aevit SMART-SHIFT User manual

SMART-SHIFT INSTALLATION

TABLE OF CONTENTS

1. OVERVIEW 1

2. INSTALLATION 2

2.1 SHIFT CABLE INSTALLATION 2

2.2 MOUNTING THE SMARTSHIFT ACTUATOR BRACKET 10

2.3 MOUNTING CONTROLLER AND TOUCHPAD 11

2.4 ELECTRICAL CONNECTIONS 11

3. CALIBRATION 15

SMART-SHIFT INSTALLATION

The EMC Smart-Shift answers all of the“shifting” needs of the individual, the installing dealer, and the driver

rehabilitation professional. This system can be installed in almost any vehicle equipped with a cable actuated

automatic transmission to remotely operate the vehicle’s shifting functions. The Smart-Shift is operated by the

four illuminated tactile buttons on the front of a small (5.5” x 3.25” x 1”) touchpad. Each button is positioned

below the icon representing the corresponding gear which it operates. Each icon has an LED to signal when

the actuator has reached the programmed position.

The Smart-Shift incorporates positional feedback so that the actuator can be automatically positioned in up to

seven selector choices; Park, Reverse, Neutral, Drive, Drive3, Drive2, and Drive1 (Drive3, 2, & 1 are not available

for all vehicles). When the vehicle is in Park and any other key is depressed, the actuator will move the shifter

cable to the selected gear, stop automatically and illuminate the LED indicator. No more missed gears or wait-

ing in trac for the actuator to slowly move. In addition, the multifunctional “D” button can be programmed

for up to four dierent Drive positions (Drive, Drive3, Drive2 & Drive1).

Operation of the system is quite simple. While the vehicle’s ignition is ON and the brakes are applied, press any

of the four buttons to move the vehicle’s transmission to the selected gear. To activate Drive 3, 2 & 1 simply

press the Drive key while in Drive. Each time the key is depressed it will cycle through each position. The “D”

LED will continually ash while you are in Drives 3, 2 & 1, with each one ashing at a dierent rate. To exit any

of the low Drives, just depress any key, and the vehicle’s transmission will be switched to that position. The

Smart Shift requires two inputs for the system to operate; 1) the ignition of the vehicle must be “On”and 2) the

brakes must be applied.

The Smart-Shift includes a Touchpad, Actuator (and mounting bracket), Controller Module, Vehicle Interface

cord, a telco cord, and an Universal installation kit. The actuator will need to be mounted in such a way that

it will interface with the vehicle’s transmission shift cable. This can be done by mounting the actuator and

bracket to the vehicle to provide solid connection that the transmission cable will reach. The Universal instal-

lation kit includes additional, smaller mounting brackets for mounting the actuator to the vehicle along with

hardware and a cable bracket to secure the tranmission shift cable to the actuator.

M11

1. OVERVIEW

1

SMART-SHIFT INSTALLATION

Mounting the actuator to the vehicle’s shift cable and than to the vehicle are the most important parts of the

entire installation process. The actuator can position itself accurately to within 1/32”of travel. If the shift cable

is not positioned mechanically correct relative to the actuator, the shift positions will vary with each applica-

tion due to freeplay in your mechanical installation. For this reason, EMC supplies the Smart-Shift mounting

bracket preassembled to the actuator. Determine the method for attaching the shift cable rst, followed by

securing the actuator mounting the bracket to the vehicle.

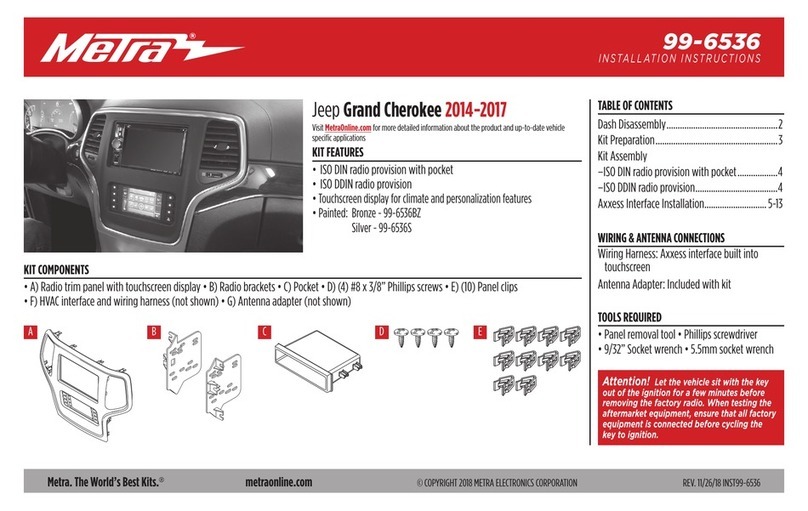

THE ACTUATOR MOUNTED TO THE SMARTSHIFT ACTUATOR BRACKET

Refer to FIGURE 1 below to understand how the actuator is attached to the actuator mounting bracket. This

