Aeroqual IQM 60 User manual

IQM Version 5.0 (Pump) revision October 2010

Aeroqual Limited

109 Valley Road, Mount Eden, Auckland 1024, New Zealand

phone +64 9 623 3013

fax +64 9 623 3012

web www.aeroqual.com

IQM 60

Indoor Air Quality Monitor

User Guide

Version 5.0

IQM 60 V5 Pump Revision October 2010

2

Table of Contents

Table of Contents ........................................................................................................................... 2

Foreword ........................................................................................................................................ 3

Statements of Compliance ............................................................................................................. 3

Warranty......................................................................................................................................... 4

For Your Safety .............................................................................................................................. 5

Technical Support .......................................................................................................................... 5

1.0 Monitor and System Components............................................................................................ 6

1.1 IQM 60 ................................................................................................................................. 6

1.2 System Components include: .............................................................................................. 6

2.0 Description .................................................................................................................... 6

2.1 Inlets.............................................................................................................................. 7

3.0 Operating Instructions .............................................................................................................. 8

3.1 Getting Started..................................................................................................................... 8

3.2 Connecting a computer........................................................................................................ 8

3.3 Reading the Datacard .......................................................................................................... 8

3.4 Testing ................................................................................................................................. 8

3.5 Maintenance ........................................................................................................................ 8

3.6 Care and Cleaning ............................................................................................................... 8

4.0 Troubleshooting........................................................................................................................ 9

4.1 Troubleshooting Guide.................................................................................................. 9

4.2 Diagnostics ................................................................................................................. 10

5.0 Calibration .............................................................................................................................. 11

5.1 Gas Module Calibration .............................................................................................. 11

5.1.1 Nafion Humidifier .................................................................................................... 11

5.1.2 Zero verification using Gas Treatment Module ...................................................... 12

5.1.3 Zero calibration ....................................................................................................... 12

5.1.3.1 Using Gas Treatment Module ............................................................................ 12

5.1.3.2 Laboratory Zero calibration ................................................................................. 12

5.1.4 Span calibration...................................................................................................... 12

5.1.4.1 Span gas ............................................................................................................. 12

5.1.4.2 Span calibration procedure ................................................................................... 13

5.2 Particle Counter Calibration ........................................................................................ 14

Flow rate .............................................................................................................................. 14

Zero Check .......................................................................................................................... 14

Span Calibration .................................................................................................................. 14

Appendix A AQM V5.x Software Instructions.................................................................... 15

Description ............................................................................................................................... 15

Setting up ................................................................................................................................. 15

Passwords ............................................................................................................................... 15

Menu Descriptions ................................................................................................................... 15

File ........................................................................................................................................... 15

Setup........................................................................................................................................ 17

Data.......................................................................................................................................... 19

Tools ........................................................................................................................................ 22

Diagnostics .............................................................................................................................. 26

Window .................................................................................................................................... 28

Help.......................................................................................................................................... 29

Additional Buttons .................................................................................................................... 29

Updating Sensor List................................................................................................................ 29

Appendix B Communication Protocol................................................................................ 30

