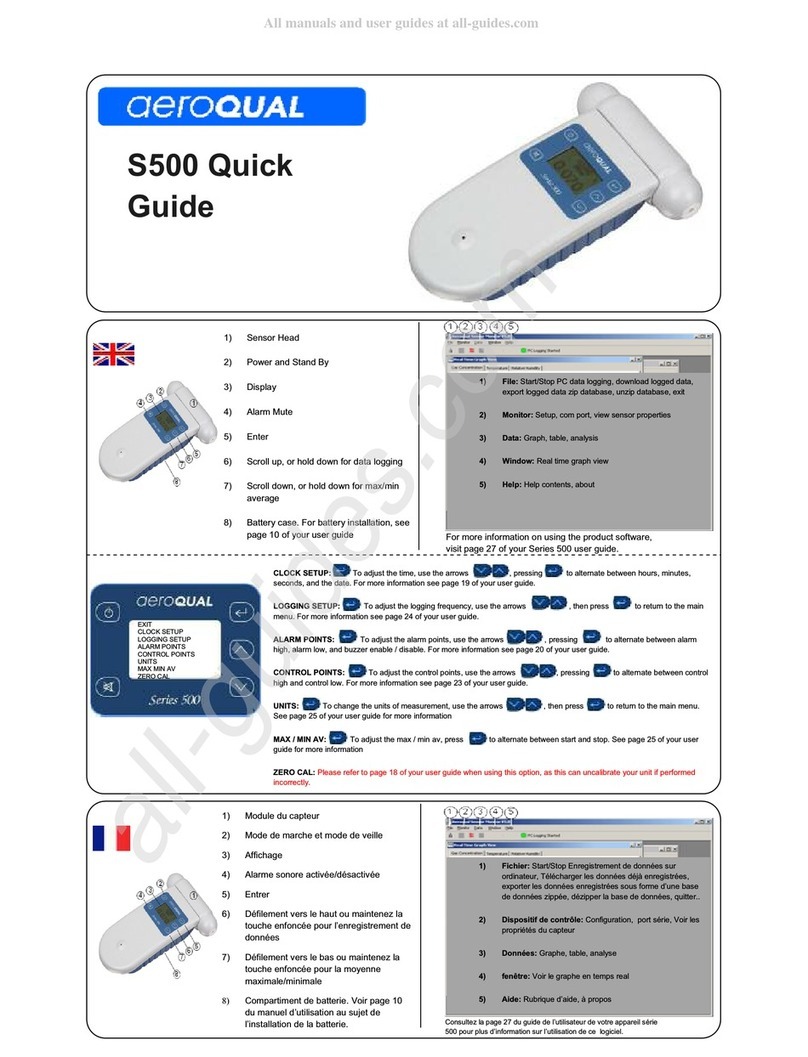

Aeroqual AQM60 User manual

Aeroqual AQM60 User Guide

Page | 2

Aeroqual AQM60 User Guide

Contents

User Guide Revision History...........................................................................................................................5

1. Description ..............................................................................................................................................6

1.1. Control Module.................................................................................................................................. 7

1.2. Gas Treatment Module...................................................................................................................... 7

1.3. Gas Modules ..................................................................................................................................... 8

1.3.1. Gas Sensor Module Specifications............................................................................................. 9

1.4. TMS Module...................................................................................................................................... 9

1.5. Compressor..................................................................................................................................... 10

1.6. Power Module.................................................................................................................................. 10

1.7. Humidity and Temperature Sensor ................................................................................................. 10

1.8. Internal Air Duct............................................................................................................................... 11

1.9. Auxiliary Module (Optional) ............................................................................................................. 11

1.10. Particle Mass Pump Modules.......................................................................................................... 13

1.10.1. Profiler Pump Module ............................................................................................................... 13

1.10.2. Nephelometer Particle Monitor ................................................................................................. 13

1.11. Electrical Connections..................................................................................................................... 14

1.12. Pneumatic Connections .................................................................................................................. 15

2. Installation and Commissioning .........................................................................................................16

2.1. Unpacking........................................................................................................................................ 16

2.2. Assembly......................................................................................................................................... 16

2.2.1. Connect Mains Power............................................................................................................... 16

2.2.2. Connect Inlet Sub Assembly..................................................................................................... 17

2.2.3. Assembly of heated inlet for PM/Profiler (Optional).................................................................. 18

2.2.4. Connect third party sensors (Optional)..................................................................................... 19

2.3. Initial Commissioning ...................................................................................................................... 19

2.3.1. Set Up....................................................................................................................................... 19

2.3.2. System Checks......................................................................................................................... 20

2.3.3. System Values.......................................................................................................................... 21

2.3.4. Zero and Span Checks for Gas Modules.................................................................................. 21

3. AQM60 Software Description ..............................................................................................................22

3.1. Computer Requirements ................................................................................................................. 22

3.2. Summary......................................................................................................................................... 22

3.2.1. File ............................................................................................................................................ 22

3.2.2. Setup......................................................................................................................................... 23

3.2.3. Data........................................................................................................................................... 23

3.2.4. Tools ......................................................................................................................................... 24

3.2.5. Calibration................................................................................................................................. 24

3.2.6. Diagnostics ............................................................................................................................... 25

3.2.7. Additional Buttons..................................................................................................................... 25

3.3. IP Modem configuration (Optional).................................................................................................. 26

3.3.1. TCP/IP connection.................................................................................................................... 26

3.3.2. IP address solutions using GPRS Systems.............................................................................. 27

3.4. Other Communication Options........................................................................................................ 28

3.4.1. RF Modem ................................................................................................................................ 28

3.4.2. GSM Modem............................................................................................................................. 28

4. Calibration .............................................................................................................................................30

4.1. Calibration Frequency..................................................................................................................... 30

4.2. AQM Calibration Basics .................................................................................................................. 31

4.2.1 Nafion Humidifier (AQM R21) ...................................................................................................... 31

4.3. Zero Calibration and Check............................................................................................................. 32

4.3.1. Automatic Zero............................................................................................................................. 32

4.3.2. Manual Zero................................................................................................................................. 32

4.4. Span Calibration and Check............................................................................................................ 33

4.4.1. Multi-Gas Calibration Standard and Gas Phase Titration......................................................... 34

Page | 3

Aeroqual AQM60 User Guide

4.4.2. Span Calibration Procedure...................................................................................................... 34

4.5. AirCal 8000 (Optional)..................................................................................................................... 35

4.5.1. Overview................................................................................................................................... 35

4.5.2. Pneumatics............................................................................................................................... 36

4.5.3. Gas cylinder Housing................................................................................................................ 36

4.5.4. Configuring the AirCal 8000 scheduler..................................................................................... 37

4.5.5. The Calibration Record............................................................................................................. 38

4.5.6. Performing a Manual Calibration .............................................................................................. 39

4.5.7. Data Displayed.......................................................................................................................... 39

5. Third Party Sensors..............................................................................................................................41

5.1. Particle Monitor................................................................................................................................ 41

5.1.1. Nephelometer ........................................................................................................................... 41

5.1.2. Inlet heater................................................................................................................................ 41

5.1.3. Inbuilt filters............................................................................................................................... 41

5.2. Profiler............................................................................................................................................. 41

5.2.1. Optical Particle Counter............................................................................................................ 41

5.2.2. Connections.............................................................................................................................. 42

5.2.3. Data Outputs............................................................................................................................. 42

5.3. Vaisala Weather Transmitter WXT520............................................................................................ 43

5.4. Sensirion T/RH Sensor SHT75 ....................................................................................................... 43

5.5. Gill WindSonic................................................................................................................................. 44

5.6. Noise Meter and Calibrator ............................................................................................................. 44

6. Field Installation....................................................................................................................................45

6.1. Site Selection................................................................................................................................... 45

6.2. Mounting.......................................................................................................................................... 45

7. Maintenance ..........................................................................................................................................47

7.1. Safety Requirements....................................................................................................................... 47

7.2. Maintenance Schedule.................................................................................................................... 47

7.2.1. Standard AQM .......................................................................................................................... 47

7.2.2. Particle Monitor......................................................................................................................... 48

7.2.3. Profiler....................................................................................................................................... 48

7.3. AQM Maintenance Procedures....................................................................................................... 48

7.3.1. Replacing the Inlet Filter........................................................................................................... 48

7.3.2. Measuring Sample Inlet Flow Rate........................................................................................... 49

7.3.3. Gas Sensor Module Flow Rate................................................................................................. 49

7.3.4. Replacing Gas Treatment Media.............................................................................................. 51

7.3.5. Leak Check Gas Sensor Plumbing........................................................................................... 52

7.3.6. Removing and Replacing AQM Modules.................................................................................. 52

7.4. Particle Monitor................................................................................................................................ 53

7.4.1. Sample Flow Check.................................................................................................................. 53

7.4.2. Purge Flow Check..................................................................................................................... 54

7.4.3. Sheath Flow Check................................................................................................................... 54

7.4.4. Leak Check............................................................................................................................... 54

7.4.5. Manual Zero Air Check............................................................................................................. 55

7.4.6. Fibre Span Check ..................................................................................................................... 55

7.4.7. Laser Current Check................................................................................................................. 56

7.4.8. Filter Changes........................................................................................................................... 56

7.4.9. Cyclone and Inlet Cleaning....................................................................................................... 56

7.4.10. Pump Module Removal............................................................................................................. 57

7.5. Profiler............................................................................................................................................. 57

7.5.1. Sample Flow Check and Adjustment ....................................................................................... 57

7.5.2. Sheath Flow Check................................................................................................................... 58

7.5.3. Leak Check............................................................................................................................... 58

7.5.4. Filter Changes........................................................................................................................... 59

7.5.5. Inlet Cleaning............................................................................................................................ 60

7.5.6. Pump Module Removal............................................................................................................. 60