method is the same for all vehicles. The only changes that occur from one vehicle to another is the design of

the Cable Bracket and the hardware for attaching the shift cable to the Nose Cone. Refer to the remainder of

this section for the Nose Cone and Cable Brackets instructions for some common EMC vehicles.

M11

2. INSTALLATION

2

2.1 SHIFT CABLE INSTALLATION

SMART-SHIFT INSTALLATION

Attach the Cable Bracket (included in KIT-SS-ASSY-

08C) to the end of the Smart Shift bracket in the

location shown in the gures above. The at side of

the bracket should be facing away from the actuator.

Secure this bracket using the (2) provided #10-32 x

3/8” button head screws and a small amount of Blue

Loctite®.

2008+

CHRYSLER /

DODGE

CABLE

BRACKET

Carefully tap the hole in the Nose Cone to #8-32.

Verify the #8-32 x 3/8” shoulder screw (included in

KIT-SS-ASSY-08C) will thread properly into the Nose

Cone. Do not install the shoulder screw at this time.

CHRYSLER TOWN & COUNTRY / DODGE GRAND CARAVAN 2008+

After calibration (see Section 3), verify the cable is

in Park. Insert the shoulder screw through the OEM

cable end and into the Nose Cone as shown, using a

small amount of Blue Loctite®.

Carefully insert the OEM shifter cable sleeve into the

Cable Bracket until the plastic ear snaps into the hole

in the Cable Bracket.

3

SMART-SHIFT INSTALLATION

TOYOTA SIENNA 20042010

Attach the cable bracket (included in KIT-SS-ASSY-

04T) to the end of the Smart Shift bracket in the

location shown in the gures above. The at side of

the bracket should be facing away from the actuator.

Secure this bracket using the (2) provided #10-32 x

3/8” button head screws and a small amount of Blue

Loctite®.

2004-2010

TOYOTA SIENNA

CABLE

BRACKET

Attach the Smart-Shift pin (included in KIT-SS-ASSY-

04T) to the Nose Cone using the supplied #6-32 x

3/8” button head screw and Blue Loctite®. Hint: Use

the 3/8” hole directly beneath the nose cone to gain

access to the underside of the nose cone in order to

insert and tighten the screw as shown.

SMART SHIFT

PIN

USE THE 3/8” HOLE

IN THE BRACKET TO

GAIN ACCESS TO THE

UNDERSIDE OF THE

NOSE CONE.

#6-32 x 3/8” BUTTON

HEAD SCREW

After calibration (see Section 3), verify that the cable

is in Park. Snap the shift cable over the pin on the

Nose Cone.

Secure the shift cable to the Smart Shift by sliding

the end of the OEM cable onto the Cable Bracket.

4

SMART-SHIFT INSTALLATION

TOYOTA SIENNA 20112019

Attach the cable bracket (included in KIT-SS-ASSY-

04T) to the end of the Smart Shift bracket in the

location shown in the gures above. The at side of

the bracket should be facing away from the actuator.

Secure this bracket using the (2) provided #10-32 x

3/8” button head screws and a small amount of Blue

Loctite®.

2011-2019

TOYOTA

SIENNA

CABLE

BRACKET

Attach the Smart-Shift pin (included in KIT-SS-ASSY-

04T) to the Nose Cone using the supplied #6-32 x

3/8” button head screw and Blue Loctite®. Hint: Use

the 3/8” hole directly beneath the nose cone to gain

access to the underside of the nose cone in order to

insert and tighten the screw as shown.

SMART SHIFT

PIN

USE THE 3/8” HOLE

IN THE BRACKET TO

GAIN ACCESS TO THE

UNDERSIDE OF THE

NOSE CONE.

#6-32 x 3/8” BUTTON

HEAD SCREW

After calibration (see Section 3), verify that the ve-

hicle is in Park. Snap the shift cable over the pin on

the Nose Cone.

Secure the shift cable to the Smart Shift by sliding

the end of the OEM cable onto the Cable Bracket.

