AERZEN Delta User manual

english

AERZENER MASCHINENFABRIK

GMBH

G4-004 M EN

168 393 000 12-2005

Operating and installtion instructions

Positive displacement blower unit

DELTA BLOWER

english

Die INFO-Seite ist vor der Inbetriebnahme durchzulesen.

Dort evtl. vermerkte Hinweise und Änderungen sind durchzuführen.

Read the INFORMATION sheet prior to commissioning.

Possible notes and changes indicated herein are to be effected.

a page INFO est à lire avant la mise en route.

Y apporter éventuellement des annotations et modifications.

De INFO-Bladzijde moet voor de inbedrijfname worden doorgelezen.

Daar eventueel opgeschreven aanwijzingen en modificaties moeten worden uitgevoerd.

Prima della messa in esercizio leggere la pagina INFO, ed eseguire eventuali

istruzioni o modifiche indicate.

Antes de proceder a la puesta en marcha, leer detenidamente la página inf rmativa y

cumplir eventuales indicaciones y modificaciones indicadas en la misma.

english

english 1 - 18

Verschleißteilzeichnungen

Wearing parts drawings

Plans des pièces d'usure

Tekening waarop aangegeven

Disegno parti soggette ad usura

Dibujo de pieza de desgaste

Ersatzteil-Bestellung

Ordering spare parts

Commande de pièces dé tachée

Bestellen van onderdelen

Pedido de repuestos

Ordinazione di pezzi di ricambio

Hersteller-Erkärung

Manufacturer Declaration

Certificat du constructeur

Verklaring van fabrikant

Declaración de fabricante

Dichiarazione del produttore

Konformitäts-Erklärung

Declaration of Conformity

Certificat de conformité

EG-Verklaring van over-

eenstemming voor machines

Declaración de conformidad

Dichiarazione di conformità

Leistungsdaten

Performance data

Performances

Capaciteitsgegevens

Datos de servicio

Dati di esercizio

INFO - Seite

Information sheet

Page infos

Info bladzijde

Pagina

Informativa

Informazioni

I n h a l t / C o n t e n t s

Aerzener Maschinenfabrik

Abteilung Technische Dokumentation

Technische Illustration & Redaktion

H.Nickel Technischer Autor

20

19

english

Hersteller-Erklärung

Manufacturer Declaration

Certificat du constructeur

Unterschrift des Herstellers

Signature of the manufacturer

Signature du constructeur

Handtekening van de fabrikant

Firma del fabricante

Firma del fornitore

Leiter Techn. Abteilung

Head of the dept.

Directeur technique

Hoofd technische afdeling

Director Dpto Técnico

Responsabile reparto tecnico

Verklaring van fabrikant

Declaración de fabricante

Dichiarazione del produttore

(Herr Seidel)

deutsch

Hiermit bestätigen wir, dass diese

Maschine den f lgenden

EG-Richtlinien entspricht:

EG-Maschinen-

Richtlinie 98/37 EG

Anhang II B

für einzubauende Maschinen

EM -Richtlinie 89/336 EG

Druckgeräte-Richtlinie 97/23 EG

Niederspannungs-

Richtlinie 73/23 EG

Die Maschine wurde konstruiert, gefertigt

und dokumentiert, in Übereinstimmung mit

den harmonisierten Normen der genann-

ten EG-Richtlinien, von Firma:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

Eine technische Dokumentation ist vollstän-

dig vorhanden.

Die zur Maschine gehörende Betriebsan-

leitung liegt vor.

Die Inbetriebnahme dieser Maschine ist so

lange untersagt, bis festgestellt wurde,

dass die Maschine/Anlage, in die sie

eingebaut werden soll, den Bestimmungen

der EG-Richtlinie entspricht !

français

N us déclar ns par la présente que

cette machine est c nf rme aux

directives CE suivantes:

Directive machine CE 98/37 CE

Annexe II B

pour les éléments destinés à être

incorporés

Directive CEM 89/336 CE

Directive équipements sous pression

97/23 CE

Directive basse tension 73/23 CE

a machine a été conçue, fabriquée et

documentée en accord avec les normes

dharmonisation des directives CE

indiquées, par la société:

Aerzener Maschinenfabrik GmbH D-

31855 Aerzen

Une documentation technique complète

est disponible.

e présent document comprend la notice

dinstructions de la machine.

Il est interdit de mettre la présente

machine en service tant que la machine/

installation dans laquelle elle doit être

incorporée naura pas été déclarée

conforme aux dispositions de la

directive CE.

nederlands

Hiermee bevestigen we, dat deze

machine aan de v lgende EG-

richtlijnen v ld et:

EG-Machinerichtlijn 98/37 EG

Bijlage II B

voor in te bouwen machines

EMC-Richtlijn 89/336 EG

Drukapparatuurrichtlijn 97/23 EG

Laagspanningsrichtlijn 73/23/EG

De machine werd geconstrueerd,

vervaardigd en gedocumenteerd in

overeenstemming met de

geharmoniseerde normen van de

genoemde EG-richtlijnen door de:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

Een technische documentatie is compleet

aanwezig.

De bij de machine behorende

bedieningshandleiding ligt ter inzage.

