Aerotech MXH Series User manual

Revision: 1.08.00

MXH Multiplier Board

Hardware Manual

Global Technical Support

Go to www.aerotech.com/global-technical-support for information and support about your Aerotech products. The website

provides downloadable resources (such as up-to-date software, product manuals, and Help files), training schedules, and

PC-to-PC remote technical support. You can also complete Product Return (RMA) forms and get information about repairs

and spare or replacement parts. For immediate help, contact a service office or your sales representative. Have your

customer order number available before you call or include it in your email.

United States (World Headquarters)

Phone: +1-412-967-6440

Fax: +1-412-967-6870

Email: service@aerotech.com

101 Zeta Drive

Pittsburgh, PA 15238-2811

www.aerotech.com

United Kingdom Japan

Phone: +44 (0)1256 855055

Fax: +44 (0)1256 855649

Email: service@aerotech.co.uk

Phone: +81 (0)50 5830 6814

Fax: +81 (0)43 306 3773

Email: service@aerotechkk.co.jp

Germany China

Phone: +49 (0)911 967 9370

Fax: +49 (0)911 967 93720

Email: service@aerotechgmbh.de

Phone: +86 (21) 3319 7715

Email: service@aerotech.com

France Taiwan

Phone: +33 2 37 21 87 65

Email: service@aerotech.co.uk

Phone: +886 (0)2 8751 6690

Email: service@aerotech.tw

This manual contains proprietary information and may not be reproduced, disclosed, or used in whole or in part without the

express written permission of Aerotech, Inc. Product names mentioned herein are used for identification purposes only and

may be trademarks of their respective companies.

Copyright © 1999-2017, Aerotech, Inc., All rights reserved.

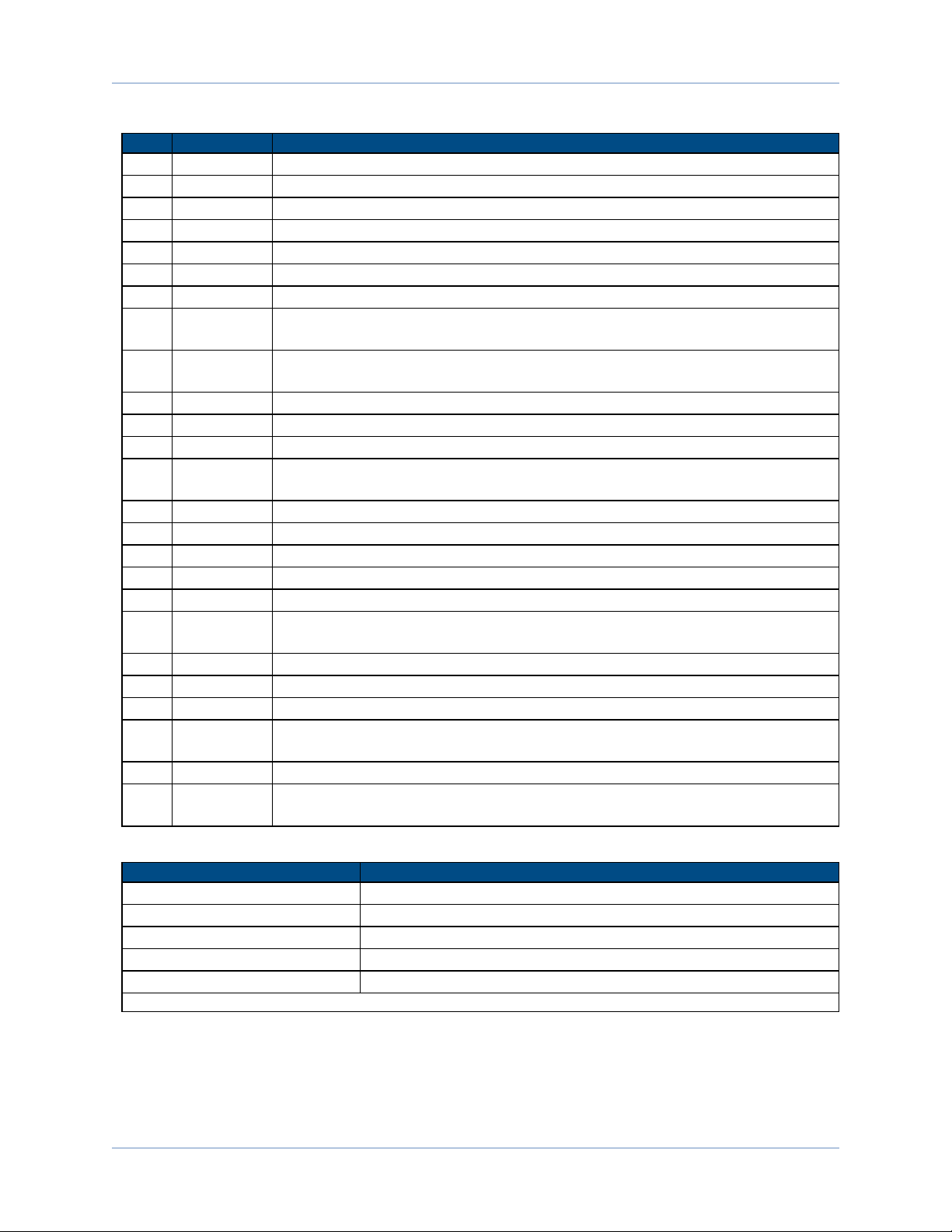

Table of Contents MXH Multiplier Option Manual

Table of Contents

MXH Multiplier BoardHardware Manual 1

Table of Contents 3

List of Figures 4

List of Tables 5

EU Declaration of Conformity 7

Chapter 1: MXHMultiplier Board 9

1.1. Introduction 9

1.2. Multiplier Signals 11

1.3. Multiplier Board Setup 11

1.3.1. Oscilloscope 11

1.3.2. Equipment and Tools Required 11

1.3.3. Adjustment Procedure 12

1.4. Hardware Configurations 15

1.4.1. Fault Circuitry (JP1) (Rev A Only) 15

1.4.2. Marker Pulse Jumper (JP4) 15

1.4.3. Reset Circuitry (JP5) 15

1.4.4. Pulse Width Jumpers (JP2 and JP3) 16

1.4.5. Test Points 16

1.4.6. Connectors (J1 and J2) 17

1.4.7. Potentiometers 20

1.4.8. Output Options 20

1.5. Output Pulse Clock Speed 21

1.6. MXHMultiplier Board Specifications 23

1.6.1. Electrical Specifications 23

1.7. Dimensions 28

Chapter 2: MXHMultiplier Board (Rev A/Obsolete) 29

Appendix A: Warranty and Field Service 31

Appendix B: Revision History 33

Index 35

www.aerotech.com 3

4 www.aerotech.com

List of Figures

Figure 1-1: MXH Multiplier Board 9

Figure 1-2: MXH Multiplier Board Configuration 10

Figure 1-3: Plot of Input and Output Signals 11

Figure 1-4: Ideal Oscilloscope Displays (Sweep and Lissajou) 12

Figure 1-5: Not-Optimum Oscilloscope Lissajou Displays 13

Figure 1-6: MXH Multiplier Board Hardware Locations 14

Figure 1-7: MXH Encoder Cable Pinouts 19

Figure 1-8: 32 MHz Count Spacing 21

Figure 1-9: 16 MHz Count Spacing 22

Figure 1-10: 8 MHz Count Spacing 22

Figure 1-11: 4 MHz Count Spacing 22

Figure 1-12: MXH General Configuration (No Output Option Selected) 24

Figure 1-13: MXH Option -1 (Sine Differential Square Wave Output) 25

Figure 1-14: MXH Option -2 (Sine & Cosine Differential Square Wave Output) 26

Figure 1-15: MXH Option -3 (Sine, Cosine, and Marker Differential Square Wave Output) 27

