Aeson Power TL-LFP Series User manual

Page 1

Installation and Operation

Manual

4.8

to 38.4

kW

h 48Vdc

Battery

Energy

Storage Unit

Page 2

Contents

Part 1 - Safety & Warning..................................................................................................................................3

Part 2 - Product Introduction..............................................................................................................................4

2.1 - Overview..............................................................................................................................................4

2.2 - Working Principle ................................................................................................................................4

2.3- Battery Management System (BMS)....................................................................................................5

2.4- Applications..........................................................................................................................................8

2.5- Battery Model Name.............................................................................................................................8

2.6 - Electric Performance...........................................................................................................................8

2.7 -Structure and Mechanical Performance...............................................................................................9

2.8 -Appearance & Mechanical Drawing...................................................................................................10

Part 3 - Technical Characteristics....................................................................................................................11

3.1 - Discharge Performance.....................................................................................................................11

3.2 - Charge Performance......................................................................................................................... 12

3.3 - Constant Current Discharge Table.................................................................................................... 12

3.4 - Constant Current Discharge Table................................................................................................... 13

Part 4 - Operation & Maintenance .................................................................................................................. 12

4.1 - Requirements for Operation Environment .........................................................................................14

4.2 - Parameter Settings of Power Plant....................................................................................................14

4.3 - Charge/Discharge Modes and Conditions.........................................................................................15

4.4 - Layout of Front Panel.........................................................................................................................15

4.5 - Shipment ............................................................................................................................................17

4.6 - Installation ..........................................................................................................................................17

Unboxing & Inspection ........................................................................................................................ 17

Preparation for Installation.................................................................................................................. 17

Installation of Rack without batteries installed....................................................................................17

Installation of Rack with batteries installed.........................................................................................21

4.7 - Storage............................................................................................................................................... 26

4.8 - Maintenance.......................................................................................................................................26

Part 5 - Troubleshooting & Solutions................................................................................................................27

Annex 1 - Instructions for LED Flicker............................................................................................................... 27

Annex 2 - Instructions for Adding Dialer............................................................................................................ 29

Annex 3 - Communication Protocol for RS232 and RS485...............................................................................30

Annex 4 –Rack Tech Data................................................................................................................................31

Annex 5 –Installation Recommendations..........................................................................................................32

Page 3

Part 1 - Safety & Warning

The TL-LFP series LiFePO4 battery system installation, operation and maintenance should

follow important recommendations in this manual:

▪The equipment must be installed by a licensed electrician.

▪Battery maintenance should be carried out by experienced professionals, fullytrainedinsafety

measuresand aware of the risks and dangers presented by the battery.

▪

Note:

Beware of the risk of electric shock by heavy current in case of battery short circuit!

Before commencing work:

•Remove watches, rings and other metal object from your hands;

•Use only tools with insulated handles;

•Please check if the package box is intact. If the box is damaged - immediately notify the supplier;

•If you find leaking liquid or white powder residue on product –stop the operation.

During the operation:

•Do not place tools or metal objects on the battery;

•Disconnect the mains AC power supply to the battery system;

•Do not use or store the battery near to the high temperature source;

•Avoid open fire near the battery;

•Avoid using liquids or other objects filled with liquid near the battery;

•Do not open or cut the battery;

•Do not to hit, throw or step on the battery;

•Use only special communication cable set between battery module(s) and charging equipment;

•The charge and discharge of the battery must be conducted within parameters set in this Manual;

•The output interface of the battery system is LIVE and under dangerous voltage when the mains

power supply is OFF - beware of electric shock or battery shortcircuit during the operation;

Page 4

Part 2 - Product Introduction

2.1 - Overview

TL Series Lithium-Ion batteries is a range of batteries packed with advanced LiFePO4

technology and possessing intelligent integrated BMS.

The TL battery range has the advantages of:

- Long cycle life;

- Light weight;

- Small size;

- Safety;

- Being environmentally friendly.

Lithium-Ion batteries of the TL Series can be used in a wide variety of indoor and outdoor

applications.

2.2 - Working Principle

The communication standby power supply (module) consists of multiple lithium iron

phosphate battery cells connected in series, and controlled by the dedicated high

performance and high reliability Battery Management System (BMS).