Page | 4

Aeroqual AQM60 User Guide

8. Troubleshooting....................................................................................................................................61

8.1. AQM60 Basics................................................................................................................................. 61

8.2. Particle Monitor/Profiler................................................................................................................... 62

8.3. Diagnostics...................................................................................................................................... 63

9. Orbit Data...............................................................................................................................................65

9.1. Specifications .................................................................................................................................. 65

9.2. Configuring the Orbit Modem.......................................................................................................... 65

9.3. Using the Orbitdata Website ........................................................................................................... 66

9.3.1. Using the Graphs...................................................................................................................... 67

9.3.2. Setting Alarms........................................................................................................................... 68

9.3.3. Downloading Data..................................................................................................................... 68

10. Appendix 1.............................................................................................................................................69

10.1. Sensor list........................................................................................................................................ 69

10.1. Auxiliary Module Wiring................................................................................................................... 70

10.1.1. Wind Sonic................................................................................................................................ 70

10.1.2. Vaisala ...................................................................................................................................... 70

10.2. RS232 Protocol ............................................................................................................................... 71

11. Appendix 2.............................................................................................................................................82

11.1. Guidelines........................................................................................................................................ 82

11.2. Technical support............................................................................................................................ 82

11.3. Copyright......................................................................................................................................... 82

11.4. Compliance...................................................................................................................................... 83

Page | 5

Aeroqual AQM60 User Guide

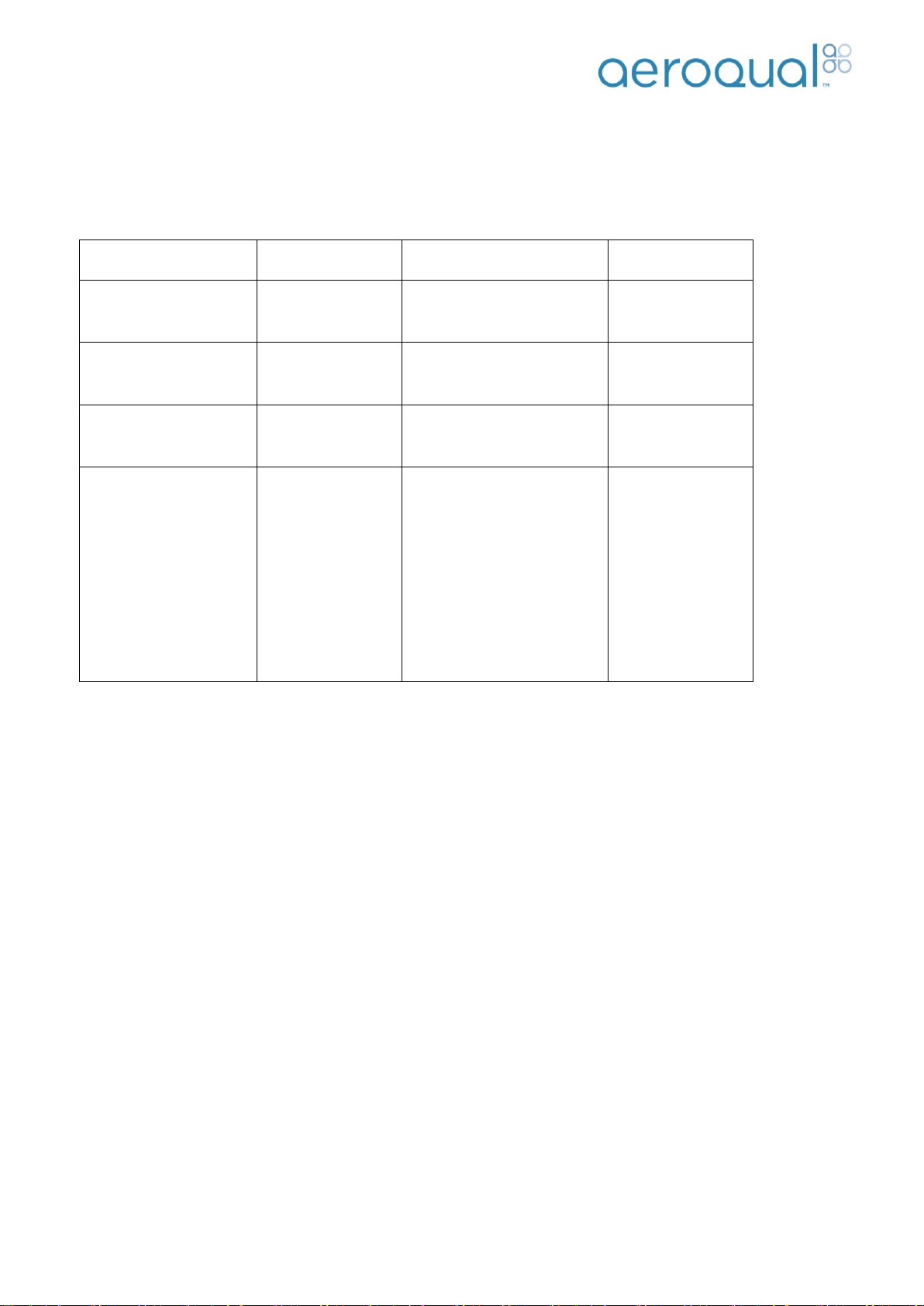

User Guide Revision History

Current version: 7.3

Description: User guide for AQM60

This user guide is a newly created document for the use of the AQM60.

Date

Revision number

Description of change

Affected pages

10/02/2014

7.1

Orbit data information

added

Section 9

30/05/2014

7.2

New Aux module

information added

Section 1.8

30/05/2014

7.2

Connection of inlet sub

assembly

Section 2.2.2

07/07/2014

7.3

Internal Fan Duct

Information

Added additional photo to

inlet sub assembly

Added note about

increasing logging period

above 2 minutes in

calibration section.

Section 1.8

Section 2.2.2

Section 4.5.4

Page | 6

Aeroqual AQM60 User Guide

1. Description

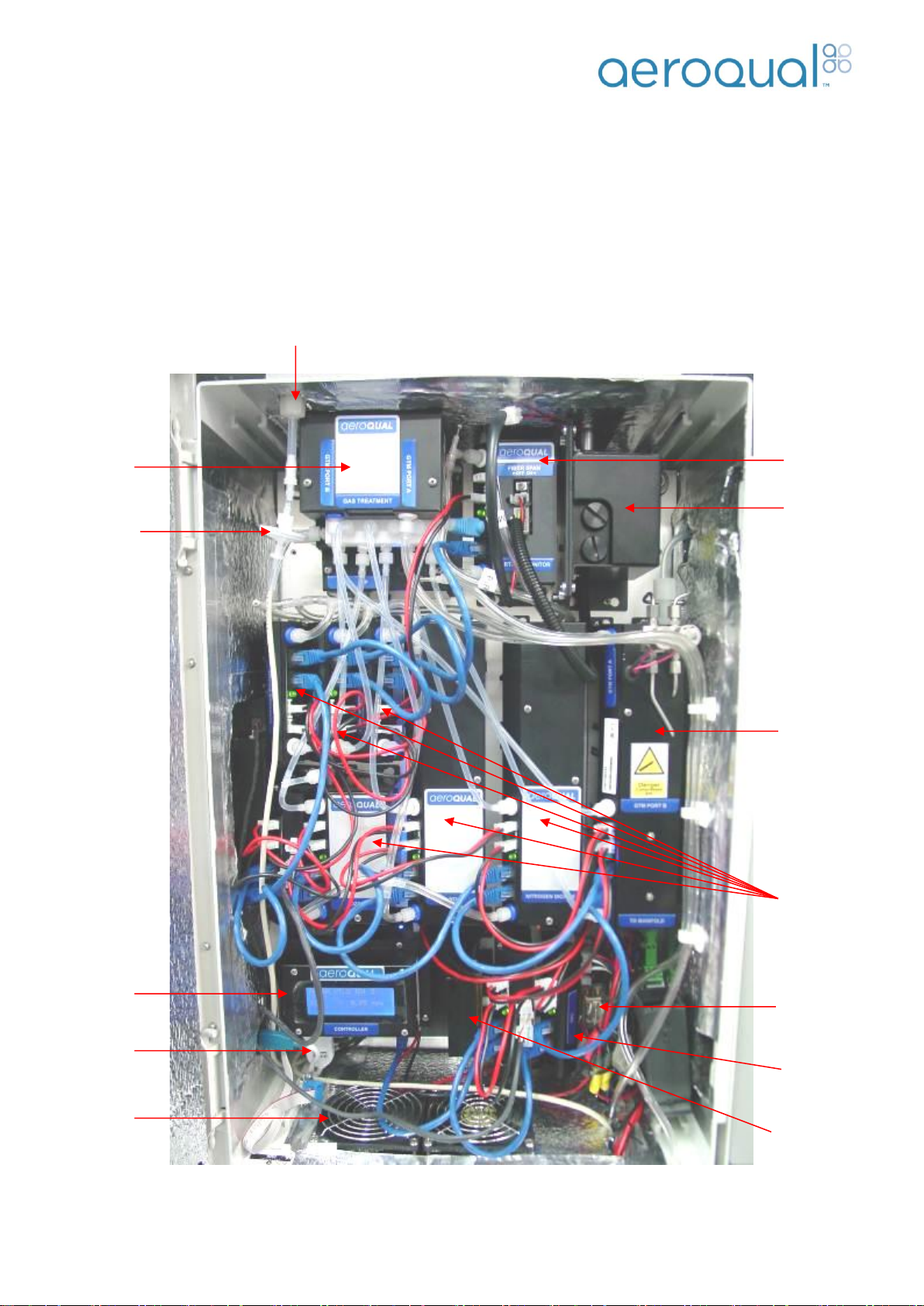

The Aeroqual AQM60 Environmental Station is a custom-built ambient air quality instrument. It’s platform is

configurable to measure common air pollutants including ozone (O3), nitrogen dioxide (NO2), carbon

monoxide (CO) and sulphur dioxide (SO2) as well as particulate matter (PM10, PM2.5) and meteorological

parameters such as temperature, humidity, wind speed and direction.