Figure 1-16: MXH Multiplier Dimensions 28

Figure 2-1: MXH Multiplier Board Hardware Locations (REV A/Obsolete) 29

Figure 2-2: MXHMultiplier Dimensions (REVA/Obsolete) 30

MXH Multiplier Option Manual Table of Contents

Table of Contents MXH Multiplier Option Manual

List of Tables

Table 1-1: Order Option Summary 10

Table 1-2: Stage Table Verification Chart 14

Table 1-3: Settings for Pulse Width Jumpers 16

Table 1-4: MXH Multiplier Board Test Points 16

Table 1-5: Pinouts for Connector J1 17

Table 1-6: Pinouts for Connector J2 18

Table 1-7: MXHCable Options 18

Table 1-8: MXH Multiplier Board Potentiometers 20

Table 1-9: Digital Differential Factory Options 20

Table 1-10: MXH Multiplier Board Models and Specifications 23

Table 1-11: MXH Multiplier Board Electrical Specifications 23

www.aerotech.com 5

MXH Multiplier Option Manual Table of Contents

6 www.aerotech.com

This page intentionally left blank.

Declaration of Conformity MXH Multiplier Option Manual

EU Declaration of Conformity

Manufacturer

Aerotech, Inc.

Address

101 Zeta Drive

Pittsburgh, PA 15238-2811

USA

Product

MXH Encoder Multiplier Box

Model/Types

All

This is to certify that the aforementioned product is in accordance with the applicable requirements of the

following Directive(s):

2014/35/EU Low Voltage Directive LVD

2011/65/EU RoHS2 Directive

and has been designed to be in conformity with the applicable requirements of the following documents when

installed and used in accordance with the manufacturer’s supplied installation instructions.

EN 61010-1:2010 Safety requirements for electrical equipment

and furthermore declares that:

It is not allowed to put the equipment into service until the machinery into which it is to be incorporated or

of which it is to be a component has been found and declared to be in conformity with the provisions of

EU Directive 2006/42/EC and with national implementing legislation, i.e. as a whole, including the

equipment referred to in this Declaration.

Authorized Representative:

Simon Smith, European Director

Address:

Aerotech Ltd

The Old Brick Kiln

Ramsdell

Tadley

Hampshire

RG26 5PR

UK

Name

/ Alex Weibel

Position

Engineer Verifying Compliance

Location

Pittsburgh, PA

www.aerotech.com 7

MXH Multiplier Option Manual Declaration of Conformity

8 www.aerotech.com

This page intentionally left blank.

Introduction MXH Multiplier Option Manual

Chapter 1: MXHMultiplier Board

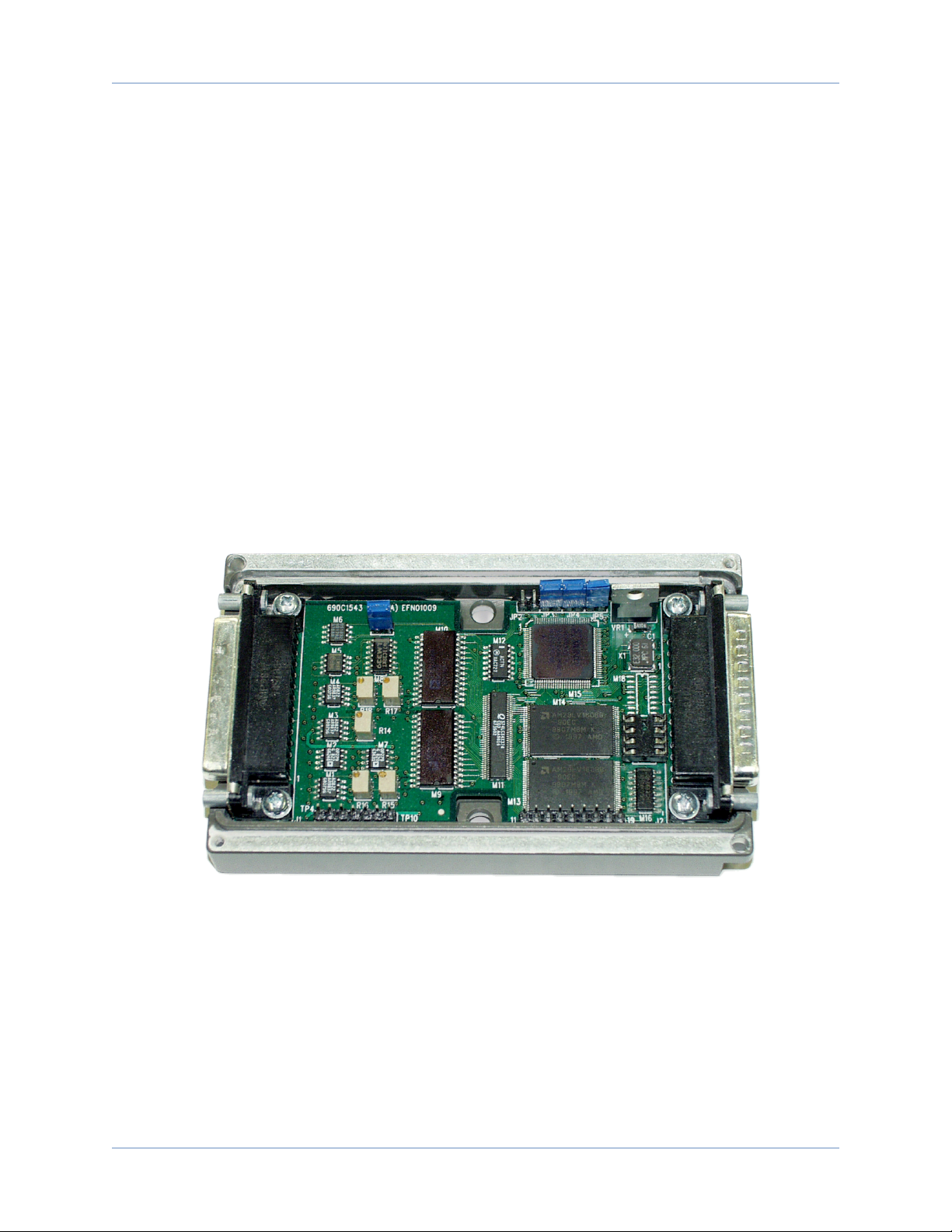

1.1. Introduction

Aerotech's MXH series multipliers are the ideal solution for high-resolution system requirements. The MXH

multiplier board is designed for use with rotary or linear sine wave encoders to increase encoder resolution.

The MXH series uses high-performance interpolation electronics to increase resolution by up to x2000.

The MXH model offers multiplication factors up to x2000. A linear encoder with a 4 µm grating period can

have resolution as fine as 2 nm.

Unlike most multiplication devices, the MXH doesn't sacrifice speed. A 32 MHz clock assures high speed

and high resolution. For example, with a resolution as fine as 8 nm, speeds of over 250 mm/s are achievable.

Aerotech's Dedication to the Science of Motion is reflected in some of the unique features of the MXH

series. Not only does the MXH boast industry-leading data rates, but for atypical resolution requirements,

Aerotech can create custom multiplication factors. This level of flexibility is unmatched by the competition

and is a result of our years of experience in the high-accuracy positioning market.

