AerWay AWATS-100-AG-4 Owner's manual

AWATSTOPDRESSSEEDER

XL‐AW75653RevC

OWNER/OPERATOR

MANUAL

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

Contents

Page

Introducon

2

WarrantyProcess

SerialNumberLogic

PartNumberLogic

AerWayWarranty

OperatorSafetyInstrucons

RecommendedMaintenance

SafetyandWarningDecals

ShaerneReplacement

OperangInstrucons

CommonParts

TorqueChart

AWATSConcreteBallasng/Specificaons

SAF‐HollandCompanies/AerWayaachments

…..………………………………………………………………………………………………………………………………...…….3

…………………………………………………………………………………………………………………………..……….4

……………………………………………………………………………………………………………………..….…….4

……………………………………………………………………………………………………………………..…………….5

………………………………………………………………………………………………………….……….7

………………………………………………………………………………………………………..….…10

……………………………………………………………………………………………………………….…….8

………………………………………………………………………………………………………..……….12‐13

…………………………………………………………………………………………………………….……..………9

…………………………………………………………………………………………………………..………………..……6

……………………………………………….…………………..…………………….11

……………………………………………………………..………………….….17

………………………………………………………………………………………………………………………………..……….16

…………………………………………………………………………………………………………………………..…….14‐15

SAF-HOLLAND Canada Limited - Norwich Facility

20 Phebe St., Norwich, Ontario N0J 1P0

Tel: 1-519-863-3414 · Fax: 1-519-863-2398

SAF-HOLLAND Canada Limited - Surrey Facility

17909 Roan Place, Surrey, B.C. V3S 5K1

Tel: 1-800-457-8310 · Fax: 1-604-574-0244

SAF-HOLLAND USA Inc. - Texas Facility

1301 Martinez Lane, Wylie, Texas 75098

Tel: 1-800-457-8310

1-800-457-8310

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

Introducon

Introducon

DearCustomer:WelcometotheAerWayfamily.

TheAerWayisdesigned,manufacturedandsoldbytheSAF‐HOLLANDGroupofCompanies.TheSAF‐

HOLLANDGroupisaworldwideorganizaonwithmanufacturingfaciliesinNorthAmerica,andaround

theglobe.

FarmersoneveryconnentintheworldnowbenefitfromthepatentedAerWay’suniqueabilityto

shaerthesoilvercallyandhorizontallyasittwistsitswaythroughtheground.

TheSAF‐HollandGroupwelcomesyoutotheworldwideAerWayfamilyofsasfiedusers.

YournewAerWayisdesignedtomeetyouragriculturalconservaonllageandaeraonrequirements.

Itseaseofoperaonandlowmaintenancerequirementswillgiveyoumanyyearsoftroublefreeopera‐

on.

Makecertainthatyoureadandunderstandtheimportantinstruconsforassembly,adjustments,opera‐

onandmaintenancecontainedinthismanual.Ifthereareanyinstruconsthatyoudonotfullyunder‐

stand,contacteitheryourdealerorSAF‐HOLLANDpersonnelforclarificaonpriortousingtheunit.

Wheninneedofreplacementparts,pleaseinformyourAerWaydealerofthemodelandserialnumberof

yourAerWay.Theserialnumberisstampedonthetopsurfaceofthecrosstubeonthemainframe.

RegularpreventavemaintenancewillkeepyourAerWayinproperoperangcondion,andprovideyou

withmanyyearsofreliable,troublefreeservice.

Shouldyourequirefurtherclarificaonorassistance,pleasecontactyourlocalAerWaydealeroroneof

theAerWayinformaonlocaonslistedonthepage17.

DEALERRESPONSIBILITY

Beforepunganewimplementintoservice,thedealermustreviewandinstructthecustomeronall

itemslistedonthePre‐DeliveryInspeconandWarrantyRegistraonForm(XL‐AW‐N‐68676‐A).Thisin‐

cludesinstruconsonthecomponentsandsafeoperaonofthemachine.Boththedealerandowner

mustsigntheformtocerfythatthelistwascompletedandtoverifythesaleandin‐servicedateforthe

machine.ThisinformaonisimportantintheeventofaWarrantyClaimwithintheapplicablewarranty

term,wherethein‐servicedateandvalidproofofpurchaseinformaonwillberequired.Complianceto

thisrequestwillhelpidenfyandexpeditetheclaimprocess.

TheDealermustreturnasignedcopyofthePre‐DeliveryInspeconandWarrantyRegistraonForm

(XL‐AW‐N‐68676‐A)toSAF‐HOLLANDtoensurethatpre‐deliveryobligaonshavebeenmet.