De inbedrijfname van deze machine is zo

lang verboden totdat is vastgesteld, dat

de machine/installatie waarin ze

ingebouwd zal worden aan de

voorschriften van de EG-richtlijn voldoet!

español

N s aseguram s de esta f rma, que la

máquina cumple c n las siguientes

Directivas de la CE:

Directiva de máquinas CE 98/37 CE

Anexo II B

para máquinas que serán montadas

Directiva EM 89/336 CE

Directiva de dispositivos

de impresión 97/23 C E

Directiva de baja

tensión 73/23 CE

a máquina fue construida, concluida y

documentada en conformidad con las

normativas harmonizadas de las Directivas

de la CE mencionadas, por la empresa:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

Se encuentra disponible una documentación

técnica completa.

Existe un manual de instrucciones de la

máquina.

¡ a puesta en marcha de esta máquina se

encuentra interdicto, hasta que se haya

detectado que la máquina/sistema donde

esta será montada, está de acuerdo con

las determinaciones de las Directivas de

la CE!

italiano

C n la presente si c nferma che la

presente macchina è c nf rme alle

seguenti direttive CEE:

Direttiva macchine

CEE 98/37 CEE

Appendice II B

per macchine da installare

Direttiva EM 89/336 CEE

Direttiva per apparecchi

ed impianti a pressione 97/23 CEE

Direttiva bassa

tensione 73/23 CEE

a macchina è stata costruita, prodotta e

documentata, in conformità alle norme

armonizzate delle succitate direttive CEEdalla

ditta:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

É disponibile la documentazione tecnica

completa.

e istruzioni per l'uso necessarie alla

macchina sono allegate.

a messa in servizio di questa macchina è

vietata fino a che non viene accertato che,

che la macchina/l'impianto in cui deve

essere installata sia conforme alle

disposizioni della direttiva CEE !

english

We herewith c nfirm that this

machine is in acc rdance with the

f ll wing EC directive:

EC machine directive 98/37 EG

Appendix II B

for machines to be installed

EM directive 89/336 EG

pressure device

directive 97/23 EG

low-voltage

directive 73/23 EG

The machine was designed, manufactured

and documented in accordance with the

harmonized standards of the stated EC-

guidelines of:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

A copy of all relevant technical information

is provided and available.

The operating manual pertaining to the

machine is provided and available.

Commissioning of this machine must not be

carried out until it is determined that the unit/

plant in which the machine is to be installed

corresponds to the regulations of the EC

guideline!

english

Konformitäts-Erklärung

Declaration of Confor ity

Certificat de confor ité

Unterschrift des Herstellers

Signature of the manufacturer

Signature du constructeur

Handtekening van de fabrikant

Firma del fabricante

Firma del fornitore

Leiter Techn. Abteilung

Head of the dept.

Directeur technique

Hoofd technische afdeling

Director Dpto Técnico

Responsabile reparto tecnico

EG-Verklaring van overeen-

ste ing voor achines

Declaración de confor idad

Dichiarazione di confor ità

(Herr Seidel)

deutsch

Hiermit bestätigen wir, dass diese

Maschine den f lgenden

EG-Richtlinien entspricht:

EG-Maschinen-

Richtlinie 98/37 EG

Anhang II A

EM -Richtlinie 89/336 EG

Druckgeräte-Richtlinie 97/23 EG

Niederspannungs-

Richtlinie 73/23 EG

Die Maschine wurde konstruiert, gefertigt

und dokumentiert, in Übereinstimmung mit

den harmonisierten Normen der genann-

ten EG-Richtlinien, von Firma:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

Eine technische Dokumentation ist vollstän-

dig vorhanden.

Die zur Maschine gehörende Betriebsan-

leitung liegt vor.

français

N us déclar ns par la présente que

cette machine est c nf rme aux

directives CE suivantes:

Directive machine CE 98/37 CE

Annexe II A

Directive CEM 89/336 CE

Directive équipements sous pression

97/23 CE

Directive basse tension 73/23 CE

a machine a été conçue, fabriquée et

documentée en accord avec les normes

dharmonisation des directives CE

indiquées, par la société:

Aerzener Maschinenfabrik GmbH D-

31855 Aerzen

Une documentation technique complète

est disponible.

e présent document comprend la notice

dinstructions de la machine.

nederlands

Hiermee bevestigen we, dat deze

machine aan de v lgende EG-

richtlijnen v ld et:

EG-Machinerichtlijn 98/37 EG

Bijlage II A

EMC-richtlijn 89/336 EG

Drukapparatuurrichtijn 97/23 EG

Laagspanningsrichtlijn 73/23 EG

De machine werd geconstrueerd,

vervaardigd en gedocumenteerd in

overeenstemming met de

geharmoniseerde normen van de

genoemde EG-richtlijnen door de:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

Een technische documentatie is

compleet aanwezig.

De bij de machine behorende

bedieningshandleiding ligt ter inzage.

español

N s aseguram s de esta f rma, que

la máquina cumple c n las siguientes

Directivas de la CE:

Directiva de máquinas CE 98/37 CE

Anexo II A

Directiva EM 89/336 CE

Directiva de dispositivos

de impresión 97/23 CE

Directiva de baja

tensión 73/23 CE

a máquina fue construida, concluida y

documentada en conformidad con las

normativas harmonizadas de las Directivas

de la CE mencionadas, por la empresa:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

Se encuentra disponible una

documentación técnica completa.