The MXH interface uses standard 25-pin D-type connectors, eliminating the need for expensive and hard to

find connectors. Limit switch and Hall-effect signals pass through the MXH, resulting in a more efficient

cabling scheme.

Figure 1-1: MXH Multiplier Board

www.aerotech.com Chapter 1 9

10 Chapter 1 www.aerotech.com

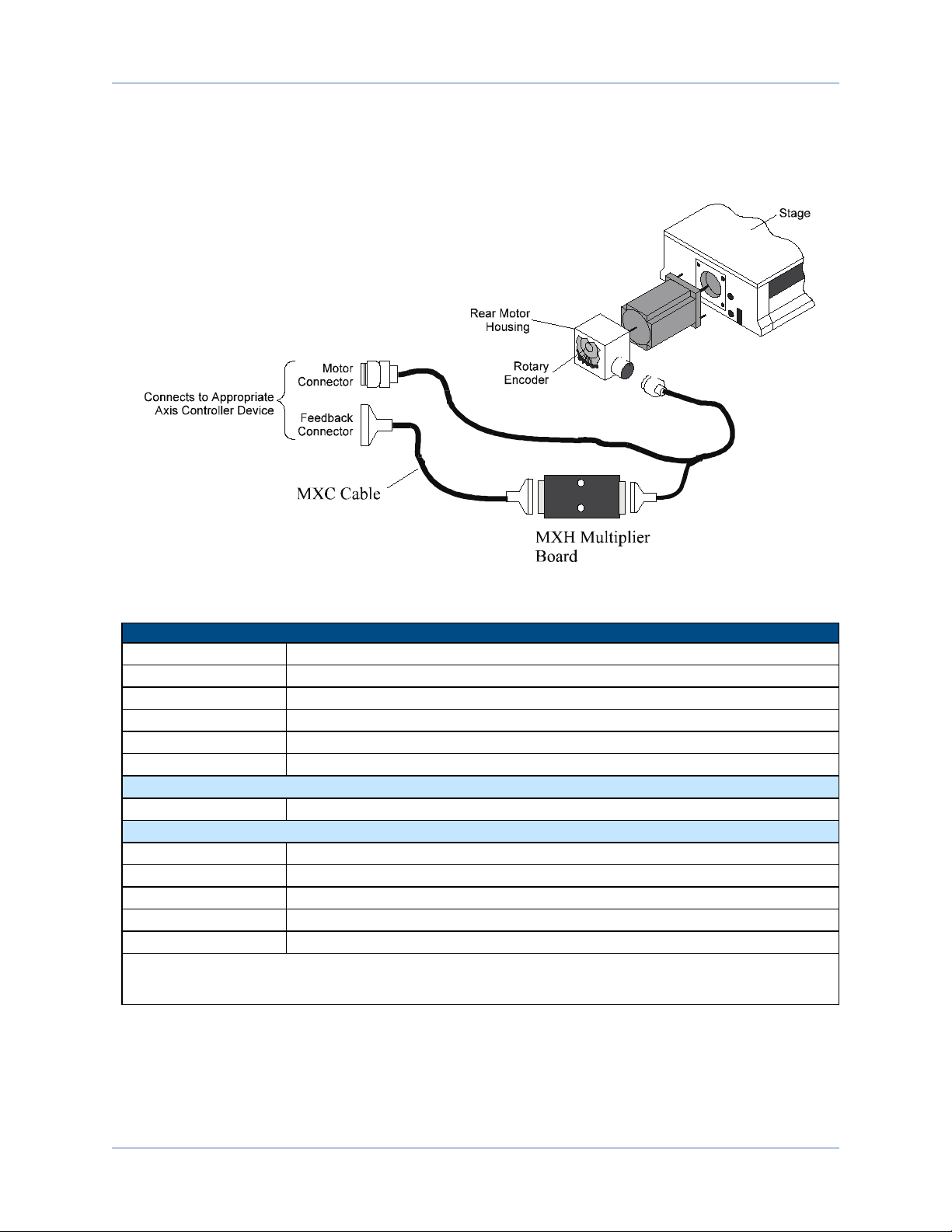

The MXH multiplier board connects between the encoder and the appropriate axis controller. Refer to Figure

1-2 for an example configuration. This connection does not affect Hall effect or limit signals; instead, it is a

simple add-in that uses mostly standard cables.

Figure 1-2: MXH Multiplier Board Configuration

Table 1-1: Order Option Summary

MXHSeries Multiplier

MXH50 External 50-times (net 200-times interpolation with quadrature) multiplier

MXH100 External 100-times (net 400-times interpolation with quadrature) multiplier

MXH200 External 200-times (net 800-times interpolation with quadrature) multiplier

MXH250 External 250-times (net 1000-times interpolation with quadrature) multiplier

MXH500 External 500-times (net 2000-times interpolation with quadrature) multiplier

MXHn-D External "n"-times custom resolution. Consult factory

Input Signal

D 1 Vpp input signal

Output Data Rate

2M 2 MHz output signal

4M 4 MHz output signal

8M 8 MHz output signal

16M 16 MHz output signal

32M 32 MHz output signal

Note: MXH multipliers are available in -A and -B versions as factory supplied configurations. Multiplication selections are possible in

0.25 increments up to MXH256, which multiplies into an integer after x4 (i.e. 0.25 or 0.5, 1.25, 33, etc. Unacceptable values are 1.7,

2.4, etc.). From MXH256 to MXH512, multiplication selections are possible in x1.0 increments.