The AQM consists of an enclosure typically containing a control module, power module, thermal

management system, gas treatment module, a number of gas sensor modules, a RH/T sensor and

associated cabling and plumbing.

Note 1: The placement of individual modules will vary depending on the user configuration

Note 2: AQM60 units dispatched from July 2014 will also include an internal air duct (Refer to Section 1.8)

Heater

Inlet Filter

Pump module

PM or Profiler

engine

Aircal 8000

(Optional)

Gas Modules

(User

Configurable)

Cooling

Fans

RS232 to

USB Adapter

Control

Module

Inlet

Gas Treatment

Module

Mains Power

12V connector

terminal

Thermal

Management

System (TMS)

Page | 7

Aeroqual AQM60 User Guide

1.1. Control Module

The control module is the interface between the RS485 sensor bus and data communication links. It contains

a display, a SD data card which logs data, a RS232 serial connector for external communication, a bus

connector for internal communication with the sensor modules and a cable connector for the Sensirion

Humidity and Temperature sensor (if fitted).

The AQM60 is supplied with a RS232 to USB adapter fitted between the Control Module and an external

USB socket fitted at the side of the enclosure. This enables the user to perform a wide range of functions

over the USB connection, without needing to open the enclosure door, such as data logging and various

system checks using the supplied Aeroqual AQM60 PC software

Note: The driver for the RS232 to USB adapter is in the software CD which comes with the

instrument.

1.2. Gas Treatment Module

The Gas Treatment Module controls the gas sampling. Inlet air is filtered through a 5 μm membrane filter and

enters the Gas Treatment Module via either the sample or zero air ports. The air is then distributed via a

PTFE manifold to the gas modules. A solenoid controls the air path which can be switched from the directly

sampled ambient air to air which has passed through internal scrubbers (zero air) in order to check the

baseline readings of the gas sensors.

Removable Display module

Front

Top

Off/On switch with LED

Controller 12VDC power input

Programming Port

RS232

Firmware (V6.2+)

Programming Dip

Switch

Firmware (V6.2+)

Base

6 way Gas Treatment

SD Card Slot

DB9 RS232

4 way T/RH

2 way Bus relay

activation

RJ45 RS485

Bus

2.1mm 12VDC relay

switched Power output

Page | 8

Aeroqual AQM60 User Guide

The Gas Treatment Module also contains a diaphragm pump which draws air through the gas modules. The

sample flow rate is controlled by a bypass screw fitted between the vacuum and pressure sides of the pump.

Note: If the AQM60 has an AirCal 8000 installed the zero air scrubbing material is located in the

AirCal module not the GTM.

1.3. Gas Modules

An example of a gas module is shown below. All modules are mounted onto the base plate using 4 or 2

bolts. They can be either full size or half size modules depending on the gas. Inlet and outlet tubes are

connected to the gas distribution manifold and exhaust respectively.

Solenoid

12VDC, 3-way, Teflon

Pump

BLDC diaphragm pump

Scrubber media

1 x activated carbon + 1 x Hopcalite + 1 x Purafil Chemisorbent

Manifold

PTFE

Fittings

Luer

Flow rate

0.2 to 1.5 LPM depending on gas modules fitted. Set by bypass screw

Sample Exhaust

RJ45 Connectors

for RS485 bus

12VDC Power

Connectors

Sample inlet

Status LED

Page | 9

Aeroqual AQM60 User Guide

1.3.1. Gas Sensor Module Specifications

(Note: these are subject to change; please contact Aeroqual for latest performance data)

1.4. TMS Module

The AQM has a thermal management control system to maintain a stable internal temperature irrespective of

ambient temperature changes. The TMS module controls the thermal management system to ensure the

internal temperature is maintained. It initiates the fans and heater when necessary to maintain the internal

temperature set.

Gas Modules

Range

Minimum

Detection

Limit

Accuracy of

Factory Calibration

Precision

Resolution

Ozone O3(GSS)

0-0.15 ppm

0.001 ppm

<±0.005 ppm

0.002 ppm

0.001 ppm

Ozone O3(GSS)

0-0.5 ppm

0.001 ppm

<±0.008ppm 0to0.1ppm;

<±10% of reading above 0.1 ppm

0.005 ppm

0.001 ppm

Nitrogen Dioxide NO2(GSS)

0-0.2 ppm

0.001 ppm

<±0.01 ppm 0to 0.1 ppm;

<±10%of readingabove 0.1ppm

0.005 ppm

0.001 ppm

Nitrogen Oxides NOx(GSS)

0-0.5 ppm

0.001 ppm

<±0.01 ppm 0to 0.1 ppm;

<±10%of readingabove 0.1 ppm

0.005 ppm

0.001 ppm

Carbon Monoxide CO (GSE)

0-25 ppm

<0.04 ppm

<±0.1ppm, 0 to 1 ppm

<±10% of reading above 1 ppm

0.1 ppm

0.01 ppm

Carbon Dioxide CO2(NDIR)

0-2000 ppm

<10 ppm

<±(10 ppm + 5% of reading)

10 ppm

1 ppm

Hydrogen Sulphide H2S(GSE)

0-10 ppm

<0.03 ppm

<±0.05ppm 0 to 0.5 ppm

<±10% of reading above 0.5ppm

0.03 ppm

0.01 ppm

Sulphur Dioxide SO2(GSE)

0-10 ppm

<0.03 ppm

<±0.05ppm 0 to 0.5 ppm

<±10% of reading above 0.5 ppm

0.05 ppm

0.01 ppm

Volatile Organic Compounds

(PID)

0-20 ppm

0.01 ppm

<±0.02ppm 0 to 0.2 ppm

<±10% of reading above 0.2 ppm

0.03 ppm

0.01 ppm

Non-methane Hydrocarbon (GSS)

0-25 ppm

<0.1 ppm

<±0.1ppm, 0 to 1 ppm

<±10% of reading above 1 ppm

0.1 ppm

0.01 ppm

Volatile OrganicCompounds

(GSS)

0-25 ppm

<0.1 ppm

<±0.1ppm, 0 to 1 ppm

<±10% of reading above 1 ppm

0.1 ppm

0.01 ppm

Particle Monitor (nephelometer)

Sizes

PM1PM2.5 or PM10

Range

0-2000 µg/m3

Accuracy

<±(2 µg/m3 + 5% of reading)

Flow rate

2.0 LPM

Resolution

0.01 µg/m3

Particle Profiler (OPC)

Sizes

PM1PM2.5 and

PM10

Range

0-500 µg/m3

Accuracy

<±(5 µg/m3 +15% of reading)

Flow rate

1.0 LPM

Resolution

0.01 µg/m3

Status

LED

12VDC

Power

Connectors

RJ45 Connectors

for RS485 bus

TMS

communication

connector

ITemp

Sensor

Connector

Page | 10

Aeroqual AQM60 User Guide

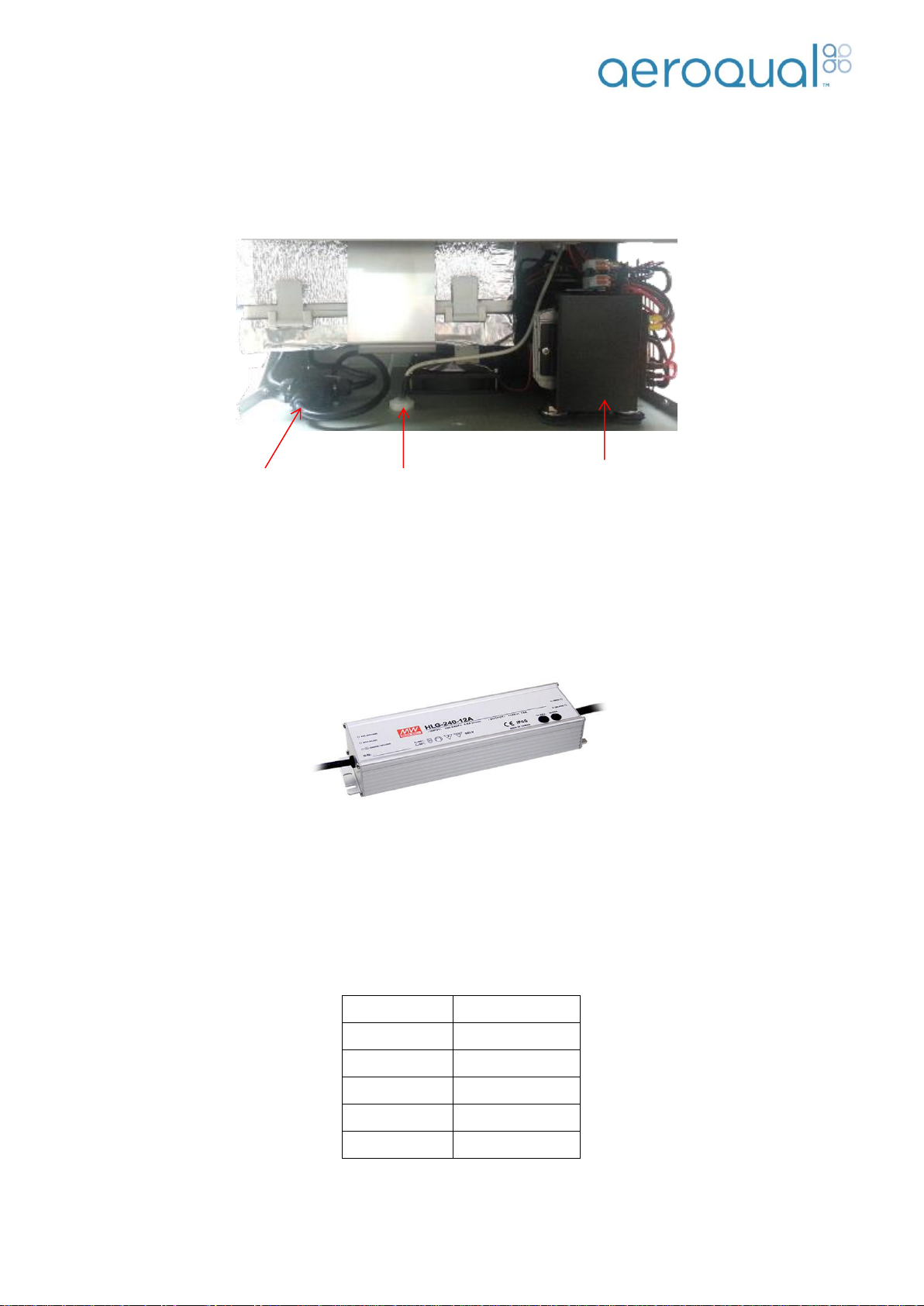

1.5. Compressor

The cooling system is a compressor refrigeration unit which is mounted at the base of the AQM60. It is a

self-contained system that provides cooling via the base on the AQM. The compressor system and inlet can

be accessed by releasing the two clips on the side of the AQM and rotating the housing upwards.

