Aerre Inox AMT Series User manual

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 2 of 29

Aerre Inox s.r.l.

Contents

Operator and Equipment Safety

AMT Mixer Description

AMT Mixer Components

Internal parts

External parts

Required Tools and Optional Equipment

Installation and Operating Parameters

Noise level and Vibrations

Positioning and Installation

Welding Plate Installation

Static Bearing Installation

Mixing Head Installation

Drive Unit Installation

Disassembly

Storage

Recycle and Disposal

Operation

Check and Calibration

Starting the Mixer

Operating Notes:

Cleaning in Place (CIP)

Sterilizing in Place (SIP)

Maintenance and Service

Routine maintenance

Identification and Labeling

Spare Parts

Troubleshooting

ATEX Certification

EC Declaration of Incorporation

PED Certification

Standard Warranty

Components of the Agitator

In the interests of development and improvement of the product, we reserve the right to alter specifications

without prior notice.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 3 of 29

Aerre Inox s.r.l.

The instruction manual is only a reminder of the main operations on device, leaving the training of

personnel to a specific preparation.

The operating and maintenance is an integral part of the technical documentation for the machine.

The manual should be carefully preserved and made available to all interested people.

These instructions have been produced after the evaluation of an analysis of "Risk Assessment" and

"Danger Reduction".

In case of lost or damaged, you can request a copy of the manual by quoting the serial number, type,

year of manufacture, stamped on the CE nameplate of the machine.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 4 of 29

Aerre Inox s.r.l.

Operator and Equipment Safety

AMT Mixer is only to be operated when mounted in a vessel. This is to avoid impact damage

from external bodies.

People with pacemaker should observe caution close and during removal mixing head and drive

unit.

Magnetic cards can be damaged if they kept in the vicinity of mixing head or drive unit.

To avoid injury from electrical shock, make sure that, in maintenance or not operation, the main

power supply is in "OFF" position and IEC plug connection is unplugged.

To avoid possible skin lesions from electrical shock, burns and contact with chemicals or volatile

liquid, make sure, that before working on the mixer, the tank will result in operator safety, heat-

treated at atmospheric pressure and sufficient time has elapsed to cooling at a temperature not

dangerous (≤ 35 ° C).

Do not insert foreign objects into the tank when the mixer is rotating as this may result in

personal injury and can damage the mixer.

MOUNTING: the mixing head is to be mounted before drive unit, to avoid any damage, specially

at the brittle tungsten carbide bearings. ALWAYS FOLLOW THE INSTRUCTIONS IN THE

MANUAL.

DISMOUNTING: the drive unit must be disassembled before the mixing head, after that, the

impeller can be raised with caution, without forcing, avoiding damage to tungsten carbide

bearings.

Before removing drive unit, check the weight of the equipment installed, may be heavy, and

acting accordingly for your safety, make sure the main power switch is locked on a switch-off

position.

NOTES:

•All installers, operators and maintenance personnel of the equipment must read and

understand this manual before installation use and application. Failure to follow the

operating instructions and installation may cause injury or equipment damage.

•Any attempt to use the AerreInox AMT mixer improperly specified in this manual or any

unauthorized modification can cause damage and void the product warranty and end

user must remove CE plate.

•Any of the following events can damage the mixer: external load, the reaction forces,

torque, corrosion, erosion, fatigue and decomposition of unstable fluids

•Before starting, the device must be fully assembled according to the instructions

contained in this manual.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 5 of 29

Aerre Inox s.r.l.

•If the control is done by the operator directly exposed, use appropriate personal

protective equipment and eye protection when operating the equipment.

•Protect motor unit against dust and dirt.

•The engine has a weight, use appropriate equipment to prevent crushing injuries.

•Install the impeller before installing drive unit.

•Do not install components close to the rotating parts of the Mixer AMT.

•During mixing, mixer components may become hot to the touch.

•Do not insert your fingers in equipment, may result in injury.

•Check the magnetic parts of the Mixer AMT after maintenance there should be no

foreign material.

•Do not run with an empty vessel.

•Ensure that the mixing head rotates clockwise.

•Check that all components of the mixer are the correct size.

•Handle the mixing head and the static bearing with care; the material of the bearing is

hard and brittle.

•Keep remote controlled medical devices and magnetic storage devices away from

magnetic parts of the AMT mixer.

•The mixing head must always be, partially or completely, submerged.

•Follow the instructions and limitations applicable to Ex AMT mixer ATEX.

•The system must be connected to the grounding system.

•Wiring of the motor in accordance with the instructions and performed only by qualified

technicians.

•The engine must match the Atex zone assigned.

•If the motor is only suitable for use in NOT hazardous or dangerous areas, should not be

used in hazardous areas classified as Zone 0, Zone 1, Zone 2.

•The stirring process will be less efficient and will cause serious damage to the static

bearing if the agitator rotates in the wrong direction. Follow the arrows indicating the

direction to check the correct rotation.

•Check that the electrical overload protection are correctly dimensioned.

•The impeller of mixer must be inserted and immersed in the liquid before starting the

machine. Not follow this arrangement involves a premature and excessive wear of the

bearing, in addition to a consequent release of particles and corpuscular.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 6 of 29

Aerre Inox s.r.l.

•Do not insert any object improper (for example bolts, screws) in the product that must be

mixed. Because of the vigorous mixing, these objects could be attracted from the

impeller and it is possible that the blades or other being impaired, if this happens, stop

immediately the machine.

•Never insert hands or other body parts or tools inside the vessel when the stirrer is

running, without proper safety equipment or before the machine is isolated from the

power source and in complete safety.

•The machine must be disconnected from the engine before performing any type of

maintenance or repair. Indicate with appropriate notice or indication that the machine is

in repairs or maintenance.

•Current electric motors have high working temperatures and the windings can even

reach 120°C, making the coverage dangerous due to the temperature. Indicate with

appropriate reporting that accidental contact can be dangerous to operators or

generally for anyone who is exposed.

•Treating the installation so that it is not possible for the operator accidentally come into

contact with moving parts of the machine during operation. Treating the geometry of

the container and provide it with security systems such that interrupt the movement of

the machine in case of inspection.

•Emergency stop should be placed close to the stirrer in place perfectly accessible and

visible (if supplied electrical control cabinet).

•The time interval between a control and the next will depend on the hours of operation of

the machine and also on the types of product in use. We recommend that they should

be always available a KIT of static bearing to shorten the downtime during

maintenance.

