Aertesi BREZZA DOUBLE Series User manual

Technical Manual

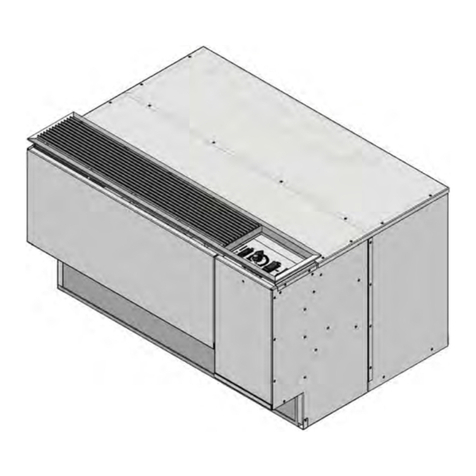

New Water Cassette

Series BREZZA DOUBLE

AERTESI srl Cassetta BREZZA DOUBLE Tecnical manual

AER.MT.I.BREDOPPIA.000.02.15 Pag.2

INDEX

1-INTRODUCTION………………………………………………………………………………………………………………………4

2- WORKING CONDITION LIMITS……………………………………………………………………………………….……….4

3- COANDA EFFECT…………………………………………………………………………………………………………………….4

4- KEY READING CODES………………………………………………………………………………………………………………5

5-TECHNICAL DETAILS………………………………………………………………………………………………………………..6

6-TECHNICAL DATA (AC motors)…………………………………………………………………………………………………8

6.1-Cassette with 3 rows coil............................................................................................................... 8

7-TECHNICAL DATA(EC motors)………………………………………………………………………………………………….9

7.1-Cassette with 3 rows coil............................................................................................................... 9

8- COIL TECNICAL DATA(AC motors)………………………………………..……………………………………………….10

8.1- Cassette with 1 or 2 rows coil ..................................................................................................... 10

9-TECHNICAL DATA OPTIONAL COILS (EC motor)………………………………………………………………………11

9.1- Cassette with1 or 2 rows coil ...................................................................................................... 11

10-DIMENSIONAL & WEIGHT…..……………………………………………………………………………………………….12

11-ACCESSORIES………………………………………………………………………………………………………………………13

11.1- Valves (V) and auxiliary tray (ADPB).......................................................................................... 13

11.2- Hose connecting valves (Flex2 and Flex4) .................................................................................. 15

11.3- Condensate drain pump Auxiliary (PSCC-BI) .............................................................................. 16

11.4- Speed motor control board....................................................................................................... 16

11.5- Flange for air delivery duct (FLMA) ........................................................................................... 19

11.6-Flange for external air intake (FLAE-FLAE2) ............................................................................... 19

12-Electrical wiring diagrams……………………………………………………………………………………………………20

12.1- Wiring diagram cassette with AC motor .................................................................................... 20

12.2-Wiring diagram cassette with EC motor ..................................................................................... 22

1-INTRODUCTION

The new Water Cassette Series units BREZZA are designed for air conditioning in residential and

commercial plants. The installation is indoor and not exposed to ice or extreme temperatures, dust-free

environment and not explosive materials. The manufacturer is not responsible in case of incorrect use.

The series BREZZA is proposed with traditional AC motors with three speeds and which EC motors with low

consumption. The table below shows the electric power saving that can be achieved with EC motors (at

constant working point of the machine).

2- WORKING CONDITION LIMITS

Electrical power supply

220 ÷ 240V / 50Hz

Inletcoil water temperature

5 ÷ 70°C

Return air temperature

10 ÷ 50°C

RH air intake

15 ÷ 70%

It is advisable to let work the Brezza Cassette at the above mentioned extremes limits of operation ONLY for

short periods, because the operation for long periods can reduce normal components.

