CONTENTS

1 Foreword.................................................................................................................................................

2 Safety........................................................................................................................................................

2.1 Safety Precautions......................................................................................................................

2.2 Abuse Operation.........................................................................................................................

3 Overview..................................................................................................................................................

3.1 Product Description...................................................................................................................

3.1.1 Features...............................................................................................................................

3.1.2 Basic Functions.................................................................................................................

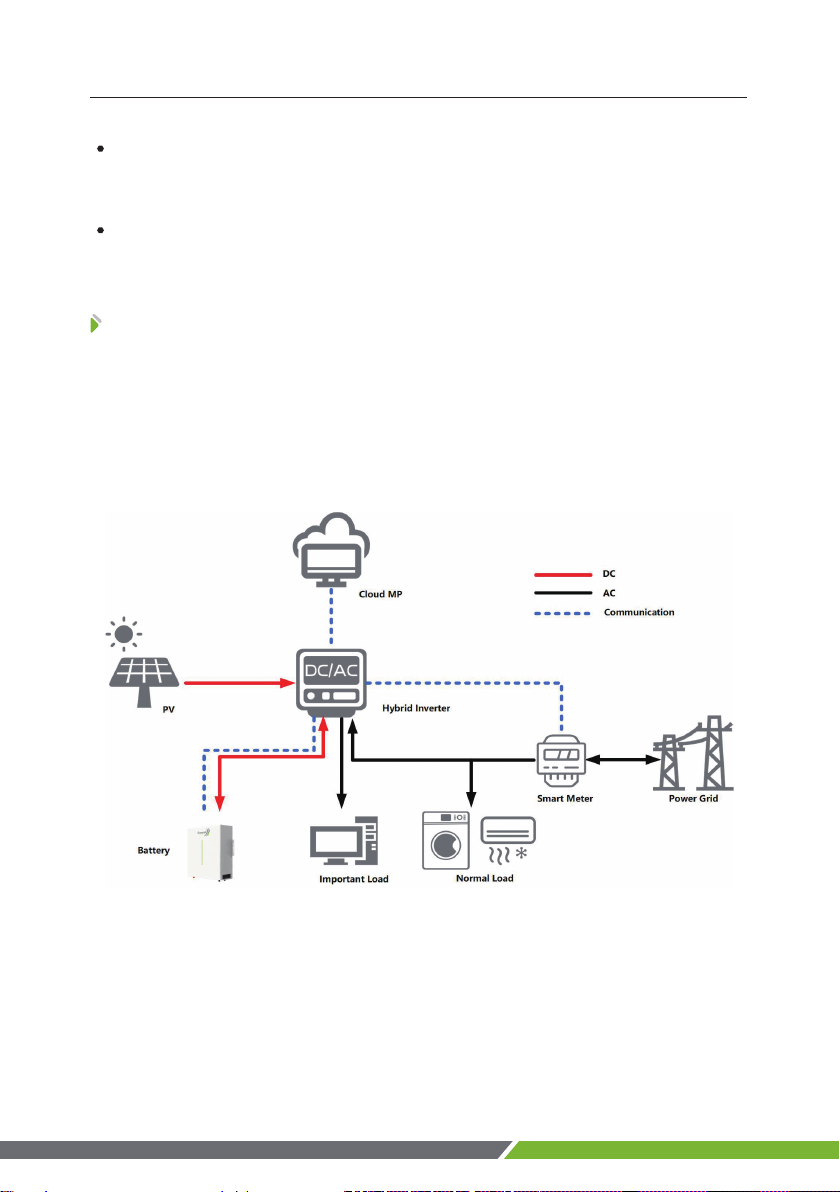

3.2 Application Scenario.................................................................................................................

4 Application Description.....................................................................................................................