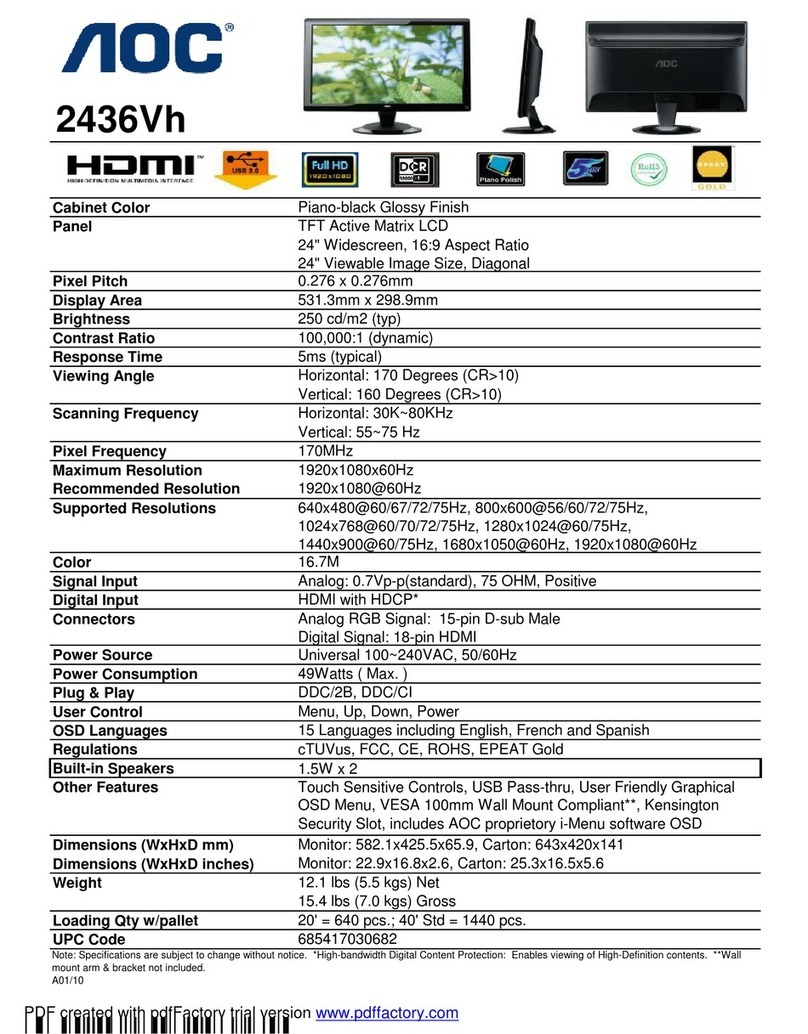

Enclosure ..................................................................................................................................... 42

External View ........................................................................................................................... 42

Description........................................................................................................................... 42

Dimensions .......................................................................................................................... 42

Front View ................................................................................................................................ 43

Rear View................................................................................................................................. 43

IQM 60 V5 Pump Revision October 2010

3

Foreword

Copyright Aeroqual Limited. All rights reserved. Reproduction, transfer, distribution or storage of part or all of the

contents of this document in any form without the prior written permission of Aeroqual Limited is prohibited.

“Aeroqual” and “Aeroqual Limited – Making the Invisible Visible” are registered trademarks of Aeroqual Limited. Other

product and company names mentioned herein may also be trademarks or trade names.

Aeroqual operates a policy of continuous development. Aeroqual reserves the right to make changes and improvements

to any of the products described in this document without prior notice.

Under no circumstances shall Aeroqual be responsible for any loss of data or income or any special, incidental,

consequential or indirect damages howsoever caused.

The contents of this document are provided "as is". Except as required by applicable law, no warranties of any kind,

either express or implied, including, but not limited to, the implied warranties of merchantability and fitness for a particular

purpose, are made in relation to the accuracy, reliability or contents of this document.

Aeroqual reserves the right to revise this document or withdraw it at any time without prior notice. The availability of

particular products may vary by region. Please check with the Aeroqual dealer nearest to you.

©Aeroqual Limited 2008. All rights reserved.

Statements of Compliance

1. The Aeroqual IQM Monitor complies with EN 61000-6-1:2001

2. The Aeroqual IQM Monitor complies with EN 61000-6-3:2001

3. The Aeroqual IQM Monitor complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) these devices may not cause harmful interference, and (2) these devices must accept any

interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

—Consult the dealer or an experienced radio/TV technician for help.

IQM 60 V5 Pump Revision October 2010

4

Warranty

Thank you for purchasing this Aeroqual product. To get maximum use of the features of your new product we

recommend that you follow a few simple steps:

•Read the guidelines for safe and efficient use.