•Depending on the products you use and your operating procedures, there is also the

danger of violent projections of product operators. This is more likely if they are used

minimal amounts of product to be mixed. The security measures will depend on your

correct assessment of danger.

•The mixer is cleaned with automatic CIP systems together with the vessel and with

different systems by means of an appropriate solvent. It is necessary that the machine

is cleaned before being taken out of service. The presence of residues produced in the

area of rotation and centering of the bearing may cause jamming with consequent

seizure.

•Risk electric shock. Switch off the power supply to the control panel and wait 5 minutes

before you start working on the equipment. (This time serves to allow the capacitor to

be able to download). Our control panels are tested before shipping. Various

adjustments and settings must be agreed with the manufacturer.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 7 of 29

Aerre Inox s.r.l.

•Always insert the impeller inside the vessel before entering the motor. Always disconnect

the geared motor before removing from the container the impeller. Ensure that it

always performs the operations of insertion and extraction in this order. Any operation

performed otherwise may cause damage to equipment due to the strong attraction of

the magnets. Avoid putting the impeller using hands are not adequately protected:

danger of crushing gear engaged.

The mixer is a unit used generally on vessels and tanks in which it is necessary to maintain a product

in suspension, or create a vortex that allows to incorporate powders and / or liquids. The magnetic

stirrer is a simple, easy to install and of low maintenance. The type of application of the agitator

avoids rotary seals which could cause leakage and put in communication the product with the external

not controlled environment.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 8 of 29

Aerre Inox s.r.l.

AMT MIXER DESCRIPTION

The magnetic stirrer AMT series is designed for specific use in the pharmaceutical and biotechnology industries,

ultra sterile applications where high standards are required for aseptic applications construction.

The most obvious advantage of the magnetic mixer is that it allows to maintain the total integrity of the vessel.

The inner surface of the tank is continuous and without mechanical seals to ensure a hygienic design without

the risk of contamination or loss. This prevents leakage and / or spillage of toxic or very expensive, preserving

the sterility of the tank and its contents.

AerreInox has long recognized and promoted the benefits of magnetic stirrer for applications in the

pharmaceutical, biotechnology and cosmetic industries.

Designed to conform to the current pharmaceutical requirements.

The geometry of the impeller (mixing head), allows an optimal axial distribution, with flow rate and cutting speed

very low suitable for different applications, such as: mix, dilute, maintain in suspension, avoid stratification in

thermal exchanges ...

The impeller is rotated by a running drive unit mounted externally to the vessel.

The mixer is designed for speeds from 50-380rpm with the application of a frequency converter (inverter).

Depending on the size and volume of the vessel and the impeller size, it can reach levels of agitation by gentle

to vigorous. You can also mix very small volumes, not feasible with conventional type mixers.

The mixer AMT offers great flexibility to use up to 800cps viscosity.

The geometry of the wings and their profile are designed to optimize the levels of agitation and allocate part of a

fluid through the impeller itself for an optimum washout.

The mixing head rotates on inserts of tungsten carbide certificate manufactured under controlled conditions to

obtain the correct size, grain structure and hardness.

All parts in contact with the product are made of stainless steel 1.4404 or 1.4435, with a finish surface mirror

polished, optional finishing for electropolishing.

Suitable for C.I.P. and S.I.P. in situ or autoclave, the mixer AMT has a drive unit which can be removed quickly

and easily. The application from the bottom allows to obtain the top of the vessel free for easy access to the

inside of the tank.

A further advantage is the use of a single interchangeable drive unit shared between multiple tanks.

A flange, machined from raw bar, is welded on the bottom of the tank (usually with a certain offset from a central

discharge bottom valve).

Inside the rotating head is a ring of special magnets, encapsulated in a stainless steel container. Welded to this

body, the mixing blades, which form overall the mixing head.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 9 of 29

Aerre Inox s.r.l.

AMT MIXER COMPONENTS

Catalog and the specifications for the components can be requested to AerreInox.

INTERNAL PARTS

All parts described in this section (including the upper part of the welding flange) in contact with the product,

have surface quality and tolerance in order to meet aseptic requirements.

Handle with care and attention these products in order to avoid damage, leaving the mixing head and the static

bearing in their packaging as long as possible to protect it from dust, bumps and impacts.

MIXING HEAD (IMPELLER)

Handle the mixing head with care. The material of the bearing is hard and brittle. Keep magnetic body away

from any iron particles that may adhere to it and contaminate the steel surface.

The driving force is transmitted to the mixing head by means of magnetic coupling.

The shape of the wings facilitates cleaning and sterilization (CIP / SIP) without the need for disassembly.

1 –magnetic body

2 –wings

3 –dynamic tungsten carbide bearing

4 –serial number

STATIC BEARING

Static bearing keeps in the correct position, the mixing head inserted on 'welding plate' inside the vessel. The

bearing is very fragile, it is therefore important to avoid impacts and shocks, and maintain the clean surface free

of contaminating particles; when the mixing head is in operation must always be immersed.

5 –static tungsten carbide bearing

6 –disk TFM PTFE / o-ring EPDM

7 –serial number

8 –locking nut

9 –disk TFM PTFE / o-ring EPDM

WELDING PLATE

Each weld plate is marked with a serial number and code for full traceability. The welding flange is welded to the

tank and is considered an integral part of the vessel. Welding plates are provided in conformity with PED

Category IV of Directive 97/23/EC.

In the inner part (tank) there is a threaded end for attachment of the static bearing through the locking nut. The

outer part is provided with connection (of different sizes depending on AMT models) to allow the connection of

drive unit.

10 –connection screw

11 –welding edge

12 –drive connection flange

13 –serial number

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 10 of 29

Aerre Inox s.r.l.