3

Warranty

WarrantyProcess

Intheeventofapotenalwarrantyclaim,besuretoidenfyandrecordtheAerWayModelNumber

(example:AWST150‐ALX3‐CCT)andSerialNumber(example:92093650001).Theenduserorservicing

dealershouldcompletetheCustomerServiceRequestform(XL‐AW‐N‐74971‐A),shippedwiththismanu‐

al,andFaxorMailacopytoyournearestSAF‐HOLLAND/AerWaylocaonlistedonpage17.

SAF‐HOLLAND’spolicyistoreviewallwarrantyclaimsandapplicableinformaonpriortotheprocessing

ofthatclaim.IfpartsarerequiredtobereturnedtoaSAF‐Hollandlocaonforinspeconandanalysis,a

returnnumberwillbeassigned.Thisnumbermustbeidenfiedonthepart(s)andtheshippingpaper

work.Claimswillberesolvedinamelymanner,onceallinformaonisprovidedandthepartsorprod‐

ucthavebeeninspected.

Ifreplacementpart(s)orproductisrequiredimmediately,contactyourlocalAerWaydealeroroneofthe

fourAerWaySAF‐HOLLANDlocaonslistedonpage2.Thepart(s)orproductwillbeexpeditedtotheend

userandinvoiced.Ifthewarrantyclaimisaccepted,theaccountwillbecreditedaccordingly.

SerialNumberLogic

PPYYDDDNNNNAWST150‐ALX3‐CCT

PP‐Plant:

YY‐Year:

DDD‐DayofYear:

NNNN‐Sequenalnumber

Norwich,Ontario,Canada‐92

2009‐09

2010‐10

Jan15‐015

Dec31‐365(nonleapyear)

(Generatedeachdaystarngat0001)

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

4

Warranty

AerWayWarranty

SAF‐HOLLANDwarranesallAerWayproductsmanufacturedbyit,whenproperlyappliedandinstalled,

tobefreefromdefectsinmaterialandworkmanshipundernormaluseandserviceforaperiodofone(1)

yearfromthedateofmanufacture.

Thiswarrantyisvoidwithrespecttoanyproductwhichhasbeenalteredfromitsmanufacturedcondi‐

on,suchasintenonalmodificaon,accident,corrosion,misuse,failuretoprovidenecessaryandrea‐

sonablemaintenanceandisexclusiveofnormalwear.Thiswarrantydoesnotcovernewearorbreak‐

ageduetounfavorablesoilcondions.

IfanyAerWayorAerWaycomponentpartisfoundtohaveadefectinmaterialorworkmanship,SAF‐

HOLLANDwillcoverthecosttorepairorreplacetheproductorpart.SAF‐HOLLANDwillprovidearea‐

sonableallowanceforremoval,andrepairorreplacement,andwillprovidepartsorreimbursementat

theacquisioncost,providedthatthisdoesnotexceedthesuggestedamount.

AllproductorpartscoveredbythiswarrantymustbemadeavailabletoSAF‐HOLLANDand/orreturned

forreviewandevaluaon.AuthorizaonfromSAF‐HOLLANDmustbeobtainedpriortoreturningany

productorparts,withfreightchargesprepaid.

SAF‐HOLLANDshallnotbeliable,inanyevent,forproximate,consequenal,specialorotherdamages,

including,butnotlimitedto,damagesforlossofproducon,lossofprofit,lossofopportunity,orinjury

topersonsorpropertyarisingoutofanybreachofthiswarranty.

Thiswarrantydoesnotsuggestnorimplysuitabilityforanyparcularapplicaon,norexpectedlifespan

oftheproductinanyparcularway.

THEREARENOWARRANTIES,EXPRESSEDORIMPLIED,INCLUDINGTHEWARRANTYOFMERCHANTABIL‐

ITY,WARRANTYOFFITNESSFORAPARTICULARPURPOSE,ORANYOTHERIMPLIEDWARRANTYARISING

BYSTATUE,COURSEOFDEALINGSORUSAGEOFTRADE,EXTENDINGBEYONDTHATSETFORTHABOVE.

ProtectyourInvestment!RemembertoreturnyourWarrantyRegistraonCard.

Pleasefillintheimportantinformaonbelow:

MN:

SN:

DP‐

UN:

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility5

PartNumberLogic

AWA‐ 100‐ AG‐ 4

TINEQUANTITYCODE

TINESPACINGCODE

3‐Threenesperrow(3‐TineStars)

4‐Fournesperrow(4‐TineStars)

‐ 7.5”spacingbetweennesonrollers

(DASH)

‐ 10”spacingbetweennesonrollersX

TINETYPECODE

‐ 8”AgriculturalShaernesAG

‐ 7”AgriculturalShaernesA7

WIDTHCODE

‐ 10footworkingwidth100

BEARINGCODE

‐ 50mmpillowblockbearings

(DASH)

PRODUCTGROUPCODE

‐ AERATIONTOPDRESSSEEDERAWATS

‐ LeafShaernesLE

TS

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

6

PartNumber

‐ HC

CAPACITYCODE

(BLANK)‐ StandardCapacity

HC‐HighCapacity

WS–FTR!