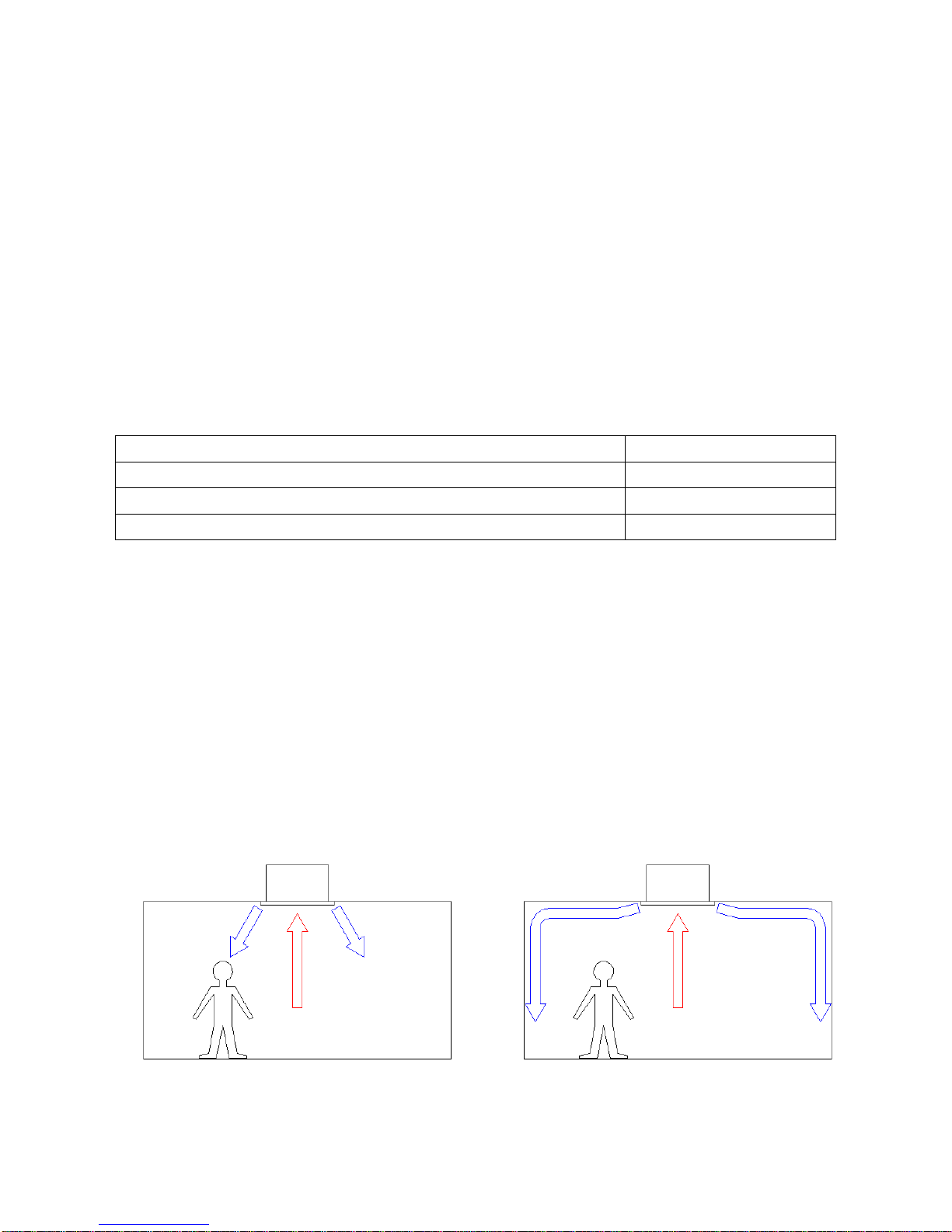

3- COANDA EFFECT

New cassette Series BREZZA has been developed to ensure a high comfort. In fact, the particular shape of

the panel as per the COANDA effect, avoids the annoying cold drafts (since ever the problem of fan-coil

cassettes).

The COANDA effect is the tendency of a fluid jet to follow the contour of a nearby surface. So the air flow

follows the ceiling, then fells nearly at the wall. Since the air speed at this point is very low, this does not

create discomfort to people.

Traditional Cassette Cassette with Coanda effect

In case where the ceiling is higher than 3m, accordingly there is the need to channel down the air flow,

Aertesi provides an accessory panel with adjustable flaps. So you can set manually, for each of the four

turns, the orientation of the flow: horizontal (with Coanda effect), or in vertical position.

Flaps on horizontal position (Coanda) Flaps on vertical position

4- KEY READING CODES

The standard version is with 3-rows coil (for versions 2 pipes) or 1 + 2 ranks (for versions 4 pipes), with fixed

blades in COANDA position. All other versions are optional.

5-TECHNICAL DETAILS

STRUCTURE: made on galvanized steel sheet, thickness 1.00mm. The robust design prevents the vibration

and it includes mounting brackets to the ceiling.

FRONTAL PANEL: painted plate thickness 0.8mm. The conformation of the baffles ensures a Coanda Effect

to the air flow output. As an accessory, you can have the adjustable deflectors to have the Coanda effect or

vertical airflow (or intermediate positions). The fresh design of the panel fits perfectly into any environment

and type of ceiling.

ACCESSIBILITY : the filter can be removed without any tools. The accessibility to internal components (fan

and condensate pump) is guaranteed by removing the front panel. Water connections, valves and electrical

panel are on the same side and thus you need only one inspection hatch in the ceiling.

FILTER: Class G1 (EN779), 6 mm thickness, made in polypropylene mesh.

FAN GROUP: The fan is made of reinforced plastic material (nylon PA6-25GF); it is backward curved blades,

directly coupled to the motor. The motor and fans are balanced after assembly to ensure, vibrations

absence. Motor is mounted on ball bearings without any maintenance.

The AC motor has three speed, degree of protection IP44, insulation class "B". Thermal protection

incorporated.

The EC motor is controlled 0-10V, IP54 protection, insulation class "B", noise emissions according to EN

61000-6-3 (civil environment), thermal motor protection and electronics, protection locked rotor.

COIL: made with copper pipe diameter 3/8 "and corrugated aluminum fins with high efficiency, with manual

air vent valve at the top. Nominal pressure PN10.

WATER TRAP: blower housing made of expanded polystyrene (EPP) with condensation molded plastic tray,

which ensures no water leakage even after a long use. The shape of the pan facilitates the outflow and

ensures minimum water stagnation.

INSULATION: cassette body insulated with cross-linked polyethylene foam 10 mm thick, class B-BL-s2d0

s1d0 according to EN13501-1. Front panel insulated with polyethylene thickness 3mm.

ELECTRICAL BOARD: made of galvanized steel plate and positioned on the same side of water

connections.