Existe un manual de instrucciones de la

máquina.

italiano

C n la presente si c nferma che la

presente macchina è c nf rme alle

seguenti direttive CEE:

Direttiva macchine

CEE 98/37 EG

Anhang II A

Direttiva EM 89/336 EG

Direttiva per apparecchi

ed impianti a pressione 97/23 EG

Direttiva bassa

tensione 73/23 EG

a macchina è stata costruita, prodotta e

documentata, in conformità alle norme

armonizzate delle succitate direttive

CEEdalla ditta:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

É disponibile la documentazione tecnica

completa.

e istruzioni per l'uso necessarie alla

macchina sono allegate.

english

We herewith c nfirm that this

machine is in acc rdance with the

f ll wing EC directive:

EC machine directive 98/37 EG

Appendix II A

for machines to be installed

EM directive 89/336 EG

pressure device

directive 97/23 EG

low-voltage

directive 73/23 EG

The machine was designed, manufactured

and documented in accordance with the

harmonized standards of the stated EC-

guidelines of:

Aerzener Maschinenfabrik GmbH

D-31855 Aerzen

A copy of all relevant technical information

is provided and available.

The operating manual pertaining to the

machine is provided and available.

english

Ersatz- und Zubehörteile

Es wird darauf hingewiesen, daß nicht von uns gelieferte Originalteile und Zubehör auch nicht von uns geprüft

und freigegeben sind. Der Einbau oder Anbau sowie die Verwendung solcher Produkte kann daher unter

Umständen konstruktive vorgegebene Eigenschaften der Anlagen beeinflussen. Für Schäden, die durch

Verwendung von nicht Originalteilen und Zubehör entstehen, ist jede Haftung des Herstellers ausgeschlossen.

Spare parts and access ries

We draw your attention to the fact that original parts and accessories not supplied by us are also not

inspected and released by us. Therefore, the installation and application of such products might influence

under certain circumstances constructively stipulated properties of the plants. Consequential damages

due to application of non-original parts and accessories release the manufacturer from any warranty and

liability.

Access ires et pièces de rechange

Nous attirons votre attention sur le fait que les accessoires et pièces dorigine nétant pas de notre fourniture

ne peuvent être controlés et pris en considératoin lors dune réclamation. intégration ou le montage ainsi

que lutilisation de telles pièces peut influencer sous certaines conditions les caractéristiques et performances

de la machine. Pour tout dommage causé du fait de pièces nétant pas dorigine ou de montage erroné, nous

déclinons toute responsabilité.

Reservedelen en t ebeh ren

Er wordt uitdrukkelijk op gewezen dat niet door ons geleverde originele delen en toebehoren ook niet door

ons getest en vrijgegeven zijn. De in of aanbouw alsmede de toepassing van zulke producten kan

derhalve onder zekere omstandigheden constructief gegeven eigenschappen van de installatie

beïnvloeden. Voor schaden, die door gebruik van niet originele delen en accessoires ontstaan, is iedere

aansprakelijkheid jegens de fabrikant uitgesloten.

Ricambi e access ri

Facciamo presente che i pezzi e ricambi originali non forniti da noi, non sono da noi controllati e accettati. Il

montaggio o limpiego di questi prodotti può in certe circostanze provocare influenze sul cattivo funzionamento

dellimpianto. Danni causati dallimpiego di parti e ricambi non originali esonerano il fornitore da ogni garanzia.

Piezas de repuest y acces ri s

Indicamos expresamente, que aquellos repuestos y/o accesorios no suministrados por nosotros no están

comprobados ni homologados por Aerzen. Su montaje, así como su utilización pueden tener incidencia en

las características prefijadas de la instalación. Por lo tanto no asumimos garantía ni responsabilidad alguna

sobre éstas piezas y de los eventuales daños posteriores y/o alteraciones de las calidades y prestaciones

de origen. Para daños originados por la utilización de piezas y accesorios no originales, se excluye cualquier

responsabilidad por parte del fabricante.

Ersatzteile, spare parts, pièces dé tachée, onderdelen, repuestos, pezzi di ricambio

- DELTA BLOWER -

english

!

Dieses Ersatzteilformular ist ein fester Bestandteil der Betriebsanleitung

und darf nicht enfernt werden !

This spare part form is an essential part of the operating manual and must not be removed !

Ce formulaire de pièce détachée est un élément essentiel de l'instruction de service

et ne doit pas écarter !

010 ð. . .

020 ð. . .

030 ð. . .

040 ð. . .

050 ð. . .

060 ð. . .

070 ð. . .

080 ð. . .

0 0 ð. . .

ØDieses Formular bitte vor dem Ausfüllen kopieren !

ØPrior to filling-in this form, please copy !

ØAvant de remplir ce formulaire, veuillez copier !

ØAlvorens in te vullen dit formulier s.v.p. kopiëren !

ØPor favor copiar este listado de cumplimentario !

ØSi prega di copiare questo formulario prima di compilarlo !

Leistungsdaten / performance data

- Ersatzteilbestellung / ordering spare parts -

lBitte richten Sie Ihre Bestellung, an die für Sie zuständige Aerzener Vertretung / -Gesellschaft.

Abruf unter (++49) 0 51 54 81 192

lPlease send your order to the Aerzen representative -company responsible for your country.

Fax polling ++49 (0) 515481192

Rechnungsanschrift --------------------------------------------------------------------------------

--------------------------------------------------------------------------------

Invoice address ------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------

Lieferanschrift --------------------------------------------------------------------------------

--------------------------------------------------------------------------------

Dispatch address ------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------

Kunden-Bestell-Nr.N° --------------------------------------------------------------------------------

Customer order no. ------------------------------------------------------------------------------------------------------

Ersatzteile / spare parts Leistungsdaten / performance data

Dit reservedelenformulier is een vast bestanddeel van het bedri fsvoorschrift en mag

niet worden verwi derd !