AcarefuloperatoristhebestinsuranceagainstanAccident.

CAUTION:beforeoperanganyequipment,readandunderstandthismanual

1.Donotwearloosefingclothingthatmaycatchonmovingparts

2.Useextremecarewhenmakingadjustments

3.Alwaysusethepropertoolsorequipmentforthejobathand.

4.WhenworkingunderoraroundtheAerWay,ensuretheframeandnesaresupportedsafelyandse‐

curely.

5.Ensurethatalltools,partsandmaintenanceequipmentareclearoftheAerWayaerservicing

6.Extremecauonshouldbeexercisedwhenoperangclosetoditches,fenceoronhillsides.

CAUTION:Turnoffallmachinery.

DANGER:AerWaynesaresharpand,ifcarelesslyhandledorimproperlyused,

cancauseseriousinjuryordeath.

7.Noridersshouldbepermiedonthetractor.NeverallowanyonetorideontheAerWayimplement

atanyme.

8.DonotaempttoremoveobstruconsorcleardebriswhiletheAerWayisinmoon.

9.Hands,feet,clothingandotherobjectsmustbekeptawayfromallmovingparts.

10.Warningandinformaonsignspostedprovideimportantinformaonforsafeoperaon;theyshould

notberemoved.

11.Observethesafetyinstruconsgivenbythemanufacturerofotherequipmentaached.

12.Workonlywithsafeaccess,e.g.HoldersandHookonLadders.

13.WhennotinusetheAerWay3‐Pointmodelshouldhavethejacklegsextendeddownandpinnedwith

thesafetyclippinsengaged.Thiswillpreventtheimplementfromppingwhendetachedfromthe

tractor.

SIT

14.Forpulltypeunits,alwaysplacetheAerWayinthe“transportposion”whenmovingextendeddis‐

tances.(Engagemanualtransportlockifsoequipped.)

15.Thetractorused,forpropertransportaon,shouldbeequalinsizeandhorsepowertotheunitused

forfieldoperaons.

16.Travelatareasonablespeed.Thiswillallowtheoperatortomaintaincompletecontrolofthetractor

andimplementatallmes.Donotexceed15mph(24km/h).

17.AerWaytransportersareonlyintendedforoffroadoperaon.