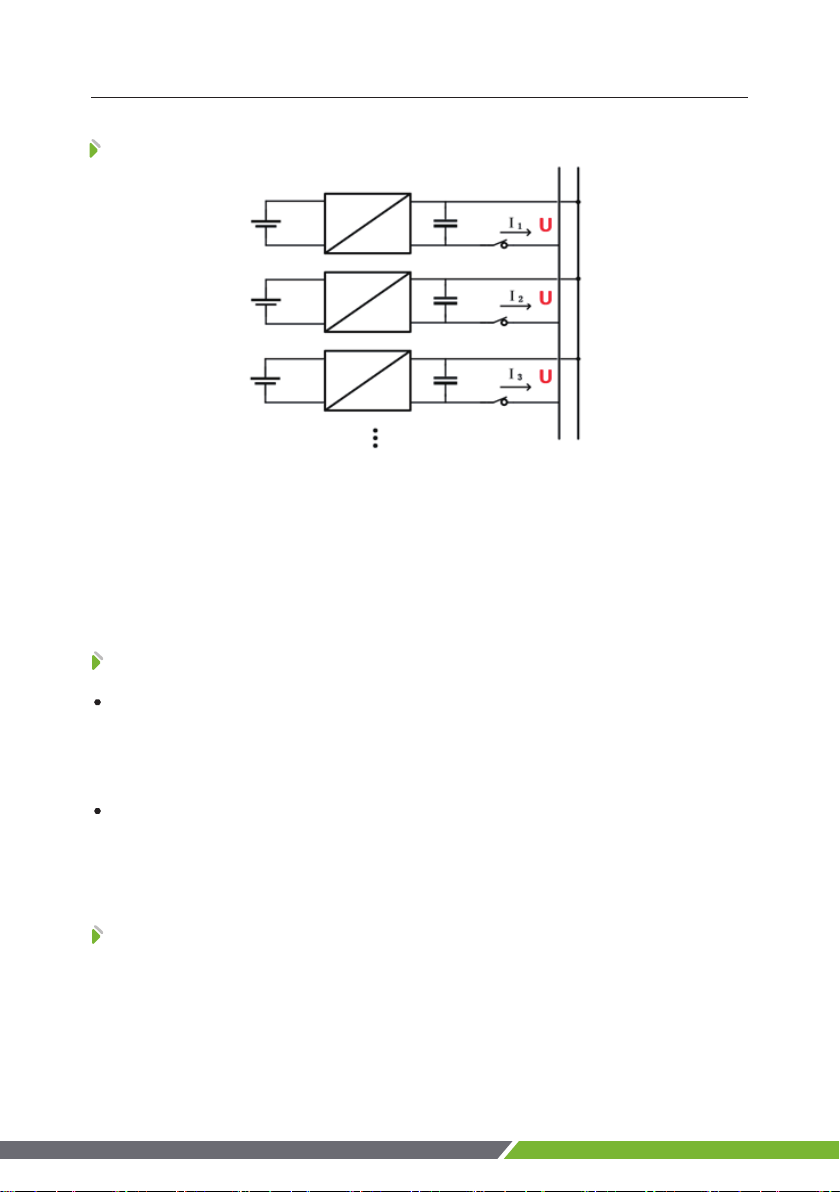

4.1 Parallel Connection Application............................................................................................

4.2 Low-temperature Application................................................................................................

4.3 Low Battery-capacity Storage (SOC≤5%)...........................................................................

4.4 Application of Nearing the Ocean.........................................................................................

5 Product Introduction..........................................................................................................................