Este listado de repuestos forma parte integrante de las Instrucciones de Servicio y

no puede per eliminado !

Questo formulario dei ricambi è parte integrante delle istruzioni di esercizio e non

deve essere staccato !

Gültig für die folgende Verschleißteilzeichnung. Applicable for the following wear part drawing.

100 ð. . .

110 ð. . .

120 ð. . .

130 ð. . .

140 ð. . .

150 ð. . .

160 ð. . .

170 ð. . .

180 ð. . .

1 0 ð. . .

200 ð. . .

210 ð. . .

220 ð. . .

230 ð. . .

240 ð. . .

250 ð. . .

Ersatzteile arkieren / Stückzahl eintragen. Mark the spare parts / fill in the quantity.

Ersatzteil-

anfrage

Spare parts inquiry

Ersatzteil-

bestellung

Spare

parts order

english

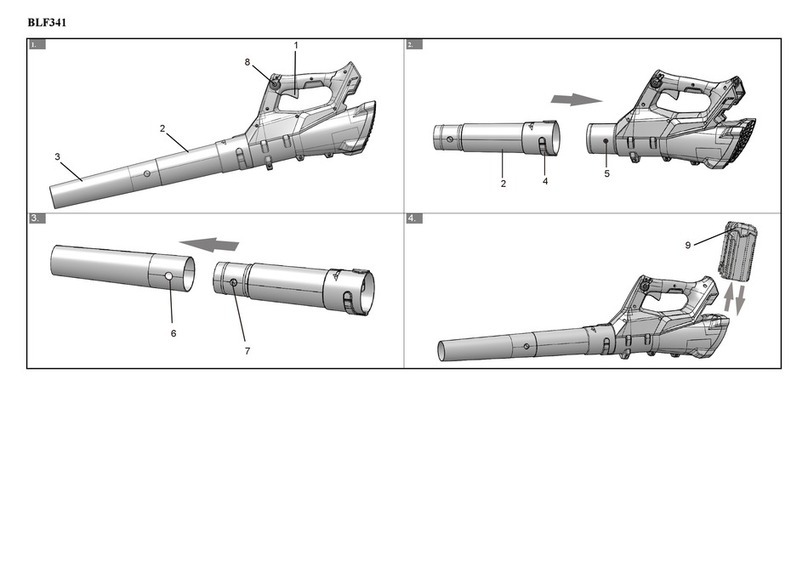

Diese Abbildung ist eine Beispiel-Darstellung und dient der Ersatzteilbestellung.

Abweichungen zu der ausgelieferten Maschine sind möglich.

Detaillierte Inf rmati nen enthält die, der Auftrags-Nummer entsprechende Zeichnung.

This figure is an example presentation and serves for spare part ordering.

Deviations to the machine supplied are possible.

The drawing gives detail information according to the order number.

DELTA BLOWER

Verschleißteilzeichnung / Wearing parts drawing

english

Diese Abbildung ist eine Beispiel-Darstellung und dient der Ersatzteilbestellung.

Abweichungen zu der ausgelieferten Maschine sind möglich.

Detaillierte Inf rmati nen enthält die, der Auftrags-Nummer entsprechende Zeichnung.

This figure is an example presentation and serves for spare part ordering.

Deviations to the machine supplied are possible.

The drawing gives detail information according to the order number.

DELTA BLOWER

Verschleißteilzeichnung / Wearing parts drawing

english

Contents Page

1. Suitability, general advice 1

2. Construction, function 2

3 . Care to be taken before and during the operation 3 - 4

4. Inad issible operation ethods 4

5 . Transport / Asse bly 4 - 5

6. Co issioning 6

7. Ad issible connecting frequencies of the drive otor 7

8. Shutdown 7

9. Operating of co pressor units 7 - 8

9.1 - with frequency converter 7

9.2 - with pole-changing otor 8

10. Attendance / Maintenance 8 - 15

10.1 Maintenance schedule 9

10.2 Inspection / -dates 9

10.3 Exchange of lubricants 10 - 11

10.4 Lube oil regulations 11

10.5 Lube oil quantities 12

10.6 Check pressure valve for functioning 12

10.7 V-belts - Installation / Exchange 13

10.8 Intake filter / starting strainer / aintenance 14

10.9 Overhauling / Failure chart 15

11. Accessories 16 - 17

12. Spare parts 18

13. Recycling 19

14. INFORMATION sheet 20

1. Suitabilit , general advice

The useful suitability of Positive Displace ent Blower Units ade by Aerzener is the oil-

free conveying and co pressing of air, also of neutral gases in odified design.

In order to ensure an opti u operation, the technical suitability li its have to be

observed.

Intake te perature t1 stated in the order confir ation applies as a bient te perature

at place of installation.

Non-observance of the technical application li its and safety regulations releases the

Aerzener Maschinenfabrik fro warranty and liability regarding replace ent for

consequential da ages. The sa e applies for defects caused by inspections carried out

not in ti e or not properly.

1

english

2. Construction, function

Unit:

The unit is delivered with ounted accessories ready to operate.

The following steps are to be effected in addition:

Connect the conveying piping.

Fill up the lube oil.

Install the electrical connection.

Mount the special accessories delivered separately - if there are any.