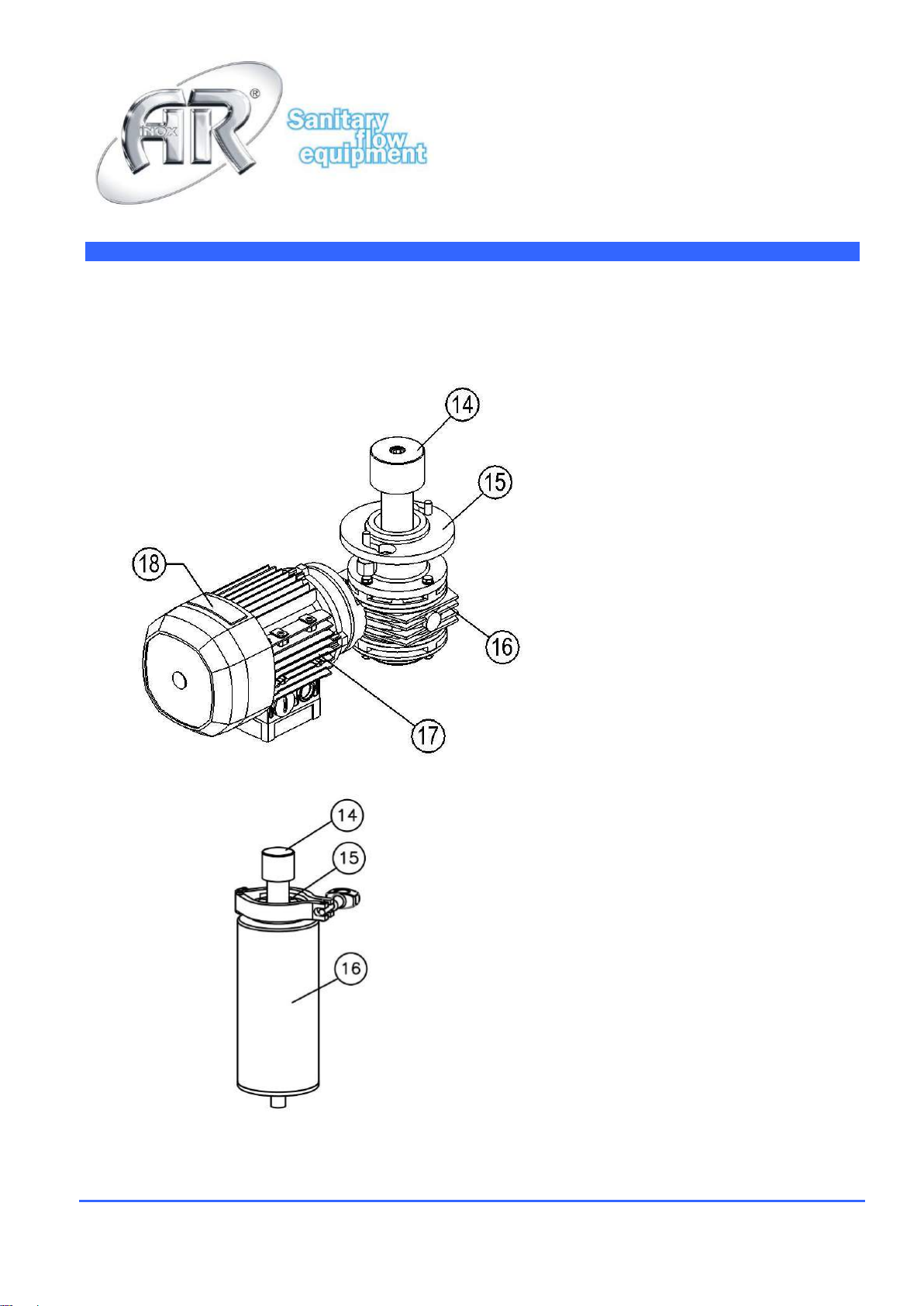

EXTERNAL PARTS

DRIVE UNIT

The unit drive delivers torque to the mixing head and is applied on the outside of the tank against flange

dedicated.

The entrainment (14) of the drive unit is magnetic and has to be stored in the package as long as possible to

protect it from damage, dirt, shocks and impacts.

230/400v AC

14 –magnetic outer drive head

15 –tank plate connection flange

16 –gearbox unit

17 –motor

18 –AMT serial number label

24v DC

14 –magnetic outer drive head

15 –tank plate connection flange

16 –gearbox/motor unit

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 11 of 29

Aerre Inox s.r.l.

REQUIRED TOOLS and OPTIONAL EQUIPMENT

TOOL

The instrument shown is usable for the introduction and extraction the impeller of the AMT magnetic mixer.

This instrument has a dual purpose: on the one side to introduce and remove the mixing head and the static

bearing; from the other side allows to screw and unscrew the locking nut, during assembly or maintenance.

This tool is supplied as optional for AMT mixer (excluding model AMT-04 dedicated only for small tanks).

SPEED SENSOR

Speed sensor of the inductive type, is a device especially used during all processes that require an effective

monitoring and adjust the speed of the impeller. The sensor is housed inside a capsule of AISI 316L which is

rigidly fixed to the impeller. The external sensor is applied on the connection plate with a stainless steel support.

Adjust the position of the sensor by changing the thread trying to maintain the minimum distance possible

between the two components. Connect the sensor (PNP) according to the instructions.

external sensor is

applied on the

adaptor flange

plate using a

stainless steel

bracket.

internal sensor is

housed inside an

AISI 316L support

rigidly fixed to the

impeller.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 12 of 29

Aerre Inox s.r.l.

INSTALLATION and OPERATING PARAMETERS

Please refer to the appropriate product specification sheet (next table) for more information.

MIXING HEAD - STATIC BEARING

Limit of the operating parameters inside the tank

PARAMETER

MINIMUM

MAXIMUM

Temperature

-10° C

152°C

pH

1

14

Viscosity

1 cP

800 cP (*)

Media

Media may not contain magnetic particles

Rotation Speed

See product specification sheet

Minimum acceleration and deceleration

time

5 sec. (specific to each application; set accordingly)

(*) For non-aqueous solutions or various products contact AerreInox.

Be sure to use an appropriate program start-up, and a engine with a good acceleration ramp.

Attention Tungsten Carbide Bearing, may be attacked and oxidized by hydrogen peroxide.