The +/- power output cables of the battery are to be connected to the +/- terminals of the

charging device.

When the mains / solar power is insufficient for the load or is interrupted, the battery will

provide the power supply to the load without delay, until the mains / solar power supply is

restored. In the case of the outage continuing for longer time than the battery has been rated

for - the BMS will disconnectthe battery from the load in order to protect the battery from over-

discharge.

Page 5

2.3- Battery Management System (BMS)

The TL–LFP Series battery modules are equipped with technologically advanced Integrated

Smart BMS.

Features of the BMS are described below:

Overcharge Protection

When the voltage of any cell comprising a module, is greater than the Overvoltage setting,

and the duration of the Overvoltage status exceeds the set time delay of the overcharge

protection, the OV Protection plate closes the MOSFET on the charging circuit and the

charging is interrupted.

When, after the OV status occurs, - the highest voltage cell indicates the voltage reduction to

the overcharge recovery mode, or below - the OV Protection plate judges that the overcharge

conditionis over. Followingthat, the charging MOSFET is open,the charger starts to supply

the battery module, and the green RUN light on the protection plate lights up signalling that

the charging is ON.

During the Overcharge condition the battery module can still discharge on the load.

Over-discharge Protection

In the case of any cell within the module, developing voltage that is lower than the over-

discharge setting, and such condition lingers longer than the over-discharge time-delay setting

–the protection plate judges that the module is in state of Over-discharge. The green RUN

light and red ALM light are both extinguished, the MOSFET on the discharge circuit closes

and the battery module discharge on the load is interrupted.

When over-discharge (undervoltage) condition occurs, the protection plate is de-activated.

When the charger supply is restored –the protection plate gets re-activated .

Overcurrent/short circuit protection and recovery

When the discharge current exceeds the short-circuit protection current settings, and the

duration of such current exceeds the time-delay of the short-circuit protection setting -

- the red ALM light will come on, and

the protection plate enters the overcurrent / short-

circuit protection status, under

which charge / discharge modes are prohibited.

After the protection plate entered the overcurrent / short-circuit protection condition, it will lock

the OV/SCprotectionstatus until time the charger restores the power supply.

Page 6

Heat Management

The thermal management BMS function can be described as follows: if the battery temperature

exceeds the set normal working parameters (higher or lower), the alarm will be raised - red ALM

light will come on and the battery will be disconnected.

When the temperature of the battery, after having been disconnected due to over-temperature

condition, drops to the set value of normal working parameters, the BMS reconnects the battery

to the load / charge, and the red ALM light is off.

The BMS temperature sampling accuracy is less than

± 2°C within the operating temperature

range. Four battery temperature detection points and one ambient temperature detection

point are supported by default. Maximum available number of temperature detection points

–16.

Battery internal heater

VHR TL48150LFP is equipped with an internal heater. The heater is rated 100W. If the battery is not under

charge

and the BMS sampling facility detects the ambient temperature that is below

0

℃ -

the BMS will turn the

heater ON.

The heater is optional for other models.

Battery capacity calculation function

To calculate the State Of Charge (SOC) of the battery –the Amper-Hour Integral and Open

Circuit Voltage (OCV) methods are implemented. The combination of adjustment of the

algorithm, the higher precision data and the independent clock system - ensures accuracy

(≤ ± 2%) of the SOC estimation.

Balancing Function

If the module battery pack is fully charged, and one of its cells has the voltage set to start the

equalization and at the same time, the cell’s maximum voltage difference is greater than the

equalization voltage difference –this cell activates the equalisation function.

The battery module is capable of conducting equalization on 7 channels simultaneously. The

maximum equalization currentaround 75mA. The equalization balancing process will be finished

when the voltage difference of the cells is less than pre-set value.

Page 7

Sleep and Wake Function

No.

Sleep condition

Wake-up condition

Remark

1

In the idle state (no charge, discharge, no

communication), the lowest voltage of any

cell is lower than the set sleep voltage (can be

set), after 30 minutes, enter normal sleep.

Charge and discharge,

communication, reset

button, soft switch

The battery with a

soft switch can be

wakened up

2

When the minimum cell voltage is lower than

the cell over-discharge protection value (can

be set) or the total voltage is lower than the

overall over-discharge protection value (can

be set), and after 1 minute, the under-voltage

sleep is entered.

