Aeropro CN45RA User manual

1

COIL ROOFING NAILER CN45RA

OPERATING INSTRUCTIONS FOR FASTENER DRIVING TOOLS OPERATED BY

COMPRESSED AIR

AIR-POWERED COIL ROOFING NAILER

Model No.: CN45RA

Residual risks

Even when the tool is used as prescribed it is not possible to eliminate all residual risk factors. The

following hazards may arise in connection with the tool’s construction and design:

Damage to lungs if an effective dust mask is not worn.

Damage to hearing if effective hearing protection is not worn.

Health defects resulting from vibration emission if the power

tool is being used over longer period of time or not adequately managed and properly maintained.

Wear eye protection.

2019

IMPORTANT:

Read all safety rules and operating Instructions carefully before first use it.

Keep this Manual for future reference.

TABLE OF CONTENTS:QUICK START GUIDE

TECHNICAL SPECIFIACTIONS

SAFETY GUIDELINES

KEY PARTS DIAGRAM

IMPORTANT INFORMATION

TYPES OF FASTENERS

OPERATING INSTRUCTIONS

MAINTENANCE

TROUBLESHOOTING

EXPLODED VIEW

PARTS LIST

2

COILROOFINGNAILERCN45RA

Technical Specifications

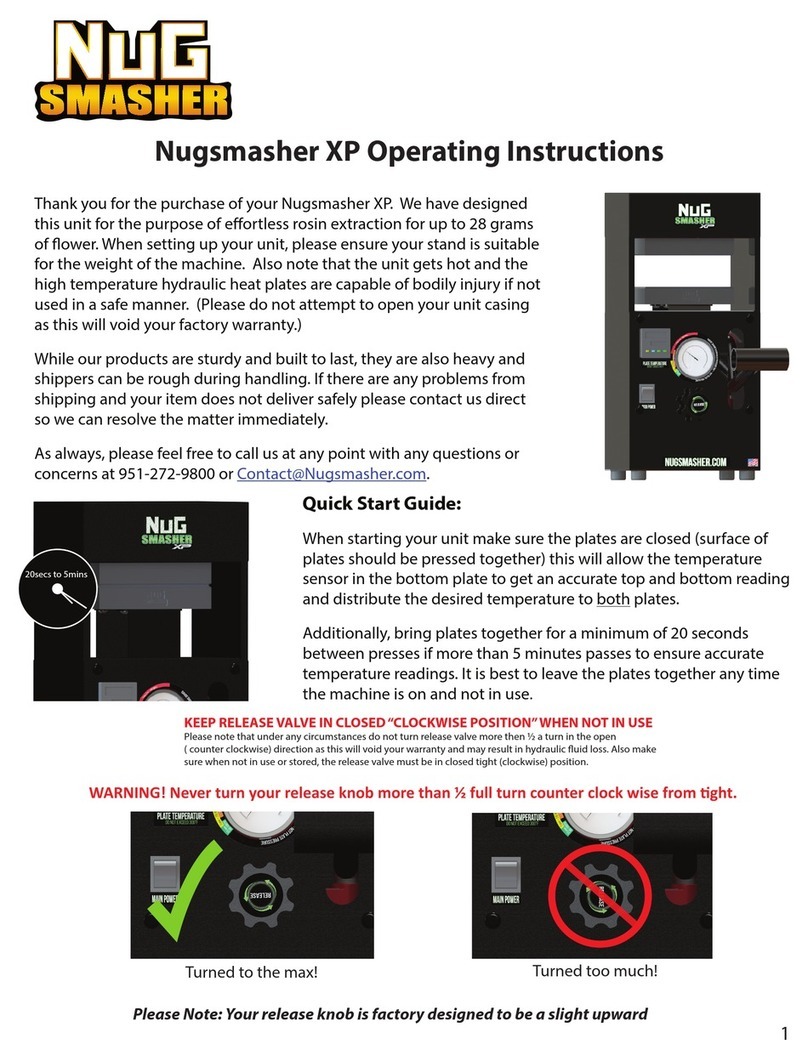

FastenerDetails:

15°7/8"to1-3/4"WireCollatedCoilRoofingNails

Operatingpressure:

70-115PSI(4.8to7.9bar)

Maximumpressure:

120PSI(8.3bar)

Airinlet:

1/4”(6.35mm)

Dimensions:

11.14”x11.02”x4.52”(283x280x115mm)

Weight:

2.5kg(5.5Lbs)

SCFM:StandardCubicfeetperminute(thevolumetricflowrateofaircorrectedtostandardizedconditionsof

temperatureandpressure).

Environmental Responsibilities

Pleaserecycleunwantedmaterialsinsteadofdisposingofthemaswaste.Alltools,hosesandpackagingshould

be sorted, taken to the local recycling centre and disposed of in an environmentally safe way.

Safetyguidelines

Thismanualcontainsinformationthatrelatestoprotectingpersonalsafetyandpreventingequipment

problems.itisveryimportanttoreadthismanualcarefullyandunderstanditthoroughlybeforeusingthe

product.thesymbolslistedbelowareusedtoindicatethisinformation.

DANGER!

Potentialhazardthatwillresultinseriousinjuryorlossoflife.

WARRNING!

Potentialhazardthatcouldresultinseriousinjuryorlossoflife.

CAUTION!

Potentialhazardthatmayresultinmoderateinjuryordamagetoequipment.

Note-Theword“note”isusedtoinformthereaderofsomethinghe/sheneedstoknowaboutthetool.

PERSONALSAFETY

These precautions are intended for the personal safety of the user and others working with the user. please take

timetoreadandunderstandthem.

DANGER!

Potentialhazardthatwillresultinseriousinjuryorlossoflife.

Keepchildrenawayfromtheworkarea.Donotallowchildrentohandlepowertools.