•Read all the terms and conditions of your Aeroqual Warranty.

oSave your original receipt. You will need it for warranty repair claims. Should your Aeroqual product

need warranty service, you should return it to the dealer from whom it was purchased or contact

Aeroqual.

Our Warranty

Aeroqual warrants this product to be free from defects in materials and workmanship for a period of 1 (one) year from the

date of shipment from the factory. Consumable items such as bearings, filters and gas scrubber media are excluded

from this warranty.

This warranty is expressly limited to the original owner who purchases the equipment directly from Aeroqual or from an

authorized Aeroqual dealer.

What we will do

If, during the warranty period, this product fails to operate under normal use and service, due to improper materials or

workmanship, Aeroqual subsidiaries, authorized distributors or authorized service partners will, at their option, either

repair or replace the product in accordance with the terms and conditions stipulated herein.

Conditions

1. The warranty is valid only if the original receipt issued to the original purchaser by the dealer, specifying the date of purchase, is

presented with the product to be repaired or replaced. Aeroqual reserves the right to refuse warranty service if this information has

been removed or changed after the original purchase of the product from the dealer.

2. If Aeroqual repairs or replaces the product, the repaired or replaced product shall be warranted for the remaining time of the

original warranty period or for ninety (90) days from the date of repair, whichever is longer. Repair or replacement may be via

functionally equivalent reconditioned units. Replaced faulty parts or components will become the property of Aeroqual.

3. This warranty does not cover any failure of the product due to normal wear and tear, damage, misuse, including but not limited to

use in any other than the normal and customary manner, in accordance with Aeroqual’s user guide for use, faulty installation,

calibration and maintenance of the product, accident, modification or adjustment, events beyond human control, improper

ventilation and damage resulting from liquid or corrosion.

4. This warranty does not cover product failures due to repairs, modifications or improper service performed by a non-Aeroqual

authorized service workshop or opening of the product by non-Aeroqual authorized persons.

5. The warranty does not cover product failures which have been caused by use of non-Aeroqual original accessories.

6. This warranty becomes void if a non-Aeroqual approved power supply is used.

7. Tampering with any part of the product will void the warranty.

8. Damage to the sensors can occur through exposure to certain sensor poisons such as silicones, tetraethyl lead, paints and

adhesives. Use of Aeroqual sensors in these environments containing these materials may (at the discretion of Aeroqual) void the

warranty on the sensor head. Exposure to gas concentrations outside of the design range of a specific Aeroqual sensor head can

adversely affect the calibration of that sensor head and will also void this warranty as it applies to the replacement of sensor

heads.

9. Aeroqual makes no other express warranties, whether written or oral, other than contained within this printed limited warranty. To

the fullest extent allowable by law all warranties implied by law, including without limitation the implied warranties of merchantability

and fitness for a particular purpose, are expressly excluded, and in no event shall Aeroqual be liable for incidental or consequential

damages of any nature whatsoever, however they arise, from the purchase or use of the product, and including but not limited to

lost profits or business loss.

10. Some countries restrict or do not allow the exclusion or limitation of incidental or consequential damage, or limitation of the

duration of implied warranties, so the preceding limitations or exclusions may not apply to you. This warranty gives you specific

legal rights, and you may also have other rights, which may vary from country to country.

IQM 60 V5 Pump Revision October 2010

5

For Your Safety

Read these simple guidelines. Ignoring these guidelines may be hazardous.

USE SENSIBLY

Use only as per this user guide.

USE AEROQUAL APPROVED SERVICE

Only approved service personnel must work on this product.

ACCESSORIES

Use only approved accessories. Do not connect incompatible products.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read the appropriate user guide for detailed safety

instructions. Do not connect incompatible products.

HAZARDOUS ENVIRONMENTS

Do not use the monitor in or near volatile fuel or chemicals.