Motor connection:

The electrical installation has to be effected by an authorized electrical fitter.

The ter inal diagra for the otor can be found in the cover of the ter inal box

as well as in the acco panying docu entation.

The otor- and control voltage is to be connected to a co on network,

where the sealing-in of the power contactor is cancelled in case of an interruption

of circuit.

Alternative: Parallel to the driving otor an electronic onitoring relay is to be

installed which cancels the sealing-in of the power contactor in case of an

interruption of circuit.

Base support:

A torsion-stable, cylindrical container serving as absorption-free discharge silencer as

well as installation basis for blowers with intake silencer, belt drive, belt guard, hinged

otor support and connection casing. The base support rests on flexible achinery

ountings and is to be placed on an even, slope-free underground.

Filter silencer:

This silencer is a co bination of intake-sided silencer and intake filter. The filter aterial

can be cleaned or replaced.

Connection casing:

consisting of: ÜA pressure valve is located for the protection of the blower

against overload.

ÜA non-return flap prevents the blower fro running in reverse

after shut-down.

The discharge-sided piping is connected to the unit via a flexible connection or via a

co pensator.

Accessories: please refer to chapter 11.

Three-lobe rotary pistons. Pulsation decrease by interference (patented).

The conveying cha ber (cylinder) is sealed against the oil cha bers (casing cover and

gear case) by piston ring labyrinth sealings and the driving shaft is sealed by a radial

seal ring.

In case the oil level is too high, oil can penetrate into the conveying cha ber in an

uncontrolled way.

Co pression heat arises upon the co pression procedure. The heat is partly released

via the outer surfaces of blower and conveying pipings to the a bient air. Outer surfaces

and conveying pipings reach te peratures which ay burn the unprotected skin.

Ü

Ü

Ü

Ü

2

english

3. Precautions prior to and during operation

ATTENTION! Draws the attention to all dangerous situations.

WARNING! Points to direct risks of persons.

Upon receipt the blower is to be checked for da ages during transport and

co pleteness by eans of delivery note and order.

Work safety rules, safety regulations as well as the operating instructions,

are to be observed.

Read the INFORMATION sheet prior to co issioning. Possible notes and

changes indicated herein are to be effected.

The following described tasks are only to be carried out by experts who are fa iliar with

the functions of the blower unit and its co ponents as well as with the safety

regulations to be kept.

This positive displace ent blower eets the European regulations for accident

prevention. Nevertheless, a residual technical risk re ains, with a possibility of

endangering persons and property. To avoid this, operators have to co ply with the

following safety regulations:

ÜIn case of acoustic hood operation the doors are to be locked by eans of the

provided ale triangular wrench and ay only be opened when the otor is

currentless and the fuses are re oved or switched off.

ÜDo not carry out any i proper repair or odification work at the blower. In case of

proble s contact the Aerzen after-sales service!

ÜOperators ust be skilled, introduced to their job and instructed!

ÜPrior to co issioning, operators ust be fa iliar with the protection-, operating- and

onitoring ele ents by eans of these instructions.

ÜUse the achine in accordance with its suitability, keep its perfor ance li its.

ÜRe ove solids, liquids and powdery substances fro the intake range.

ÜSafety appliances, such as e.g. belt guard, in case of acoustic hood design hand

protection and hood ele ent, otor guard / E ergency-OFF etc. ust not be

re oved while achine is running. Risk of injury !

ÜEnsure that the otor is currentless upon working at the unit.

ÜDo not operate when electrical connections, belt guard and pressure valve are

defective or issing.

ÜNo operation with open intake- or pressure socket / blower stage, as: positive

displace ent achines are forced conveying achines with risk of injury in the range

of conveying cha ber.

ÜRisk of burns!

In case of opened or non-existing acoustic hood wear safety gloves when the blower

surface is at operation te perature!

ÜUse ear protection in case of blower operation !

Due to the respective operating condition, the sound pressure level can deviate fro

the entioned operating data. Therefore a sound pressure level higher than 85 dB(A)

can be possible at short notice.

ÜUpon oil change pay attention to the oil te perature.The oil te perature ust not exceed

60 °C. Risk of co bustion at oil te perature exceeding 60 °C !

ÜOnly tools that correspond to the standard and design of the bolts, nuts and fittings ust

be used.

Read irst,

then operate!

3

english

ÜDanger of poisoning by inhalation and risk of causticization by touching when

using cleaning agents and sprays.

ÜFollow anufacturers instructions as well as applicable regulations!

4. INADMISSIBLE OPERATION METHODS

ÜWrong direction of rotation.

ÜSwitching-on - during run-down.

- upon rotating in reverse direction.

ÜInad issible pressure increase.

ÜRe aining under or exceeding the li it speed.

ÜExceeding the li it-discharge te perature / please also refer na e plate.

ÜPole-changing to lower speed prior to standstill of the otor.

ÜOperation without oil filling.

5. Transport / Assembl

During transport of the blower unit the following points ust be always observed:

ÜThe hinged otor support ust be always locked by eans of the transport locking

screw / refer to page 10.7. Re ove the V-belts fro the pulleys.

ÜProtect the blower unit fro i pacts.

ÜThe unit is to be transported by eans of crane, high-lift truck, elevating truck or

si ilar.

ÜLift the unit only according to sketch.

Concerning units without acoustic hood, transport is effected by application of the

transport devices at three resp. four eyelets (hinged otor support / base fra e) / or

below the transport lugs.