Keepairhoseawayfromheat,oil,andsharpedges.Checkairhoseforwearbeforeeachuseandensurethatall

connectionsareproper.Alwaysensurethattheworkpieceisfirmlysecuredleavingbothhandsfreetocontrolthe

3

COIL ROOFING NAILER CN45RA

tool.Always ensure that the tool has stopped before putting it down after use, in the interest of safety and to

prevent possible damage to the tool/user.

Keep proper footing at all times in order to ensure correct balance.

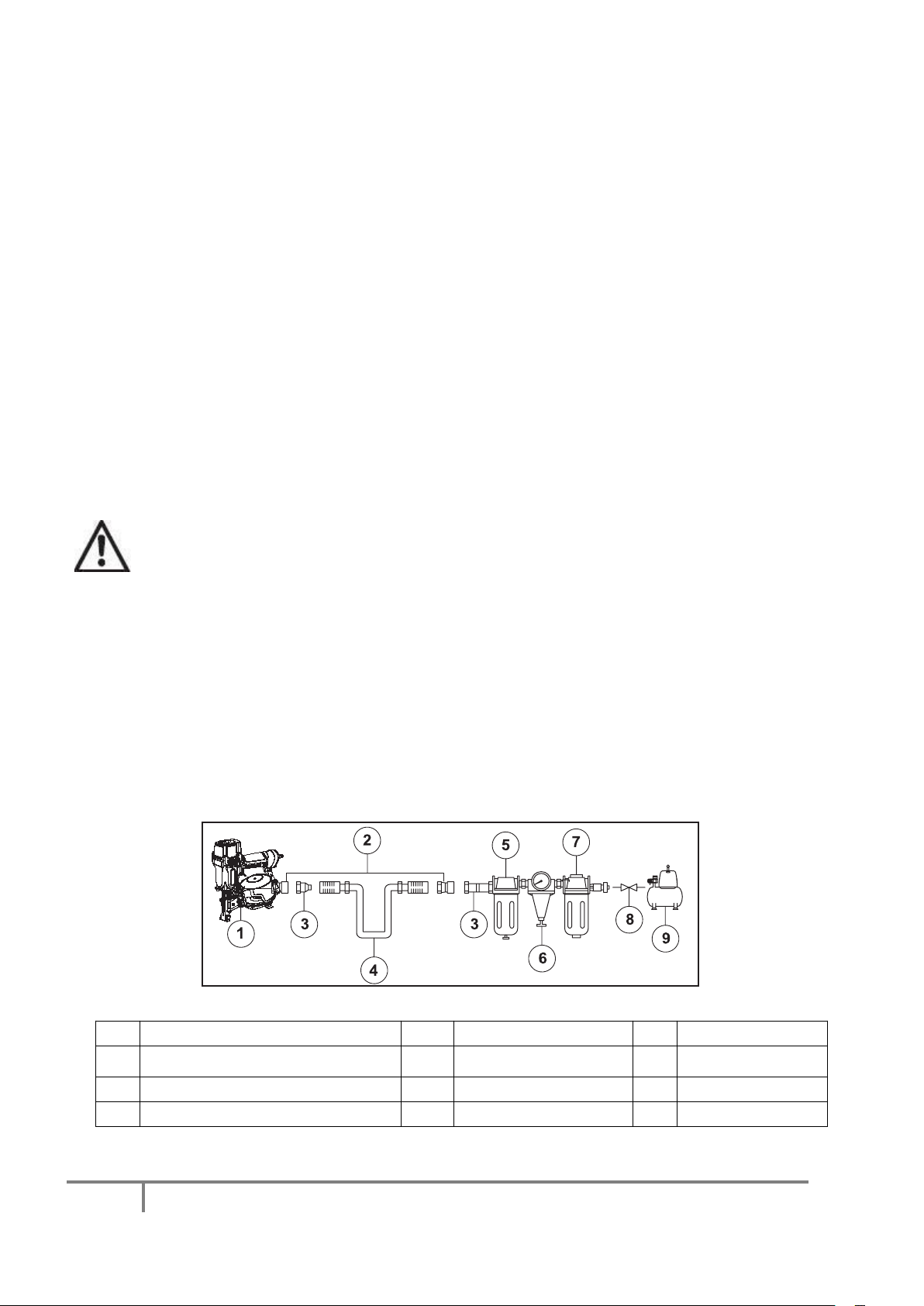

Do not use oxygen or any other combustible or bottled gas to power

air-powered

tools. Failure to observe this warning can cause explosion and serious personal

Use a minimum of 25’(7.6m) of hose to connect the tools to the compressor.

Failure to comply will result in serious injury or loss of life.

Risk of electric shock: Do not expose a compressor to rain. Store it

indoors. Disconnect

the compressor from power source before servicing. Compressor must be

grounded. Do not use grounding adaptor.

Risk of personal injury: Do not direct compressed air from the air hose toward the user or other

personnel. Risk of inhalation: Never directly inhale the air produced by the compressor.

Risk of bursting: Do not adjust the pressure switch or safety valve for any reason. They have been

preset at the factory for this compressor’s maximum pressure. Tampering with the pressure switch or

the safety valve

Risk of burns: The pump and the manifold generate high temperatures. In order to avoid burns or

other injuries, do not touch the pump, the manifold or the transfer tube while the compressor is running.

Allow the parts to cool down before handling or servicing. Keep children away from the compressor at

all times.

Risk of bursting: Make sure the regulator is adjusted so that the compressor outlet

pressure is set lower than the maximum operating pressure of the tool. Before

starting

the compressor, pull the ring on the safety valve to make sure the valve moves

freely.Drain water from tank after each use. Do not weld or repair tank. Relieve all

pressure in the hose before removing or attaching accessories.

WARNING!

Potential hazard that could result in serious injury or loss of life.