WELDING PLATE

PARAMETER

MINIMUM

MAXIMUM

Temperature

-80° C

200°C

Pressure

-1 barg

10 barg

DRIVE UNIT

Define the operating parameters outside the vessel

PARAMETER

MINIMUM

MAXIMUM

Ambient temperature

0° C

40°C

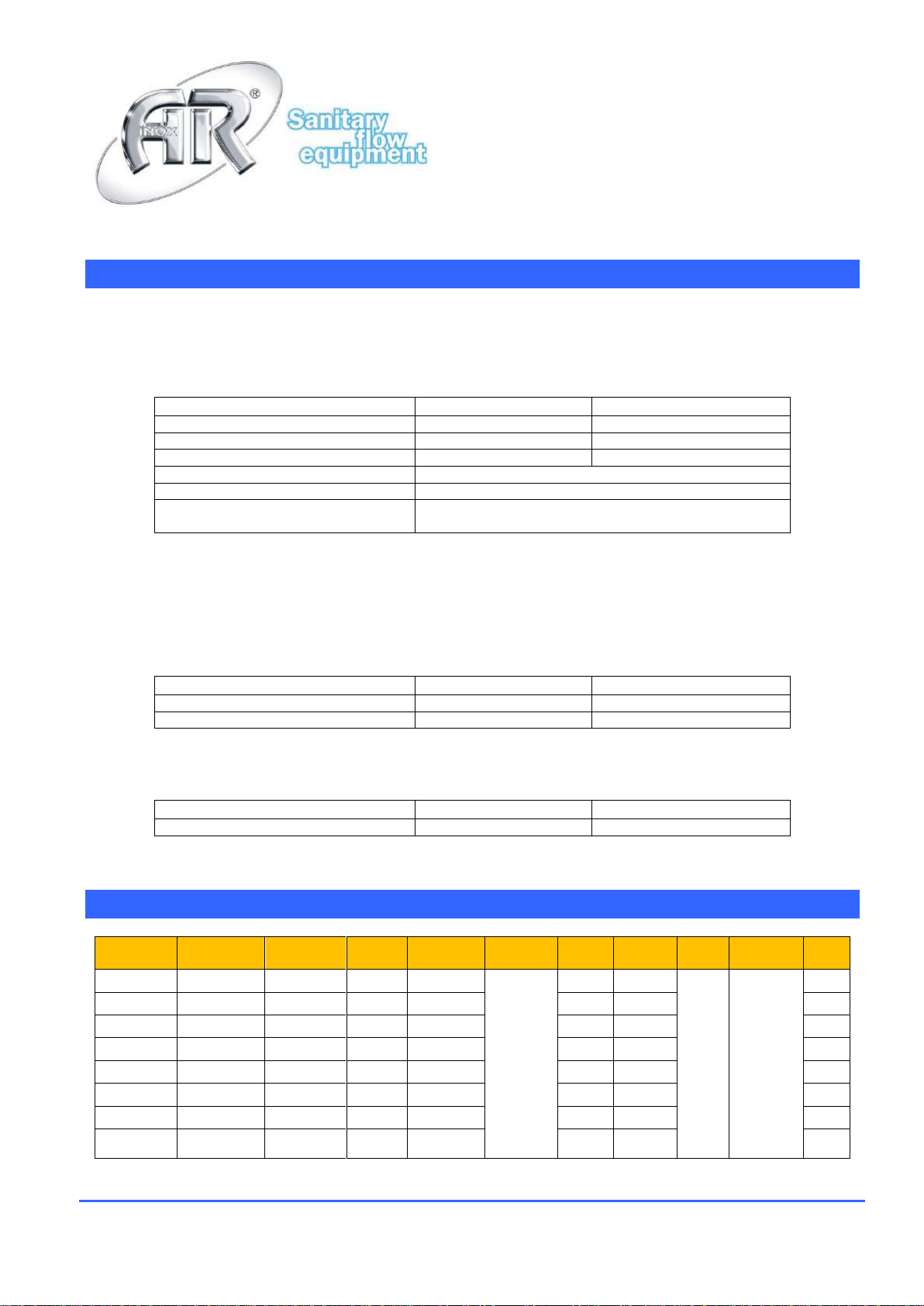

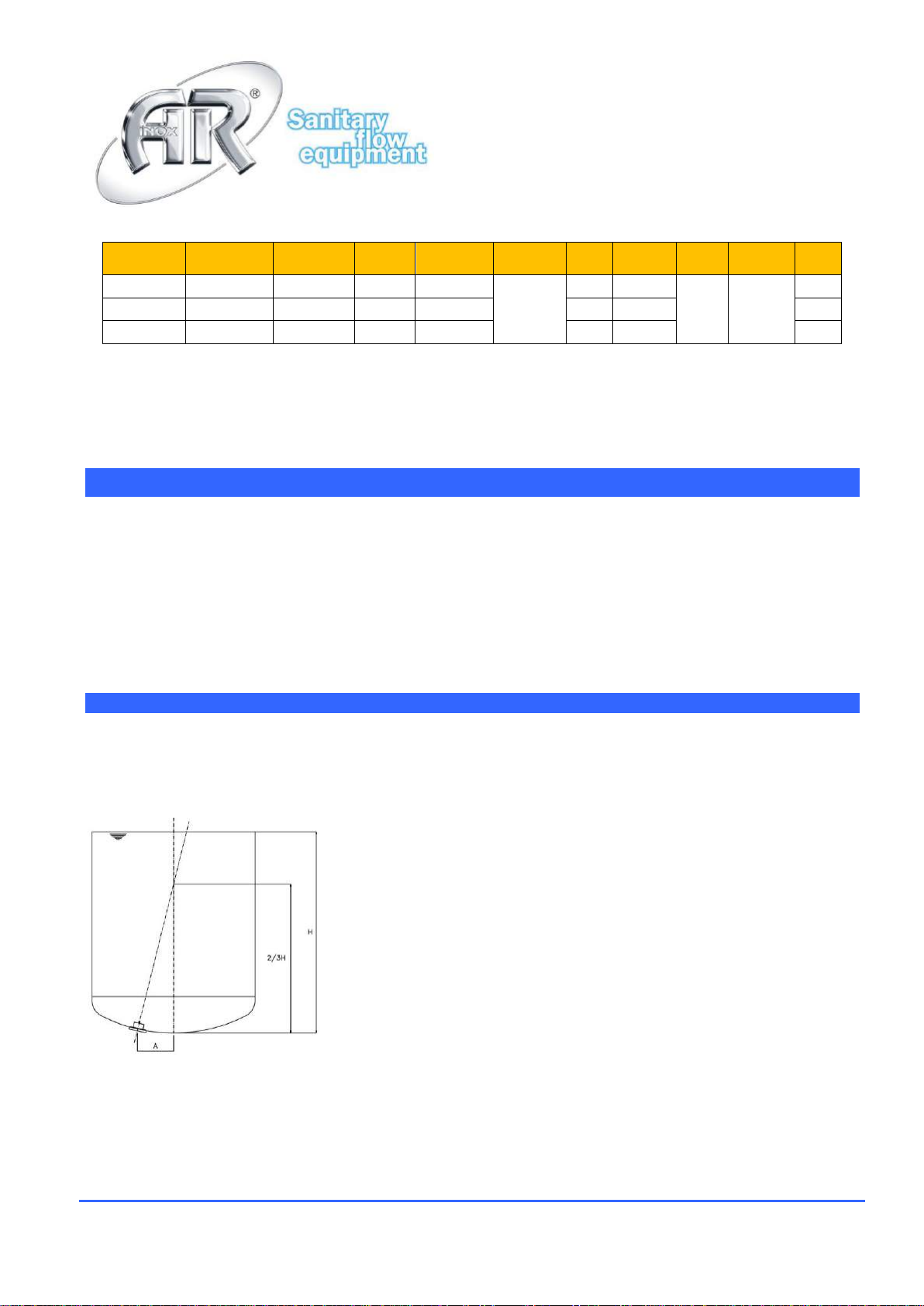

PRODUCT SPECIFICATION SHEET

MODEL

working

volume (lt)

