéro de série.

Manuel utilisateur - SEFA LP 130 V3

www.sefa.fr 19

Français

CARACTERISTIQUES

Document non contractuel : en fonction des progrès techniques, nous nous réservons

le droit de modifier les caractéristiques de nos produits.

Caractéristiques

Poids en ordre de marche 15 kg

Hauteur 472 mm

Profondeur 544 mm

Largeur 246 mm

Dimensions du plateau 130x130 mm

Alimentation électrique 220/240 V single phase + ground 50/60 Hz

Puissance 400 W

Ampérage 5 A

Alimentation électrique (version US) 110/120 V single phase + ground 50/60 Hz

Puissance (version US) 600 W

Ampérage (version US) 6 A

Alimentation pneumatique 4 - 8 bars

Pressage 2 - 7,5 bars (membrane : 8 bars)

Gonflage membrane (AIR PRO) 0,5 bars

Régulateur électronique température

Précis à +/- 1%

Réglable de 0 °C - 220 °C

Minuterie électronique

Précis à +/- 1%

Réglable de 0 s - 59 min 59 sec

Conditions d’utilisation

Bruit < 70 dB (A)

Température ambiante d’utilisation 10 °C - 35 °C

Hygrométrie < 90%

Effort de pressage max 940 daN

2021-03-25

20 www.sefa.fr

Français

GENERALITES

Cette presse à thermo coller a été conçue pour effectuer une production intensive

tout en respectant l’article L 233-5 du code du travail, pour assurer la sécurité de l’utili-

sateur. Cette presse a été conçue pour un opérateur travaillant face à la machine.

Raccord d’alimentation

en air

Poignée réglage hauteur

plateau chauffant

Contre-écrou

moleté

Plateau chauffant

avec carter de

sécurité

Plateau froid avec

mousse silicone

Bouton

Arrêt d’urgence

Régulateur

de pression

Manomètre

Ecran tactile

Pédale départ cycle

Table of contents

Languages:

Other Sefa Power Tools manuals

Sefa

Sefa DUPLEX MINI PRO User manual

Sefa

Sefa LM V3 Series User manual

Sefa

Sefa ROTEX AIR PRO User manual

Sefa

Sefa CLAM SPORT V3 User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa CLAM 45M User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa ROTEX V3 Series User manual

Sefa

Sefa Initium iCAP 2 User manual

Sefa

Sefa BR 180 PCAS User manual