Do not allow unskilled or untrained individuals to operate the air powered tools.

Do not use the air powered tools for any task other than that it is designed to perform.

Do not use the air tools unless you have been trained to do so. Only a qualified person should use the tool.

Locate the compressor in a well-ventilated area for cooling, and must be a minimum of 12”(31cm) away from the nearest wall.

Protect the air hose and the power cord from damage and puncture. Inspect them for weak or worn spots every week, and replace them if

necessary . Always wear hearing protection when using the air compressor. Failure to do so may result in hearing

loss.

Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or in an elevated position that could allow the unit to fall or be tipped

over. Always replace a damaged gauge before operating the unit again.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

Always ensure that the tool has stopped before connecting to the air supply.

4

COIL ROOFING NAILER CN45RA

Do not wear watches, rings, bracelets, or loose clothing when using any air tool.

Do not overload the tool. Allow the tool to operate at its optimum speed for maximum efficiency.

Do not use a tool that is leaking air, with missing or damaged parts, or that requires repairs. Verify that all screws

are securely tightened.

For optimal safety and tool performance, inspect the tool daily in order to ensure free movement of the trigger,

safety mechanisms, and springs.

Always keep your air tools clean and lubricated. Daily lubrication is essential to avoid internal corrosion and

possible failures.

Ensure the floor is not slippery and wear non-slip shoes. Floors should be kept clean can clear.

Always follow all workshop safety rules, regulations, and conditions when using the tools.

Carry the tool by the handle only. Do not carry the tools with a finger on the trigger. Do not carry the tool by the

hose, magazine or any other parts.

Do not use the tool near or below freezing temperatures, as doing so may cause tool failure.

Do not store the tool in a freezing environment to prevent ice formation on the operating valves of the tool, as

doing so may cause tool failure.

Handling and storage of oil: Use with adequate ventilation. Avoid contact of oil with eyes, skin, and clothing. Avoid

breathing spray or mist. Store in a tightly closed container in a cool, dry, well-ventilated area free from

incompatible substances.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

Disconnect tool from the air supply and turn off the compressor before performing any

maintenance, or changing accessories, when the tool is not in use, when it is being handed

to another person, and when it is left unattended. Failure to comply may result in

moderate injury or damage to equipment.

Use safety goggles and ear protection:

Wear safety glasses with side shields when operating the tool/compressor and

verify that others in the work area are also wearing safety glasses.

Requirements and must provide protection from flying particles from the front and the sides.

Air powered tools are loud and the sound can cause hearing damage. Always wear ear

protection to

prevent hearing damage and loss. Failure to comply may result in moderate injury.

NOTE: Recycle unwanted materials father than disposing of them as waste. Sort the tools, hoses, and package

into specific categories and take to the local recycling centre or dispose of them in an environmentally safe way.

5

COIL ROOFING NAILER CN45RA

UNPACKING

-If you discover the stapler is damaged after you have signed for delivery, please immediately where you buy for

advice.

-Save the containers and all packing materials for possible inspection by the carrier or its agent. Otherwise, filing

a freight claim can be difficult. When you are completely satisfied with the condition of the shipment, you should

inventory the equipment.

-After you open the box, you should find the following. Model CN45RA Inventory (Figure 1)