MXH Multiplier Option Manual Introduction

Introduction MXH Multiplier Option Manual

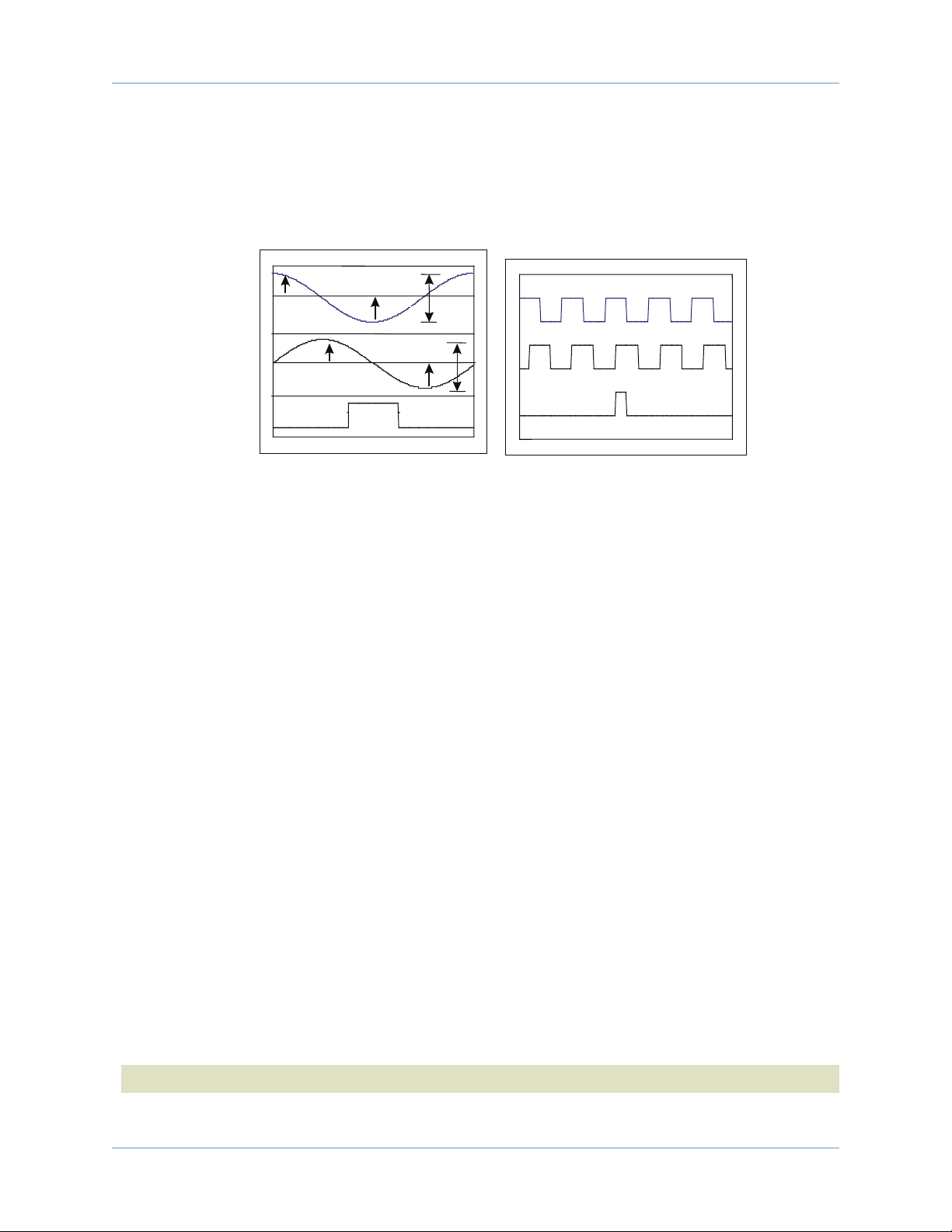

1.2. Multiplier Signals

The multiplier board accepts 1 V peak-to-peak voltage input signals. The outputs are square wave, RS-422

TTL compatible signals. The input marker signal is expected to be active high and located at the 255° point of

the 360° electrical cycle. The plots illustrated in Figure 1-3 show typical input and output signals (cosine,

sine, and marker).

INPUT SIGNALS

(After amplification on the MX board)

OUTPUT SIGNALS

COSINE

SINE

MARKER

TP10 - COSINE

Approx. Ref 2.5 V

0V

TP9 - SINE

Approx.

Ref 2.5 V

0V

TP6 - MARKER

1.9V

3.8Vpk-pk

3.8Vpk-pk

1.9V

1.9V

1.9V

Figure 1-3: Plot of Input and Output Signals

1.3. Multiplier Board Setup

The MXH Multiplier is designed to work with perfectly sinusoidal signals with no DC bias (offset). The actual

magnitude of the sine and cosine signals is not as important as the value of one signal relative to the other.

The MXH multiplier is a “ratio-metric” device, which means that the sine and cosine signals should be

adjusted for equal peak amplitudes. Any gain imbalance between the sine and cosine signals will result in

cyclic interpolation errors in the MXH output.

Any DC bias (offset) in sine or cosine will also cause cyclic interpolation errors in the multiplied output.

The gain and DC bias can be adjusted for each signal on the MXH multiplier circuit board.

1.3.1. Oscilloscope

Generally, systems operating at less than optimum performance due to interpolation errors will exhibit the

following symptoms:

1. A constant whining noise can be heard when running at low speeds.

2. At high speeds, a chirping noise can be heard when the table is accelerating and decelerating.

3. Using Aerotech’s application software as a diagnostic tool, a harmonic or a sub-harmonic of the

fundamental encoder frequency may be seen in the position error or velocity error plots of the axis

scope window.

1.3.2. Equipment and Tools Required

1. A two-channel oscilloscope capable of being isolated from ground and displaying a Lissajou pattern (X,

Y) of the sine and cosine encoder signals

2. Small slotted tip screwdriver or adjustment tool.

N O T E : The amplified signals can not exceed 4V peak-to-peak or a loss of accuracy occurs.

www.aerotech.com Chapter 1 11

12 Chapter 1 www.aerotech.com

1.3.3. Adjustment Procedure

1. Verify that oscilloscope is isolated from ground.

N O T E : An oscilloscope that is not isolated may cause permanent damage to the multiplier.

2. Connect signal common of scope to TP5 (2.5 VDC reference voltage), channel A scope probe to TP10

(COS-N), and channel B scope probe to TP9 (SIN-N). Refer to Figure 1-6 for MXH part locations.

3. Display encoder signals as a Lissajou pattern on the oscilloscope (x y mode).

4. Set channels A & B of the oscilloscope for 0.5 VDC per division, and zero the scope reference to the

center of the display.

5. Move table over the entire range of travel at a low speed, and verify that the peak to peak amplitude of

the circular pattern is between 2 to 3.9 Vp-p.

6. Move the table to the area where the amplitude is the largest, and verify or adjust for the following. (See

Diagram A – Diagram H in Figure 1-4 and Figure 1-5 for examples.)

i. COS-N gain is 3.8 Vp-p (+/- 0.1 Vp-p). Adjust R16 if necessary.

ii. COS-N DC offset is 0 VDC (+/- 0.1 VDC). Adjust R15 if necessary.

iii. SIN-N gain is equal to COS-N gain (+/- 0.1 Vp-p). Adjust R18 if necessary.

iv. SIN-N DC offset is 0 VDC (+/- 0.1 VDC). Adjust R17 if necessary.

v. Phase error is 0 degrees (+/- 4.5 Degrees). Adjust R14 if necessary.

vi. Repeat steps 6i through 6v.

7. Move table over the entire range of travel at a low speed and verify the following information in Table 1-

2.