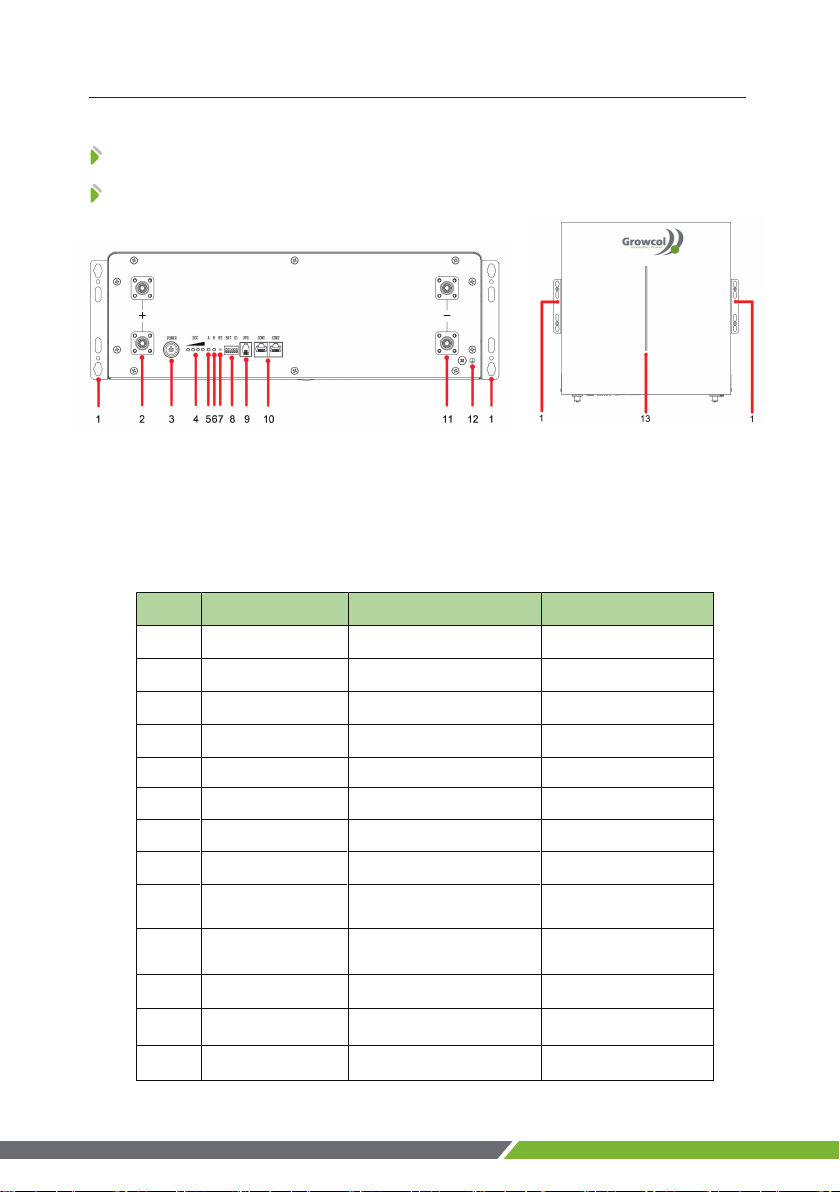

5.1 Panel Introduction......................................................................................................................

5.1.1 Panel Function...................................................................................................................

5.1.2 Indicator Description......................................................................................................

5.1.3 DIP Address........................................................................................................................

5.1.4 Communication Port Definition..................................................................................

6 Installation..............................................................................................................................................

6.1 Tools Preparation........................................................................................................................

6.2 Unpacking and Inspection.......................................................................................................

6.3 Preparing for Installation.........................................................................................................

6.4 Installation....................................................................................................................................

6.4.1 Wall Mouning...................................................................................................................

6.4.2 Rack Mouning...................................................................................................................

6.5 Cable Connection.......................................................................................................................

6.5.1 Power Cable Connection...............................................................................................

6.5.2 Communication Cable Connection............................................................................

6.5.3 120Ω Resistor Connection............................................................................................

7 Power On.................................................................................................................................................

7.1 Power-on Operation (For professionals).............................................................................

7.1.1 Power-on Check................................................................................................................

7.1.2 UIWare Configuration.....................................................................................................

7.2 Power System Parameter Setting................................................................................................

8 Shipment & Maintenance & Storage...........................................................................................

8.1 Shipment.......................................................................................................................................

8.2 Maintenance................................................................................................................................

8.2.1 Battery Maintenance Considerations.......................................................................

8.2.2 Routine Maintenance.....................................................................................................

8.3 Battery Storage...........................................................................................................................

9 Trouble Shooting.................................................................................................................................

10 Warranty...............................................................................................................................................

11 Abbreviations.....................................................................................................................................

1

2

2

2

3

3

3

3

4

5

5

5

5

6

7

7

7

8

10

11

11

12

12

13

13

13

16

18

18

20

21

22

22

22

23

24

25

25

25

25

26

27

28

29

30