shaking

vigorously

shaking

bland

visc. MAX

(cPoise)

Power

supply

power

(Kw)

power

(EX Kw)

RPM

RPM

regulation

weight

(kg)

AMT-02

05 - 20

5

15/20

150

230/400 v

3ph (AC)

0,06 Kw

0,09 Kw

50÷380

Inverter

10-50 Hz

4

AMT-04

10 - 50

10

50

200

0,12 Kw

0,25 Kw

6,5

AMT-06

50 - 150

50

150

200

0,25 Kw

0,25 Kw

12

AMT-08

150 - 500

150

500

500

0,55 Kw

0,55 Kw

18

AMT-12

300 - 2000

300

2000

800

0,75 Kw

0,75 Kw

31

AMT-20

1000 - 3000

1000

3000

500

1,50 Kw

1,10 Kw

45

AMT-32

2000 - 6000

2000

6000

600

2,20 Kw

2,20 Kw

55

AMT-64

3000 - 15000

3000

10000

25000

700

5,50 Kw

5,50 Kw

114

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 13 of 29

Aerre Inox s.r.l.

MODEL

working

volume (lt)

shaking

vigorously

shaking

bland

visc. MAX

(cPoise)

power

supply

power

(W)

power

(EX W)

RPM

RPM

regulation

weight

(kg)

AMT-02

05 - 20

5

15/20

150

24 v DC

64 W

//

50÷380

elettronic

drive

4

AMT-04

10 - 50

10

50

200

84 W

//

6,5

AMT-06

50 - 150

50

150

200

250 W

//

8

NOISE LEVEL and VIBRATIONS

Noise levels are measured in accordance with ISO 1680 standard, and are within the maximum limits imposed

by the CEI 2-24 / IEC 34-9.

The vibration level falls in the class N standard, in accordance with standard CEI 2-23 / IEC 34-14.

POSITIONING and INSTALLATION

Install the AMT mixer components in the following order:

1- Welding plate

2- Static bearing

3- Mixing head

4- Drive unit

Follow all installation recommendations, precautions and warnings contained in this manual.

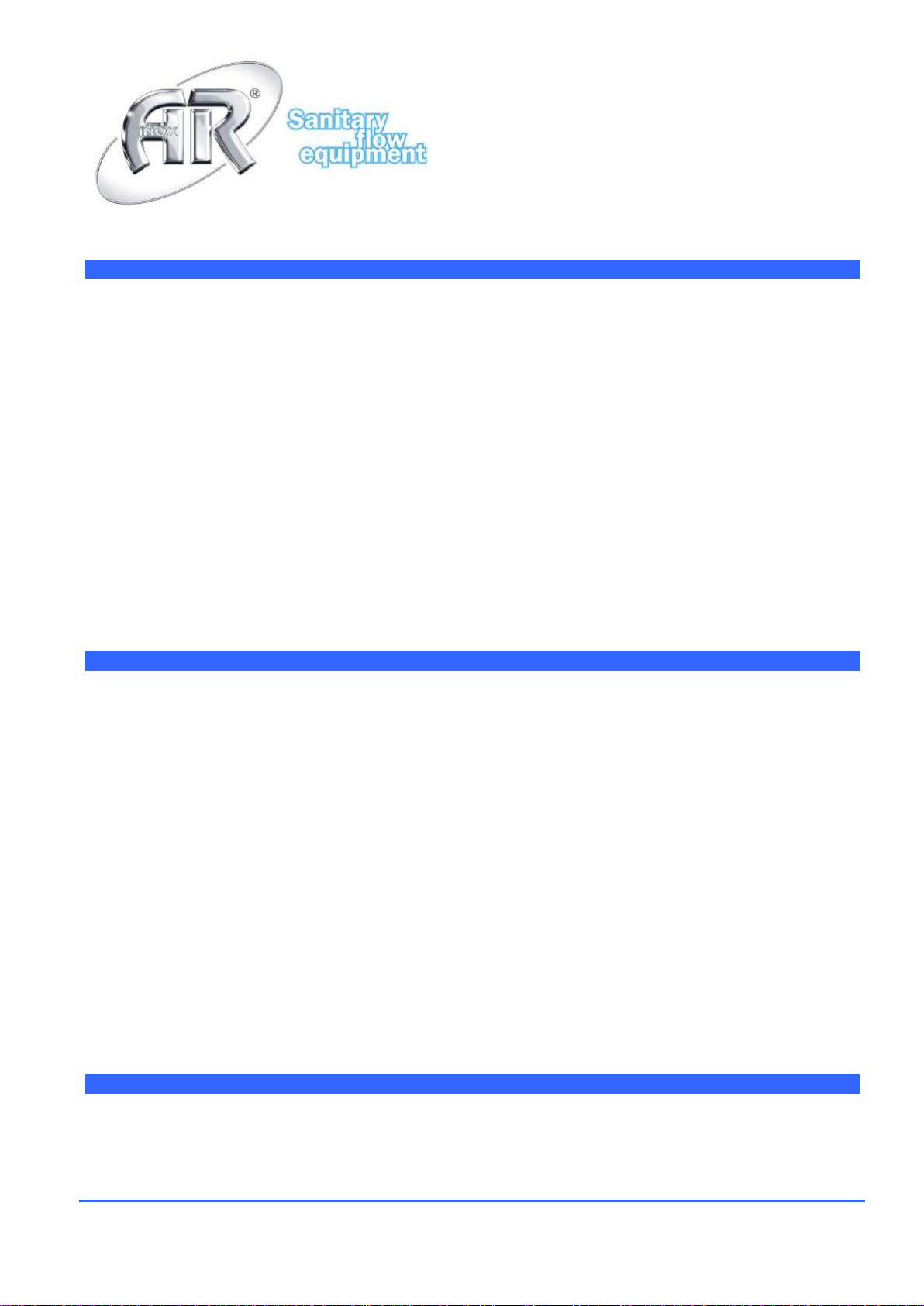

1 - WELDING PLATE Installation

The welding flange must be placed in a position on the bottom tank according to the following rules and

conditions:

Liquid

When the flanges are welded in containers subject to pressure, the requirements of

the code calculation pressure of the tank must be met. For tanks designed and

constructed in BS 5500 the outermost part of the flange must be within 10% of the

diameter of the receptacle (see Figure 3.5.4 (0) of BS5500).