CONDENSATE DRAIN PUMP: centrifugal type, equipped with a double level float (on-off pump and alarm)

and check valve (to avoid the return of odors from the plughole and reduce the noise power). The maximum

head of the pump is 650mm, measured from the edge of the panel.

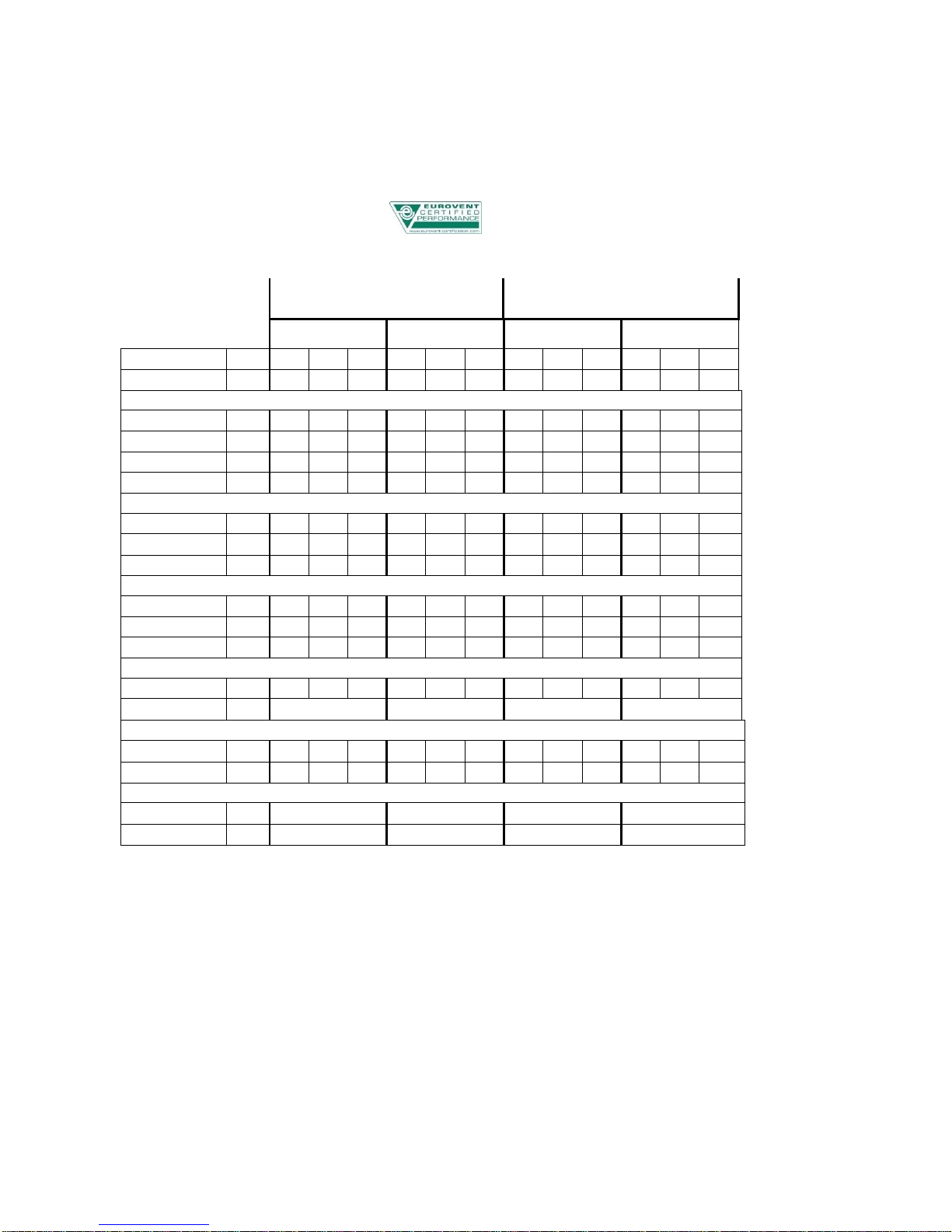

6-TECHNICAL DATA (AC motors)

6.1-Cassette with 3 rows coil

2 TUBI

4 TUBI

133

163

135

165

Speed(E)

min

med

max

min

med

max

min

med

max

min

med

max

Airflow

mc/h

560

800

1140

860

1260

1470

560

800

1140

860

1260

1470

COOLING –Air 27°C b.s. , 19°C b.u. –Input water temperature 7°C , output water temperature 12°C

Total capacity(E)

kW

4,11

5,51

7,46

5,88

8,10

9,16

3,52

4,75

6,23

5,00

6,69

7,47

Sens. capacity(E)

kW

2,94

4,00

5,30

4,25

5,72

6,44

2,57

3,37

4,36

3,58

4,68

5,20

Water flow

l/h

706

946

1279

1008

1389

1571

603

815

1069

859

1148

1281

Δp water(E)

kPa

3,3

5,6

9,8

6,3

11,3

14,1

3,8

6,4

10,5

7,0

12,0

14,6

HEATING –Air 20°C –inlet water temperature 50°C ,same for cooling flow

Capacity(E)

kW

4,79

6,50

8,71

6,91

9,44

10,66

-

-

-

-

-

-

Water flow

l/h

706

946

1279

1008

1389

1571

-

-

-

-

-

-

Δp water(E)

kPa

3,1

5,3

9,2

6,0

10,7

13,4

-

-

-

-

-

-

HEATING –Air 20°C - inlet water temperature 70°C , output water temperature 60°C

Capacity(E)

kW

-

-

-

-

-

-

5,25

6,69

8,47

7,03

8,96

9,90

Water flow

l/h

-

-

-

-

-

-

476

606

767

637

811

896

Δp water(E)

kPa

-

-

-

-

-

-

3,5

5,5

8,3

6,0

9,2

11,2

ELECTRIC MOTOR ABSORTION

Consumption(E)