1.6. Power Module

Two Meanwell HLG240-12A 192W 12V Single Output Class 2 with PFC Power Units are mounted on the

outside of the enclosure. One powers the compressor and the second powers the modules. It has features

including universal AC input (90-280VAC) and IP65 rating.

1.7. Humidity and Temperature Sensor

The Humidity and Temperature Sensor is a Sensirion single chip device which contains a capacitive polymer

sensing element for relative humidity and a band-gap temperature sensor. More detailed specifications are in

the table below. The temperature and humidity sensor is housed in a connector located on the bottom of the

enclosure. It is connected directly to the Control Module.

Humidity

Resolution

0.1 %RH

Range

0 to 100 %RH

Temperature

Resolution

0.1 °C

Range

-40 to 120 °C

Temperature &

Relative Humidity

Sensor

Compressor

Junction box for

mains connection

Page | 11

Aeroqual AQM60 User Guide

Programming Dip

Switch

Programming

Port

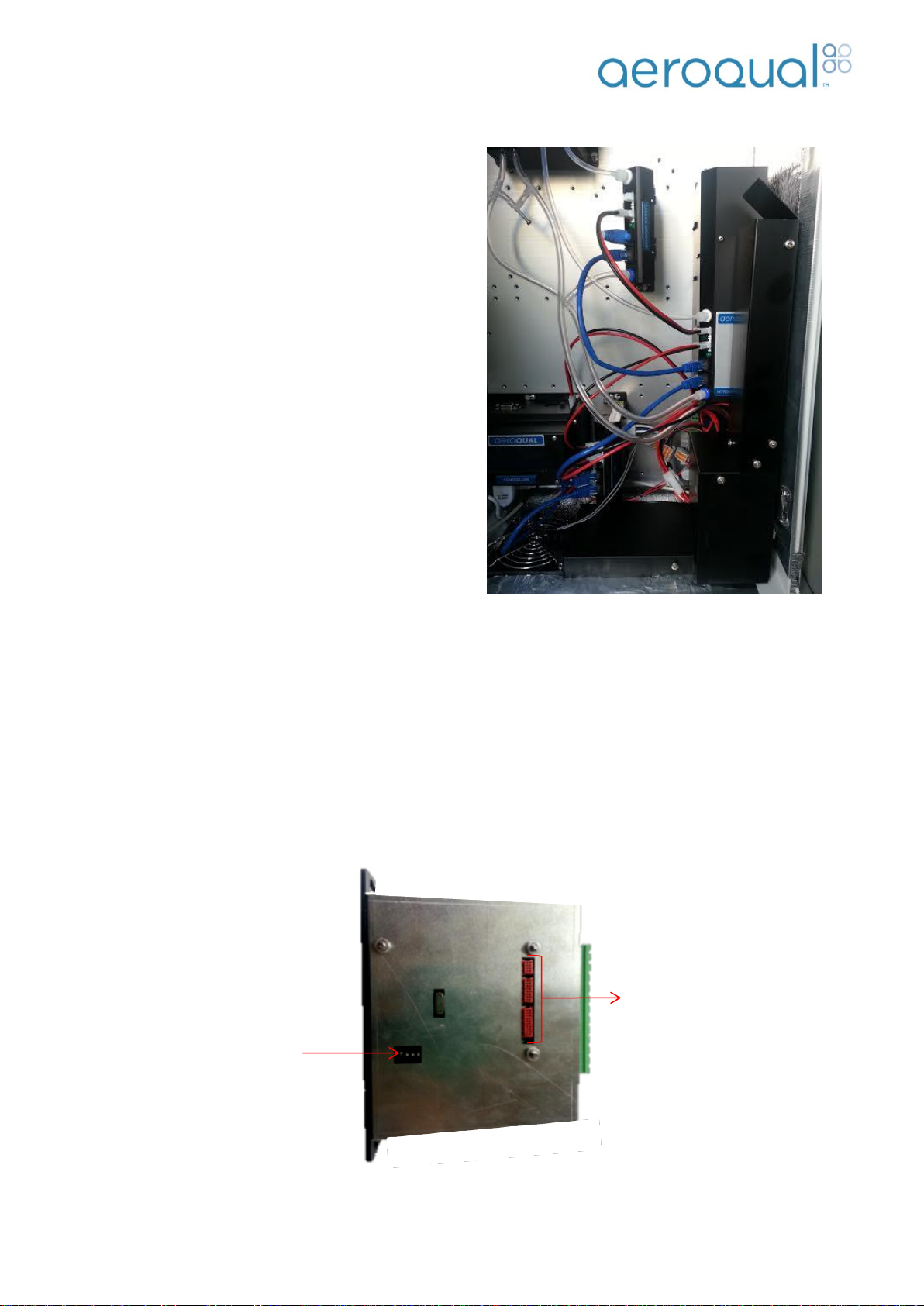

1.8. Internal Air Duct

AQM60 units dispatched after July 2013 will include an

internal air duct (chimney). The chimney is a new

feature to improve thermal stability inside the AQM60

base system. Changes to both the heating and cooling

sub-systems ensure optimum airflow around the

enclosure, minimising thermal gradients thus

temperature effects on the sensors. This optimised

airflow has been coupled with enhancements to the

thermal measurement and control sub-system allowing

an even tighter temperature control ban.

The chimney will come pre-installed. However, there will

be times when the chimney may need to be removed

for servicing.

To remove the chimney the two screws, that connect

the chimney to the fan grill on the base of the

enclosure, need to be removed. The chimney should

then slide out and the two connectors behind can be

easily disconnected.

Note 1: The chimney is stuck to the side of the enclosure with double sided tape which may need to

be replaced when removing/replacing the chimney.

Note 2: The NOx/NO2 module can be removed without taking out the chimney by undoing the

mounting plate screws completely and sliding the module out.

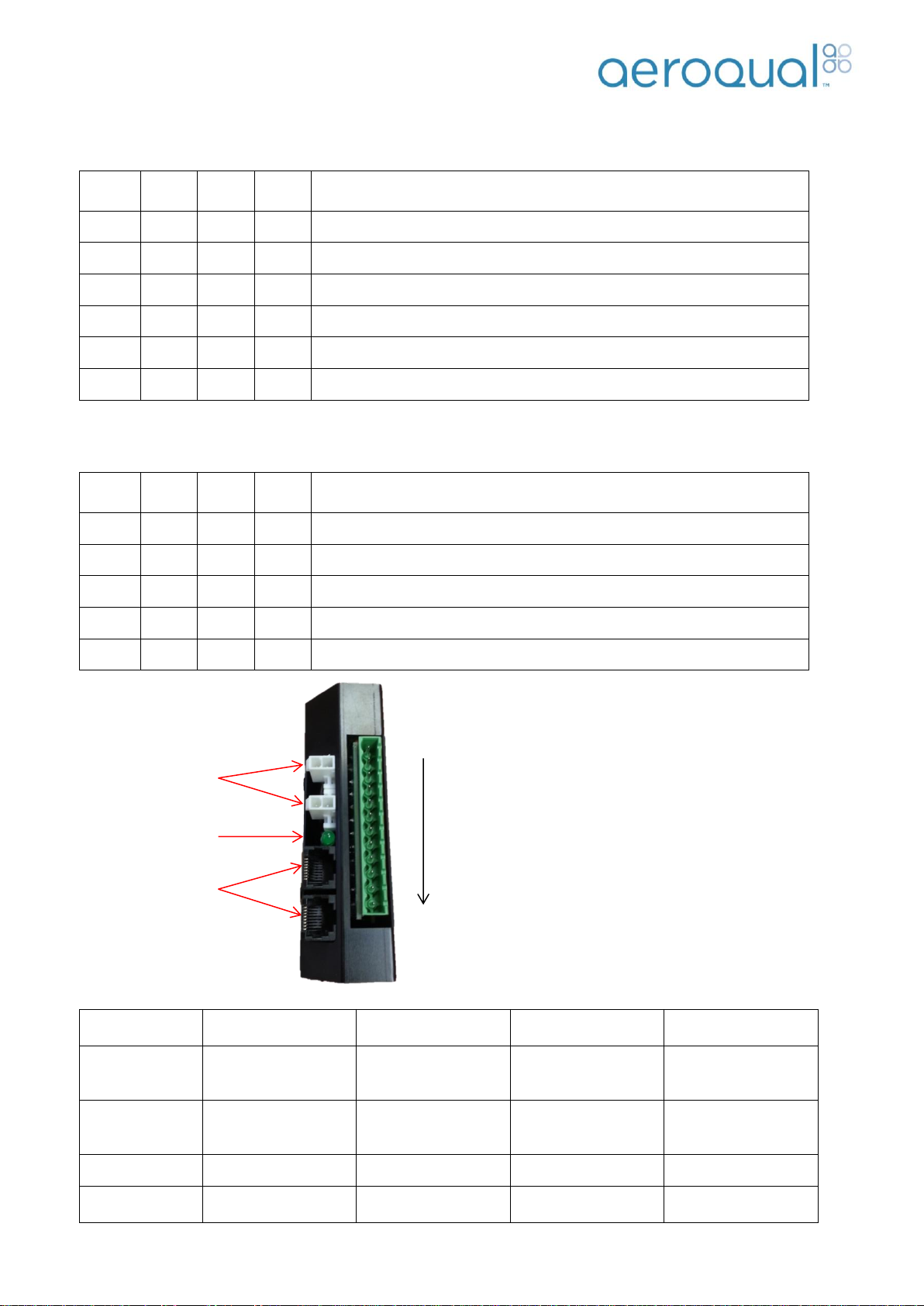

1.9. Auxiliary Module (Optional)

The auxiliary module acts as an interface between third party sensors and the AQM60 communication bus.