The distance between the welding flange and any other welding must be at least 4

times the thickness of the receptacle (15 mm minimum).

the hole for the welding flange does not have to be performed across a welded joint

in the bottom of the vessel or adjacent components.

For receptacles not by pressure, welding in the region of the end fitting convex must

be avoided.

the flange of the agitator must be positioned so that its axis passing through the

center of the vessel appears to about 2/3 of the height of the liquid (H).

The dimension "A" is relative to the type of agitation to be obtained. Consult

AerreInox for the optimal size.

Welding pad positioning

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 14 of 29

Aerre Inox s.r.l.

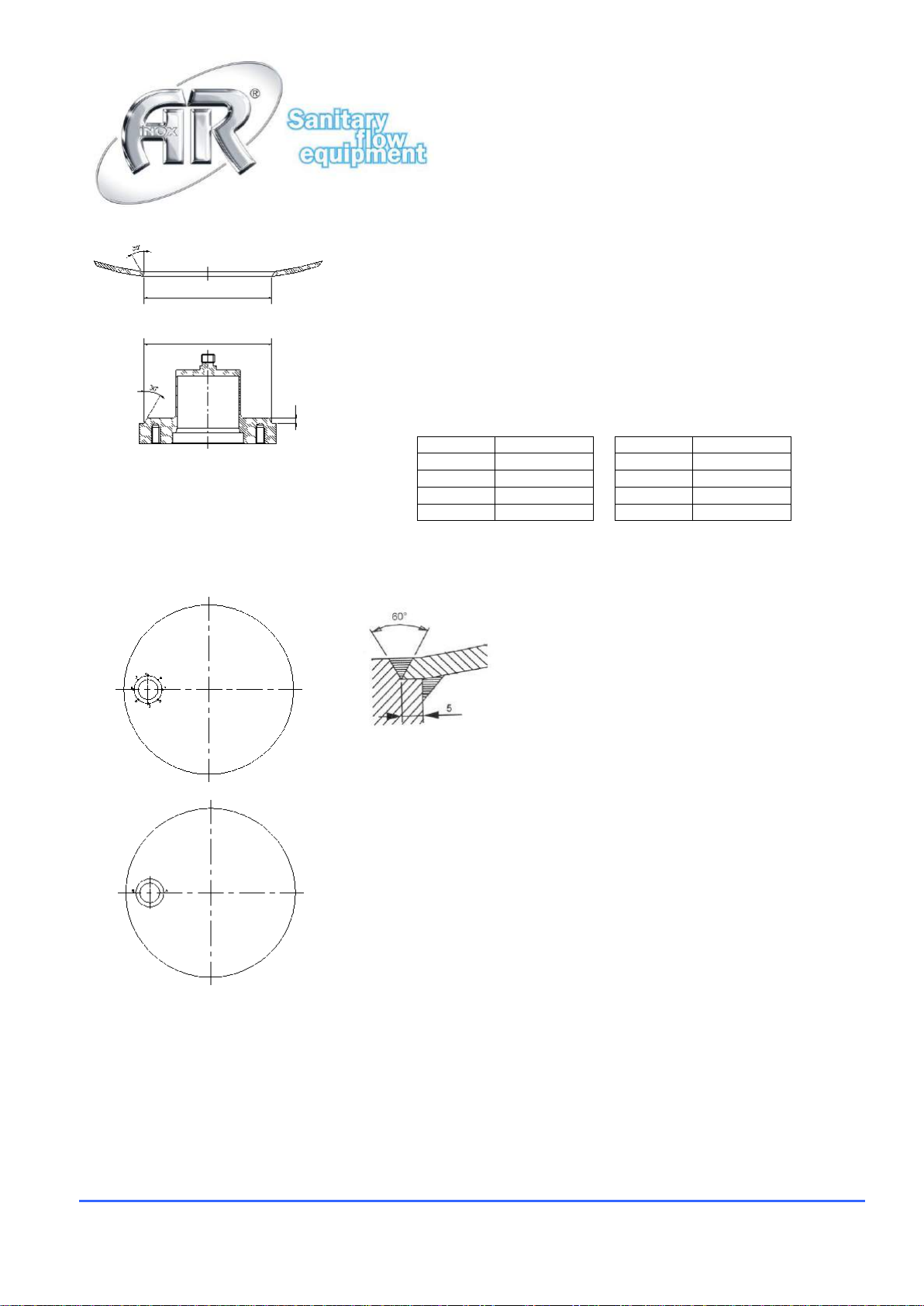

PREPARATION FOR WELDING

Refer to the figure on the left: for this type of connection of the flange, the same

requires machining with bevels from work on it as shown in the second figure on the

left. The flange can be supplied with a bevel design made, if requested at time of

order.

Once the position of the welding plate has been determined, is to be track the hole

on the outer surface of the convex bottom. The hole must be performed with plasma

cutting, ensuring a dimension as indicated in the table. Is essential that between the

hole and caulking the flange is performed for a proper filling.

MODEL

Ø hole (mm)

MODEL

Ø hole (mm)

AMT-02

55

AMT-12

140

AMT-04

60

AMT-20

175

AMT-06

75

AMT-32

240

AMT-08

115

AMT-64

268

(a) Hole preparation

(b) Machining detail for welding pad mixer

The flange must be positioned in the hole oriented

correctly, start with the execution of a series of points

from the inside of the container to eight positions in the

sequence shown in the first figure on the left, check at

this step the flange, ensuring that is resting on the

bottom and normal.

Refer to the second picture. From inside the tank, made a pass 360° continuous

TIG run from point A with filler wire of 1.2 mm in diameter from 30 to 40 volts /

110 to 120 Amps. Make a second pass from the point B. In case of need for a

third pass should be carried out from point A to point B.