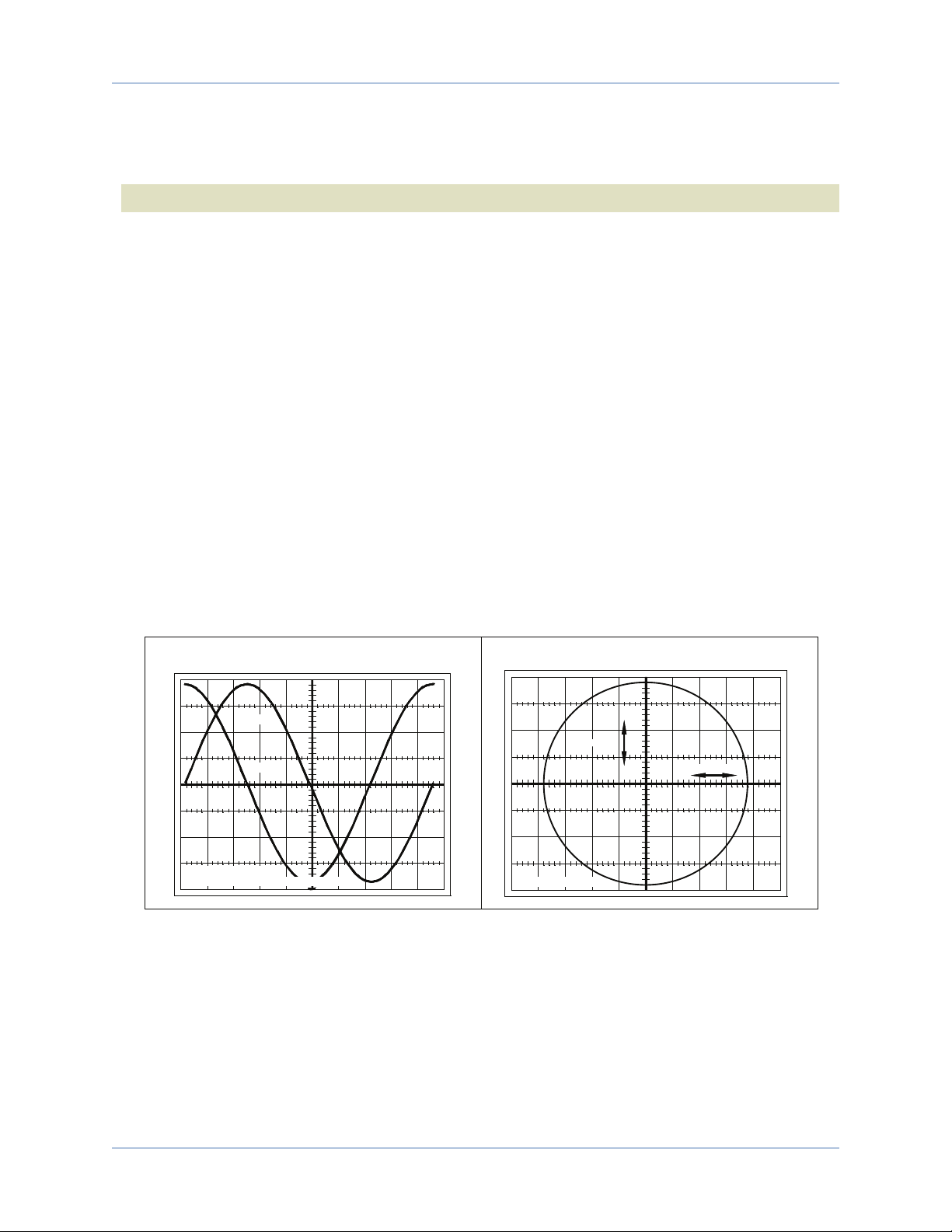

Diagram A (Ideal)

SIN-N & COS-N Sweep Display No Phase, Gain or Offset Error

Diagram B (Ideal)

SIN-N & COS-N Lissajou Display No Phase, Gain, or Offset Error

COS-N

SIN-N

0.5 VOLT/DIVISION

0.1 MILLISECOND/DIVISION

0.5 VOLT/DIVISION

COS-N

SIN-N

Figure 1-4: Ideal Oscilloscope Displays (Sweep and Lissajou)

MXH Multiplier Option Manual Introduction

Introduction MXH Multiplier Option Manual

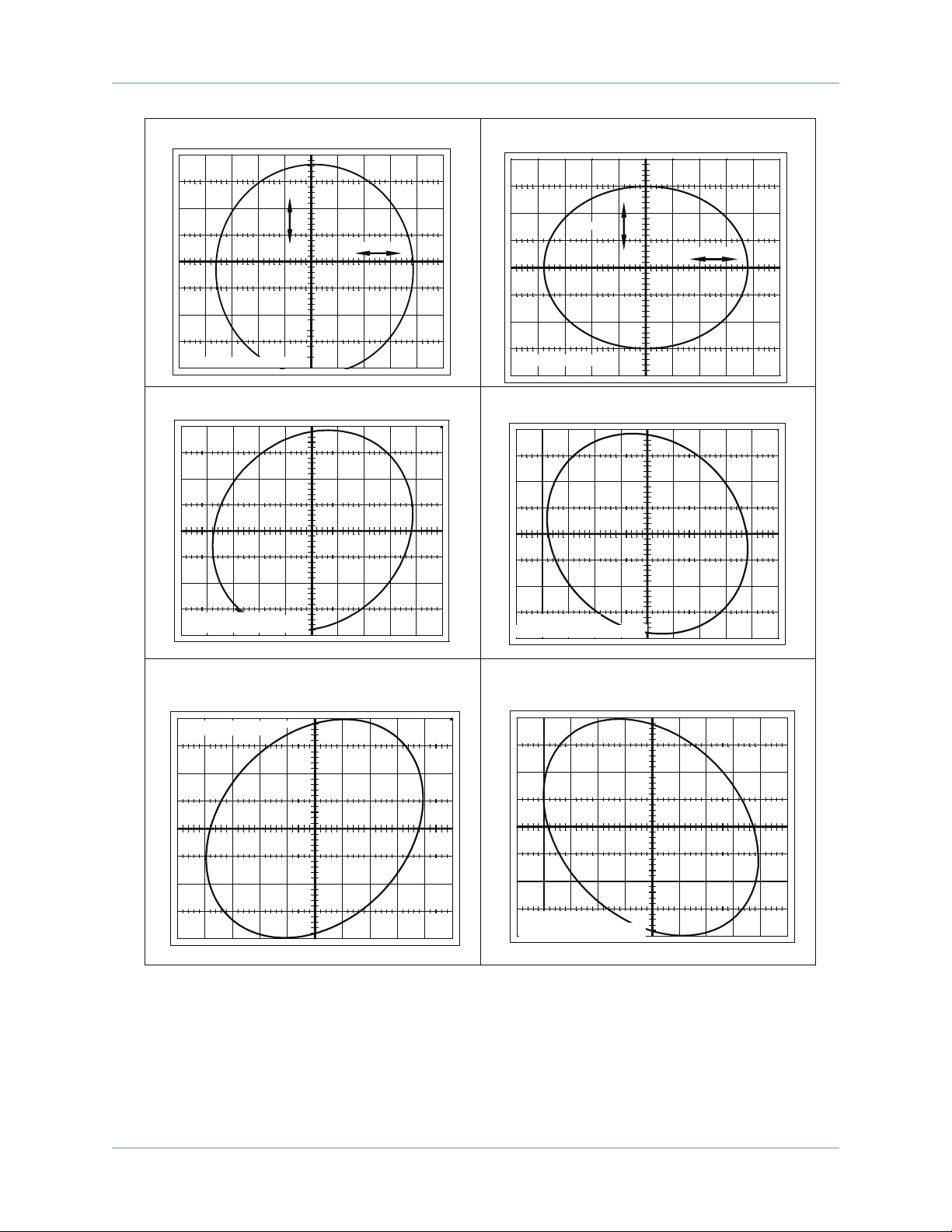

Diagram C (Not Optimum)

SIN-N & COS-N Lissajou Display DC Offset Error: SIN-N –0.1V, COS-N +0.1V

Diagram D (Not Optimum)

SIN-N & COS-N Lissajou Display Gain Error: SIN-N 3Vp-p, COS-N 3.8Vp-p

0.5 VOLT/DIVISION

SIN-N

COS-N

SIN-N

COS-N

0.5 VOLT/DIVISION

Diagram E (Not Optimum)

SIN-N & COS-N Lissajou Display Showing Phase Error of +4.5º

Diagram F (Not Optimum)

SIN-N & COS-N Lissajou Display Showing Phase Error of -4.5º

0.5 VOLT/DIVISION

4.5 DEGREE PHASE ERROR

0.5 VOLT/DIVISION

-4.5 DEGREE PHASE ERROR

Diagram G (Not Optimum)

SIN-N & COS-N Lissajou Display Showing Phase Error of + 9º

Diagram H (Not Optimum)