Upon asse bly the following points are to be observed:

ÜUpon dispatch Positive Displace ent achines are preserved for 12 onths and packed

accordingly. Upon a storage for ore than 12 onths, the preservation is to be repeated,

observe TN0 1175.

ÜDuring storage pay atttention to proper preservation, packing and if necessary

nitrogen filling, according to TN0 1175. Test interval every 6 weeks.

Negative influences are to be re oved i ediately to guarantee a continuous preservation.

ÜInter ediate storage in dry, clean and vibrationless roo s.

ÜDuring storage relieve the V-belts.

ÜIn case of shutdown for ore than 6 weeks, preserve conveying cha ber, pistons and

polished parts.

ÜPlace unit on even, vibrationless and slope-free ground. If necessarry - there is the

possibility to dowel the units. In this case, only one anchor bolt per achine foot

is sufficient.

ÜRe ove the packing aterial co pletely. In case of acoustic hood design ensure free

section of the inlet- and exhaust silencer.

ÜEnsure sufficient aeration and ventilation at place of asse bly / inlet- and exhaust air.

The following standard installation conditions have to be adhered to:

A bient te perature : -10°C to 40°C

Rel. air hu idity : 0% to 80%

Che ical-free at osphere

ÜCheck the blower for s ooth running / tight running ay be the consequence of

distortion or foreign particles.

correct

wrong

4

english

5

ÜIn case of air conveyance re ove the plastic plugs fro the condensate drillings.

This ay lead to a slight air flow to the outside, flushing the condensate drillings.

ÜIn view to conveyance of "Technical Gases" the condensate drillings are closed. If

theconveying ediu tends to develop condensate built-up, the condensate can be

drained depending on the operation case, e.g. by eans of storage tanks, residual

gas pipings or by short-ter opening of the lower drillings.

ÜIn order to avoid electrostatic supercharging of the units, otor, acoustic hood and

base fra e are to be earthed via the provided connections.

ÜFix piping separately, so that stable connection can be established. Connection via

flexible connection co pensator.

ÜConnect electric otor. For its technical details, refer to the na e plate or the

internal side of the ter inal box. Please pay attention to the operating anual

for the otor enclosed separately! The connection shall only be carried out by

authorized electricians.

ÜInstall connection cable for electric otor in such a way that no da ages ay occur

by ove ents of the hinged otor support. Refer instructions G4-031... .

ÜIn case of otor- and belt drive asse bly provided by the

custo er the arked di ensions (X) have to be adhered to

according to Aerzen general tables. Only then, an opti u

design of the drive unit can be guaranteed.

ÜNoise prevention is to be taken into consideration! Pipings

and foundations can be incited to self-vibrations with sound

release.

ÜEnsure that in case of unit planning the safety instructions and

the technical docu ents of the co ponent suppliers are observed.

ÜPrior to co issioning fill up oil.

picture 1

Connection cable transfer

r

VDE 0298

Chapter from G4-031...

Kabel cable Kunststoffkabel

plastic-instulated cable

r

o = 0,6 kV

15 x d

12 x d

o > 0,6 kV

15 x d

15 x d

einadrig single-core

mehradrig multi-core

90 S - 1080 L

english

6. Commissioning

The blower unit is installed in accordance with chapter 5 of these instructions.

In case of initial co issioning:

Fill up lube oil / refer to chapter 10.3 - 10.5

Check oil filling screw and drain valve for tight fit and i per eability.

Pay close attention to co issioning re arks and lubrication intervals of

drive otor anufacturer !

Depending on design, cut off rubber nipple on top of the pressure gauges (if existing) or

turn deaeration bracket to OPEN.

Check direction of rotation.

Also refer to red direction of rotation shield on the blower.

No V-belts ust be placed on the otor disc.

Re ove locking screw between pulley and otor casing.

Start driving otor for a short ti e (approx.1 to 2 seconds).

Please also refer to the instructions of the supplier of electric co ponents

resp. of the plant anufacturer.

ATTENTION ! Incorrect direction of rotation during operation will destroy blower.

Upon looking on the driving shaft the blower rotates anticlockwise.

Direction of rotation of drive otor and blower ust be equal.

In case of correct direction of rotation the following tasks are to be effected:

Re ove transport locking screw of the hinged otor support / refer to 10.7.

Check align ent of the pulleys.

Lift hinged otor support by eans of hydraulic jack.

Put on V-belts (refer to chapter 10.7).The V-belts are tensioned by the otor weight.

Close openings for otor driving shaft in belt guard with pre- ounted,

ovable protection covers.

Slide protection covers up to ax. 2 c to otor driving shaft and secure.

Connect pipings with unit ready to operate,

stickers concerning safety instructions ust be legible and safety devices

are to be inspected.

Open slide valves available at the unit. Operation can start.

Switch on drive otor!

Switch off after approx. 20 seconds and verify the s ooth run-down of the blower.

Should pressure valve blow off, switch off i ediately and re ove cause of failure.

Then, switch on again and check EMERGENCY-OFF switch!

Now the unit is ready to operate!

Þ

Þ

Þ

Þ

Þ

Þ

Þ

Þ

Starting

Operation

Preparation

6

english

7

7. Admissible connecting frequencies of the

drive motors

To 160 kW = 6 starts per hour

Fro 200 kW = 3 cold starts or 2 war starts

ÜFor further indications and advice, please refer to the docu entation of the

otor anufacturer.