W

60

76

100

108

144

174

60

76

100

108

144

174

Max absorption

A

0,46

0,80

0,46

0,80

SOUND DATA

Sound power(E)

dB(A)

39

46

56

53

63

66

39

46

56

53

63

66

Sound pressure

dB(A)

30

37

57

44

54

57

30

37

57

44

54

57

(E)= EUROVENTcertificated data

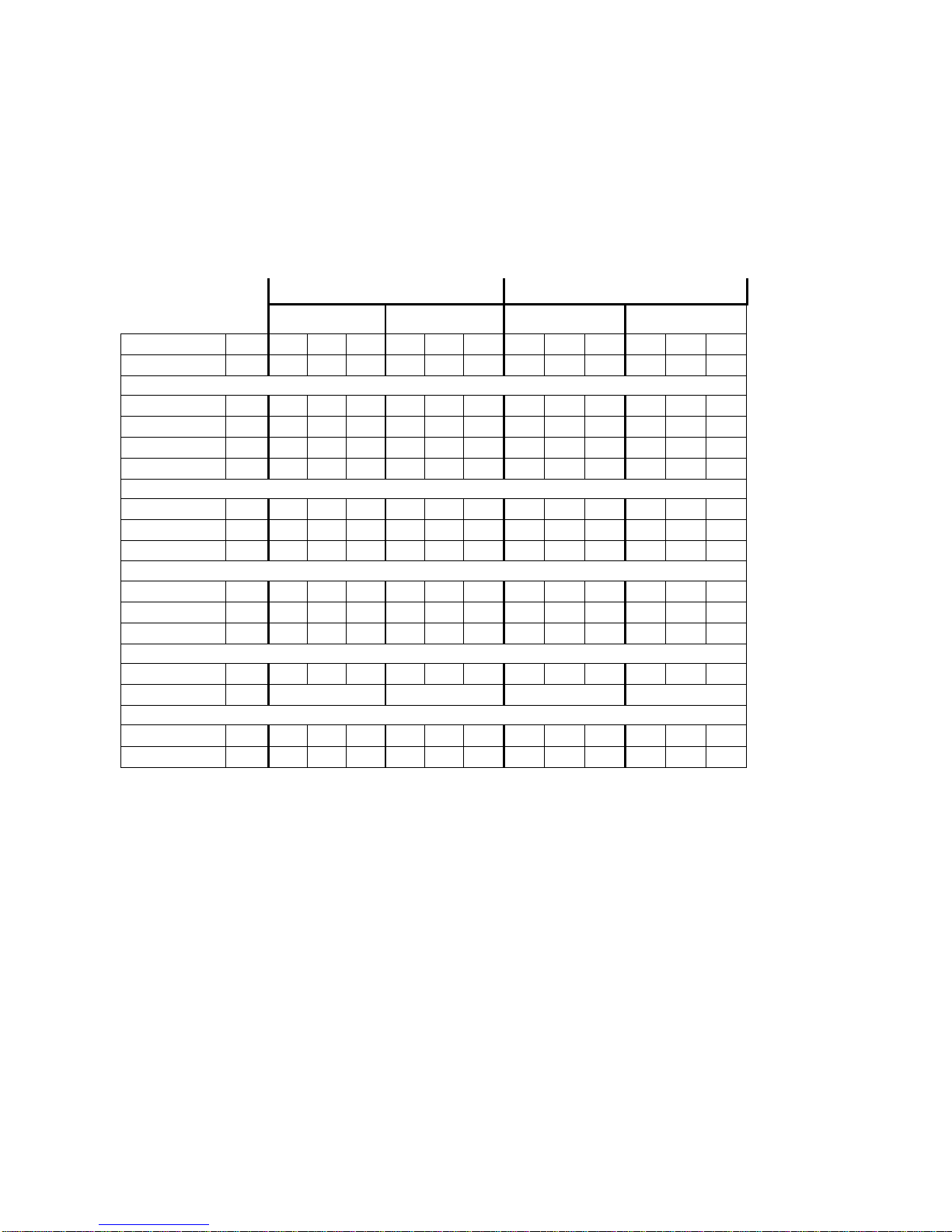

7-TECHNICAL DATA(EC motors)

7.1-Cassette with 3 rows coil

2 PIPES

4 PIPES

133

163

135

165

Speed(E)

4V

7V

10V

4V

7V

10V

4V

7V

10V

4V

7V

10V

Airflow

mc/h

410

760

1120

570

1050

1520

410

760

1120

570

1050

1520

COOLING –Air 27°C d.b. , 19°C w.b.. –inlet water temperature 7°C , output water temperature 12°C