Finally, it should be resumed in reverse and continuously at 360° fill TIG welding

across the flange, with filler wire 1.6 mm in diameter. If necessary, the welding

can be performed in two or three steps.

Sequence for tack welds

Continuous root runs

FINAL GRINDING and POLISHING STAGE

After the flange was allowed to cool by natural convection to ambient temperature, the welds must be brushed

and / or polished until it reaches the desired finish. If necessary, any excess of material or scratch can be

identified and re-polished.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 15 of 29

Aerre Inox s.r.l.

2 - STATIC BEARING Installation

NOTE

- Make sure that the tank appears clean and completely dry inside;

- Do not use any abrasive or improper on the support surface;

- Handle with care static bearing;

- Make sure the static bearing and locking nut are clean;

- If necessary to enter in the tank, follow all local regulations regarding operator safety.

STEP TO INSTALL STATIC BEARING

1) Ensure the correct position of the washers / o-ring on the bushing static and locking nut.

2) To ensure minimum friction, lubricate the visible part of the washer / o-ring with a small veil of purified

water.

3) Make sure the flange is clean, dry and free of foreign material.

4) Position the static bearing with locking nut with a suitable tighten tool.

5) Make sure that the instrument chosen to tighten fit the nut, then screw to pack the nut and washers / o-

ring and static bearing to the face of welding flange. Tighten the lock nut to the torque recommended

appropriate.

3 - MIXING HEAD Installation

NOTE

- ALWAYS install the mixing head before installing the drive unit;

- Handle with care mixing head;

- Be very careful when mounting the mixing head on static support, the bearings of the mixer are fragile;

- Do not mount the drive unit before installing the mixing head (the powerful magnetic force between the

mixing head and the external magnetic drive can cause serious damage to the bearings, and personal

injury);

- If necessary to enter in the tank, follow all local regulations regarding operator safety.

STEP TO INSTALL MIXING HEAD

1) Remove any foreign particles from the magnetic mixing head. If the mixing head must be placed on the

table, position the dynamic bearing toward the floor to prevent magnetic particles that go to adhere to

the magnetic surface of the mixing head.

2) Remove the drive unit.

3) Install the mixing head with the appropriate tools. Because of the dimensions of the mixing head the

sizes 04 - 32 - 64 must be installed by hand.

4) Carefully position the mixing head with small movements while go down on static support.

5) Place the mixing head and make sure that rotates smoothly.

4 - DRIVE UNIT Installation

NOTE

- Never operate on drive unit without frequency converter (inverter);

- Handle the drive unit with caution to avoid personal injury and damage crush to equipment;

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 16 of 29

Aerre Inox s.r.l.

- ATTENTION! because of the strong magnetic attraction of components, do not pair the mixing head

with the drive unit;

- The drive unit has a weight, use suitable equipment to avoid injury from crushing;

- See installation technical bulletins of electric motors for the power information;

- Connection to power supply must be performed by a licensed electrician in accordance with the

regulations, directives and the code's safety.

- Ensure that all incoming power is equipped with emergency stop and with on/off locked switch in both

positions;

- Make sure that the motor cables are shielded (to avoid interference);

- Make sure the drive is properly connected to ground;

- Store the engine in a non-humid and water proof room. Make sure that during maintenance the motor is

on a stable surface to avoid falls or vibration;

- The bearing of the mixing head should be moistened with liquid before starting the unit;

- Check the direction of rotation: start the engine, make sure that magnetic outer drive head rotate

clockwise, a mark on the drive unit indicates the correct direction of rotation.

INSTALL AMT-02 / AMT-04 / AMT-06 DRIVE UNITS

AMT-02 , AMT-04 and AMT-06 models use a connection

type clamp that allows a random orientation of the welded

flange.

1) Install the drive unit on the weld plate.

2) Without using gasket, position the clamp (1”1/2”, 2" or 2"1/2) around the weld plate and the flange of the

drive unit.

3) Tighten the clamp connection just found the correct orientation.

INSTALL AMT-8 DRIVE UNIT

The AMT-08 model has two shaped pins on mounting

flange of mixer. The normal orientation of the buttonhole

assembly is as shown in Figure A in such a way as to bring

the axis of the mixer on the center line of the vessel.

1) Insert the two shaped pins in welding plate.

2) Install the drive unit on the welding plate and let the two pins fit into the buttonhole on the drive unit.

3) Rotate the drive unit counterclockwise until the stop position (about 10°).

4) Tighten the two nuts with a wrench.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 17 of 29

Aerre Inox s.r.l.

Position when Mixer

dismounted

Angle through which Mixer

rotates in order to be

dismounted

Figure A

Position when Mixer

mounted

Figure B

INSTALL AMT-12 / AMT-20 / AMT-32 / AM-64 DRIVE UNITS

Model AMT-12 have 8 M8 threaded holes in the flange of

the mixer.

Model AMT-20 have 9 M8 threaded holes in the flange of

the mixer.

Models AMT-32 and AMT-64 are screwed (n.8xM12) in the

flange of the mixer and are not designed for quick removal

due to the size and weight of the drive unit.

The normal orientation of the mounting bolts is offset from

the central axis of the tank (see Figure B) so as to place

the axis of the mixer on the center line of the vessel.

1) Install the drive unit on the weld plate.

2) Align the holes in the flange of the drive unit to the threaded holes of the plate welding.

3) Tighten the screws in the welding plate and then tighten with a wrench.

DISASSEMBLY

IMPORTANT: Remove the mixer in the following order to avoid personal injury and damage to the equipment:

1- Drive unit

2- Mixing head

3- Static bearing

Dismount the drive unit following the mounting instructions in reverse order.

ATTENTION: Before dismounting the drive unit, ensure that:

- The circuit breaker is locked in the OFF position;

- The tank is empty, and at atmospheric pressure;

- The temperature of the vessel is less than 35°C, and all utilities connected are intercepted;

If you need to enter into the vessel, follow all local safety regulations before do it.

Be sure that you can handle the weight of the motor unit which can be heavy, use a lifting device for the larger

models.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 18 of 29

Aerre Inox s.r.l.

STORAGE

Interpose wood or other non-magnetic material between the floor and the equipment to avoid direct contact with

risk areas.

Do not store the unit in places exposed to weather or moisture.