Hex Wrench 3mm

Hex Wrench 4mm

Safety Goggles

Oil Pot

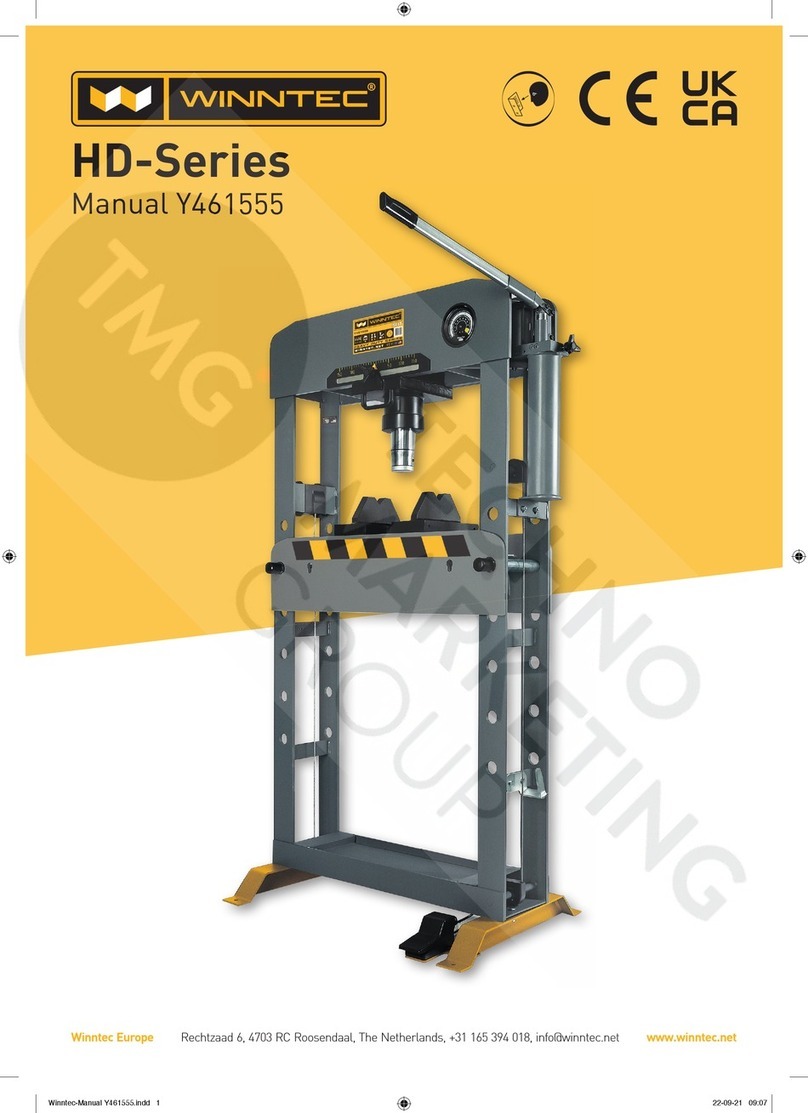

KEY PARTS DIAGRAM

1

Exhaust Cover

6

Magazine

2

Gun Body

7

Shingle Guide

3

Drive Guide

8

Air Inlet Plug

4

Nail Guide

9

Handle

5

Magazine Release Knob

10

Trigger

1

2

3

4

5

6

7

8

9

10

6

COILROOFINGNAILERCN45RA

IMPORTANT INFORMATION

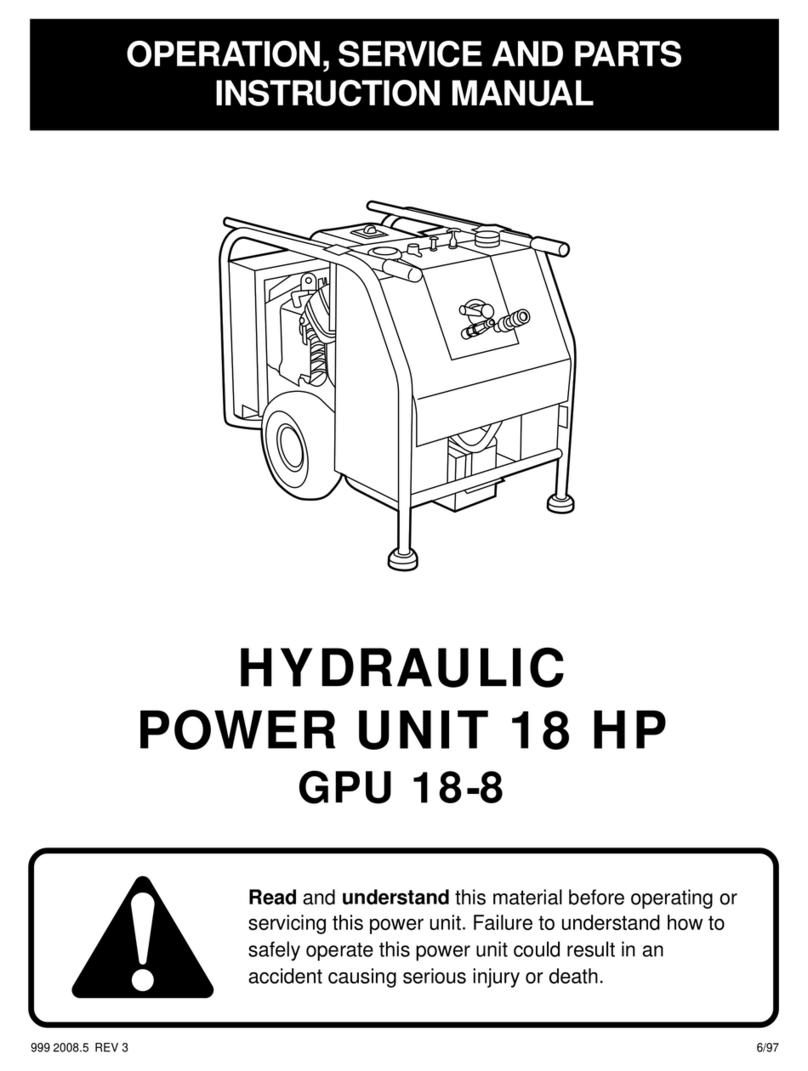

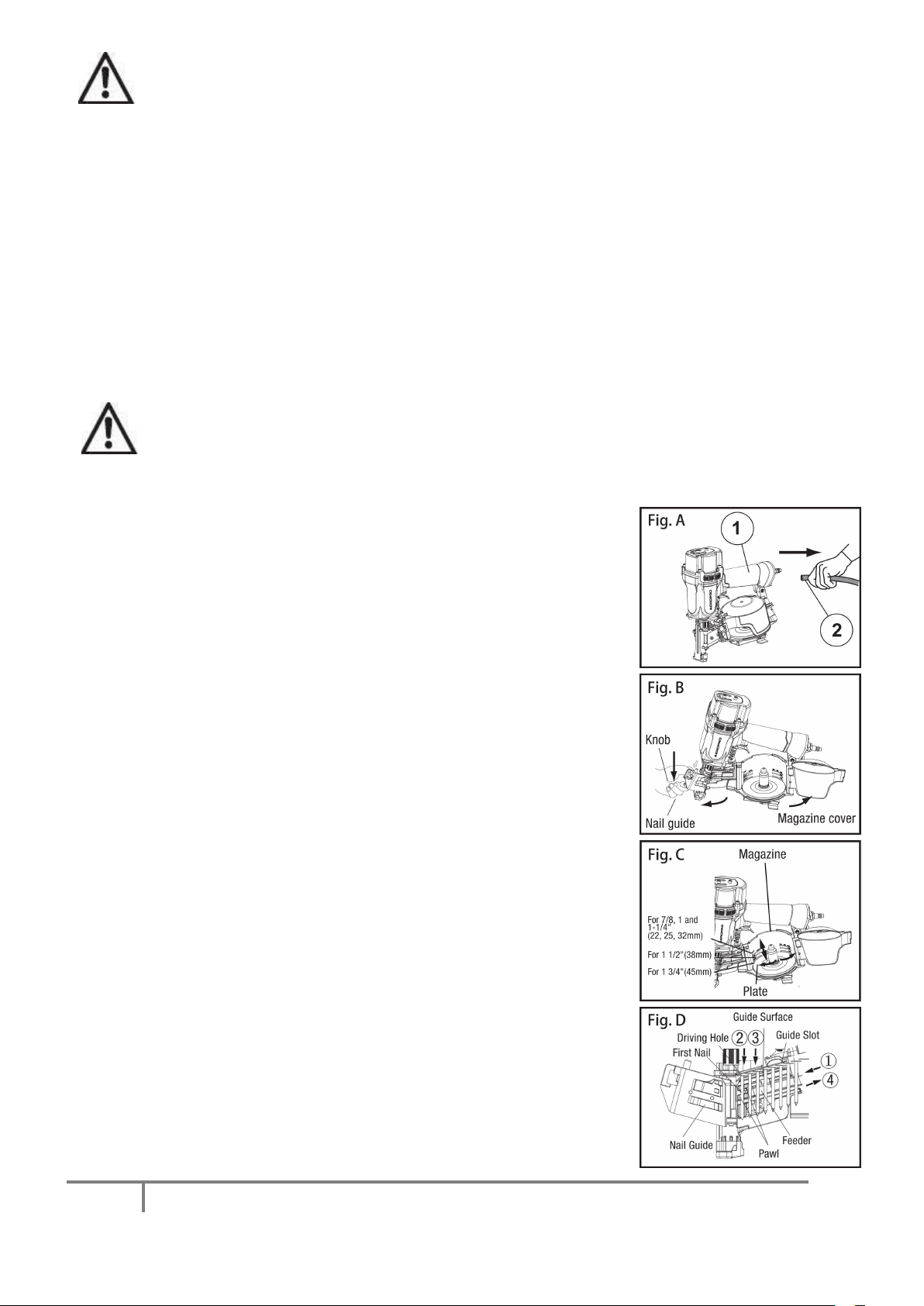

Compatible compressors

GUIDELINES FOR PROPER USE AND OPERATION

Be sure to use a proper air compressor with air powered tools.

Generaluse

TheAEROPRO15°WireCollatedCoilRoofingNailerCN45RAdrives7/8"to1-3/4"15°WireCollatedCoilRoofing

Nails.Thetoolislightweightanddurable,standsuptotheelementsandprovidesconsistentlyaccurateresults

over the life of the tool.An ideal tool for a variety of construction projects,including installation of asphalt roofing

shinglesandinsulationboards.Italsofeaturesahigh-capacityside-loadmagazine,tool-lessdepth

adjustment,durableconstruction,andmore.

Air system

Alwaysuseclean,dry,regulated,compressedairat5.5to7.5bar(80to110psi).

Donotexceedthemaximumorminimumpressures.Operatingthetoolatthewrongpressure(toolowortoohigh)

willcauseexcessivenoiseorrapidwearoftool.

WARNING!

Potentialhazardthatcouldresultinseriousinjuryorlossoflife.

Keephandsandotherpartsofthebodyawayfromthetoolsdischargeandworkingareaswhenconnectingthe

airsupply.Failuretocomplycouldleadtoseriousinjuryorlossoflife.

Itisrecommendedthatafilter-regulator-lubricatorisusedandlocatedasclosetothetoolaspossible.