OperatorSafetyInstrucons

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility7

Safety

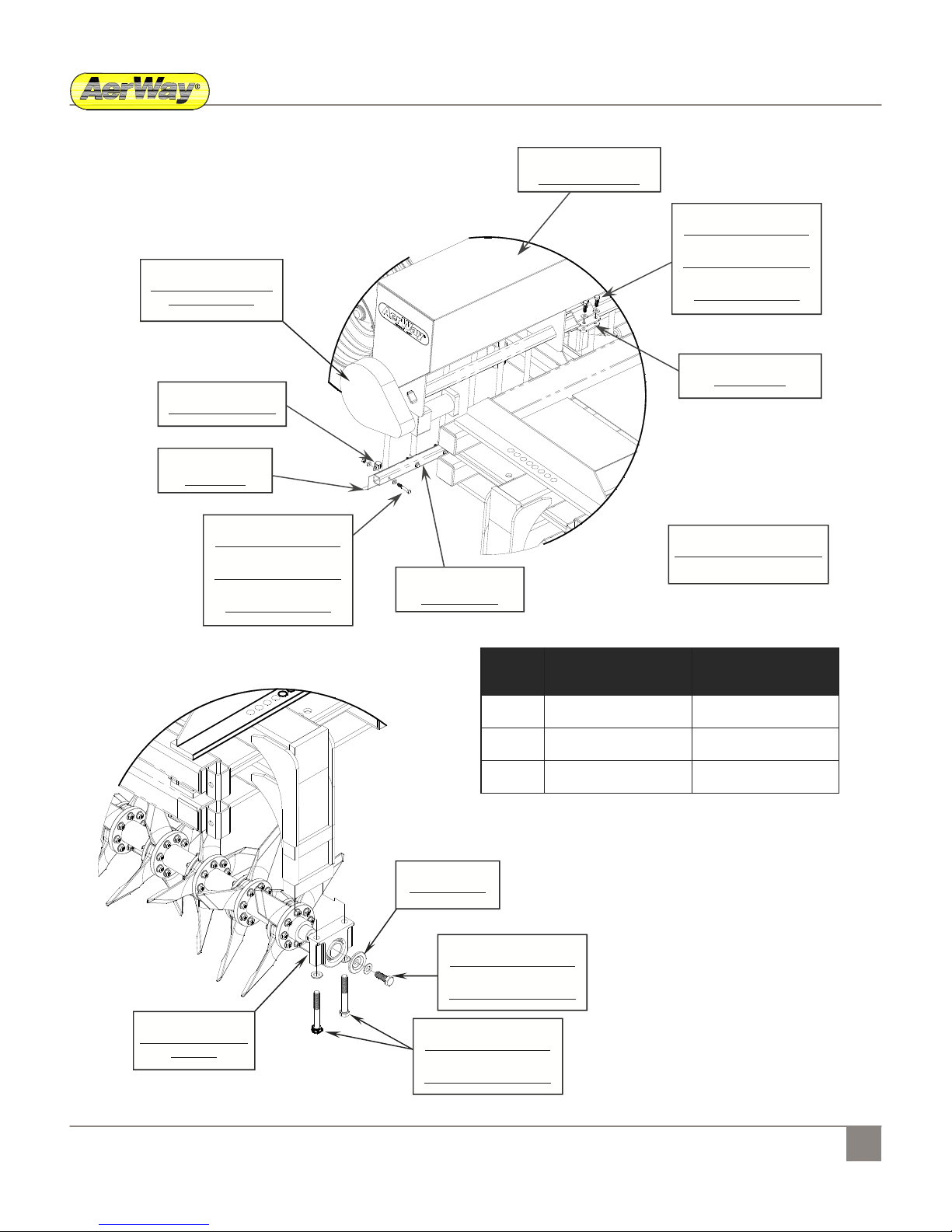

SafetyandWarningDecals

REARVIEWFRONTVIEW

SIDEVIEW

4

2

3

Thesedecalsmustbeinstalledandkeptvisibleandlegible.

Failuretoinstalldecalsorpainngoverthemcouldresultinunsafeoperaon.

ITEMNUMBER1234

DESCRIPTIONORANGE

REFLECTIVETAPE

RED

REFLECTIVETAPE

ROTATING

TINESDECAL

CAUTION

DECAL

PARTNUMBERXB‐56515XB‐56514XB‐64229XB‐64228

AWS/AWXQTY:2QTY:2QTY:2QTY:1

1

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

8

Safety

1.CompletelyretractsupportlegsaerliingtheAerWayusingthetractorhydraulicsystem.

2.LowertheAerWaytothegroundtoengagethenesintotheground.Addballasttotheweighttray

oftheAerWayunlthedesireddepthofnepenetraonintothegroundisachieved.Thesoiltype,

moisturecontentandtheamountofcompaconpresentwilldeterminetheamountoftheballast

weightrequired.Maximum700poundsperfootofAerWaywidth.

3.Theweightusedasballastmustbeproperlyfiedandsecuredtotheframe.

4.Withthenesengagedintothegroundatfullworkingdepth;adjustthetoplinkposionunlthe

AerWayframeisparalleltotheground.

5.Excessivestonycondionscouldresultinneandrollerdamage.Inthiscaseitmaybenecessaryto

reducetheballast.

6.Drivethetractoratspeedswhicharesafe(tractorstability&steeringabilityismaintained)andcom‐

fortable.

CAUTION:Excessivetractorspeedorradicaloperaonwhenturningcanendangervehicle

operaonandoperatorsafety.

7.Severelycompactedtrafficareasmayhavetobeaeratedseveralmes.

8.Formoreaggressiveculvaon,adjusttherollerstoamoreaggressiveswingangle.Therearefivepo‐

sionstochoosefromtosuityourindividualrequirements.NeveroperateyourAerWaywithdiffer‐

entswinganglesengsontheLHandRHswingarms.

OperangInstrucons

TOPLINKADJUSTINGHOLES

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility9

Operaon

RecommendedMaintenance

RBML

TheAWATSlineofmachinescomeequippedwithpermanentlylubricatedbearingswhichrequirenoad‐

dionallubricaonormaintenance.

WheelBearingsinLiAssemblyshouldbedisassembledandbearingspackedwithgreaseonceayear.

Thehubscomewithfactoryinstalledgreasefingsforgreasingthehubthroughouttheseason.Forag‐

gressivecondionsgreaseshouldbeliberallyputinthehubssocontaminaonwillnotreachthebear‐

ings.Thisshouldbecompletedateveryusageforaggressivecondions.

