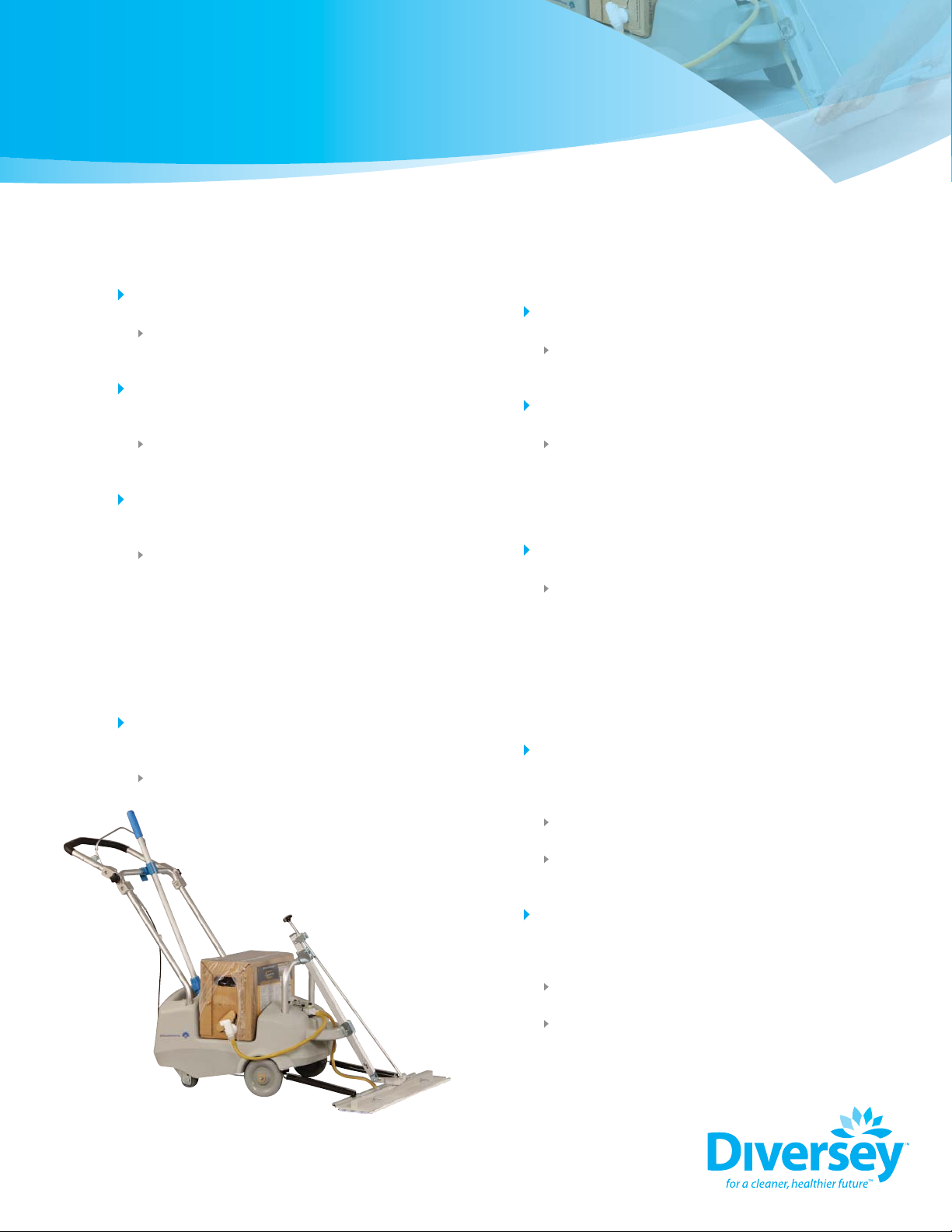

diversey TrailBlazer User manual

©2010 Diversey, Inc., 8310 16th Street, Sturtevant, WI 53177-1964

LIT30096 (10/133)

www.diversey.com

Pump is not moving/

spinning/rotating

1. Is the bail down?

The pump will only operate when the bail is in the

down position

User should verify that the bail is in the

down position

2. Is the TrailBlazer being pulled in the proper direction?

The pump with only move with the bail in the down

position and when the TrailBlazer is pulled in the proper

direction

User should verify that the bail is in the down position

and the unit is being pulled in the proper direction.

3. Is the pump cable tight?

The pump cable (similar to a bicycle brake cable) can

become loose during shipping, installation or after

continued use.

User should tighten the pump cable by following

the proper procedures in the user manual or cable

repair video.

Pump is moving/spinning/

rotating but it is making a

clicking noise

1. Is the pump cable tight?

The pump cable (similar to a bicycle brake cable) can

become loose during shipping, installation or after

continued use.

User should tighten the pump cable by following

the proper procedures in the user manual or cable

repair video.

Pump is moving but no nish

is coming out of the manifold

1. Is the white tap on the oor nish BIB (bag-in-box)

turned on?