Ifafilter-regulator-lubricatorinnotinstalled,placeupto6dropsofcompressoroilintotheinletplugbeforeeachuse.Ifa

filter-regulator-lubricatorisinstalled,keeptheairfilterclean.Adirtyfilterwillreducetheairpressuretothetool,

whichwillcausereductioninpower,efficiency,andgeneralperformance.

Foroptimalperformance,installaquickconnectortothetoolandaquickcoupleronthehose,ifapplicable.

Verifythatalloftheconnectionsintheairsupplysystemaresealedinordertopreventairfromleaking.

NO.

Description

NO.

Description

NO.

Description

1

AEROPROAIRCOILROOFINGNAILER

4

AirHose

7

Filter

2

Quickconnector

5

Lubricator

8

Cut-offvalve

3

Quickcoupler

6

Regulator(0to8.3Bar)

9

Aircompressor

7

COIL ROOFING NAILER CN45RA

WARNING!

Potential hazard that could result in serious injury or loss of life.

Do not use the tool if it is not in proper working order.

Do not use oxygen,carbon dioxide or any other combustible, or bottled gas to power this tool.

Do not use this tool in the presence of any flammable liquids or gases.

Keep hands and other parts of the body away from the firing head during use.

Do not point the tool towards the operator or other people.

Never attempt to clear a jammed fastener while the air hose is connected.

Do not drive a fastener on top of an existing fastener. Failure to comply could lead to serious injury or loss of life.

TYPES OF FASTENERS

Please see the TECHNICAL SPECIFIACTIONS.

WARNING!

Potential hazard that could result in serious injury or loss of life.

The use of any other types of fasteners will cause the tool to jam. Failure to comply could lead to serious injury or loss of life.