PPM

GreaseallpivotpointsontheAerWayattheendofeachday.Besuretooperatemechanismaergreas‐

ingtoallowgreasetoreacharoundthepinarea.Allpinsshouldberemovedonceayearandgreaseap‐

pliedtopintopreventprematurecorrosion.Thisisagoodmetoalsoinspectpinsandholesforwear

andreplaceasnecessary.

TMRI

Inspectnesforsignsofexcessivewearorbreakagepriortooperaon.Re‐torqueneboltsto90‐lbs

plusahalfturn,aer10hoursofoperaonfrominialstart‐up.Verifytorqueontheneboltsaereve‐

ry30hoursofoperaonandadjustifrequired.

Ifnesarewornexcessively,damagedorbroken,replacethemasquicklyaspossibletoensuretheprop‐

erandefficientoperaonoftheAerWayimplement.Refertopages12and13forfurtherinstrucons.

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

10

Maintenance

PULLTYPEAERWAYS

AWATSSpecs

AWATS‐100‐AG‐410’10.5’(126”)642450lbs60‐100

*HORSEPOWERREQUIREMENTS(6‐10HP/FT)MAYVARYDEPENDINGONFIELDCONDITIONS

AWATS AerWay Specifications

MODEL NUMBER WORKING

WIDTH

OVERALL

WIDTH

TINE

QTY

MACHINE

WEIGHT

HORSEPOWER

REQUIRED*

8”SHATTERTINES

AWATS‐100‐AG‐4XA‐74873‐01XA‐74873‐028460”

AWATS AerWay Rollers

LH ROLLER

ASSEMBLY

RH ROLLER

ASSEMBLY

# OF ROWS

PER ROLLER

# OF TINES

PER ROW

OVERALL

ROLLER LENGTH

MODEL NUMBER

PULLTYPEAERWAYS

AWATSConcreteBallasng

AWATS‐100‐AG‐4‐5x750lbs3750lbs

AWM AerWay Ballasting

7000lbs700lbs

AW-BLK550-02

QUANTITY

AW-BLK750-02

QUANTITY

TOTAL BLOCK

WEIGHT

GROSS

WEIGHT

WEIGHT

PER FOOT

MODEL NUMBER

“X”

AW‐BLK550‐02:550lbballastblock

AW‐BLK750‐02:750lbballastblock

15”Wide·20”High·24”Deep

20”Wide·20”High·24”Deep

15”

20”

24”

24”

AWATS‐100*26.00”

Five750lbBlocks

“X”

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility11

Ballasng/Specificaons

AWATS‐100‐AG‐4‐HC‐ 5x750lbs3750lbs7000lbs700lbs

AWATS‐100‐AG‐4‐HC10’10.5’(126”)642450lbs60‐100

AWATS‐100‐AG‐4‐HCXA‐74873‐01XA‐74873‐028460”