For nish to ow out of the BIB the white tap needs to be

in the on position

User should turn the white tap on the BIB to the on

position (towards the baseplate)

2. Are the feed lines connected properly?

The feed lines need to be connected to the proper pump

inlet & outlet to allow nish to ow

User should verify that the long feed line connector

is attached to the pump inlet on the open side of the

TrailBlazer and the short feed line is connected from

the manifold to the pump outlet on the closed side

of the TrailBlazer.

3. Is the internal pump tube stuck?

The internal pump tube can get stuck during long

periods of storage.

User should remove the pump, then use ngers

to break any part of the white internal pump tube

that appears stuck. See instruction manual for

detailed information.

Finish is puddling/pooling

at the end of passes

1. Is the bail being moved up early enough?

When nearing the end of each pass with the TrailBlazer

the bail should be moved to the up position to eliminate

excess nish from puddling/pooling up at the end of

each pass.

User should move the bail to the up position no later

than 10’ before the end of each pass and as early as 15'.

User should also use the clean up tool to cleanup the

excess nish.

2. How much of each nish pass being overlapped?

It is recommended to only overlap each pass by 3", if

more overlapping is occurring it will cause increased

nish on the side of the overlap potentially causing

puddling/pooling of nish.

User should operate the TrailBlazer only overlapping

each nish pass by no more than 3".

User should also use the clean up tool to cleanup the

excess nish.

TrailBlazer Troubleshooting

TrailBlazer®

©2010 Diversey, Inc., 8310 16th Street, Sturtevant, WI 53177-1964

LIT30096 (10/133)

www.diversey.com

TrailBlazer is leaving thick

lines of nish on the side of

the nish pass

1. It is recommended to only overlap each pass by 3", if more

overlapping is occurring it will cause thick lines of nish to

form on the overlapping side.

User should operate the TrailBlazer only overlapping

each nish pass by no more than 3".

User should also use the clean up tool to clean up the

excess nish.

Finish is coming out streaky

or uneven:

1. Is the pad saturated properly?

If the pad is not saturated properly in the beginning of

each use the pad will leave streaks of nish.

User should lower bail and pull the unit back and

forth about 2'–3' each time until the streaks are gone

then nish laying nish properly.

2. Is the pad positioned properly?

If the pad is not positioned properly it is possible that

the pad can cover the manifold holes blocking the nish

from coming out

.

User should reposition the pad properly insuring

that the manifold holes are not covered.

3. Is the pad hardened/crusted?

The pad should be washed after every use to make sure

that nish does not dry within the pad.

User should replace the hardened/crusted pad with

a new one, properly saturate with nish, and then

begin nishing.

If the user does not have any extra pads and they

must lay nish they can do the following steps.

•

Properly dilute 2 gallons of stripper into a bucket,

soak the pad for 5 minutes, then rinse the pad in

warm water for 10 minutes wringing the pad every

20 seconds to fully remove the stripper solution. The

stripper solution is completely gone when bubbles

are no longer forming when the pad is wringed

out. If stripper solution is not fully removed it will

prevent the nish from being applied properly.

Always wear the recommended PPE shown on the

label or MSDS sheet for your stripper chemical.

JohnsonDiversey does not recommend this

procedure to be used more than once per pad, call

your source to order for TrailBlazer Rinsable Pads.

4. Is the nish coming out of the manifold holes evenly?

Finish needs to be owing out of all manifold holes

evenly for the nish to go down properly.

User should replace the manifold with a new one as

the manifold is clogged and cannot be cleaned.

Finish is shooting/

spraying out of the top

manifold holes:

1. Is the pad positioned properly?

If the pad is not positioned properly it is possible that the

pad can cover the manifold holes blocking the nish from

coming out the bottom holes forcing it out the top holes.

User should reposition the pad properly insuring

that the manifold holes are not covered.

2. Is the manifold clogged?

If the manifold had bottom holes that are clogged it will

force the nish out of the top holes.

User should replace the manifold with a new one as

the manifold is clogged and cannot be cleaned.

Velcro pad is falling o

of the baseplate:

1. Is the pad positioned properly?

The pad must be positioned properly to allow it to stick

properly to the Velcro once it is saturated with nish.

User should insure that the pad is positioned

properly with the back edge of the pad near the

bottom manifold holes but not covering them.

2. Is the pad oversaturated?

If vast amount of sq. ft. is being nished it is possible for the

pad to become oversaturated causing the pad to fall o of

the Velcro.

User should put the bail in the up position and

continue nishing to remove the excess nish from

the pad.

3. Is the Velcro lled with lint/debris?

Velcro only works properly if the Velcro is clean from

debris/lint.

User should check to see if signicant debris/lint has

accumulated in the Velcro. User should spend a few

minutes removing the debris/lint after every few

nish applications to insure proper Velcro strength.

TrailBlazer Troubleshooting

Other manuals for TrailBlazer

1

Popular Power Tools manuals by other brands

Rittal

Rittal 4052.000 operating instructions

JEI DRILLING & CUTTING SOLUTIONS

JEI DRILLING & CUTTING SOLUTIONS STEELBEAST BM-7 Operator's manual

AEG

AEG OMNI-JS Original instructions

General International

General International 40-350 manual

MGF

MGF M18 ONEFHIWF34 user guide

Makita

Makita LS1216 instruction manual