Charge, reset button,

soft switch

The battery with a

soft switch can be

wakened up.

3

Battery will enter to normal sleep after

keeping idle state (no charge and discharge,

no communication) for 24 hours.

Charge and discharge,

communication, reset

button, soft switch

The battery with a

soft switch can be

wakened up

4

Forcing sleep through the host computer or

soft switch

Reset button, soft switch

N.A.

Communication function

Battery communicate with a computer, server or host through RS485, upload and save the

collected

information. CAN bus communication, 3G/4G communication and Bluetooth

communication can be optioned.

Anti-theft function

When the external load is disconnected, the BMS cannot detect the load resistance, and it will

enter into a locked state, unable to conduct charging and discharging

Note: 1. Please refer to “Specification of each models” for detail BMS parameter setting value.

2. LCD display screen is provided as an option.

3. Anti-theft function is provided as an option.

4

. Thermal management in low temperature heating and high temperature heat dissipation

is optional.

Page 8

2.4- Applications

▪Telecommunication

▪Indoor distribution system

▪Energy storage system

2.5- Battery Model Name

2.6 - Electric Performance

Table 2.1 - Battery Model & Electric Performance

Page 9

2.7 -Structure and Mechanical Performance

Table2.2 - Mechanical Performance

Page 10

2.8 -Appearance & Mechanical Drawing

Page 11

Part 3 - Technical Characteristics

3.1 - Discharge Performance

Fig. 3.1 - Constant Current Discharge Curve of TL-LFP Series @25℃

Fig. 3.1 - Discharge Curve of different temperature of TL-LFP [email protected]

Page 12

3.2 - Charge Performance

Fig. 3.3 - Charge Characteristic with Various Current Limitation of TL-LFP Series

3.3 - Constant Current Discharge Table

Table 3.1Constant Current Discharge Table(25℃)