HEALTH AND SAFETY IN THE WORKPLACE

Aeroqual Monitors and Sensor Heads are used to monitor ambient gas concentrations. Aeroqual

does not guarantee user safety. In hazardous environments, an appropriate Health and Safety

plan should be in place.

WARNING Do not switch the monitor on before reading the User Guide.

IQM 60 V5 Pump Revision October 2010

6

1.0 Monitor and System Components

1.1 IQM 60

The Aeroqual IQM 60 Environmental Monitor is a custom-built indoor air quality instrument which can be

configured with up to six gas sensor modules as well as options such as a particle counter. The

configuration of the instrument supplied is determined by the sensor modules and options that were

ordered.

The IQM60 uses an internal pump to sample the air via the gas sensor inlet and the particle counter inlet if

fitted.

This manual describes the general use and operation of the IQM Environmental Monitor. The Product

Information Sheet supplied at the front of the folder will specify the “as-built” monitor and the packing list of

shipped items. Please check that all the components have been supplied as per your order and contact

your dealer or Aeroqual on email at: sales@aeroqual.com if any of the components are missing.

1.2 System Components include:

•IQM 60 Monitor

•12VDC Regulated Power Supply

•Temperature and humidity sensor extension cable

•Computer CD containing software for data logging and calibrating IQM

•Data Card (1GB)

•Data card reader

•Serial Cable

•Nafion humidifier

2.0 Description

NOTE 1. Insert the data card by pressing in gently until the card latches in place. To remove the data

card gently press inwards and then let go to release the latch. Always turn off the IQM 60

before removing or inserting the data card.

Gas sample inlet

SD data card

Power on/off

RS 232 serial port

Temperature and RH

sensor

Display

Particle counter inlet

IQM 60 V5 Pump Revision October 2010

7

2.1 Inlets

The IQM is supplied with an isokinetic probe for the particle counter inlet and a teflon filter for the gas

sensor inlet. These should be fitted before starting the IQM. There is also a zero filter supplied for zero

checking the particle counter.

isokinetic probe

for particle counter

zero particle filter

for zero checking

the particle

counter

inlet filter for gas

sensors

IQM 60 V5 Pump Revision October 2010

8

3.0 Operating Instructions

3.1 Getting Started

The IQM 60 is simple to operate:

•Ensure that the 12VDC power supply to the IQM 60 is connected (rear panel).

•Ensure the datacard is correctly inserted in the slot.

•Turn on the power switch (front panel).

•Remove the inlet cap and fit the supplied filter to the inlet

Note: The IQM 60 should be allowed to run for 60 minutes so that it is fully warmed up before taking

readings.

3.2 Connecting a computer

The connection of a computer to the IQM 60, the installation of the software and its use are described in

Appendix A.

3.3 Reading the Datacard

Data is stored on the data card as a daily file. The format of the data is a tab delimited file which can be

opened with standard graphical software such as MS Excel. Always turn off the IQM 60 before removing or

inserting the data card. To remove the data card gently press inwards and then let go to release the latch.

3.4 Testing

Zero and span checks should be performed with humidified air (detailed description provided in section 5).

Aeroqual supplies a Nafion gas humidifier. If the IQM is to be deployed in environments with low or high

absolute humidity it is recommended that the sensors be zero and span calibrated under those conditions,

since the sensors are slightly sensitive to changes in absolute humidity.

3.5 Maintenance

The IQM is designed to operate without maintenance for extended periods. The following table outlines a

periodic maintenance schedule for the IQM. This schedule is based on experience under normal operating

conditions and may need to be modified to suit specific operating conditions.

Interval

Item

Procedure

Weekly

Gas Sensor zero check

Particle Counter zero check

Perform using inbuilt Zero scrubber

Perform

1Month Inlet particulate filter

Particle Counter flow test

Check/replace

Perform

6Months Gas Sensor Span calibration

Perform

1Year Particle Counter Factory Service

Contact Aeroqual for instructions

3.6 Care and Cleaning

Keep the IQM dry. Avoid water and/or condensation as humidity and liquids containing minerals may

corrode electronic circuits.