ÜPlease also refer to chapter 2, otor connection.

8. Shutdown

Shutdown:

By eans of the power switch of the otor. Following standstill of the blower, withdraw

fuses. Ensure that the slide valves in the pipings are closed. Preserve the conveying

cha ber if standstill lasts longer than 6 weeks. Rotate the blower regularly by hand,

in order to prevent da ages which ay arise fro standstill.

In case of danger:

Press EMERGENCY-OFF button.

For details please refer to the instructions of the supplier of electric co ponents resp. of

the plant anufacturer.

9. Operation of compressor units

9.1 with requency converter

The following has to be taken into consideration:

ÜIn case the frequency converter is provided by others the electrical and

echanical characteristics of the driving otor are to be taken into account.

ÜThe ini u frequency ust always be set in a fixed anner.

Upon operation this frequency ust not be re ained under.

ÜThe axi u frequency ust be set under consideration of the axi u

otor speed and the axi u blower- / co pressor speed.

ÜThe run-up ti e of driving otor fro standstill up to ini u speed ay be 3 to 6

seconds.

ÜThe frequency converter ust be designed for operation of a work achine with

constant load o ent.

Min.- or ax. speeds are not to be re ained under or exceeded.

Shutdown

english

ÜThe highest ad issible voltage increase speed of the otor converter is

1200 V/ms. When exceeding the value, e.g. due to too long cables, frequency

converter ake etc. a otor throttle / otor filter coil corresponding to the frequency

converter is to be applied. A renunciation of these co ponent parts ay lead to a

da age of the otor isolation and to a otor breakdown.

ÜThe ax. speed regulation speed on Positive Displace ent blowers /Screw

co pressors after run-up to in. speed for regulation ti e upward and downward is

1 Hz per second.

Min.-frequency = 20 Hz // Max.-frequency = 50 Hz results in a regulation ti e fro

in. to ax. of 30 seconds.

ÜThe ax. current li it of the otor ust not be exceeded.

Observe the details on the otor na e plate.

ÜIn order to avoid operational failures the function "flying restart circuit" ust not be

para eterized in the control of the frequency converter. Upon shutdown of the

frequency converter a re-start is only per itted following co plete standstill of

blower resp. co pressor.

9.2 with pole-changing motor

The following has to be taken into consideration:

ÜBetween a change of otor speed

- fro high to low speed the otor ust have reached each ti e

speed zero.

- fro low to high speed switching can be effected directly, undelayed.

10. Attendance / Maintenance

The attendance / aintenance consists of the following points:

Inspection - Pressure valve test - Exchange o lubricants - Lube

oil regulations - Exchange o V-belts - Intake ilter maintenance -

Attendance

In case of questions, please refer to the Aerzen after-sales service.

Please state the following in your queries:

ÜOrder- and serial nu bers.

ÜDescribe arisen failures / alfunctions as detailed as possible.

ÜSteps taken so far to re ove the failures.

Is the blower sent back to the supplier, the following easures are to be carried out:

ÜDrain the oil, otherwise it is a transport of hazardous goods.

ÜProvide unpolished parts with a preservation oil.

ÜClose blower flanges by eans of blind covers.

8

english

10.1 Maintenance schedule

Maintenance intervals

We rec mmend carrying ut maintenance n the bl wer at

the intervals specified bel w. The perating h urs refer t

n rmal perating c nditi ns. Other intervals c uld apply

depending n envir nmental c nditi ns. In this case please

c nsult Aerzener Maschinenfabrik.

After the first

3 Oh

After the first

25 Oh

Weekly

After the

first 500 Oh

After each 1000 Oh

- 1/2 yearly in clean

environment

- monthly in dusty

environment

After each 4000 Oh

r 1/2 yearly

After each 8000 Oh

r yearly

After each 20000

Oh

r after 3 years

Starting strainer, if installed

- check; if no more contaminant it can be removed

Retaining screws and fittings

- re-tighten after machine has cooled l

Intake filter

- check filter contaminaton, replace if necessary, max. -45 mbar

- replace filter insert

l

l

Air intake penings

- check on acoustic hood and clean

l

l

V-belt c nditi n

- check, replace if necessary lll

l

V-belt pulley alignment

- check, adjust if required ll l l l

Pressure valve

- check for function ll

Oil level

- check ll

Lubricating il

- exchange

*at end temperatures of above 120° C ll

l*

N n-return valve

- check for wear and tightness l

Drive m t r

- carry out maintenance

- observe grease replacement intervals

- observe maintenance intervals and specifications of motor manufacturer!

- in cas of Aerzener motors observe additional information 4PG-702!

Main inspecti n / maintenance

- replacing wearing parts

- check complete machine l

Whenever carrying ut w rk n the bl wer, it must be switched ff, t prevent injury and damage! T gaurantee l ng

service life and ptimum perating c nditi ns, the maintenance w rk listed in the f ll wing table must be carried ut

at the specified intervals.

Have the bl wer checked by Aerzener service at the specified intervals r yearly. Or: Take ut a

maintenance c ntract with Aerzener Maschinenfabrik. Thr ugh regular and pr per maintenance

Aerzener Machinenfabrik gaurantees maximum safety f r y ur perati n.

l

Only for asti ht shaft seal, grease

- exchange

*at end temperatures of above 120° C ll

l*

10.2 Inspection / - dates

After 3 years or 20,000 operating hours we reco end a general inspection at site by an Aerzen

technician. On this occasion a preventive overhauling of wearing parts, such as bearings, sealings or

si ilar is effected. We reco end to keep wearing parts on stock, in order to avoid waiting ti es and

non-productive ti es in case of failures.