Total capacity(E)

kW

3,11

5,28

7,35

4,17

6,96

9,42

2,61

4,56

6,13

3,58

5,83

7,66

Sens.capacity(E)

kW

2,19

3,85

5,22

2,99

4,95

6,60

1,98

3,25

4,29

2,61

4,09

5,35

Water flow

l/h

534

905

1260

716

1195

1616

448

783

1052

614

1001

1315

Δp water(E)

kPa

2,1

5,3

9,4

3,5

8,6

14,8

2,2

6,0

10,1

3,9

9,3

15,3

HEATING –Air 20°C –inlet water temperature 50°C , same for cooling flow

Capacity(E)

kW

3,60

6,24

8,57

4,87

8,12

10,95

-

-

-

-

-

-

Water flow

l/h

534

905

1260

716

1195

1616

-

-

-

-

-

-

Δp water(E)

kPa

1,8

4,9

9,0

3,3

8,2

14,2

-

-

-

-

-

-

HEATING –Air 20°C - inlet water temperature 70°C , output water temperature 60°C

Capacity(E)

kW

-

-

-

-

-

-

4,16

6,47

8,29

5,32

7,96

10,16

Water flow

l/h

-

-

-

-

-

-

377

586

751

481

721

919

Δp water(E)

kPa

-

-

-

-

-

-

2,2

5,1

8,1

3,5

7,4

11,7

ELECTRIC MOTOR ABSORTION

Consumption(E)

W

6

18

42

10

36

97

6

18

42

10

36

97

Max absorption

A

0,34

0,76

0,34

0,76

DATI SONORI

Sound power(E)

dB(A)

34

48

59

41

57

66

34

48

59

41

57

66

Sound pressure

dB(A)

25

39

50

32

48

57

25

39

50

32

48

57

ENERGY SAVING CLASS

FCEER (E)

A

A

A

A

FCCOP(E)

A

A

A

A

(E)= EUROVENT certificated data

8- OPTIONAL COIL TECNICAL DATA(AC motors)

8.1- Cassette with 1 or 2 rows coil

2 PIPES

4 PIPES

132

162

134

164

Speed

min

med

max

min

med

max

min

med

max

min

med

max

Airflow

mc/h

560

800

1140

860

1260

1470

560

800

1140

860

1260

1470

COOLING –Air 27°C d.b. , 19°C w.b.. –inlet water temperature 7°C , output water temperature 12°C

Total capacity

kW

3,37

4,53

5,94

4,80

6,39

7,12

2,28

2,94

3,73

3,12

3,99

4,40

Sens.capacity

kW

2,49

3,26

4,20

3,44

4,52

5,02

1,67

2,14

2,67

2,22

2,86

3,11

Water flow

l/h

578

778

1019

824

1096

1221

391

504

640

535

684

754

Δp water

kPa

3,2

5,5

9,0

6,1

10,2

12,4

2,9

4,5

6,9

4,9

7,8

9,3

HEATING –Air 20°C –inlet water temperature 50°C , same for cooling flow

Capacity

kW

4,12

5,45

7,10

5,76

7,63

8,53

-

-

-

-

-

-

Water flow

l/h

578

778

1019

824

1096

1221

-

-

-

-

-

-

Δp water

kPa

3,0

5,2

8,6

5,9

9,8

12,0

-

-

-

-

-

-

HEATING –Air 20°C - inlet water temperature 70°C , output water temperature 60°C

Capacity

kW

-

-

-

-

-

-

5,25

6,69

8,47

7,03

8,96

9,90

Water flow

l/h

-

-

-

-

-

-

476

606

767

637

811

896

Δp water

kPa

-

-

-

-

-

-

3,5

5,5

8,3

6,0

9,2

11,2

ELECTRIC MOTOR ABSORTION

Consumption

W

60

76

100

108

144

174

60

76

100

108

144

174

Max absorption

A

0,46

0,80

0,46

0,80

SOUND DATA

Sound power

dB(A)

39

46

56

53

63

66

39

46

56

53

63

66

Sound pressure

dB(A)

30

37

57

44

54

57

30

37

57

44

54

57

9-TECHNICAL DATA OPTIONAL COILS (EC motor)

9.1- Cassette with1 or 2 rows coil

2 PIPES

4 PIPES

132

162

134

164

Speed

4V

7V

10V

4V

7V

10V

4V

7V

10V

4V

7V

10V

Airflow

mc/h

410

760

1120

570

1050

1520

410

760

1120

570

1050

1520

COOLING –Air 27°C d.b. , 19°C w.b.. –inlet water temperature 7°C , output water temperature 12°C

Total capacity

kW

2,46

4,38

5,85

3,43

5,57

7,30

1,75

2,86

3,68

2,32

3,53

4,51

Sens.capacity

kW

1,92

3,13

4,14

2,52

3,96

5,12

1,34

2,07

2,64

1,69

2,50

3,19

Water flow

l/h

423

751

1004

588

956

1253

299

491

632

398

606

774

Δp water

kPa

1,8

5,2

8,7

3,3

7,9

13,0

1,7

4,3

6,8

3,0

6,2

9,8

HEATING –Air 20°C –inlet water temperature 50°C , same for cooling flow

Capacity

kW

3,16

5,25

7,00

4,18

6,65

8,73

-

-

-

-

-

-

Water flow

l/h

423

751

1004

588

956

1253

-

-

-

-

-

-

Δp water

kPa

1,7

4,8

8,3

3,1

7,5

12,5

-

-

-

-

-

-

HEATING –Air 20°C - inlet water temperature 70°C , output water temperature 60°C

Capacity

kW

-

-

-

-

-

-

4,16

6,47

8,29

5,32

7,96

10,16

Water flow

l/h

-

-

-

-

-

-

377

586

751

481

721

919

Δp water

kPa

-

-

-

-

-

-

2,2

5,1

8,1

3,5

7,4

11,7

ELECTRIC MOTOR ABSORTION

Consumption

W

6

18

42

10

36

97

6

18

42

10

36

97

Max absorption

A

0,34

0,76

0,34

0,76

SOUND DATA

Sound power

dB(A)