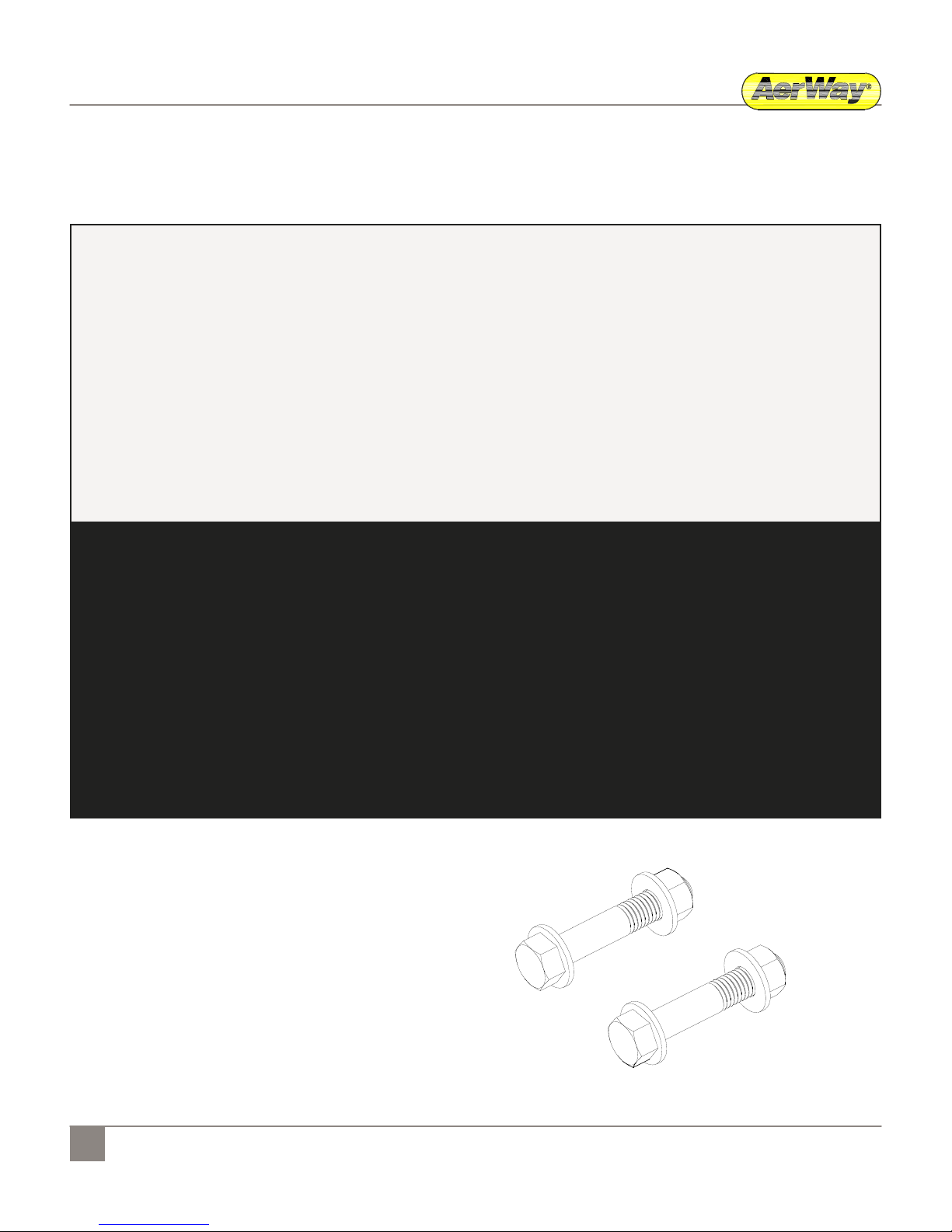

ShaerneReplacement

Ensurethatringsarenotbentandboltholesarenotelongated.

Alwayscleanallmangsurfacesfreeofdirtandcontaminaon.

1.Assembletherollerasshownbelowwiththenebetweentheclampingringswithwashersunderthe

boltheadandnut.

2.Installthenesintheorientaonshownbelow.Note:Thestamp“AerWay”onthenewillbe

poinngtowardstheoutsideoftheAerWay.Seethediagrambelow.

3.Themounngringsareindexedaroundtherollershasothenesappearinaspiralpaernwhen

viewedfromtheendoftheroller.Besuretomakenoteofthepaernoneachrollerbeforeremov‐

ingtheoldnesandtoinstallthenewnesinthatsamepaern.Refertopage13fordetails.

4.Torquethelocknutto90Ft‐Lbsthenconnueturningnutanaddional½turn.

LEANOFTINELEANOFTINE

FrontView

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

12

TineReplacement

ShaerneReplacement‐Helix

Ensurethatringsarenotbentandboltholesarenotelongated.

Alwayscleanallmangsurfacesfreeofdirtandcontaminaon.

1.TheTinesareindexedaroundtherollershasothetheyappearinaspiralpaernorhelixwhen

viewedfromtheendoftheroller.Thedireconofthishelixisessenaltotheproperfunconof

yourAerWay.Besuretomakenoteofthepaernoneachrollerbeforeremovingtheoldnesand

toinstallthenewnesinthatsamepaernasshownbelow.

2.Oncetheproperhelixhasbeenestablishedforoneneperrow,mounttheremainingnesensuring

thenesineachrowareequallyspacedaroundtherings.Theremaybeun‐usedholesineachring

dependinguponhowmanynesperstarareused.

3.RefertoPages11fortherequiredrollerforeachlocaononyourAerWay.

“‐01”Roller(XA‐75455‐01Tine,LHHelix)“‐02”Roller(XA‐75455‐02Tine,RHHelix)

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility13

TineReplacement

CommonParts

XA‐66242‐22900

(HOSEASSY,229.00"LG)

XB‐64942

(SWIVELJACK,5000#)

XB‐53990

(JACKLEGPIN

XB‐53989

(CLIPPIN)

XA‐53308

(PIN,CATII,1‐1/8"X7"LG.)

XB‐53987‐01

(LYNCHPIN,1/16")

XA‐66229

(TOPLINK)

XA‐53271

(PIVOTPINASSY)

XB‐21‐S‐375‐2500P

(PIN,SPRING3/8"X2‐1/2")

XB‐63440

(CLEVISPIN,1",5"LG)

XB‐53946

(HAIRPIN‐3/16"DIA.)

XA‐63317

(HOSECLAMP)

XB‐T‐45

(1/2”LOCKWASHER,GR.5)

XF‐21‐050F5‐P

(1/2”‐20HEXNUT,GR.5)

XB‐53985

(ADJUSTINGPIN,1"X7"LG.)