Do not use or store in dusty, dirty areas.

Do not store or turn off the monitor in temperatures below 5°C.

This unit is designed for use at temperatures between 5°C and +45°C. If you wish to use the monitor

outside this range you will need an additional environmental enclosure. Sudden changes in

temperature will cause condensation that may damage the electronic components.

Do not drop, knock or shake as this could lead to internal damage.

IQM 60 V5 Pump Revision October 2010

9

4.0 Troubleshooting

4.1 Troubleshooting Guide

Symptom Possible Cause Fault isolation/Solution

Gas sensor readings incorrect Insufficient warm up

Incorrect zero calibration

Incorrect span calibration

Sensor module leaking

Sensor pump failed

Allow the sensors to fully warm up after power

down. This may require 60 minutes or more.

Repeat zero calibration with clean air. Check

media in Gas Treatment module.

Perform span check.

Check for leaks

Measure flow. If pump has failed replace.

NO2sensor reading very high

Incorrect zero calibration

O3Scrubber failed

Repeat zero calibration with clean air. Check

media in Gas Treatment module.

Challenge the NO2sensor with 0.1 ppm of O3.If

the response is large (>0.5 ppm) then the

scrubber has failed. Replace.

Gas Sensor readings noisy or

unstable

Leaks

Particulate filter

Leaks dilute the sample stream and can cause

low span readings and incorrect zero readings.

Perform a leak test.

Replace if dirty.

“NR” or “9999” in Data table

(No response)

Occasional NR or “9999” in Data

Table

No Response from Sensor module.

Not connected correctly.

Computer too slow

RF noise in environment.

Check the electrical connector on the sensor

module is firmly connected

Test with a faster computer.

Try to reduce RF noise

COMMUNICATION

No communication over RS232

RS232 cable disconnected

Control Module Failed

Reconnect cable

Replace Control Module

PC Data logging stopped IQM power blackout interrupted

data logging.

USB to serial hub not working

Close and restart IQM software.

Check USB connectors. Check the Moxa serial

hub is present on the device hardware menu in

the PC. If not reload driver software and re-

install.

No data on SD card

Card not correctly installed in slot.

Data logging interval set too large.

Data card module fault

Turn off IQM and install card in slot correctly.

Set logging interval in configuration to a lower

interval.

Send control module to factory for replacement

module.

RF communication fails RF modem incorrectly configured Follow modem manual instructions to

reconfigure RF modem

IQM 60 V5 Pump Revision October 2010

10

4.2 Diagnostics

The IQM has a number of sources for diagnostic information if a problem arises. These are described

below:

Event log A large number of instrument events are logged on the event log file which is

located on the SD data card. This can be downloaded remotely (if a modem is

fitted) and in many cases can be used to determine whether a site visit is required.

Event Code Examples

Meanin

g

O3 :P.F. 2008/11/12 23:45

Pump failure

O3 module pump failure on 12 Nov

2008 at 23:45

NO2 :S.F. 2008/11/12 23:45

Sensor failure

NO2 module sensor failure on 12 Nov

2008 at 23:45

Power on: 2008/11/12 10:12

AQM Power turned on at 10:12 am on

12 November 2008

Zero Cal at 2008/11/12 11:24

Zero Calibration started at 11:24 on

12 November 2008

Config at 2008/11/12 13:12

0x01,05,30,40,50,B0,F8,00,00,00,00,00,00,00,00,00,

00

AQM configuration saved at 1:12 pm

on 12 November 2008

Sensor codes listed

O3 : NR 2008/11/12 12:42

O3 module no data report at 12:42 pm

on 12 November 2008

NO2 Scrubber FAILED: 2008/11/12 15:36

NO2 scrubber failed at 3:36 pm on 12

November 2008

Messages

This is located on the AQM PC software tool bar. If the AQM is connected to the computer then event

messages will be written to the Messages window in real-time.