34

48

59

41

57

66

34

48

59

41

57

66

Sound pressure

dB(A)

25

39

50

32

48

57

25

39

50

32

48

57

ENERGY SAVING CLASS

FCEER

A

A

A

B

FCCOP

A

B

A

A

10-DIMENSIONAL & DRAWINGS

132/162

133/163

134/164

135/165

Unit gross Weight

kg

56

60

56

60

Internal volume main coil

litri

2,6

4,0

2,8

2,8

Internal volume auxiliary coil

litri

-

-

1,2

1,2

1

Batteria principale IN

1/2"

2

Batteria principale OUT

1/2"

3

Batteria ausiliaria IN

1/2"

4

Batteria ausiliaria OUT

1/2"

5

Scarico condensa

d.12

11-ACCESSORIES

Accessories available are:

HYDRAULIC ACCESSORIES

A/K/C

V22

V22 2-way valve ON-OFF 230V

A/K

V42

V42 2-way valve ON-OFF for 4 pipe

A/K

V23

V23 3-way valve ON-OFF 230V

A/K

V43

V43 3-way valve ON-OFF 230V for 4 pipe

A/K

V22M

V22M Valve 2-way modulating 0-10V

A/K

V42M

V42M Valve 2-way modulating 0-10V for 4 pipe

A/K

V23M

V23M valve 3 way modulating 0-10V

A/K

V43M

V43M valve 3 way modulating 0-10V for 4 pipe

A/K

ADPB

ADPB Water trap auxiliary (supplied as standard)

K

FLEX2

Hoses for parallel connection valves (2 pipes)

K

FLEX4

Hoses for parallel connection valves (4 pipes)

K

PSCC-BI

PSCC-BI Auxiliary Condensate drain pump

A

ELETTRICAL ACCESSORIES

TR24

Transformer 230Vac-24VAC, 20VA for modulating valve

A

SC3

3-speed motor control board (for EC motor)

A

AERAULIC ACCESSORIES

FLMA

Flange for discharge air duct

B

FLAE

Flange for fresh air intake

B

A = accessory supplied mounted on the base;

K = accessory kit supplied unassembled;

B = accessory supplied assembled, but not mounted on the base

11.1- Valves (V) and auxiliary tray (ADPB)

We recommend the use of motorized valves, to prevent the formation of condensation on the surface of the

unit when the fan is stopped.

Valves can be supplied to the unit assembled or in kit (disassembled parts). All codes kits include two

valves, one for each battery in double cassette. The drain pan is supplied as standard with the cassette,

without extra-price (ADPB)

The cassette have two double 1200x600 kit valves, one for the right battery and one for the left battery. Both

kits valves are connected in parallel, the aim is a kit consisting of hoses and TEE brass (see paragraph on

accessory Flex2 - Flex4).

OUT IN OUT IN

2 pipes (hot/cold) 2 pipes (not present)

4 pipes (cold) 4 pipes (hot)

Valves group and auxiliary tray (cassette double 1200x600)

Heating/cooling valve (2 pipes)

Valve cooling (4 pipes)

Hot valve (only

4 pipes)

Heating/cooling valve (2

pipes)

Valve cooling (4 pipes)

Valve cooling (4 pipes)

Hot valve (only

4 pipes)

Auxiliary drain pan

VALVES FOR MAIN COILS

---

132-133-134-135-162-

163-164-165

VALVES FOR AUXILIARY COILS

134-135-164-165

---

GENERAL FEATURES

Size connections

1/2"

3/4"

Kv (valvola 2 vie)

1,7

2,5

Kv (valvola 3 vie, via diritta)

1,7

2,5

Kv (valvola 3 vie, by-pass)

1,2

1,6

Max differential pressure

2,0bar

1,0bar

Nominal pressure

16bar

Nominal pressure

4-110°C

ON-OFF ACTUATOR

Power supply

230V-50Hz (24V-50Hz on request)

Power consumption

2,5W

Running time

180s

Feature (valve + actuator) N.C.

N.C. (usually closed)

Protection

IP44

MODULAT ACTUATOR

Electrical supply

24V-50Hz

Power consumption

1,5W

Travel time

8S

Control signal

0-10V

Impedance control signal

100k

Protection

IP43

11.2- Hose connecting valves (Flex2 and Flex4)

To facilitate the parallel connection of the valves, described in the previous paragraph, you can use the

accessory Flex2 (for 2-pipe systems) and Flex4 (for 4-pipe systems). The kit consists of hoses with braided

stainless steel (with 3/4 "for the valve) and brass TEE to connect the pipes from 3/4". You can also directly

connect the hoses to the coil, inserting an adaptor nipple 1/2 "-3/4" (nipple not supplied).