SIN-N & COS-N Lissajou Display Showing Phase Error of - 9º

+ 9 DEGREE PHASE ERROR

0.5 VOLT/DIVISION

0.5 VOLT/DIVISION

-9 DEGREE PHASE ERROR

Figure 1-5: Not-Optimum Oscilloscope Lissajou Displays

www.aerotech.com Chapter 1 13

14 Chapter 1 www.aerotech.com

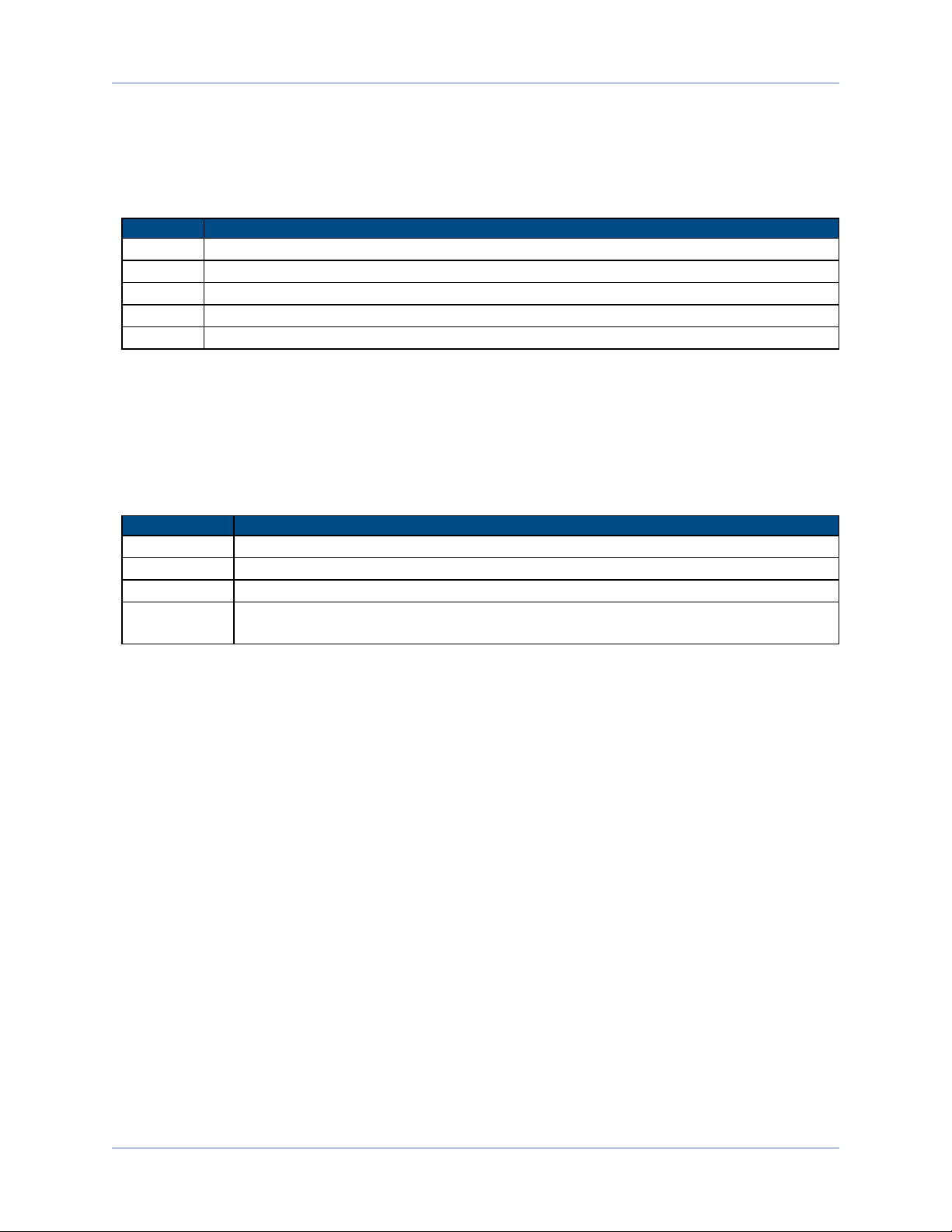

Table 1-2: Stage Table Verification Chart

Lissajou Pattern Optimum Acceptable

Signal Amplitude 3 to 3.8 Vp-p 2 to 4.0 Vp-p

Gain Error ≤ 2.5% of Signal Amplitude (Vp-p) ≤ 5.0% of Signal Amplitude (Vp-p)

DC Offset Error ≤ 2.5% of Signal Amplitude (Vp-p) ≤ 5.0% of Signal Amplitude (Vp-p)

Phase Error ≤ 4.5 º ≤ 9.0 º

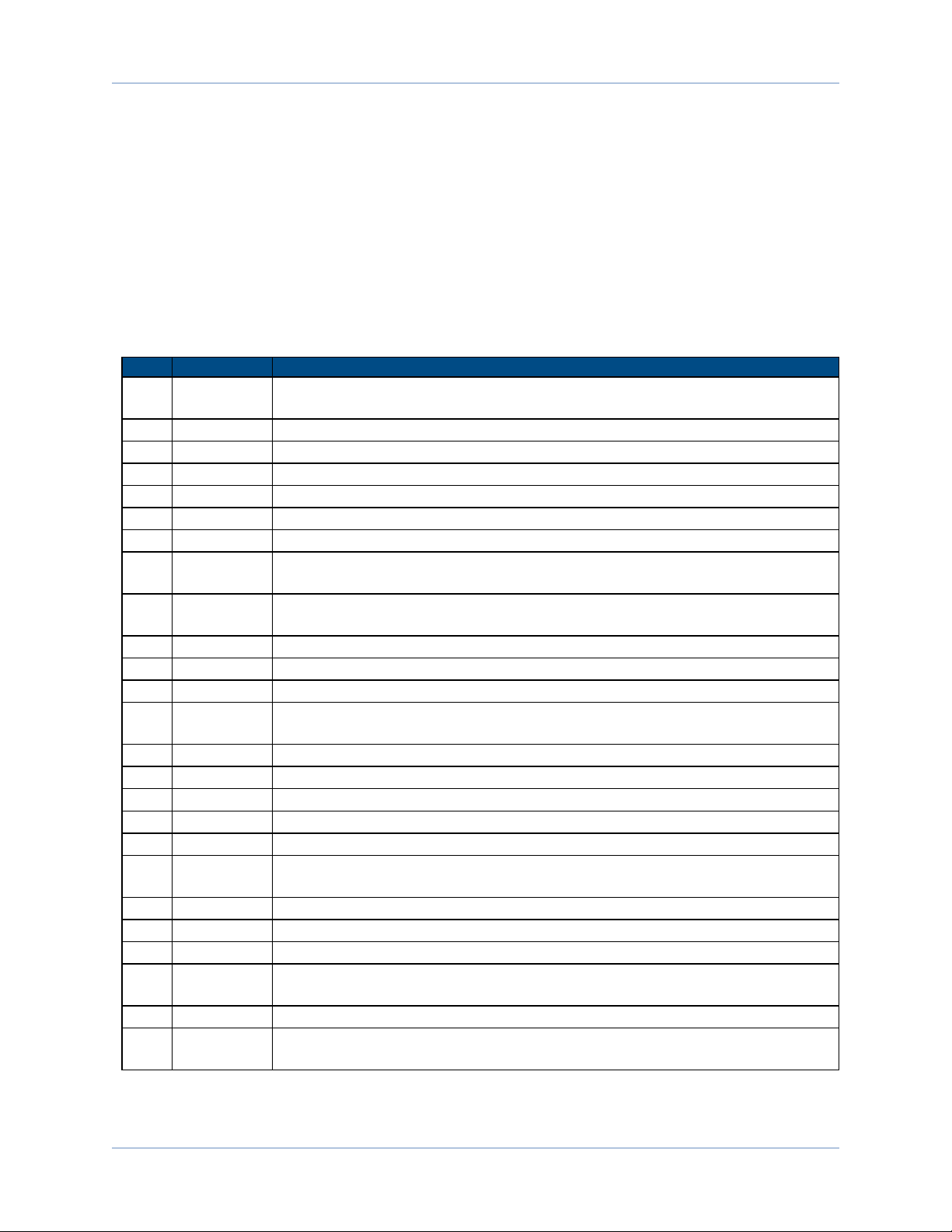

J3 F.S.