OPERATING INSTRUCTIONS

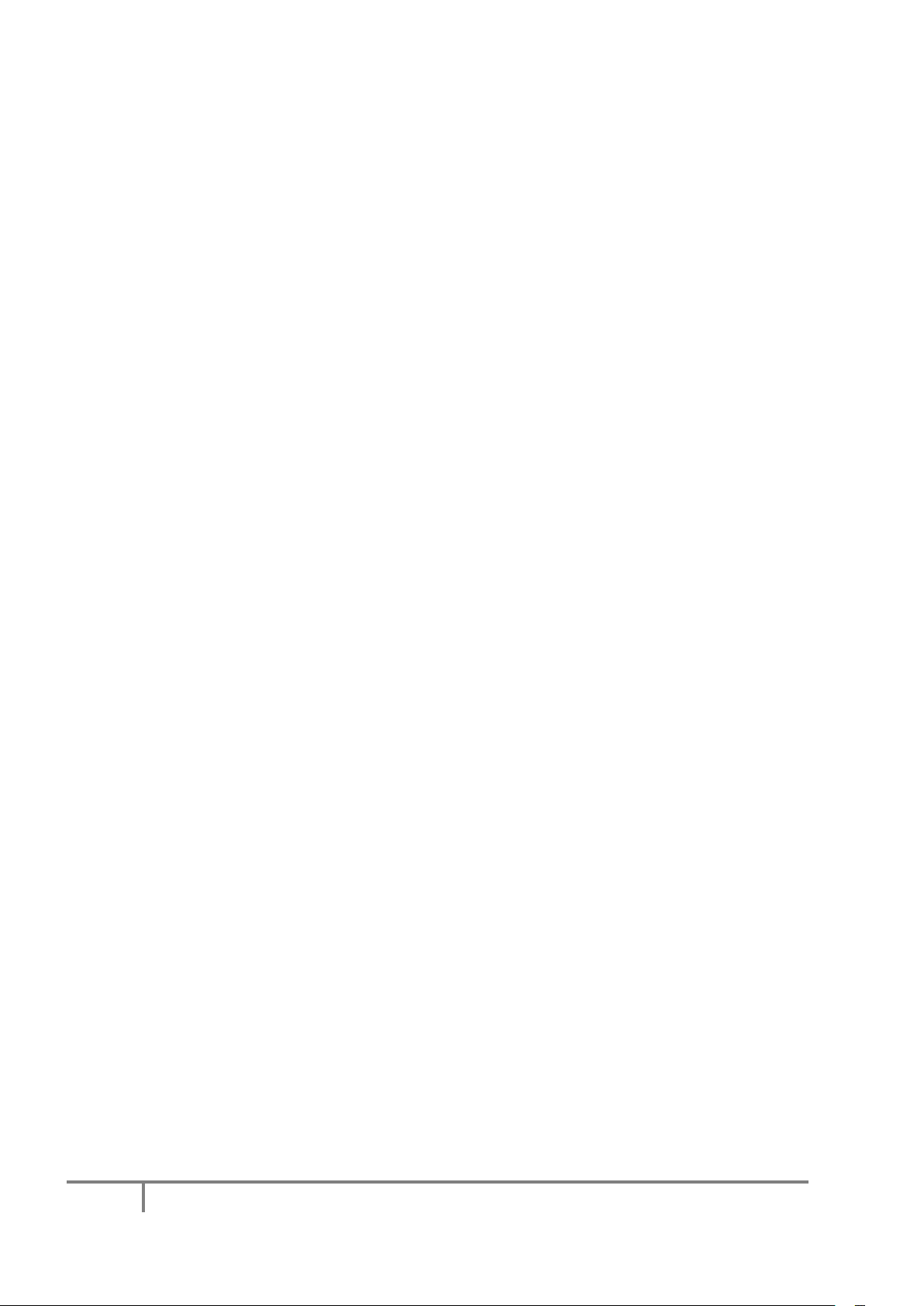

Loading Nails

1. Disconnect the tool(1)from the air supply(2)(Fig.A).

2. Grip the nail guide and knob with finger.Press the knob down,swing

the nail guide open and open the magazine cover (Fig.B).

3. Adjust the position of the nail holder to correspond with the

nail length.The nail will not feed smoothly if the nail holder is not

correctly adjusted.

• Turn the nail holder about 90°counter-clockwise.

• Move the nail holder up and down to align the plate of the nail holder with

the mark on the magazine that correspond with the length of the nails

being used.

• Turn the nail holder 90 clockwise until you hear“click"(Fig.C).

4. Place the nails in the magazine.Insert the first nail coil into the

magazine opening.

• Uncoil enough nails to reach the driving hole.

• Insert the first nail into the driving hole and the second nail between the two

pawls of the feeder.

• Fit the nail heads in the guide slot.

• Pull the nails to the right.After checking and making sure that the magazine

cover is closed,hook your fingers on the nail guide and knob,turn the nail

guide clockwise while pressing the knob downward,and then close the nail

guide completely.

• Lock the knob completely (Fig.D).

8

COIL ROOFING NAILER CN45RA

Operation

The AEROPRO Air-powered Coiled Roofing Nailer CN45RA is equipped with a push lever at the nailing

point and

will not operate unless the push lever is depressed (pushed upwards).

Bump fire(multiple shots)

• Pull the trigger with the nailer off the workpiece.

• Drive a nail by pressing the nailer against the workpiece to

depress the push lever.

• Drive additional nails by moving the nailer along the workpiece with

a bouncing motion.Each depression of the push lever will drive a nail.

When the required nails have been driven, remove finger from the trigger(Fig.E).

Adjusting The Nailing Depth

To assure that each nail penetrates to the same depth,be sure that:

①The air pressure to the Nailer remains constant (regulator is installed

and working properly)

②The nailer is always held firmly against the workpiece.If nails are driven

too deep or too shallow into the

workpiece,adjust the nailing depth using the following instructions.

1. Disconnect air hose from nailer(Fig.F).

2.

If the nails are driven too deep,

pull the adjuster downward

and turn counter-clockwise(Fig.G)

If nails are driven too shallow,

pull the adjuster downward

and turn clockwise(Fig.H)

When the adjuster is released it will spring back up and can be set with a click at each 1/4 rotation.The

adjuster changes the nailing depth approximately 0.25 mm per 1/4 rotation.

3.Connect the air hose and perform a nailing test,ALWAYS WEAR EYE PROTECTION.

4.If additional adjustments are necessary,DISCONNECT AIR HOSE FROM NAILER and repeat step 2

9

COIL ROOFING NAILER CN45RA

Clear A Jammed Nail

To clear a jammed nail

• Disconnect the tool from the air supply line.

• Open the nail guide and insert a rod into the outlet.Tap the rod with a hammer.

