8Operation Technical Manual

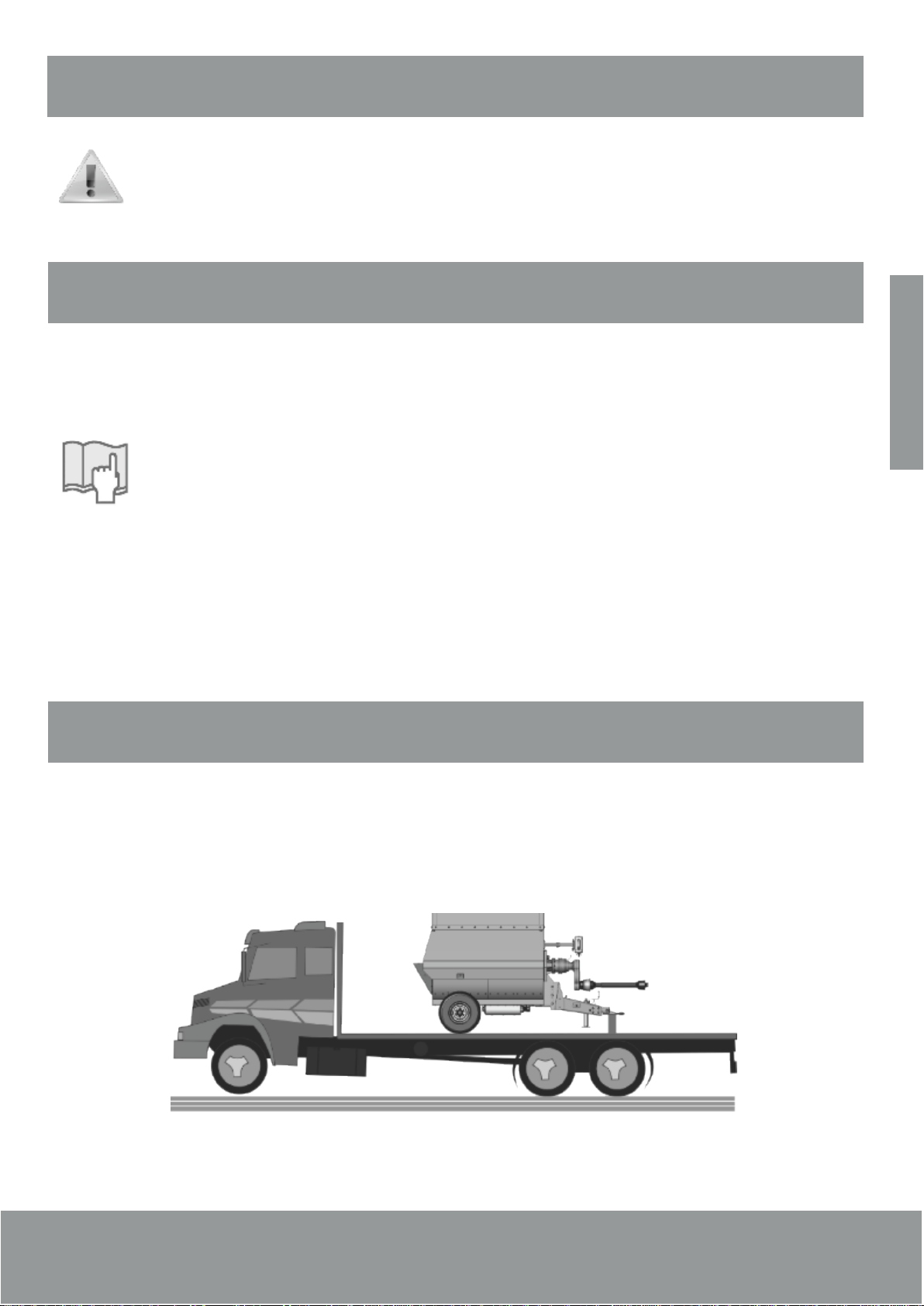

Elevation

Use only the four hooks found within the four corners of the upper

carriage compliance with the details of the scheme to the side and

performing operations with adequate equipment, depending on the

weightindicatedinthemanual.