1

M11

M10

J1

Female

TP4

TP5

TP6

TP7

TP8

TP9

TP10

TP11

TP12

TP13

TP14

TP15

TP16

TP17

TP18

TP19

JP2

JP3

JP4

JP5

J2

Male

X1

32 MHz

1

VR1

EZ1086CT

C1

+

M17

1

M16

M15

R15

R16

R17

R18

R14

1

M14

26LS32

M13

M12

JP1

0 OHM

M19

XC17S30XL

M18

AM26LS32

M20

AM26LS32

1

690C1543 Rev. C

M7

M6

M5

M4

M3

M2

M1

M9

M8

Figure 1-6: MXH Multiplier Board Hardware Locations

MXH Multiplier Option Manual Introduction

Introduction MXH Multiplier Option Manual

1.4. Hardware Configurations

The amplified input signals at Test Points TP9 and TP10 (refer to Figure 1-6 for locations) should be

configured for normal 3.8 V peak-to-peak signals, see the explanation in Section 1.3. However, the multiplier

board has an acceptable range of amplified input signals from 2V peak-to-peak to 4V peak-to-peak.

The following sections discuss the hardware used to configure the MXH multiplier board. The hardware is

accessible by removing two screws securing the dust cover to the board.

1.4.1. Fault Circuitry (JP1) (Rev A Only)

The fault circuitry detects input signal magnitudes below 0.5 Volt peak-to-peak. If a fault is detected, all

outputs are set to a high impedance state. Fault detection is enabled with jumper JP1 in. Removing JP1

defeats fault detection. For jumper location, refer to Figure 1-6.

1.4.2. Marker Pulse Jumper (JP4)

The marker pulse jumper in the default setting of JP4 sets the pulse width to the minimum pulse width. In

this case, the marker is one output pulse wide and is qualified with the input marker. When JP4 is out, the

marker signal of the encoder is an output and is the same width as the input pulse and no qualification is

performed. For jumper location, refer to Figure 1-6.

1.4.3. Reset Circuitry (JP5)

The default setting (jumper in) of the reset circuitry jumper (JP5) resets the board if a fault is detected. The

faults that can occur are a loss of 5V, loss of clock signal, and low input signal magnitudes.

www.aerotech.com Chapter 1 15

16 Chapter 1 www.aerotech.com

1.4.4. Pulse Width Jumpers (JP2 and JP3)

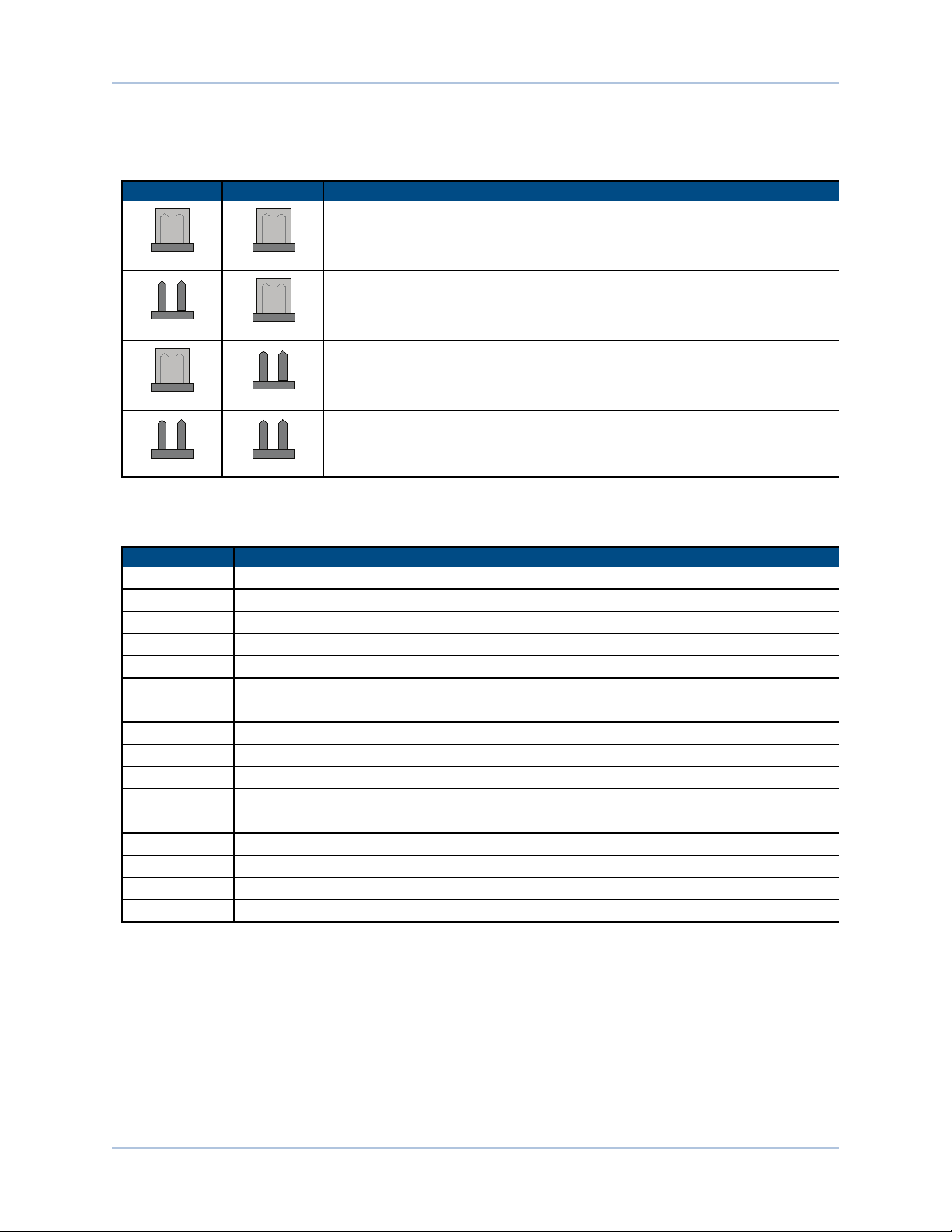

Table 1-3: Settings for Pulse Width Jumpers

JP2 JP3 Function

1

1

Minimum pulse width = 0.03125 µs

Master clock frequency = 32 MHz

1

1

Minimum pulse width = 0.0625 µs (default)

Master clock frequency = 16 MHz (default)

1

1

Minimum pulse width = 0.125 µs

Master clock frequency = 8 MHz

1

1

Minimum pulse width = .25 µs

Master clock frequency = 4 MHz

1.4.5. Test Points

Table 1-4: MXH Multiplier Board Test Points

Test Points Function

TP4 Ground

TP5 Sin Reference (Approx. 2.5V)