Page 13

3.4 - Constant Current Discharge Table

Part 4 - Operation & Maintenance

4.1 - Requirements for Operation Environment

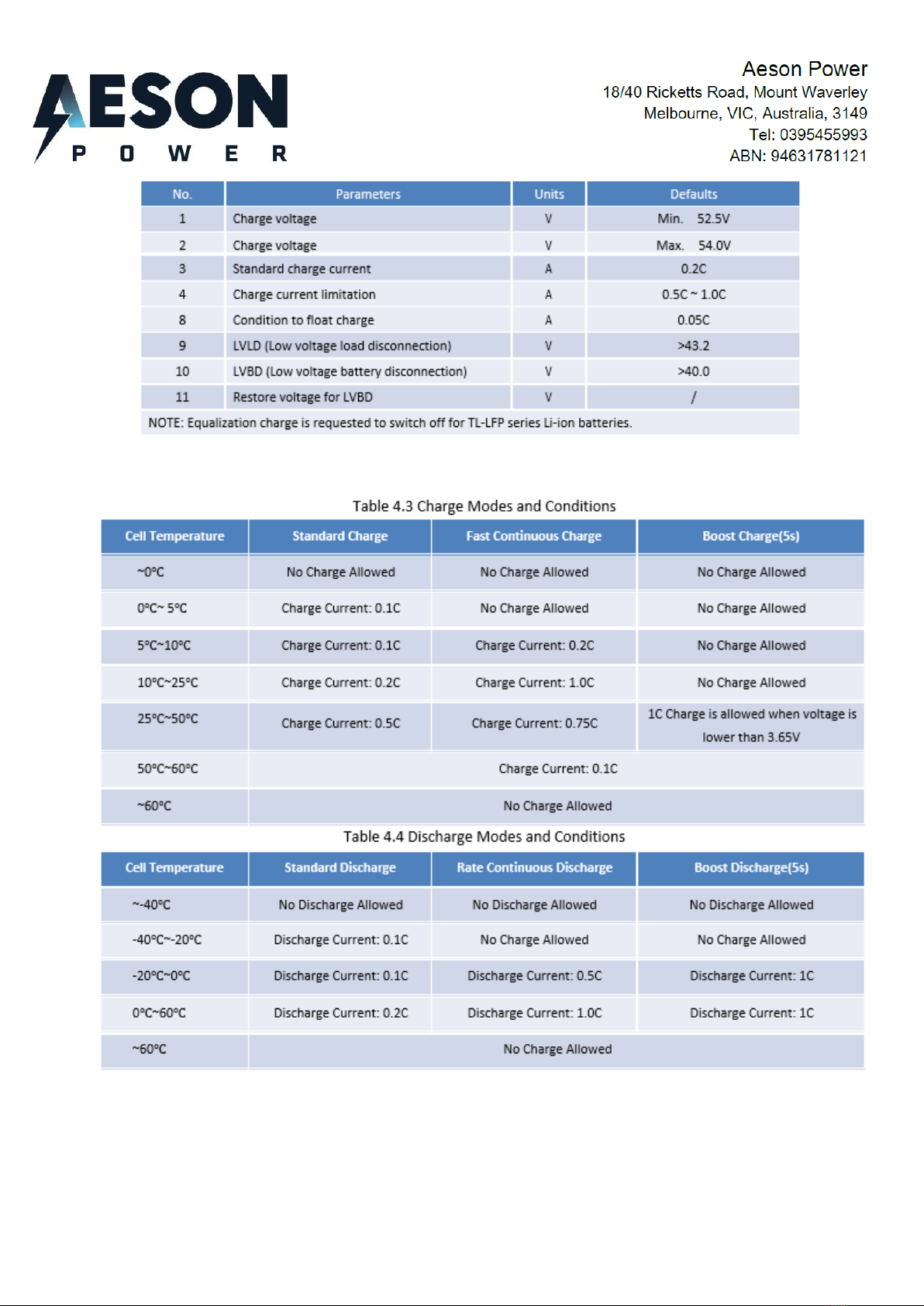

4.2 - Parameter Settings of Power Plant

Lead-acid batteries can be replaced by lithium battery of TL-LFP series if power is matched. Table 4.2

Parameter settings of power plant for lithium-ion battery.

Table 4.2 - Parameter Settings of Power Plant for TL48V-LFP Series Batteries

Page 14

4.3 - Charge/Discharge Modes and Conditions

Page 15

4.4 - Layout of Front Panel

Table 4.5 - Instruction for Layout of Front Panel

No.

Marks

Functions

Detailed Information

1

SOC

Indicators for

capacity

There are four green LED lights in front panel indicating SOC.SOC is short for

state of charge. Each SOC LED light represents 25% of rated capacity.

Detailed information is

shown in Annexed Table 1.1.

2

ALM

Indicator for

alarms

There is one red LED light in front panel indicating alarms. Detailed

information is

shown in Annexed Table 1.2.

3

RUN

Indicator for

running status

There is one green LED light in front panel indicating running status.

Detailed

information is shown in Annexed Table 1.2.

4

ADD

Address of

communication

ADD is applicable to modules connected in parallel. ADD consists of four

binary bits,

and maximum quantity of batteries connected in parallel is

64pcs (2^6). Detailed

information is shown in Annex 2.

5

RS232

Up-link

communication

port

It is adopting RS-232 series port to upload data. Contents of data transmit

include BMS

parameters, battery running status, alarms, etc. Generally,

speed rate of RS-232 is

200bps. RS232 up-link communication can be

available for the battery module with a

binary communication address of

0000

(Master PACK). Protocol for RS232

communication is shown in Annexed Table 3.1

1

2

3

4

5

6

7

8

8

9

Page 16

6

RS485

Cascading

communication

port

It is adopting RS485 series port communication pattern to upload data.

Communication

of modules connected in parallel (Slave PACKs) is available

through RS 485. Data of

slave PACKs will be transmitted to Master PACK.

Protocol for RS232 communication is

shown in Annexed Table 3.2

7

RESET

Reset button

Press RESET button when abnormity occurs to assure stability of battery

performance.

8

Battery

Output

Battery

Output

Using terminals with two or four cores. Polarities are +, -, +, - from left to right.

The two ‘+’and ‘-’are equal relatively.

9

Power

Button

ON/OFF Soft

switch

When battery is turned-off, battery get into sleep mode, and cuts-off output,

power and alarm outputs.