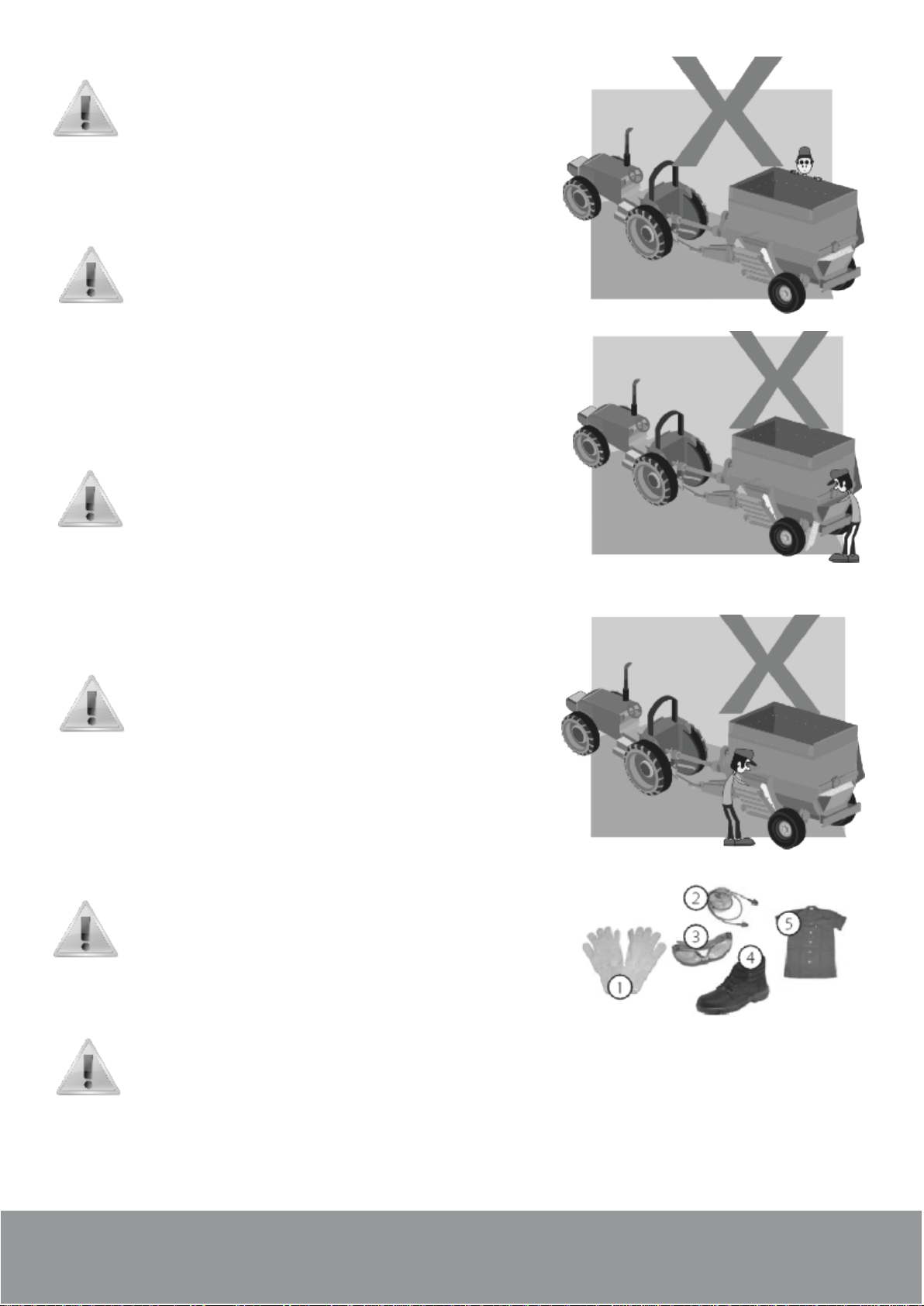

Safety Standards

-Theinstructionsinthismanualandthoseposteddirectlyonthemixer,

inparticularthoserelatingtosecurity,shouldbereadcarefully.

- Staff who makes any kind of intervention throughout the life cycle must have rigorous technical

expertise,specific trainingand experience andrecognized byspecific sectors wherethe equipmentis

installedandknowhowtousethenecessarytoolsforworkandprotectiveequipmentequipment(PPE)

appropriate according to D. Lgs. 626/94. Failure to observe these requirements may result in risks to

safetyandhealthofpeople.

- Use the mixer for the purposes specified by the manufacturer. The use of the mixer improperly can

causerisktosafetyandhealthofpeopleandeconomiclosses.

-Keepthemixerunitatitsmaximumefficiencybyfollowingthemaintenancescheduleprovided.Good

maintenance will get better performance, a work activity over a long and constant maintenance of

safetyitems.

- To perform maintenance work in areas difficult to access or dangerous, the technical precautions

havebeentakentosafetyforhimselfandforothersinaccordancewiththelawsofsafety.

- All maintenance, inspection and repairs must only be done by a technician, aware of the risks

involved. It is therefore necessary to predict the operating procedures for the entire machine, suitable

foradministrationofthehazardsthatcanbepresentedandmethodstopreventthem.Thecoachmust

alwaysworkwithgreatcare,payingcloseattentioninobservanceofsafetystandards.

- At work, use only clothing and / or appropriate personal protective devices listed in the instructions

providedbythemanufacturerandthoseprovidedforinlawsrelatingtosafety.

-Replacewornbyoriginalspareparts.Useoilsandgreasesrecommendedbythemanufacturer.

-Donotdumppollutingmaterialsintotheenvironment.Disposeofthelawsonthematter.

-Having madethe replacement ofthe lubricant, youshould proceedto clean thesurfaces ofthe mixer

unitandthefloorneartheareaof intervention.