XA‐75052‐P

(PIN,°1.25",6.25"OAL)

XB‐1108

(3/8”HARDENEDWASHER)

XF‐01‐038C5‐150P

(HHCS,3/8”X1.50”,GR.5)

XF‐31‐038C5‐P

(3/8”LOCKNUT,GR.5)

ITEM#2

XB‐74200

(TWINCLAMPKIT,3/4")

XA‐65275

(CYLINDERLOCKOUT)

ITEM#1

XB‐65145

(CLEVISPIN,1.00",4.5"LG)

XB‐65838

(COTTERPIN,3/16"DIA

x1‐1/2"LG)

XB‐63348

(CLEVISPIN,1",3"LG)

XB‐65838

(COTTERPIN,3/16"DIA

x1‐1/2"LG)

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

14

ReplacementParts

UNITSBUILTPRIORTOJAN.2013

ITEM#PART#DESCRIPTIONREQ'D

QTY

1XB‐75652CYLINDER,TIEROD,3"X12"STROKE1

2XB‐56005ELBOW,MALE,‐8NPTF,‐6JIC2

UNITSBUILTAFTERTOJAN.2013

ITEM#PART#DESCRIPTIONREQ'D

QTY

1XB‐65272CYLINDERHYDRAULIC,3"X12"STROKE1

2XB‐56252ELBOW,MALE,‐8O.R.B.,‐6JIC2

CommonParts

XA‐75614

(50mmPILLOWBLOCK,

NO‐LUBE)

XF‐01‐075C8‐550P

(HHCS,3/4”X5.50”,GR.8)

XB‐63061

(3/4”HARDENEDWASHER)

XF‐01‐075C8‐200P

(HHCS,3/4”X2.00”,GR.8)

XB‐63061

(3/4”HARDENEDWASHER)

XA‐74869

(ENDRETAINER)

XB‐75135

(ELECTRICDRIVE,12V,1/8

HP,WITHGUARD)

ITEM#1

(LINEARAPPLICATOR)

XA‐74965‐B

(CLAMPPLATE)

XF‐01‐050C8‐150P

(HHCS,1/2”X1.50”,GR.8)

XF‐41‐050‐8P

(1/2”HARDENEDWASHER)

XF‐31‐050C8‐P

(1/2”LOCKNUT,GR.8)

XF‐01‐038C5‐250P

(HHCS,3/8”X2.50”,GR.5)

XB‐1108

(3/8”HARDENEDWASHER)

XF‐31‐038C5‐P

(3/8”LOCKNUT,GR.5)

XB‐75143

(STEELCLAMP,15/16")

ITEM#2

(DEFLECTOR)

ITEM#3

(SPREADERBAR)

XA‐75566

(WIREROPE,1/8"DIAX12"LG)

**NOTSHOWN**

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility15

ReplacementParts

ITEM#AWATS‐100‐AG‐4AWATS‐100‐AG‐4‐HC

1XB‐75119XB‐76342

2XA‐75136‐04XA‐76336‐01

3XA‐75061‐04XA‐76335‐01

TorqueChart

SAEGRADE8SAEGRADE8

COARSETHREADFINETHREAD

CLAMPCLAMP

SIZELOADPLAINPLATEDSIZELOADPLAINPLATED

1/4‐20(.250)2,85012.Ibs.9.lbs.1/4‐28(.250)3,26314.lbs.10.Ibs.

5/16‐18(.3125)4,72525.lbs.18.Ibs.5/16‐24(.3125)5,11327.lbs.20.lbs.

3/8‐16(.375)6,97544.lbs.33.lbs.3/8‐24(.375)7,87549.lbs.37.lbs.

7/16‐14(.4375)9,60070.lbs.52.lbs.7/16‐20(.4375)10,65078.lbs.58.Ibs.

1/2‐13(.500)12,750106.lbs.80.lbs.1/2‐20(.500)14,400120.lbs.90.Ibs.

9/16‐12(.5625)16,350153.lbs.115.lbs.9/16‐18(.5625)18,300172.lbs.129.lbs.

5/8‐11(.625)20,325212.lbs.159fl.Ibs.5/8‐18(.625)23,025240.Ibs.180.lbs.

3/4‐10(.750)30,075376.lbs.282.Ibs.3/4‐16(.750)33,600420.lbs.315.lbs.

7/8‐9(.875)41,550606.lbs.454.lbs.7/8‐9(.875)45,825668.Ibs.501.lbs.

1‐8(1.000)54,525909.lbs.682.lbs.1‐12(1.000)59,700995.lbs.746.lbs.