• Remove the jammed nail with a slotted screwdrive.

• Cut the deformed collated wire with shipls.Correct the deformation.

• Remove the non-jammed nails that are stored in the tool's magazine.

• Operate the magazine latch and slide the pusher back to open the magazine for checking the jammed nails.

• Use pliers or any appropriate tool to remove the jammed nails.

• Close the magazine cover and slide the pusher to its original position.

• Reload the nails into the tool magazine.

• Reconnect the air supply line to the tool's air inlet.

• Test fire 3 to 5 nails into a piece of scrap wood in order to ensure proper operation.

Maintenance

•Disconnect the tool from the compressor before adjusting, clearing jams, servicing &maintenance, relocating

and during non operation. Regular lubrication, if your tool without using the in-liner automatic oilier, place 2 or 6

drops of pneumatic tool oil into the air inlet before each work day or after 2 hours of continuous use depending in

the characteristic of workpiece or type of fasteners.

•Air-operated tools must be inspected periodically, and worn or broken parts must be replaced to keep the tool

operating safely and efficiently. Check and change all worn or damaged O-ring, Seals, etc. Tighten all the screws

and caps to avoid personal injury. This should be done by an expert. Make regular inspection for free

movement of trigger, Spring and safety mechanism to assure safe system is complete and functional: no loose

and missing parts, no building or stocking parts. Keep magazine and nose of tool clean and free of any dirt lint

or abrasive particles. When temperatures are below freezing, tools should be kept warm by any convenient,

safe method.

10

COILROOFINGNAILERCN45RA

Troubleshooting

SYMPTOM

PROBLEM

SOLUTIONS

Airleakneartopoftoolor

intriggerarea

1.O-ringintriggervalvearedamage.

2.Triggervalveheadaredamage.

3.Triggervalvestem,sealorO-ringare

damaged.

1.CheckandreplaceO-ring.

2.Checkandreplace.

3.Checkandreplacetriggervalvestem,

seal or O-ring

Airleaknearbottomoftool.

1.Loosescrews.

2.WornordamagedO-ringsor

bumper.

1.Tightenscrews.

2.CheckandreplaceO-ringsorbumper.

Airleakbetweenbodyand

cylinder cap.

1.Loosescrews.

2. Worn or damaged O-rings or seals.

1.Tightenscrew.

2.Check and replace O-rings or bumper.

Bladedrivingfastenertoo

deep.

1.Wornbumper.

2.Airpressureistoohigh.

1.Replacebumper.

2.Adjusttheairpressure.

Tooldoesnotoperatewell:

cannotdrivefasteneror

operatesluggishly.

1.Inadequateairsupply.

2.Inadequatelubrication.

3.WornordamagedO-ringsorseals.

4.Exhaustportincylinderheadis

blocked.

1.Verifyadequateairsupply.

2.Place 2 or 6 drops of oil into air inlet.

3.CheckandreplaceO-ringsorseal.

4.Replacedamagedinternalparts.

Toolskipsfasteners.

1.Wornbumperordamagedspring.

2.Dirtinfrontplate.

3.Dirtordamagepreventsfasteners

frommovingfreelyinmagazine.

4.WornordryO-ringonpistonorlack

oflubrication.

5.Cylindercoversealleaking.

1.Replacebumperorpusherspring.

2.Cleandrivechannelonfrontplate.

3.Magazineneedstobecleaned.

4.O-ringneedtobereplaced.And

lubricate.

5.ReplaceSealingwasher.

Tooljams.

1.Incorrect or damaged fasteners.

2.Damagedorworndriverguide.

3.Magazineornosescrewloose.

4.Magazineisdirty.

1.Change and use correct fastener.

2.Checkandreplacethedriver.

3.Tightenthemagazine.

4.Cleanthemagazine.