It is configured with different operating modes which can be selected by using the dipswitches located on the

side of the module. Aeroqual has integrated a number of third party sensors and is able to supply the

auxiliary module preconfigured for your sensors.

Page | 12

Aeroqual AQM60 User Guide

Firmware: AUX_MODULE_01.

Use for: Analogue inputs, Vaisala WXT520 weather, Gill Windsonic wind, Cirrus MK:427 noise.

1

2

3

4

Function

OFF

OFF

OFF

OFF

Default - standard Auxiliary module with AN1, AN2, Freq

ON

OFF

OFF

OFF

Vaisala WXT520 with RS232 communication + AN1, AN2, Freq

OFF

ON

OFF

OFF

Vaisala WXT520 with RS232 communication + Cirrus MK427 Noise

ON

ON

OFF

OFF

Wind Sonic with RS232 communication + AN1, AN2, Freq

OFF

OFF

ON

OFF

Wind Sonic with RS232 communication + Cirrus MK427 Noise

ON

OFF

ON

OFF

Cirrus MK427 Noise module only

Firmware: AUX_MODULE_02.

Use for: Analogue inputs, Met One MSO weather, Met One 034b wind, Cirrus MK:427 noise.

1

2

3

4

Function

OFF

OFF

OFF

OFF

Default - standard Auxiliary module with AN1, AN2, Freq

ON

OFF

ON

OFF

Cirrus MK427 Noise module only

OFF

ON

ON

OFF

Met One MSO with RS232 communication + Cirrus MK427 Noise

ON

ON

ON

OFF

Met One MSO with RS232 communication + AN1, AN2, Freq

OFF

OFF

OFF

ON

Met One 034B analogue module + Cirrus MK427 Noise

Example of wiring:

Wind Sonic

(Pin 1) GND,

SIGNAL GND

(Pin 2) 12V

(Pin 5) RX

(Pin 6) TX

Vaisala

(Pin 1) GND for

operating, data &

heating

(Pin 2) 12V for

operating & heating

(Pin 5) RX

(Pin 6) TX

Met One MSO

(Pin 1) GND,

SIGNAL,

COMMON, SHIELD

(Pin 2) 12V

(Pin 5) RX

(Pin 6) TX

Met One 034B

(Pin 1) GND

(Pin 12) VCC

(Pin7) WD

(Pin 9) WS

Cirrus MK:427

(Pin 1) GND,

ACTUATOR GND

(Pin 2) 12V, LOOP

IN

(Pin 8) LOOP OUT

(Pin 12)

ACTUATOR IN

Pin 12

Pin 1

Status LED

12VDC Power

Connectors

RJ45 Connectors

for RS485 bus

Wiring of Aux Module:

PIN 1: GND

PIN 2: 12V FUSED

PIN 3: RESERVED

PIN 4: RESERVED

PIN 5: RX

PIN 6: TX

PIN 7: 0-5V IN

PIN 8: 4-20mA IN

PIN 9: FREQ IN

PIN 10: AGND

PIN 11: METONE 034B PWR

PIN 12: TIMED RELAY

Page | 13

Aeroqual AQM60 User Guide

A programming port is also exposed through the side of the module to allow custom programs to be loaded

into the module.

Note 1: Aeroqual can supply a standard programming tool for distributors to reprogram the auxiliary

module to the specified requirements.

Note 2: Please refer to third party sensor manuals for instructions on wire outputs. The Wind Sonic

comes with an Aeroqual supplied cable and therefore wire outputs will be sent with the cable.

1.10. Particle Mass Pump Modules

The Pump Modules for the optical mass sensors contain a microprocessor for mass calculation and a pump

for sampling. There is a different pump module for the Nephelometer and optical particle counter (Profiler)

sensor modules

1.10.1. Profiler Pump Module

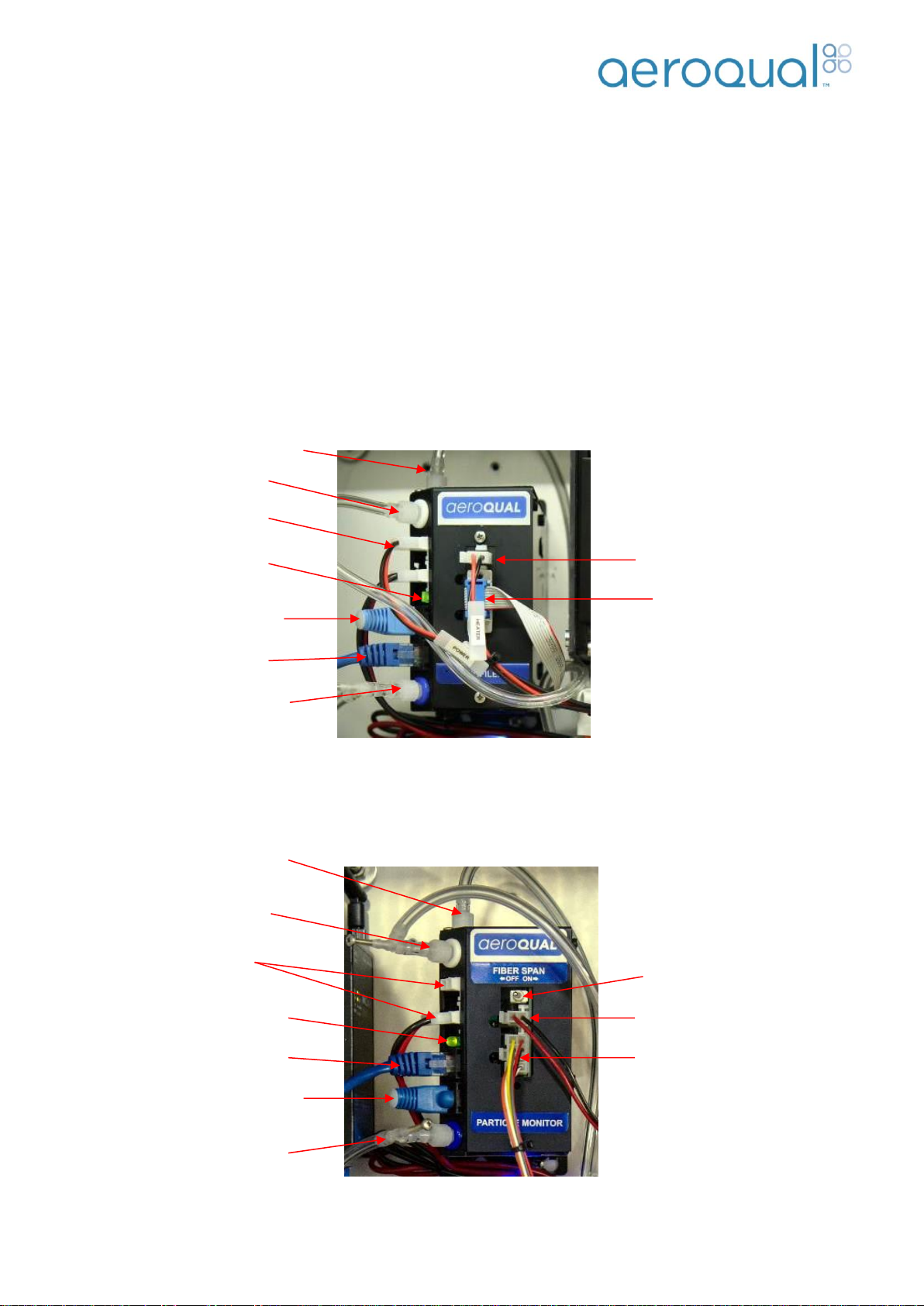

1.10.2. Nephelometer Particle Monitor

Purge line

Exhaust line with

flow adjuster

Inlet heater connector

RS232 connector from

optical engine.