Diagnostics

This is located in the AQM PC software. If the AQM is connected to the computer then individual sensor

modules can be interrogated to determine if there is a problem not picked up by normal fault detection as

well as fine tune the sensor performance. Only qualified personnel should use this menu as incorrect use

may result in sensor malfunction. Please consult Aeroqual Technical Support to understand how to use this

feature.

IQM 60 V5 Pump Revision October 2010

11

5.0 Calibration

5.1 Gas Module Calibration

All the Gas modules in the IQM can be calibrated in the unit by applying certified gas to the IQM inlet. All

Zero and span calibrations or checks should be performed with humidified air and use single gas mixtures

in a balance of air. If the IQM is to be deployed in environments with very low or high absolute humidity it is

recommended that the sensors be zero and span calibrated under those conditions, since the sensors are

slightly sensitive to changes in absolute humidity.

Zero and span adjustments on the IQM60 V5 are performed by adjusting the OFFSET and GAIN values

under the Calibration menu. The equation that relates the OFFSET and GAIN to the Gas reading is given

below:

Gas Reading = GAIN x (Module Reading - OFFSET)

All the Gas modules in the IQM can be calibrated in the unit by applying certified gas to the IQM inlet.

All zero and span calibrations or checks should be performed with gas mixtures in a balance of

air. Note: the calibration standard may be in a balance of N2 but it should be diluted with air

prior to presenting to the IQM.

Fluorocarbon (PTFE, FEP or PFA) tubing and fittings should be used for all sample lines.

Warm up the IQM for at least 12 hours before attempting a gas sensor calibration

5.1.1 Nafion Humidifier

ANafion tubing membrane humidifier is supplied with the IQM which can be used to humidify the air

delivered to the IQM during calibrations. Two lengths of 1/4” Teflon tubes are supplied to enable

connection to sample lines and the IQM inlet.

Span gas and zero air is typically dry (~0%RH) and the sensors used in the IQM require 50 +/-20% RH for

best performance. The Nafion membrane is selectively permeable to water vapor (although some other

compounds such as ammonia, alcohols, acetone, and acetic acid may also be transported across the

membrane see www.permapure.com for further information) and the direction of transport is driven by the

concentration gradient across the tubing wall. The humidifier is designed to extract water vapor from the

surrounding ambient air and transfer this into the dry span or zero gas source. The resultant humidity in the

sample gas is roughly half of that of the ambient air. If the surrounding air humidity is less than 50% it is

recommended that the membrane is positioned above a water bath to increase the humidity in the sample

air. Also, Make sure that the air surrounding the membrane is not contaminated with hydrocarbons that

could be transported across the nafion to the sensors. If in doubt contact Aeroqual.

Nafion humidifier

IQM 60 V5 Pump Revision October 2010

12

5.1.2 Zero verification using Gas Treatment Module

The Gas Treatment Module contains a zero air scrubber which can be automatically or manually turned on

to periodically measure the zero of the instrument. The automatic zero verification is set in the

Configuration file under Zero Readings. This turns on the gas treatment module for 30 minutes during

which time the sensors continue to measure. This procedure is repeated at a user defined interval between

1and 255 hours. It is recommended that this procedure is used when making field measurements.

5.1.3 Zero calibration

5.1.3.1 Using Gas Treatment Module

You may use the zero air scrubber in the Gas Treatment Module to undertake a manual zero calibration.

Before doing this you should check that the media are in good condition or if possible replace with fresh

media.