1‐1/8‐7(1.125)68,7001288.lbs.966.lbs.1‐14(1.000)61,1251019.lbs.764.lbs

1‐1/4‐7(1.250)87,2251817.lbs.1363.lbs.1‐1/8‐12(1.125)77,0251444.Ibs.1083.lbs.

1‐3/8‐6(1.375)103,9502382.lbs.1787fl.lbs.1‐1/4‐12(1.250)96,6002012.lbs.1509.lbs.

1‐1/2‐6(1.500)126,4503161.1bs.2371.lbs.1‐3/8‐12(1.375)118,3502712.lbs.2034.Ibs.

1‐1/2‐12(1.500)142,2753557.Ibs.2668.Ibs.

SAEGRADE5SAEGRADE5

COARSETHREADFINETHREAD

CLAMPCLAMP

SIZELOADPLAINPLATEDSIZELOADPLAINPLATED

1/4‐20(.250)2,0258.lbs.6.lbs.1/4‐28(.250)2,32510.lbs.7.lbs.

5/16‐18(.31253,33817.Ibs.13.Ibs.5/16‐24(.3125)3,67519.lbs.14.Ibs.

3/8‐16(.375)4,95031.lbs.23.lbs.3/8‐24(.375)5,58835.Ibs.26.Ibs.

7/16‐14(.4375)6,78850.lbs.37.Ibs.7/16‐20(.4375)7,57555.lbs.41.lbs.

1/2‐13(.500)9,07576.Ibs.57.lbs.1/2‐20(.500)10,20085.lbs.64.Ibs

9/16‐12(.5625)11,625109.Ibs.82.lbs.9/16‐18(.5625)12,975122.lbs.91.lbs.

5/8‐11(.625)14,400150.lbs.112.lbs.5/8‐18(.625)16,350170.Ibs.128.Ibs.

3/4‐10(‐750)21,300266.lbs.200.lbs.3/4‐16(.750)23,775297.Ibs.223.lbs.

7/8‐9(.875)29,475430.Ibs.322.lbs.7/8‐14(.875)32,475474.Ibs.355.Ibs.

1‐8(1.000)38,625644.Ibs.483.Ibs.1‐12(1.000)42,30070.lbs.529.lbs.

1‐1/8‐7(1.125)42,375794.lbs.596.lbs.1‐14(1.000)32,275721.lbs.541.lbs.

1‐1/4‐7(1.250)53,7751120.lbs.840.Ibs.1‐1/8‐12(1.125)47,475890.lbs.668.lbs.

1‐3/8‐6(1.375)64,1251470.lbs.1102.lbs.1‐1/4‐12(1.250)59,5501241.Ibs.930.lbs.

1‐1/2‐6(1.500)78,0001950.lbs.1462.lbs.1‐3/8‐12(1.375)72,9751672.Ibs.1254.lbs.

1‐1/2‐12(1.500)87,7502194.lbs.1645.Ibs.

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility

16

TorqueChart

SAF‐HOLLANDCOMPANIES

SAF‐HOLLANDCompanies

SAF-HOLLAND Canada Limited - Norwich Facility

20 Phebe St., Norwich, Ontario N0J 1P0

Tel: 1-519-863-3414 · Fax: 1-519-863-2398

SAF-HOLLAND Canada Limited - Surrey Facility

17909 Roan Place, Surrey, B.C. V3S 5K1

Tel: 1-800-457-8310 · Fax: 1-604-574-0244

SAF-HOLLAND USA Inc. - Texas Facility

1301 Martinez Lane, Wylie, Texas 75098

Tel: 1-800-457-8310

1-800-457-8310

AerWayAachments

Thefollowingoponalaachmentsareavailable:

‐ AK‐75742,HARROWCARRIERKIT(CANBEUSEDWITHAW‐CH11‐3CHAINHARROW)

‐ AK‐75743,TOOLBAR,6”x4”x10,AWATS‐100

‐ AW‐BLK550‐02,550#CEMENTBLOCK(CANHOLDSIX—3300#)

‐ AW‐BLK750‐02,750#CEMENTBLOCK(CANHOLDFIVE—3750#)

XL‐AW75653RevCAmendmentsanderrorsreserved©SAF‐HOLLANDCanadaLimited‐NorwichFacility17

XL‐AW75653RevC

AWATSTOPDRESSSEEDERMANUAL

This manual suits for next models

1

Table of contents

Popular Seeder manuals by other brands

KingKutter

KingKutter Seeder none Operation and parts manual

Terrateck

Terrateck T.CG.PL5 instruction manual

Earth Way

Earth Way 1001-B Assembly and operating instructions

Toro

Toro 23508—400000000 Tool Turn Guide

Monosem

Monosem MONSHOX NG Plus ME user manual

Wolf Garten

Wolf Garten Sow Master EC-M operating instructions