12VDC power

connection

RS485 termination

dongle

RS485 bus cable

Sample line

Power on LED

Inlet heater connector

Cable from optical engine

12VDC power

connection

RS485 termination dongle

RS485 cable

Exhaust line with flow

adjuster

Power on LED

Sample in

Sheath air out with

flow adjuster

Fibre span switch

Page | 14

Aeroqual AQM60 User Guide

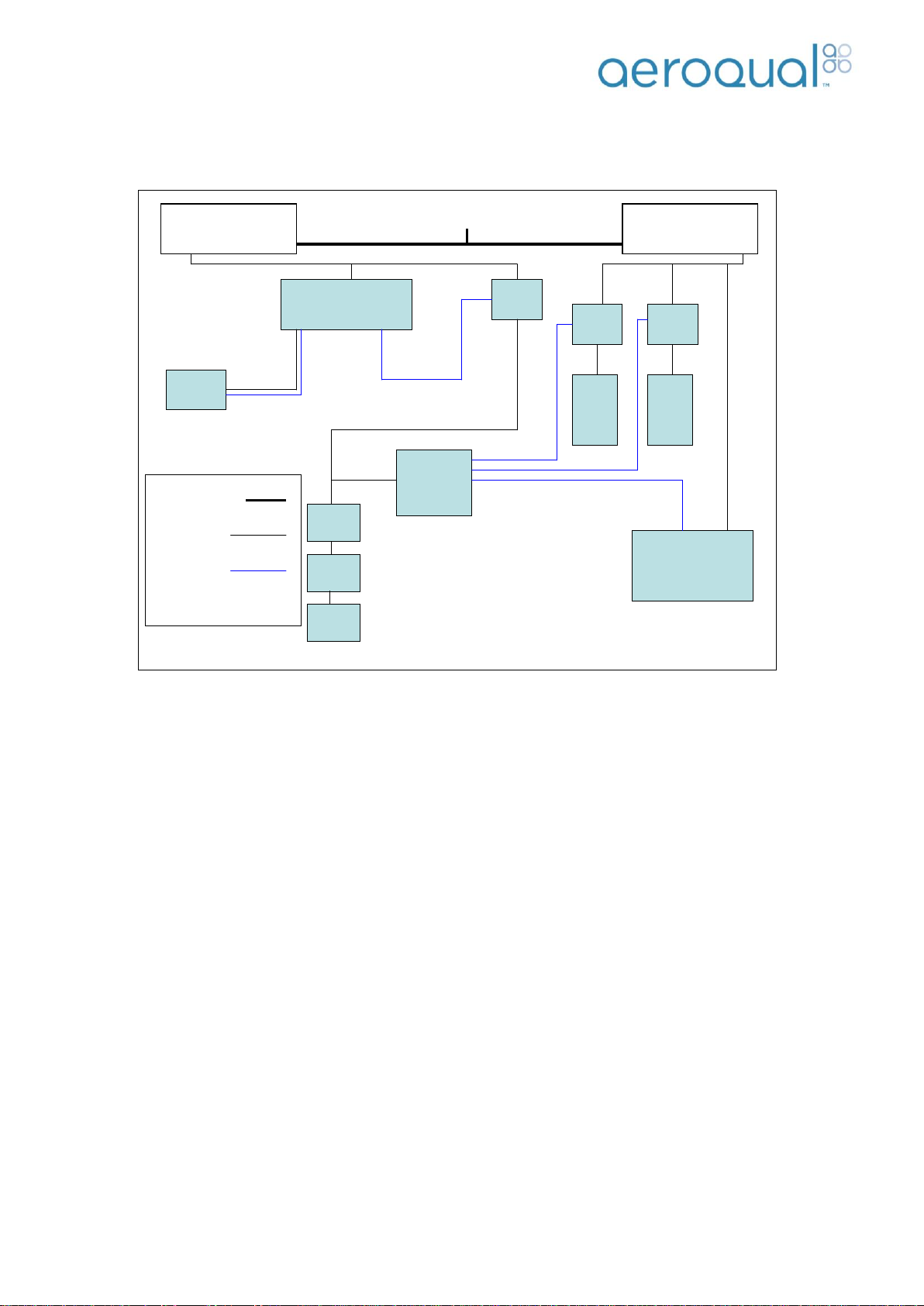

1.11. Electrical Connections

RS485 Bus

The two wire RS485 bus connections are made using 20 cm CAT5 cables between the sensor modules. The

last module on the bus also has a blue termination dongle fitted. The termination dongle should not be

removed.

12 VDC Power Bus

All modules inside the AQM60 operate from the 12VDC power. The power is supplied by a daisy chain of

black and red cables. A relay is activated by the Control Module on/off button to allow the sensor bus to be

powered.

Status LED

Each module includes a status LED which indicates that the electrical status of the module is functioning

correctly. It does not relate the calibration status of the module.

a) Continuous on indicates correct electrical functionality

b) Slow flash (1 second) indicates warm up period

c) Fast flash (0.2 seconds) sensor failure

d) LED not on indicates no power to module.

Controller

GTM

Power supply one

12V

Compressor

Module

power

relay

TMS

module

gas

module

gas

module

Heater

power

relay

TMS heater

12 V Power

Signal

Power supply two

12V

Mains Power

Mains power in

Fan

relay

TMS fans

TMS = thermal

management system

Controller

GTM

Power supply one

12V

Compressor

Module

power

relay

TMS

module

gas

module

gas

module

Heater

power

relay

TMS heater

12 V Power

Signal

Power supply two

12V

Mains Power

Mains power in

Fan

relay

TMS fans

TMS = thermal

management system

Controller

GTM

Power supply one

12V

Compressor

Module

power

relay

TMS

module

gas

module

gas

module

Heater

power

relay

TMS heater

12 V Power

Signal

Power supply two

12V

Mains Power

Mains power in

Fan

relay

TMS fans

TMS = thermal

management system

Controller

GTM

Power supply one

12V

Compressor

Module

power

relay

TMS

module

gas

module

gas

module

Heater

power

relay

TMS heater

12 V Power

Signal

Power supply two

12V

Mains Power

Mains power in

Fan

relay

TMS fans

TMS = thermal

management system

Controller

GTM

Power supply one

12V

Compressor

Module

power

relay

TMS

module

gas

module

gas

module

Heater

power

relay

TMS heater

12 V Power

Signal

Power supply two

12V

Mains Power

Mains power in

Fan

relay

TMS fans

TMS = thermal

management system

Page | 15

Aeroqual AQM60 User Guide

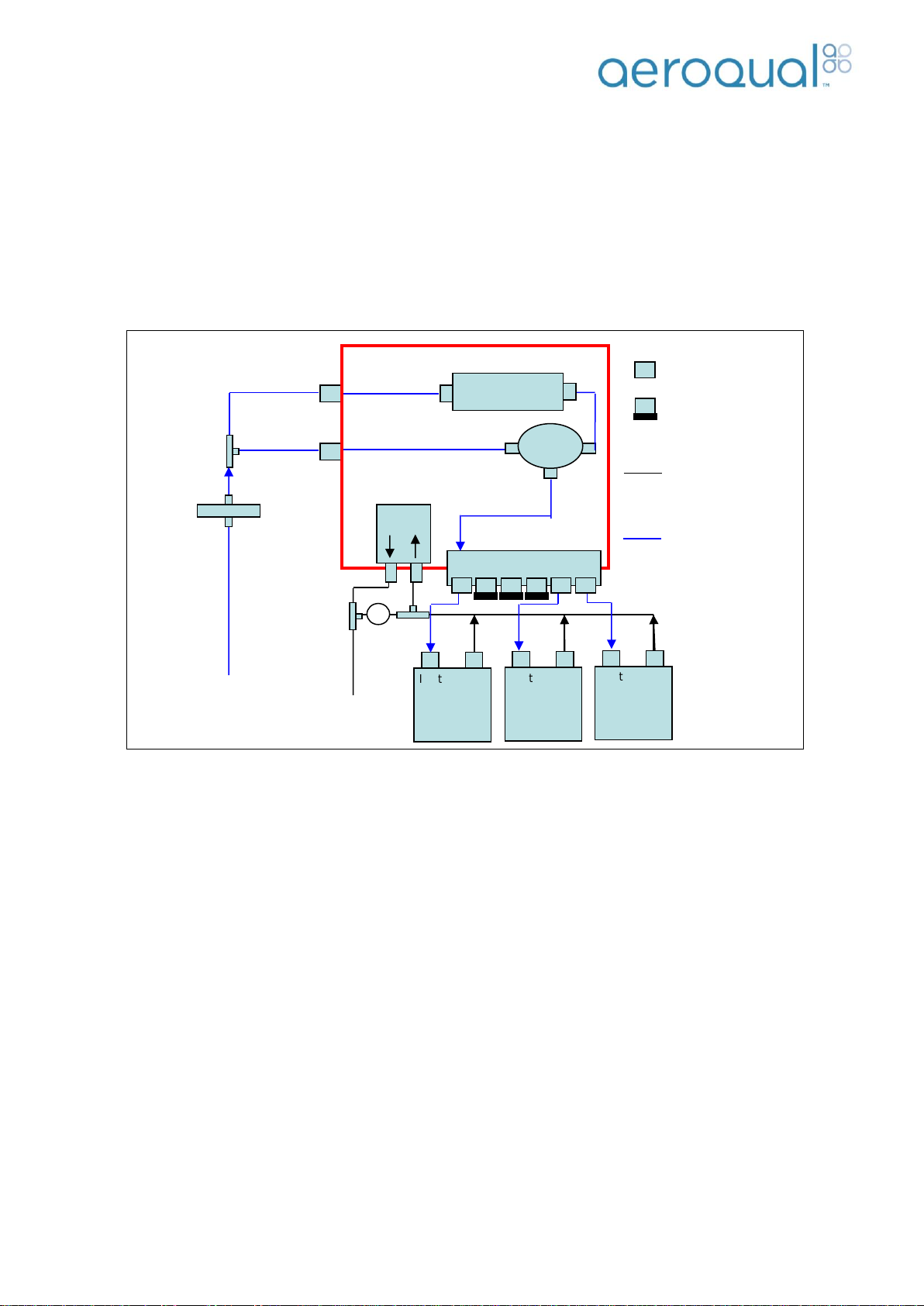

1.12. Pneumatic Connections

The airlines and connections are shown in the figure below for a three gas AQM. The sample gas passes

into the Gas Treatment Module (GTM) and is distributed to the sensors via a PTFE manifold. The gas

modules sample from the PTFE manifold via a central pump located in the gas treatment module. The

solenoid can switch between the ambient air sample and air which has passed through an absorbent

scrubber for baseline measurements. The sample inlet tubing is PTFE tubing which is inert and smooth

walled. The module exhaust tubing is Tygon 3603 PVC tubing.