BRASS TEE

FLEX INOX

Accessory for flexible double cassette 1200x600

11.3- Condensate drain pump Auxiliary (PSCC-BI)

The supplementary condensate drain pump is supplied assembled outside of the box, at the side of the

drainage pipe. Then must provide for the possibility of inspection also on this side.

Maximum water flow

20 l/h

Maximum discharge height

10m (4l/h)

Sound pressure 1m

28dB(A)

Supply

230V –50/60Hz

Micro switch alarm

NC 8° resistivi 250V

Thermal Protection

90°C (riarmo automatico)

Protection

IP54

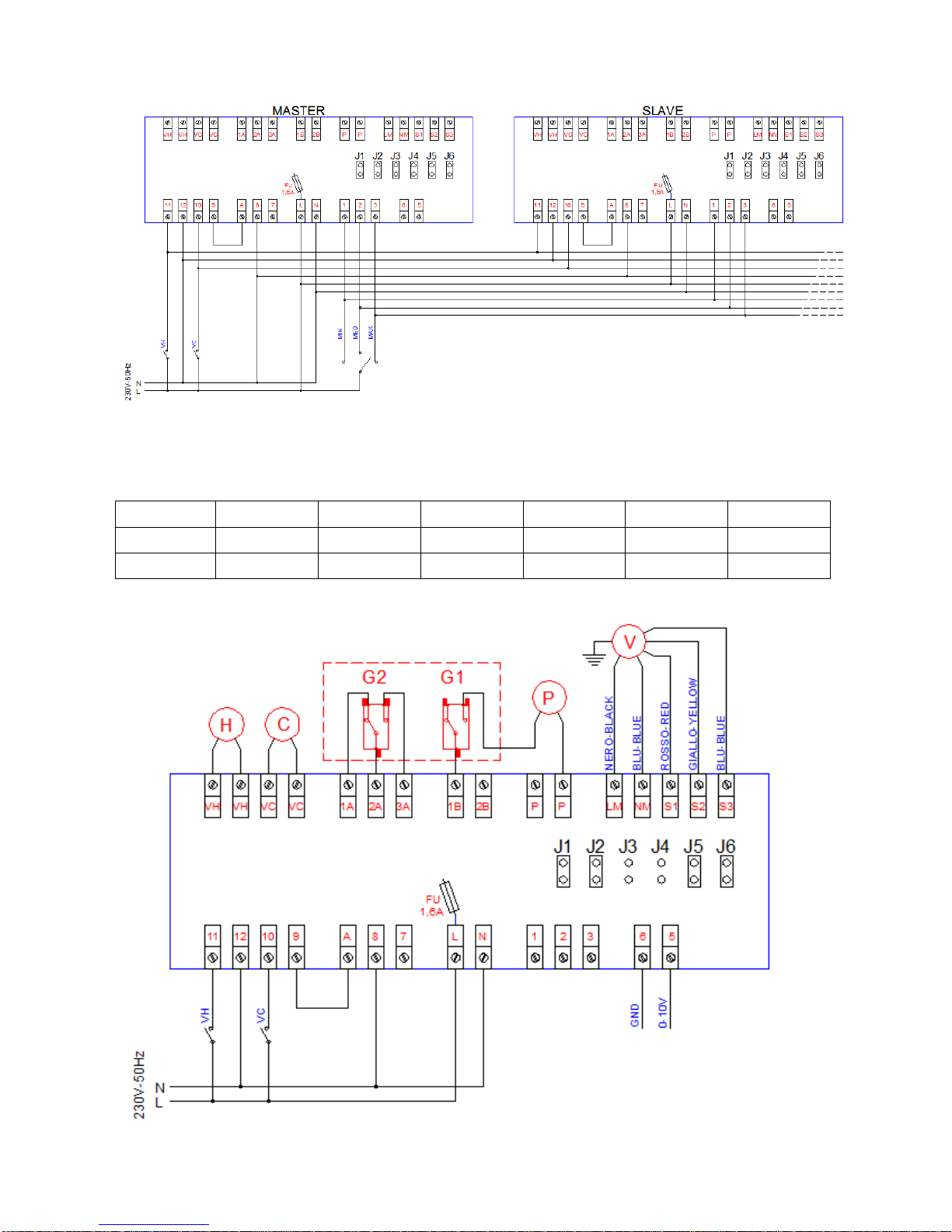

11.4- Speed motor control board SC3

The 3-speed motor board allows you to control the EC motor with a traditional thermostat 3-speed or with a

thermostat with 0-10V signal. With this accessory, it is also possible to control more than one unit with a

single thermostat (not addressable master-slave).

For each double cassette, you need two cards SC3 (to be considered as a slave of the other).

CONTROL FROM EXTERNAL THERMOSTAT

VH

Contact on-off valve heating (4 tubes)

VC

Contact on-off valve cooling (2-4 tubes)

MIN

Minimum fan speed

MED

Minimum fan speed

MAX

Maximum speed fan

GND

Reference signal 0-10V

0-10V

0-10V signal for motor control

ELECTRICAL CONNECTIONS FOR 3 SPEEDSCONTROL : you must close the jumpers J3 and J4; jumpers

J1, J2, J5, J6 are reserved to factory settings and should not be changed.