1. Turn on the zero scrubber manually by clicking on PC software, Tools- >Turn On Zero Scrubber.

2. Allow the AQM to sample until stable readings are obtained (about 30 - 60 minutes).

3. Adjust the OFFSET values for each gas sensor via the Calibration --> Calibrate OFFSET-->enter

password “password”--> select gas--->enter new OFFSET

new OFFSET = old OFFSET + AQM60 gas reading

5.1.3.2 Laboratory Zero calibration

The IQM can be re-zeroed via the PC software using a zero air source with relative humidity of 50% +/-

20%. Aeroqual can supply a humidifier that uses a Nafion membrane to humidify the air.

1. Connect a source of zero air to the IQM through the sample port using ¼ inch Teflon tubing. Use a

Tfitting to ensure the IQM is sampling the gas flow at atmospheric pressure. The zero air should

be at least 1.5 LPM (check there is excess flow at the exhaust of the T fitting).

2. Allow the IQM to sample until stable readings are obtained (about 30-60 minutes).

3. Adjust the OFFSET values for each gas sensor via the Calibration --> Calibrate OFFSET-->enter

password “password”--> select gas--->enter new OFFSET

new OFFSET = old OFFSET + AQM60 gas reading

5.1.4 Span calibration

The sensors can be manually span calibrated by modifying the individual gain factors for each sensor.

Introduce a known concentration of span gas into the instrument and adjust the gain factor to set the

correct concentration reading. Note: a sensor zero point calibration should always be performed before

undertaking a span calibration.

5.1.4.1 Span gas

Span gas mixtures should be single gas mixtures that are certified and be in a balance of air.

DO NOT USE MIXTURES THAT CONTAIN MORE THAN ONE SPAN GAS COMPONENT

DO NOT USE A SPAN GAS IN A BALANCE OF NITROGEN UNLESS DILUTION IS GREATER

THAN 50 TIMES WITH ZERO AIR.

The mixture should also be humidified to about 50 +/-20% RH by either using a Nafion membrane

humidifier or by bubbling the zero grade air through water prior to mixing with the gas standard. Aeroqual

can supply a Nafion humidifier which is suitable for IQM units containing O3, NO2, CO, SO2 and VOC

sensor modules. Excessive gas concentrations should be avoided as these may damage the sensors or

cause contamination of the internal tubing. Recommended span points for gas sensors are given in the

table below.

IQM 60 V5 Pump Revision October 2010

13

Gas

Span Point / ppm

O3 0.100

NO2 0.100

CO 25

VOC (isobutylene) 10

NMHC (isobutylene) 10

CO2 1000

PID (isobutylene) 10

Certified calibration standards that can be used with the IQM include certified gas bottles, diluent

calibrators, or ozone calibrators.

5.1.4.2 Span calibration procedure

1. Perform zero calibration.

2. Connect a source of span calibration gas to the IQM through the sample port. Use a T fitting to

ensure the IQM is sampling the gas flow at atmospheric pressure. The span gas flow should be at

least 1.5 LPM (check there is excess flow at the exhaust of the T fitting).

3. Allow the IQM to sample the gas until a stable reading is obtained (about 30 minutes).

4. Adjust the IQM60 sensor gain factor to set the correct concentration reading

Calibration -->Calibrate Gain-->enter password “password”--> select gas--->enter new gain factor

new Gain factor = old Gain factor x Span gas concentration / AQM60 gas reading

Please note: The change is logged in the EVENTLOG file on the SD card.

Example of Span Calibration Equipment

Calibrator

Calibration

Gas zero

air Tfitting

exhaust

RS232 serial

cable

nafion

humidifier

IQM 60 V5 Pump Revision October 2010

14

5.2 Particle Counter Calibration

Flow rate

The sampling flow rate should be checked monthly and adjusted if required. To test the flow rate:

1. Remove the isokinetic probe and connect a flow meter to the barb fitting of the particle inlet using a short

piece of flexible 1/8 “ ID tubing, Tygon tubing is a good choice.