Note: The ports on the manifold which are not used must be capped off to prevent leaks.

An adjustable bypass valve is included between the vacuum and pressure side of the pump. This is to allow

an adjustment to be made to the module flow rates and to relieve the excess pressure placed on the pump

when only one or two modules are installed.

The total sample flow rate will be dependent on the number of gas sensor modules in the AQM. All module

flows are controlled by critical orifices located within the sensor modules. See Section 7.3.3.for expected flow

rates.

AQM inlet

¼’ Swagelok

compression fitting

Solenoid

Pump

Zero

Scrubber

Inlet

Exhaust

Gas

Module

Inlet

Exhaust

Gas

Module

Inlet

Exhaust

Gas

Module

AQM exhaust

= Luer fitting

= Capped luer

fitting

= Tygon tubing

= PTFE tubing

Filter 5 µm

PTFE

Flow

Bypass

Valve

Gas treatment module (GTM)

Page | 16

Aeroqual AQM60 User Guide

2. Installation and Commissioning

The purpose of this section is to enable the user to correctly assemble, commission, and install their AQM.

Undertaking the commissioning procedure correctly is an important part of the product

transfer process and customer acceptance. It confirms that you have received the product in

good working order and it has been shipped to you without damage.

The full commissioning process will require gas calibration and flow equipment (not supplied with the AQM).

In the absence of gas calibration and flow measurement capabilities, measurement of outside air over a 24

hour period and comparison of this data with measurements from a local “reference” air monitoring station

will provide evidence of correct span operation.

2.1. Unpacking

a) Examine the Shockwatch label on the side of the shipping box. If the indicator is red do not refuse

shipment. Make a notification on delivery receipt and inspect for damage. If damage is discovered,

leave item in original packaging and request immediate inspection from carrier within 15 days of

delivery date (3 days international).

b) Verify the serial number label on the documentation matches the serial label on the AQM (located on

inside of enclosure).

c) Verify that all components have been shipped as per the packing slip. Contact your Distributor or

Aeroqual if you suspect any parts are missing.

d) Unpack the AQM.

e) Remove all internal shipping/packaging material from the AQM enclosure.

f) Retain the packaging.

Note: Always transport the AQM in the cardboard box and two piece aluminum skins with foam

packing provided to avoid breakages. Wrap all peripheral assemblies in their original packaging also.

The AQM is a sensitive instrument and should be transported with care.

2.2. Assembly

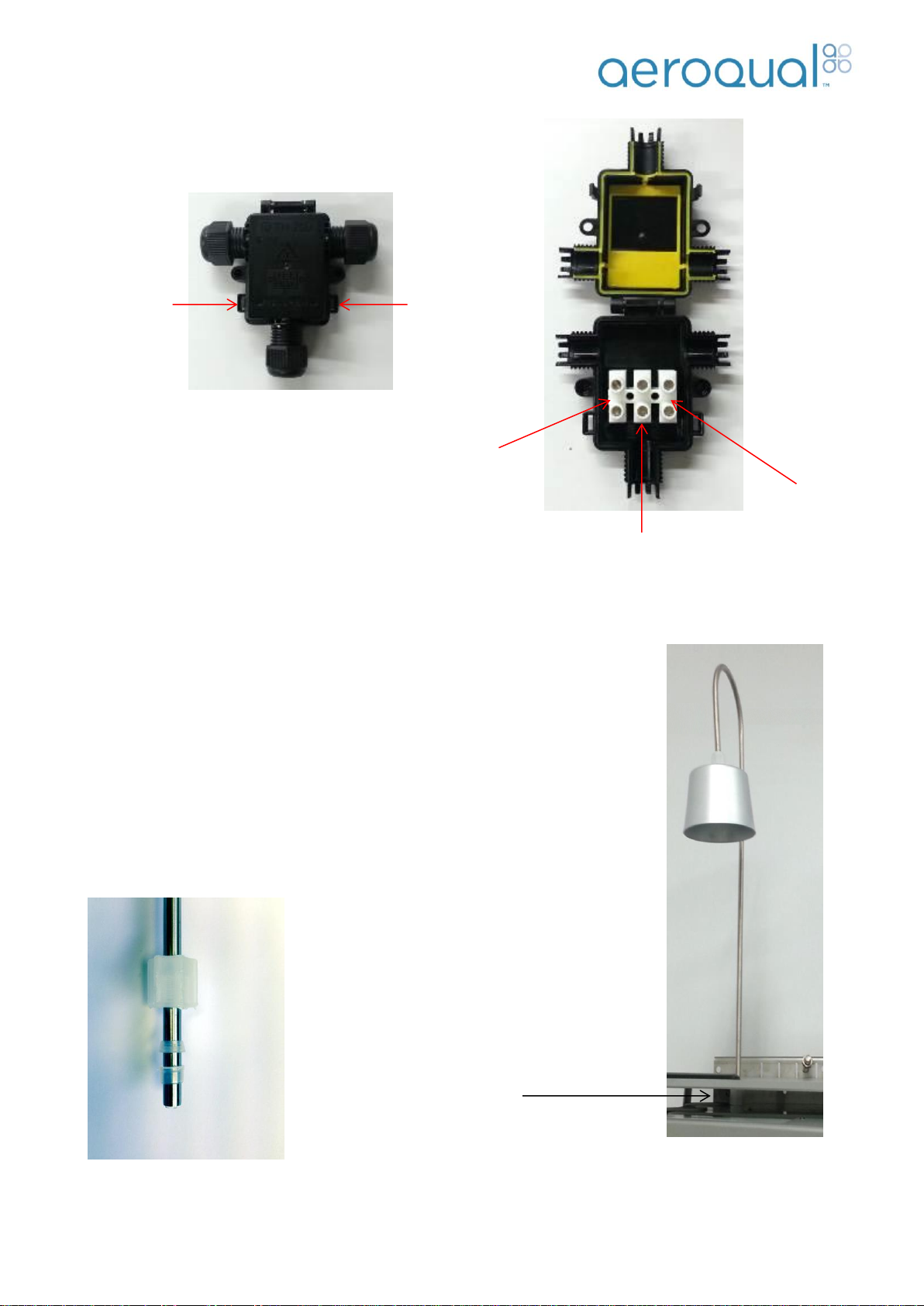

2.2.1. Connect Mains Power

Caution: The high voltage mains supply must be wired by a certified electrician in

compliance with local electrical regulations.

Locate the 3 port junction box on the outside of the AQM cabinet:

Unscrew from the enclosure

Remove the three gland nuts

Insert a small flat bladed screwdriver to lever the retaining clips, on each side where indicated

Wire a mains electrical cable to the terminal block provided (Live, Ground and Neutral).

Close the lid to the 3 port junction box and replace the three gland nuts.

Page | 17

Aeroqual AQM60 User Guide

2.2.2. Connect Inlet Sub Assembly

Once the AQM60 has been connected the inlet sub assembly needs to be

installed to prevent unwanted materials, such as water and dust, being drawn into

the instrument. The sub assembly pipe is connected to the inlet at the top of the

AQM60 using a Kynar gland. The pipe needs to be securely inserted into the

Kynar gland and then the fitting needs to be tightened.

Ensure the two piece ferrule set is present inside the Kynar gland before screwing

it on, and be sure the orientation of the two pieces is correct as shown in the

image below. Failure to do this could result in a leak or could lead to water

entering the sample tubing which will permanently damage the sensor modules.

Kynar Gland

Neutral

(Blue)

Ground

(Green/Yellow)

Live

(Brown)