For a period of storage exceeding 60 days, protect all mating surfaces, such as flanges and shaft on the drive

system with a suitable anti-oxidation product.

For storage periods longer than 6 months, rotate the external rotor head (magnetic outer drive head) on drive

system every 1-2 months.

RECYCLE and DISPOSAL

Recycle and dispose of equipment according to local laws and regulations.

OPERATION

CHECK and CALIBRATION

IMPORTANT: Do not starting AMT Mixer dry this can damage the bearing.

Make sure that the installation was successful.

Make sure that you are not working in the tank and never work next to the drive unit while it is connected to its

power source.

Make sure that a sufficient level of fluid covers the mixing head and the static bearing to ensure sufficient

lubrication, otherwise disassemble the drive unit to remove the mixing head and immerse it in clean water.

Reset the speed potentiometer leading / regulator to zero.

Start the mixer AMT at low speed (50 rpm) and carefully, slowly increase the speed.

Check that the direction of rotation of the mixing head is in a clockwise direction looking from above. If turned

counterclockwise, see troubleshooting and contact your electrician / maintenance.

Stop the mixer and check immediately if any signs of malfunction, abnormal noise, or smoke or smell.

The most important parameters (acceleration time, deceleration, speed max, min. Rpm) for the normal work

must be set case by case and depend on the specific application.

MAX RPM must not be adjusted to threshold / set too low, because the cleaning process requires relatively high

speeds in order to obtain the best results. The RPM MAX should not be regulated by exceeding the maximum

threshold as a function of max rpm specific, see the technical data of any size mixer.

STARTING MIXER

The mixing head is delivered clean 'factory', but not sterile. Before being used must undergo proper treatment of

cleaning with CIP systems.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 19 of 29

Aerre Inox s.r.l.

Fill the tank to the minimum level that it completely covers the mixing head and the bushing static to provide

sufficient lubrication to the bearing.

Check that the operating parameters of your control panel (if supplied) are correct for your device.

If you have not already planned your electrical panel, you simply perform a manual start at minimum speed.

Now, you can start AMT Mixer.

In extreme working conditions, can occur disconnection of the magnetic coupling, (ie the engine is running but

the mixing head does not rotate) if this happens, the bushing can be damaged by impact and be damaged. To

avoid any inconvenience, the acceleration time and the max. rpm must be adapted to the specific application.

make sure that foreign objects do not enter in the tank when the mixer is in rotation, this can affect the operation

of the device.

OPERATING NOTES

- Fill the tank with the liquid, start the mixer and then add solid material.

- Avoid the accumulation of large amounts of solids on the bottom of the container.

- Always make sure that the mixing head be always covered with liquid during operation in ATEX zone.

- If the mixer has run dry, start the mixer maintenance to check the bearing and consult the

troubleshooting section.

CLEANING in PLACE (CIP)

The AMT mixer model is designed to fit into cycles of cleaning (CIP). The groove in the mixing head are to

guarantee that the flow of the fluid is distributed through its internal parts.

To achieve this, the mixing head must be immersed and rotated at a speed determined minimum.

The result of the cleaning depends on many parameters such as: temperature, time, the chemical composition

of the detergent, mechanical condition, speed and type of product to be removed.

In the absence of a minimum level it is possible to use these alternative methods: washing heads static or rotary

or cleaning by immersion.

Make sure that the bearing are continuously lubricated (or submerged).

Cleaning usually consists of several cycles ie, pre-rinse, clean with base and / or acid detergent, rinsing after

cleaning the main acidic or basic and final rinse.

The exact operating conditions for CIP must be validated for each application.

These cleaning methods do not remove the magnetic particles, to achieve this mixing head must be removed

(after having removed the drive) and cleaned separately.

Magnetic particles can cause corrosion and damage also cause a decoupling and cause disconnection of the

mixing head and seriously damaging the tank.

Quality System

Certified ISO 9001

AMT Installation and User Guide Rev.8.doc

Page 20 of 29

Aerre Inox s.r.l.

STERILIZING in PLACE (SIP)

AMT mixer is perfect designed for sterilization in place (SIP) without any need for dismounting. Based on

individual conditions you can choose one of following methods.

ATTENTION: permanents magnets in the mixing head and the rotor are heat stable up to +225°C, NEVER

expose these parts therefore to higher temperature.

The drive unit and gearbox should not be exposed to ambient temperature above +70°C.

Ensure that mixing head must be covered with fluid before starting following sterilization.

Steam SIP

The vessel with the mixing head and the mounted drive unit are steam sterilized.

- Into heating phase, start the AMT mixer at a low speed and rotate a few seconds, approx. every five

minutes.

- When the sterilization temperature in the vessel has been reached, stop AMT mixer.

- To remove any condensation inside the mixing head, during sterilization rotate AMT mixer a few

seconds approx. every five minutes.

Super Hot Water SIP (SHW)

The vessel with the mixing head and the mounted drive unit are sterilized with super heated water.

- Fill the vessel with WFI (water for injection) to a suitable level.

- During heating sterilization and cooling AMT mixer should rotate. Vortexes (suction whirlpools) must not

arise, check this by water level and speed.

- During the emptying phase AMT mixer must not rotate.

Sterilization in Autoclave or Hot Air Oven

ATTENTION: Before dismounting the drive unit, ensure that:

- the main power switch is locked on a switch-off position;

- Be certain that you can handle the weight of the drive unit that may be heavy;

- use a lifting device for the larger models;

The vessel and the mixing head without drive unit is sterilized in an upright position in an autoclave or hot air

oven; otherwise the mixing head will slide off the static bearing. This will damage the mixing head, bearings and

vessel.

AUTOCLAVE: dismount drive unit. At least one pre-vacuum period must be used to eliminate air pockets. The

vessel with mixing head in place, are sterilized at a max. temperature of +140°C in the autoclave.

HOT AIR OVEN: dismount drive unit. The vessel with mixing head in place, are sterilized in hot air oven at a

max. temperature of +225°C.

This manual suits for next models

8

Table of contents

Popular Mixer manuals by other brands

Cleform

Cleform Gilsom Mixers 59016A Operator's guide & parts manual

Collomix

Collomix AOX-S operating instructions

Scarlett

Scarlett SC-HM40S01 instruction manual

Vonyx

Vonyx VMM-F Series instruction manual

Hamilton Beach

Hamilton Beach HMD300 Operation manual

Harbor Freight Tools

Harbor Freight Tools 92390 Assembly and operating instructions