4.5 - Shipment

The battery system will either come in 2 different packaging solutions depending on your

needs, the first option will be shipped as a complete battery system ready to be installed and

connected at site. The second solution is shipped in 2 parts with batteries removed from the

rack to assist the customer with site requirements. All options are shipped on pallets that will

either require a forklift or pallet jack for final positioning. With the second option for the parts

are broken down on pallets for a 2-person manageable lift to final positioning. Violent vibration,

impaction or squeezing should be avoided in the transport process; neither rack or batteries

should be exposed to sunlight nor rain. The rack and batteries shall be shipped by normal

transportation such as by road, by train, by ocean or by air.

4.6 - Installation

Unboxing & Inspection

•

Please read this manual before installation.

•

Please inspect the package before unboxing, if any damage with contents, please contact

the supplier as soon as possible.

•

This device shall be installed and operated by professionals.

Preparation for Installation

•

Rack & batteries shall not be placed in direct sunshine or close to a heat source.

•

Rack shall be installed in place with good ventilation to assure enough heat

dissipation.

•

Rack shall be placed in an area with clean ambient temperature with low humidity not

exceeding 25 degree Celsius.

Page 17

Removal of Rack from shipping Pallet

1) Rack with no batteries installed.

•

Rack transport mounting screws will need to be removed before final positioning.

•

Remove covers in the bottom of the rack as shown in the picture as shown below to gain

access to the transportation bolts and plates.

•

Using a shift, spanner or socket, remove the M12 nuts and bolts plus the transportation

plates from the pallet.

•

Once the rack is free from the pallet, lift the rack from the pallet and place on the ground.

•

Remove bottom side panels on the rack so that a pallet jack or set of furniture lifters can

be placed underneath the rack to move into its final position.

•

Once in final position, start installing the batteries into the rack, please note each battery

has been labelled with a number on the front of them for placement back into the rack.

The lifting of the batteries back into the rack requires a 2 person lift to safely install.

•

Check all DC circuit breakers are off, and all batteries are off before reconnecting the pre

wired battery cabling to each battery, please note all cabling is black but is marked with

red and black heat shrink to differentiate between positive and negative battery cabling

and terminals on the battery.

Remove cover at each end of the rack as shown in the below pictures to gain access to

the transport bolts

Page 18

The transport bolts are M12, use shifters, spanners or sockets to remove these bolts to

free the rack from the pallet.

Once transportation Screws have been removed from the Rack, it is safe to remove the rack

from the pallet, please note to remove the rack from the pallet it is recommended the use of

more than 2 people to safely lift the rack from the pallet and on to the floor.

Once the rack is on the ground, remove the side covers to insert pallet jack or furniture lifters

to move into its final position.

Page 19

Below are recommended furniture remover dollies to lift and move the rack into the final

location.

•

Insert battery module into rack, using the two fixing handles of each battery module and

use the M6 screws to fix in to position.

•

Connect ‘+’ of the Battery positive terminal to red cables, and connection ‘-’of the Battery

negative terminal to black cables.

Page 20

Installation of Battery Modules if supplied under option 2

1) Rack with batteries installed.

•

Rack transport mounting screws will need to be removed before final positioning.

•

Remove covers in the bottom of the rack as shown in the picture as shown below to gain

access to the transportation bolts and plates.

•

Using a shift, spanner or socket, remove the M12 nuts and bolts plus the transportation

plates from the pallet.

•

Remove bottom side panels on the rack so that a set of furniture lifters can be placed

underneath the rack.

•

If a fork lift is available, use to remove the rack from the pallet. Otherwise use the below

procedure.

•

Once the rack is free from the pallet, Use a saber saw or hand saw to remove certain

sections of the pallet as pictured below so the furniture lifters canbe inserted on both sides

of the rack, pump the furniture lifters up so the rack is lifted above the pallet by 3 to 5mm.

Check the furniture lifters are secure and safe to handle the weight of the rack with the

installed batteries, then cut off the front section of the pallet and pull the pallet out from

underneath the rack. Once the pallet has been removed from underneath the rack let the

furniture lifters down so the rack is on the ground.

•

Now the rack is on the ground the furniture lifters or a pallet jack can be used to move into

its final position.

This manual suits for next models

2

Table of contents