2. Turn on the IQM and note the flow meter reading. The flow rate should be 1.0 +/- 0.05 LPM

3. The flow rate can be adjusted by a screw flow adjuster located underneath the bottom panel of the IQM

(see below). To remove the bottom panel, remove the two screws located at the bottom rear corners of the

casing and the bottom panel lifts off. Use a screw diver to adjust the screw in the T piece fitting. Turn the

screw clockwise to decrease the flow and counter-clockwise to increase the flow.

Zero Check

It is recommended to periodically perform a zero count test as described below. False counts caused by air

leaks or spurious noise will cause errors that are especially apparent when sampling relatively clean

aerosols.

1. Attach a filter with a rating of 0.45µm or better to the particle inlet nozzle. The filter must be large enough

that it does not create a restriction and load down the small vacuum pump inside the IQM. One zero

particulate filter is supplied with the IQM.

2. Since the air passing through the IQM is now virtually particle free the output particle count should be

zero. If it is not, check for leaks around the tubing to the particle counter.

Span Calibration

There are no user serviceable components inside the particle counter instrument. The cover on the particle

counter should not be removed or opened for servicing, calibration or any other purpose except by a factory

authorized person. To do so will void warranty and may result in exposure to invisible laser radiation that

can cause blindness. Contact Aeroqual for service information. Calibrating particle sensors like the one in

the IQM requires specialized equipment and a skilled technician. The particle counter should be factory

calibrated on a yearly basis.

Particle Counter flow

adjustment screw

IQM 60 V5 Pump Revision October 2010

15

Appendix A AQM V5.x Software Instructions

Description

The AQM V5.x Software is designed to be a simple interface for communicating with the IQM monitor via a

PC. It can be used to configure the IQM, initiate the zero calibration routine, modify gain factors, poll data

and display the data in either table or graphical format. The software runs in Java VM1.5 (supplied with

software) and the database is an open source HSQLDB Java database. Data can be easily exported to a

spreadsheet for manipulation. The software also incorporates a GSM modem connection which can be

used to connect to and operate an IQM unit remotely.

The software is compatible with IQM firmware versions 4.0 and higher only.

Computer Requirements

•CD-ROM Drive

•RS232 port

•Windows OS version 2000 or later

•100 Mb of spare hard drive space

•recommended 256 Mb RAM

•recommended 1 GHz processor speed

Setting up

1. Install IQM CD into drive and extract the “Aeroqual AQM V5.x for Vista” or launch the

AQM_4.x.exe software if you have earlier versions of Windows OS.

2. Launch software

Click Setup---> COM Port.

Select correct COM port settings Port, 38400, 8, 1, N, N

Click OK

Passwords

The factory set passwords for the IQM are:

System password: password

Diagnostic password: george

Menu Descriptions

File

Search monitor

Searches for available IQM monitors.

Start Data Logging Starts data logging from the IQM monitor.

Stop Data Logging Stops data logging from the IQM monitor.

Export Logged Data Exports logged data from the IQM monitor.

Import Files Imports file (aql file).

IQM 60 V5 Pump Revision October 2010

16

Download Files Downloads files from the IQM; including daily files and event log (see

below)

Update sensor list updates the sensor list on the database.

Zip database zips the database.

Unzip database Unzips the database (prompted by a warning message). (See below)

Exit Ctrl X Exits the AQM software.

IQM 60 V5 Pump Revision October 2010

17

Setup

Configuration Ctrl P Configures the IQM (System password required). (See below)

IQM 60 V5 Pump Revision October 2010

18

Operations Changes the operation of the IQM. (See below)

Test Connection Tests the connection to the IQM monitor. (See below)

IQM 60 V5 Pump Revision October 2010

19

COM Port Ctrl M Configures the COM port for communicating with the IQM Monitor. (See below)

Data

IQM 60 V5 Pump Revision October 2010

20

Graph --> Real Time Graphs real time data from the IQM Monitor. (See below)

Graph --> Logged Data Graphs Logged data from the IQM Monitor. (See below)

Table of contents

Other Aeroqual Monitor manuals