11

COILROOFINGNAILERCN45RA

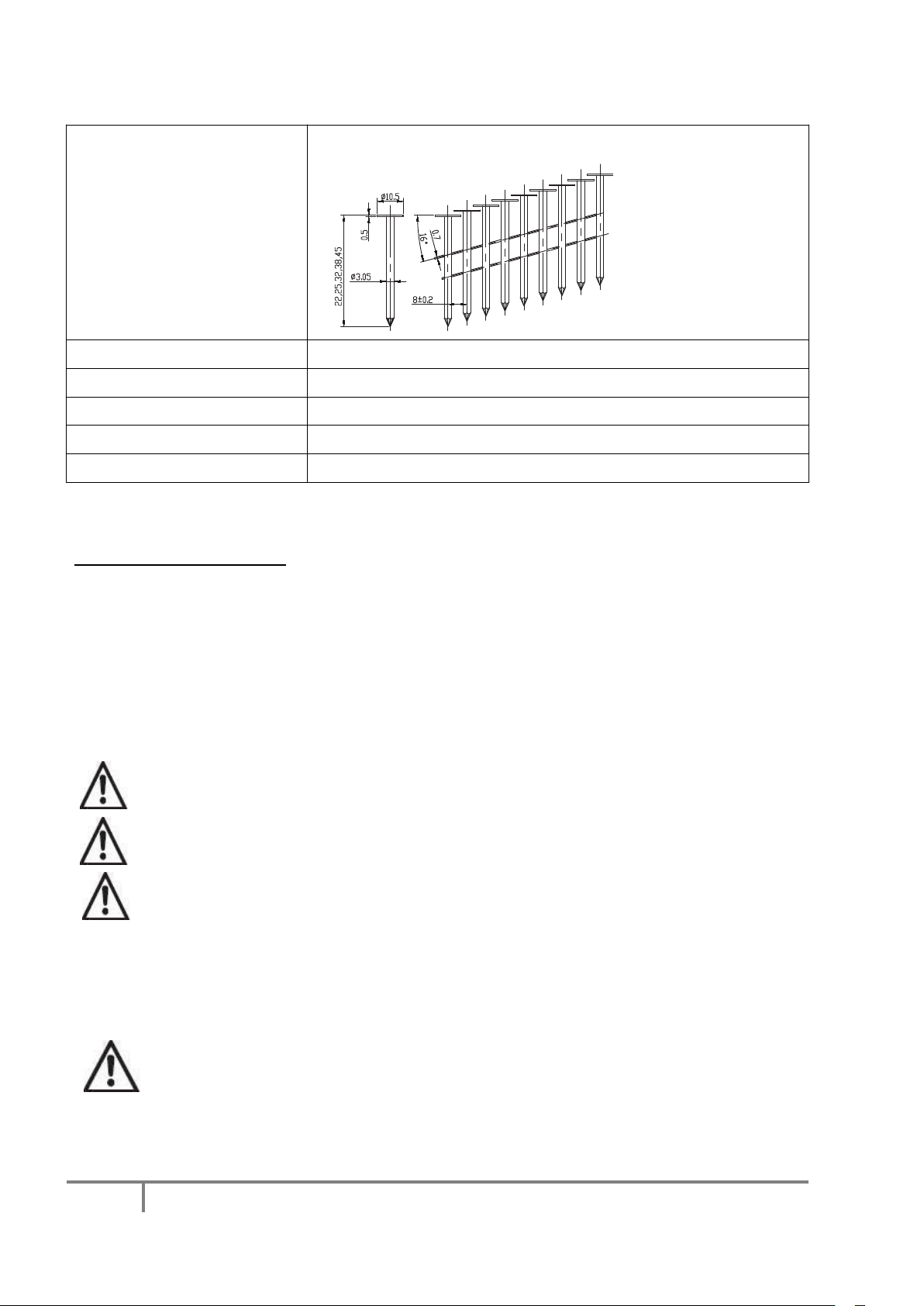

Explode DrawingExplode Drawing

Issue date:2019.5.7

Version:C/0

12

COILROOFINGNAILERCN45RA

Spare Parts List

Note:ifyouneedsparepartsofthismodel,plsfeelfreetocontactusorthedistributorwhereyouboughtthistool.

Tks!

No. Description Qty. No. Description Qty. No. Description Qty.

1 Screw M5*30 2 37 Flat Washer d=5 1 74 Adjustable Knob 1

2 Exhaust Cover 1 38 Handle Sleeve 1 75 Nut M6*18 1

3 Screw M5*8 2 39 O-Ring 36.3*3.55 1 76 Movable Plate 1

4 Cylinder Cap 1 40 End Cap 1 77 Plate Lock Pin 1

5 Non-Slip Gasket 2 41 Air Connector 1 78 Trigger 1

6 Anti-Collision Frame 2 42 Air Connector Protection 1 79 Pin 3*10 1

7 Cylinder Cap Washer 1 43 Pin 3*30 2 80 Trigger Spring 1

8 Switch Valve Seal 1 44 Mandrel Spring 1 81 Compress Spring 1

9 Air Plug 1 45 O-Ring 3.55*2 1 82 Screw M4*10 2

10 Switch Valve 1 46 Mandrel 1 83 Pin 3*28 1

11 O-Ring 30.5*3.5 1 47 Valve Seat 1 84 Upper Nail Stopper 1

12 Piston Assembly 1 48 O-Ring 11.8*1.5 3 85 Lower Nail Stopper 1

13 O-Ring 65*2 3 49 Rectangular Washer

12.3*8*3

1

86

Compress Spring

1

14 O-Ring 41.5*2.4 1 50 Sphere 1 87 Baffle 1

15 Upper Collar 1 51 Fixed Plate 1 88 Magazine Cover 1

16 Cylinder 1 52 Switch Seat 1 89 Tray Cap 1

17 Cylinder Seal Gasket 1 53 Switch Lever 1 90 Screw M4*50 1

18 Cylinder Spring 1 54 91 Spring Washer 4 1

19 O-Ring 56*2.4 1 55 O-Ring 2.8*1.8 1 92 Flat Washer d=4 1

20 Lower Collar 1 56 Trigger 1 93 Adjustable Lever 1

21 O-Ring 47*2.4 1 57 Push Lever 1 94 Bushing 2

22 Gun Body 1 58 Push Lever Sleeve 1 95 Circlip 1

23 O-Ring 5.3*1.22 2 59 O-Ring 8.75*1.8 1 96 Nail Tray 1

24 O-Ring 43.5*2.65 1 60 O-Ring 14.2*1.9 1 97 Magazine 1

25 Washer 2 61 Nail Pusher Piston 1 98 Magazine Cover Pin 1

26 Seal Gasket 1 62 O-Ring 11.2*1.8 1 99 Bolt M4 1

27 O-Ring 41*1.6 1 63 Pusher Seal Gasket 1 100 Magazine Guard 1

28 Screw M5*8 2 64 Nail Pusher Cap 1 101 Guided Limit Block 1

29 Drive Guide Baffle 1 65 Lock Bushing 1 102 Guide Seat 1

30 Drive Guide 1 66 Screw M5*10 3 103 Screw M5*14 2

31 Drive Guide Block 2 67 Torsion Spring 1 104 Guide Block 1

32 Screw M5*25 8 68 Nail Pusher 1 105 Screw M5*25 1

33 Safety Frame Compress Spring 1 69 Nail Pusher Pin 1 106 Oil Pot 1

34 Nut M5*16 1 70 Nail Pusher Pin Sleeve 2 107 Hex Wrench M5 1

35 Bolt M5 4 71 Movable Plate Pin Sleeve 1 108 Hex Wrench M4 1

36 Safety Frame Assembly 1 72 Movable Plate Pin 1 109 Safety Goggles 1

Table of contents

Other Aeropro Power Tools manuals