TP6 Squared up marker signal from encoder

TP7 Cos reference (Approx. 2.5V)

TP8 NC

TP9 Amplified input sine wave (0 - 5V)

TP10 Amplified input cosine wave (0 - 5V)

TP11 A/D sample clock

TP12 HDC

TP13 LDC

TP14 M14 Flash reset

TP15 M13 Flash reset

TP16 Flash Ready/Busy signal

TP17 Output marker, square wave

TP18 Output sine, square wave

TP19 Output cosine, square wave

MXH Multiplier Option Manual Introduction

Introduction MXH Multiplier Option Manual

1.4.6. Connectors (J1 and J2)

There are two connectors on the MXH multiplier board; J1, which receives signals from a sinusoidal

encoder, and J2, that outputs the frequency-multiplied RS-422 pulses. The “multiplied” signals are then

taken to the controller through the breakout or interface boards. J1 is a 25-pin female “D” style connector. J2

is a 25-pin male “D” style connector. The pinouts for these connectors are listed in Table 1-5 and Table 1-6.

The MXH box only uses the SIN, COS, and Marker signals. Hall effect, Limit, and the rest of the signals are

passed directly through the MXH box with minor or no modification. As with any high frequency signal

transfer over cables, strict guidelines for interconnecting cables should be followed for noise-less, properly

phased signal delivery. Figure 1-7 is an illustration of the MXH encoder cable with the pinouts.

Table 1-5: Pinouts for Connector J1

Pin Signal Description

1 Shield Tied to motor ground. Grounded when connected to an interface board through

chassis and J2, pin 1.

2 Tied to J2-2

3 Encoder +5V Supplies 5V to encoder

4 Ground Analog ground. Supplies ground to encoder, tied up with J1, pins 20, 21.

5 Hall Effect B From motor, connected to J2, pin 5. 10K pull-up attached.

6 Marker - Analog sinusoidal input from encoder.

7 Marker + Analog sinusoidal input from encoder.

8Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

9Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

10 Hall Effect A From motor, directly connected to J2-10. 10K pull-up attached

11 Hall Effect C From motor, directly connected to J2-11. 10K pull-up attached

12 CW Limit From motor, directly connected to J2-12. 10K pull-up attached

13 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

14 COS + Analog sinusoidal input from encoder.

15 COS - Analog sinusoidal input from encoder.

16 +5V Supplies 5V to encoder

17 SIN + Analog sinusoidal input from encoder.

18 SIN - Analog sinusoidal input from encoder.

19 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

20 Ground Analog ground. Supplies ground to encoder, tied up with J1, pins 4, 21.

21 Ground Analog ground. Supplies ground to encoder, tied up with J1, pins 4, 20.

22 Home Limit Directly connected to J2, pin 22. 10K pull-up attached.

23 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

24 CCW Limit Directly connected to J2, pin 24. 10K pull-up attached.

25 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

www.aerotech.com Chapter 1 17

18 Chapter 1 www.aerotech.com

Table 1-6: Pinouts for Connector J2

Pin Signal Description

1 Shield Grounded when connected to an interface board.

2 Tied to J1-2

3 Encoder +5V Supplies 5V to motor encoder through J1, pin 3.

4 Ground Supplies ground to encoder, tied up with J2, pins 20, 21.

5 Hall Effect B Brings Hall signal directly from motor to interface board through J1, pin 5.

6 Marker - Multiplied RS-422 out from MXH to interface board.

7 Marker + Multiplied RS-422 out from MXH to interface board.

8Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

9Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

10 Hall Effect A Brings Hall signal directly from motor to interface board through J1, pin 10.

11 Hall Effect C Brings Hall signal directly from motor to interface board through J1, pin 11.

12 CW Limit Brings Hall signal directly from motor to interface board through J1, pin 12.

13 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

14 COS + Multiplied RS-422 out from MXH to interface board.

15 COS - Multiplied RS-422 out from MXH to interface board.

16 +5V Supplies 5V from the interface board to MXH, tied to J1, pin 16.

17 SIN + Multiplied RS-422 out from MXH to interface board.

18 SIN - Multiplied RS-422 out from MXH to interface board.

19 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

20 Ground Supplies ground to encoder, tied up with J2, pins 4, 21.

21 Ground Supplies ground to encoder, tied up with J2, pins 4, 20.

22 Home Limit Brings Home Limit directly from motor to interface board through J1, pin 22.

23 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

24 CCW Limit Brings CCW Limit directly from motor to interface board through J1, pin 24.

25 Output option dependent (refer to Section 1.4.8. and Figure 1-12 through Figure 1-

15).

Table 1-7: MXHCable Options

Cable Description

MXC-xx MXH to controller cable

BFCMX-xx MXH to motor or controller cable

DC-DDMX-xx ADR to MX box feedback cable

DC-MSOMX-xx DC Brush Motor to MXH cable

PFCMX-xx MXH to (controller) flying lead cable

“xx” is the available length in feet

MXH Multiplier Option Manual Introduction

Introduction MXH Multiplier Option Manual

Note: Maximum Cable Length Is 10 Meters

Twisted Pairs Are 1-4 Turns / Inch

ENCODER

SHIELD TO CASE

SINE +

SINE –

COSINE +

COSINE –

MARKER –

MARKER +

+5V

COMMON

MX BOARD J1 (25 PIN MALE D)

SHIELD (CONNECTOR SHELL)

17 SINE +

18 SINE –

14 COSINE +

15 COSINE –

6 MARKER –

7 MARKER +

3 +5V

21 COMMON

20 COMMON

OUTER SHIELD

TWIST

TWIST

TWIST

TWIST

INNER SHIELD

Figure 1-7: MXH Encoder Cable Pinouts

www.aerotech.com Chapter 1 19

20 Chapter 1 www.aerotech.com

1.4.7. Potentiometers

For the location of the pots on the MXH multiplier board, refer to Figure 1-6.

Table 1-8: MXH Multiplier Board Potentiometers

Pot Function

R14 Phase adjust between sine and cosine signals

R15 Balance for encoder cosine signal

R16 Gain adjust for encoder cosine signal

R17 Balance for encoder sine signal

R18 Gain adjust for encoder sine signal

1.4.8. Output Options

The following Digital Differential factory options are available; refer to Figure 1-12,Figure 1-13,Figure 1-14,

and Figure 1-15. All four of these options provide RS-422 differential square wave output signals produced

after multiplication. Options 1-3 add additional outputs providing RS-422 signals from the un-multiplied input

signals

Table 1-9: Digital Differential Factory Options

Option Code Description

NONE Differential square wave sine / cosine multiplied signals (standard)

-1 Differential square wave output of un-multiplied sine signal

-2 Differential square wave output of un-multiplied sine and cosine signals

-3 Differential square wave output of un-multiplied sine, cosine and marker (unqualified)

signals.

MXH Multiplier Option Manual Introduction

Other manuals for MXH Series

1

This manual suits for next models

6

Table of contents

Other Aerotech Media Converter manuals

Popular Media Converter manuals by other brands

Patton electronics

Patton electronics 2072 Installation and operation manual

ADLINK Technology

ADLINK Technology PCI-8124 user manual

Hama

Hama 00083215 operating instructions

Sumake

Sumake ST-2275 Operator instructions

WebGate

WebGate SDI2HD instruction manual

SRS Lighting

SRS Lighting DSR10-3 instruction manual