9

english

10

10.3 Exchange of lubricants

In case of gastight design depending on type of sealing

Weekly - Check oil level in the oiler, if necessary - refill the oiler.

Yearly - Provide shaft sealing with roller bearing grease / so e operating hours

before oil change, so that the surplus of grease is flushed out.

Fill up oil

ÜDrain valve (c) ust be closed / ensure tight fit.

ÜOpen oil flling (b).

ÜFill up oil / at first not until center of sight glass /

oil can run down the inside walls.

ÜAdjust oil level to center of sight glass.

Pay close attention to both oil cha bers

being filled separately and drained.

It is also i portant that the oil levels are checked at both sight glasses.

GM 3S -

GM 80 L

GM 90S -

GM 400 L

a - easuring device

connection

b - oil filling

c - oil drain /

drain valve

d - oil level

oil level too high

oil in the conveying

chamber

oil level too low

mechanical

damage at bearings

and gear wheels

oil level at

machine standstill

Weekly

Check level in the

oiler refill oil, if

necessary

Shaft sealing with

roller bearing grease

lubricate again /

several operating

hours prior to oil

change so that the

excess grease is

flushed

At gastight design depending on the sealing method

Exa ple

- oiler

- grease lubricating

bush

- lubricating nipple

*

Re-lubricati n

GM 3S - 30

GM 35S - 130

GM 150S - 400

» 5 cm³

» 10 cm³

» 20 cm³

Lubricating grease, when usin the

oil types acc. to oil specification, point 1 and 2,

>> except poly lycol oils <<

KHC-2P- 0

Filling at works

KLÜBER PETAMO GHY 133 N

Lubricating grease,

when usin of poly lycol oils, point 3

MPG2K-40

KLÜBER SYNTHESO PROBA 270

lA mixing of different greases is to

be avoided.

lA re-lubrication is admissible only

with the same grease.

lIf these greases are not available,

they are to be removed completely and

to be replaced for other greases acc. to

KHC-2P-30 resp. MPG2K-40.

lNote sealing consistency with Viton.

english

11

1

Exa ple a) b)

Drain oil

a) b) Screw cap (1), threaded socket (1) off the drain valve.

In case of very tight fit of the cap (1), threaded socket (1), the valve is to be

fastened by eans of an open-end spanner and ite (1) is to be loosened by

another spanner.

a) Screw on the delivered hose.

a) Drain valve opens auto atically.

a) Lead hose end into a collection reservoir.

b) Open hand valve, lead waste oil into a reservoir

a) b) Effect proper disposal of used oil.

a) Re ove hose fro drain valve.

b) Close hand valve, screw threaded socket (1)

under holding the valve

a) Seal drain valve with the cap (1) by hand.

a) b) As soon as the co plete drain valve loosens,

it is to be replaced by a new valve with a new sealing.

10.4 Lube oil regulations for "Standard"

Positive Displacement blowers

Require ents to lube oil characteristics

lKine atic viscosity at 100°C at least 13 cSt ( ²/s).

lKine atic viscosity at 100°C at least 28 cSt ( ²/s), only applicable for ite 3.

lKine atic viscosity at -10°C < = 3500 cSt ( ²/s).

lOil additives, with the following minimum characteristics:

- EP wearing protection additives for use in anti-friction bearing gearboxes

- oxidation stability up to 110°C, at item 3 from 110°C up to 220°C oil temperature

- foam suppression agent

- Detergents for loosening of deposits

- Neutrality compared to sealing materials made of Viton (Fluorine-Propylene-Methyl)

- Neutrality compared to single-package-synthetic resin primer

1. One- or two-shift operation / intermittent service

application conditions - intake te perature up to 60°C

- discharge te perature up to 140°C

- a bient te peratures which ay re ain under 10°C .

Ü5W-40 / full-synthetic high-perfor ance light otor oil, as per oil specification

- API CF or higher - ACEA B3 / E3 or higher

Example Aerzen Special oil Order No. 160 754 or 160 755

2. Continuous operation 24 hours / day

application conditions - intake te perature up to 60°C

- discharge te perature up to 140°C

- a bient te peratures above 10°C all the year round

Ü5W-40 see also ite 1

ÜPAO gearbox oils / full-synthetic Poly-Alpha-Olefins

Example MOBIL SHC 629 / and as mentioned under item 1

3. Operation at continuous oil temperatures above 120 C

application conditions - continuous oil te peratures above 120°C

- at oil te peratures above 160°C the oil change intervals halve

ÜISO VG 220 / synthetic lube oil with a basic oil type Polyglycol

Example ESSO Glycolube 220 ARAL Degol GS 220

4. Lube oils in foodstuff and pharmaceutic industry

Lube oils, approved acc. to USDA H1 can be used.

Example Klüberoil 4 UH1-100 application at conveying discharge temperatures up to 100°C

Klüberoil 4 UH1-220 application at conveying discharge temperatures from 100°C up to 140°C

General

ÜIn case of a change-over fro one oil brand to another an oil change has to be carried out

after 24 operating hours.

ÜFor filling or refilling the oil cha bers, lube oil of the sa e brand and sa e type is to be

used only.

ÜAll the oil brands can be used observing the specification.

Table of contents