Model

J1

J2

J3

J4

J5

J6

7x-13x

opened

closed

closed

closed

closed

closed

9x-16x

closed

opened

closed

closed

closed

closed

ELECTRICAL CONNECTIONS FOR CONTROL SIGNAL 0-10V: you must open the jumpers J3 and J4;

jumpers J1, J2, J5, J6 are reserved to factory settings and should not be changed.

Model

J1

J2

J3

J4

J5

J6

7x-13x

closed

closed

opened

opened

opened

opened

9x-16x

closed

closed

opened

opened

closed

opened

11.5- Flange for air delivery duct (FLMA)

You can connect up to 3 throws ducted through D.160 collars. The available prevalence is a function of the

number of collars connected and the air flow rate. Collars positions are represented in the figure below.

11.6- Flange for external air intake (FLAE-FLAE2)

It is possible to connect an external air intake via a D.100 collar. The maximum flow of outside air is

100MC/h. The outside air has to be treated, filtered and must not be at a low temperature.

The flange for fresh air intake has FLAE code or FLAE2 code. These have different installation points on the

unit, as in the drawing below.

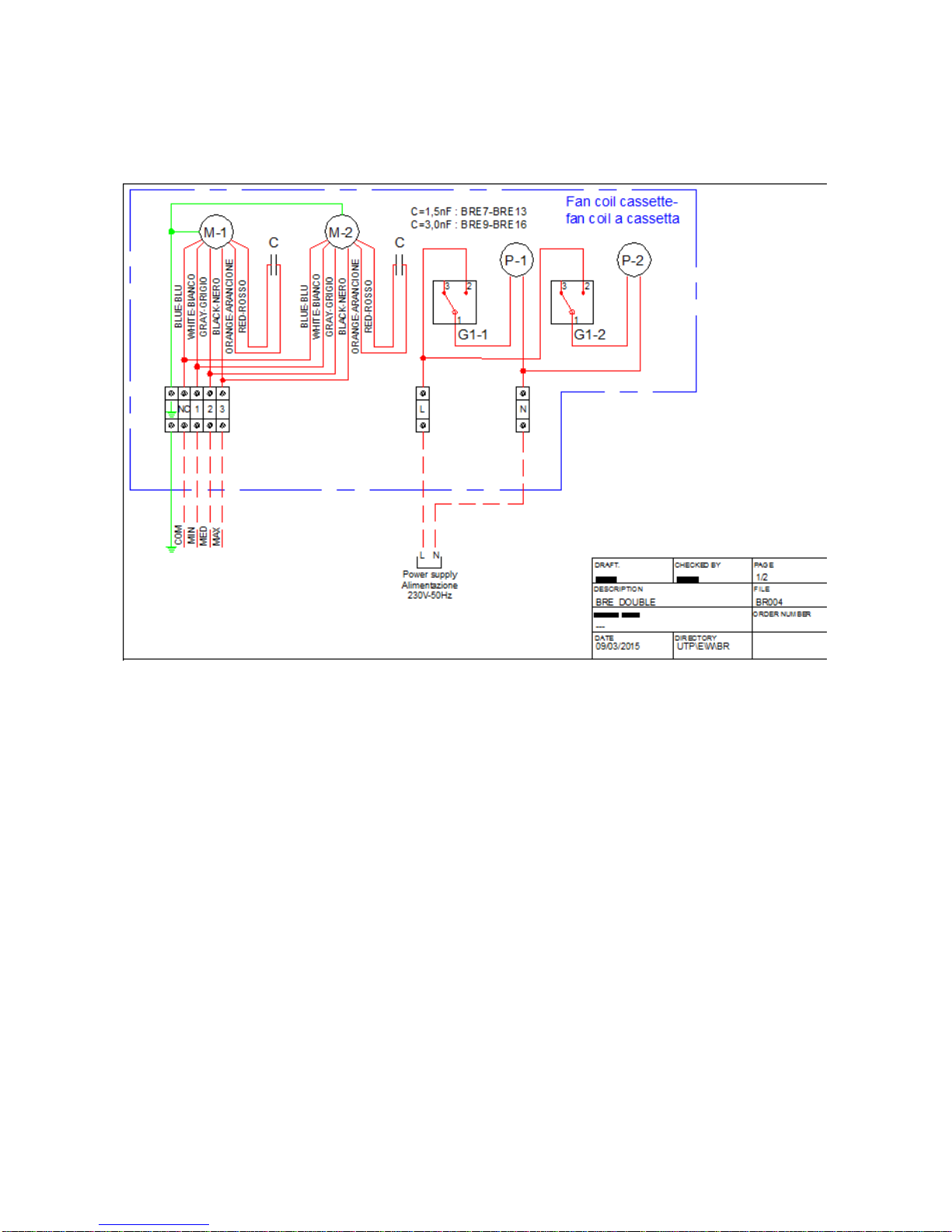

12-Electrical wiring diagrams

12.1- Wiring diagram cassette with AC motor

Table of contents

Other Aertesi Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Soleus Air

Soleus Air KC-15U owner's manual

Retro Aire

Retro Aire R30C Installation, operation & maintenance manual

CLIMAVENETA

CLIMAVENETA a-CHD U-2T 606+2209 OPERATING AND INSTALLATION Manual

GE

GE AEC14 Owner's manual and installation instructions

Rotenso

Rotenso MIRAI W user manual

McQuay

McQuay MCK020A Technical manual