Retaining

clip

Retaining

clip

Page | 18

Aeroqual AQM60 User Guide

Power cable from

heated inlet

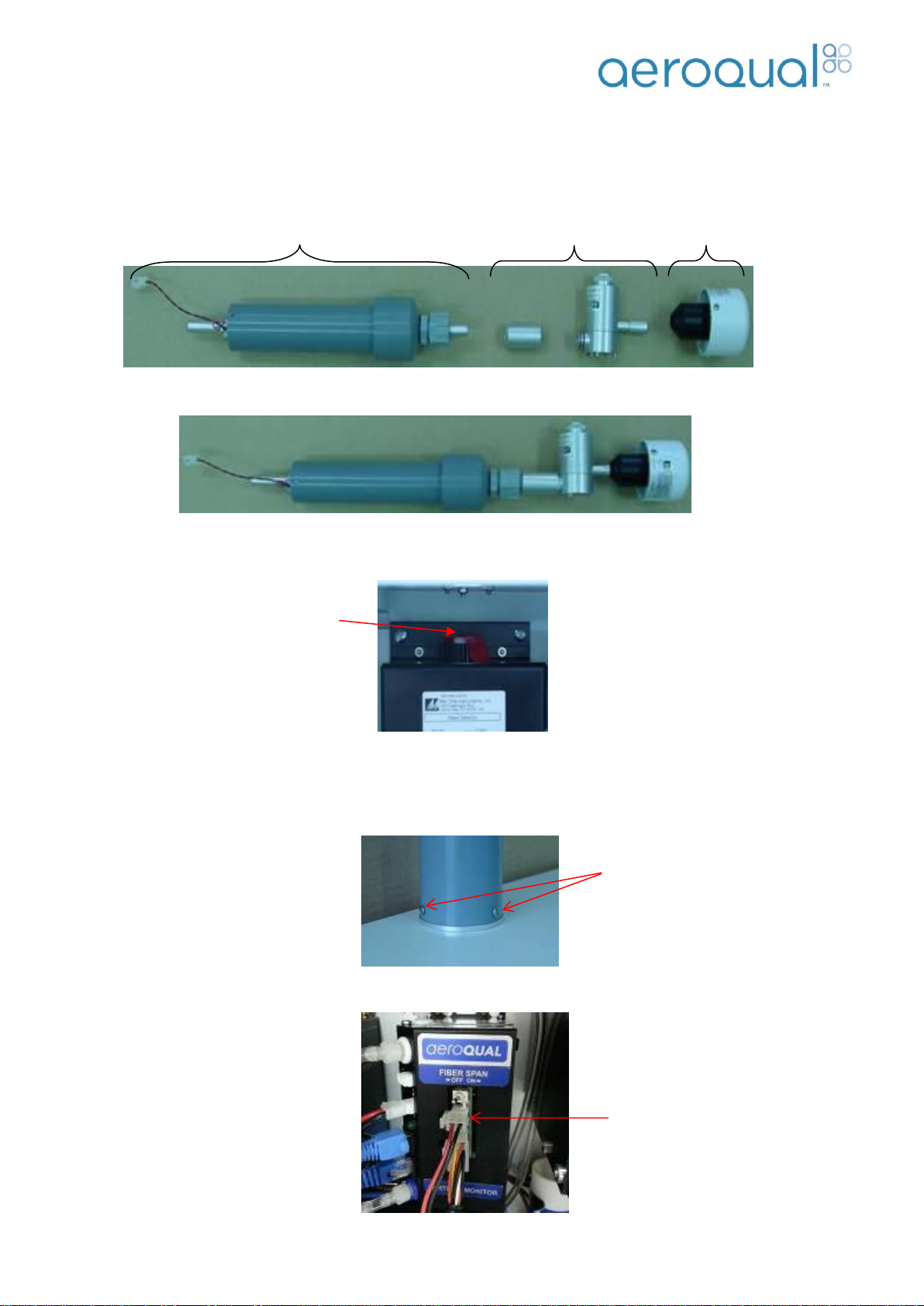

2.2.3. Assembly of heated inlet for PM/Profiler (Optional)

Parts List:

A. Inlet Tube/Heater including power cable

B. Sharp Cut Cyclone (if fitted)

C. TSP Inlet

i. Connect parts A, B and C

ii. Open door of enclosure and remove protective cap from the optical engine

iii. Insert Inlet Tube Assembly through base mount and fix the three mounting screws

Note 1: The top plate solar shield may need to be removed to screw in the mounting screws

Note 2: Ensure the power cable is fed through the inlet hole when connecting

iv. Connect power to Inlet Tube/Heater inside the enclosure

A

B

C

Mounting

Screws

Protective

Cap

Page | 19

Aeroqual AQM60 User Guide

2.2.4. Connect third party sensors (Optional)

Third party sensors such as the Vaisala Weather Transmitter WXT520 or Gill Windsonic are connected to

the unit using the external plug. This is located on the right hand side of the enclosure. Once connected, they

should automatically start reading.

Note: Turn off the AQM60 before plugging in any external third part sensor.

2.3. Initial Commissioning

The objective of the initial commissioning process is to enable the user to gain knowledge in the operation of

the instrument and to demonstrate that it is operating correctly prior to a remote installation. The process

consists of a set of tasks that check that the AQM is operating correctly.

Equipment required:

AQM Logbook

Computer with Aeroqual AQM V6.X PC software loaded

Flow meter covering the range 0-2.5 LPM

Zero air source

Span gases corresponding to the sensors in the AQM

Calibrator or gas flow meters for generating suitable span gas concentrations

Humidifier (Nafion tubing supplied with AQM)

Note 1: Before starting the commissioning process it is important that the AQM is fully warmed up by

running overnight and sampling either outside ambient air or indoor air with an activated carbon

filter connected to the inlet.

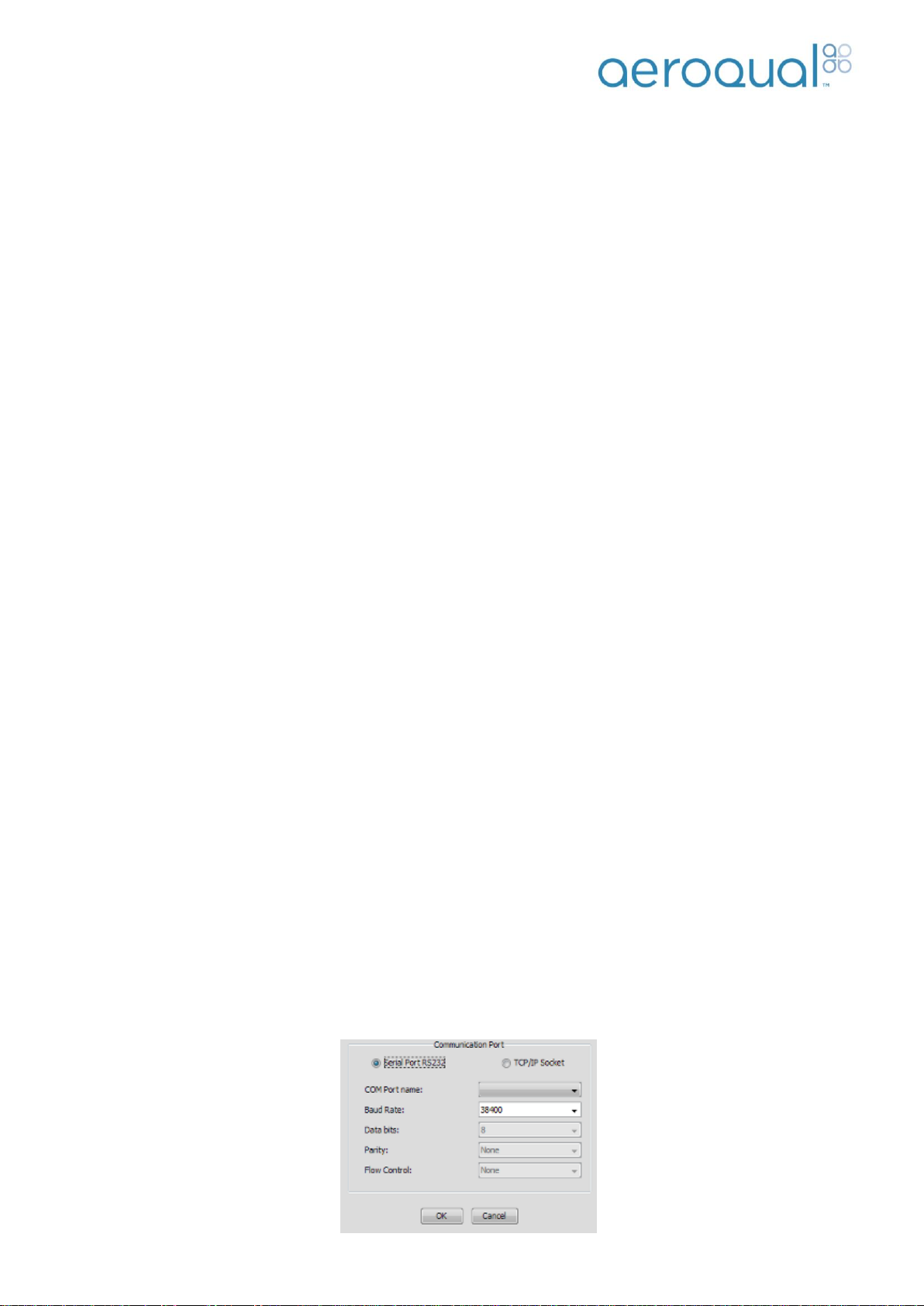

2.3.1. Set Up

1. Once the AQM60 is assembled and power is connected install the SD card into the control module.

Note 1: The TMS blower will start as soon as the mains power is connected.

2. Start the AQM60 by pushing the on/off switch on the control module (See Section 1.1 for location of

On/Off switch)

3. Connect the instrument using a computer via the USB cable to the outside of the enclosure

4. Install Aeroqual AQM software

5. Configure the AQM60 instrument:

a. Launch Aeroqual AQM PC software. Select Setup Communication Port

b. Select Serial Port RS232 and the relevant Com port. Press OK when complete.

Note: To determine the COM port number use windows ‘Device Manager’

The settings should be as seen below:

Page | 20

Aeroqual AQM60 User Guide

c. A table listing the modules configured will appear. Check the correct sensors in the AQM60

have been configured. These should match the sensors on the invoice and the sensors

listed in the instrument logbook. If they do not match click “Setup” ”Configuration” and

enter the password “Password”. Move across the relevant modules. Once completed press

“Save” then “Close” (See Section 3.2.2.).

d. Select Setup Operations.

e. Enter Data Report Rate (2 minutes is the minimum) and select “Auto Zero Function OFF”

Click save and close to complete. Note that increasing the report time can cause problems

especially during calibration. (see later the section on calibration) It is recommended to leave

the logging frequency at 2 minutes, and to perform averaging at lower frequencies in

software such as Microsoft Excel.

6. Set AQM60 Real Time Clock

f. Click on Tools Update Real Time Clock (this will synchronise the AQM60 clock with the

computer date/time)

7. Start data-logging to confirm sensor communication and operation is correct.

g. Click Data Table Real Time to launch real time data table.

h. Click File Start Data logging. Data will start being displayed in Real Time Table.

2.3.2. System Checks

Controller display correct

With the AQM on, open the door and observe the display on the controller. This should be scrolling

with sensor readings.

TMS setting

Close the door to the AQM and wait for the internal temperature to stabilise.

Check (and record) that the internal temperature is stable and that it has reached the set point

defined in the logbook e.g. Set point = 30°C

SD card logging correct

Verify the AQM is data logging correctly to the SD card by clicking “File” “Download Files” in the

PC software.

A daily log file (DLYYMMDD.AQL) containing the AQM sensor data is created each day.

System events such as power on, configuration updates, calibration events and system faults are

logged to an EVENTLOG.AQL file.

Table of contents

Other Aeroqual Accessories manuals