5

SMART-SHIFT INSTALLATION

HONDA ODYSSEY 20082010

After calibration (see Section 3), verify that the

vehicle is in Park. The shift cable should t into the

OEM cable connector that is already mounted on

the Smart Shift Nose Cone. Once in place, secure the

cable to the connector by sliding the retaining clip

over the OEM cable and sliding the lock over the

retaining clip.

Attach the Cable Bracket (included in KIT-SS-ASSY-

04T) to the end of the Smart Shift bracket in the

location shown in the gures above. The at side of

the bracket should be facing away from the actuator.

Secure this bracket using the (2) provided #10-32 x

3/8” button head screws and a small amount of Blue

Loctite®.

2008-2010 HONDA

ODYSSEY

CABLE

BRACKET

Insert the Smart-Shift pin (included in KIT-SS-ASSY-

04T) through the OEM shift cable connector. Using

the provided #6-32 x 3/8”button head screw, attach

the pin to the actuator Nose Cone as shown using a

small amount of Blue Loctite®.

OEM shift cable connector

Secure the shift cable to the Smart Shift by sliding

the end of the OEM cable onto the Cable Bracket and

rotating.

OEM Shift Cable

Retaining Clip Retaining Clip Lock

OEM Shift Cable Con-

nector

Smart Shift pin

6

SMART-SHIFT INSTALLATION

HONDA ODYSSEY 20112017

After calibration (see Section 3), verify that the

vehicle is in Park. The shift cable should be secured

to the Nose Cone using the 5/16”x 3/4” long button

head bolt and 5/16” lock nut.

Secure the shift cable to the Smart Shift by sliding

the end of the OEM cable onto the Cable Bracket and

rotating.

Attach the Cable Bracket (included in KIT-SS-ASSY-

04T) to the end of the Smart Shift bracket in the

location shown in the gures above. The at side of

the bracket should be facing away from the actuator.

Secure this bracket using the (2) provided #10-32 x

3/8” button head screws and a small amount of Blue

Loctite®.

2011-2017

HONDA ODYSSEY

CABLE

BRACKET

Drill out the nose cone hole to 5/16”. Using a 5/16” x

3/4” long button head bolt and 5/16” lock nut, test

t the OEM shifter cable to the to the actuator Nose

Cone as shown. Hint: Use the 3/8”hole directly be-

neath the Nose Cone to gain access to the underside

of the Nose Cone in order to insert and tighten the

screw as shown.

OEM shift cable connector

7

SMART-SHIFT INSTALLATION

GM SILVERADO / SIERRA 20152018 & 2019 2500 only

After calibration (see Section 3), verify that the ve-

hicle is in Park. Press the shift cable over the pin on

the Nose Cone.

Attach the Cable Bracket (included in KIT-SS-ASSY-

05M) to the end of the Smart Shift bracket in the

location shown in the gures above. Secure this

bracket using the (2) provided #10-32 x 3/8”button

head screws and a small amount of Blue Loctite®.

2015-2019

SILVERADO /

SIERRA

CABLE

BRACKET

Attach the Smart-Shift pin (included in KIT-SS-ASSY-

05M) to the nose cone using the supplied #6-32 x

3/8” button head screw and Blue Loctite®. Hint: Use

the 3/8” hole directly beneath the Nose Cone to gain

access to the underside of the Nose Cone in order to

insert and tighten the screw as shown.

SMART SHIFT

PIN

USE THE 3/8” HOLE

IN THE BRACKET TO

GAIN ACCESS TO THE

UNDERSIDE OF THE

NOSE CONE.

#6-32 x 3/8” BUTTON

HEAD SCREW

Slide the OEM shift cable through the Smart Shift

cable bracket. It will snap in place. Secure the OEM

shift cable to the Smart Shift Cable Bracket by sliding

a zip tie around the clip, underneath the tabs, so

they cannot be compressed or slid out of the Cable

Bracket.

8

SMART-SHIFT INSTALLATION

GM SILVERADO / SIERRA 2019 1500 only2020

After calibration (see Section 3), verify that the

vehicle is in Park. Secure the shift cable to the Nose

Cone using the OEM preassembled hardware and a

small amount of Blue Loctite®.

2020

SILVERADO /

SIERRA

Attach the Cable Bracket (included in KIT-SS-ASSY-

19S) to the end of the Smart Shift bracket in the loca-

tion shown in the gures above. Notch the side of

the Smart Shift bracket. Secure this bracket using the

(2) provided #10-32 x 3/8”button head screws and a

small amount of Blue Loctite®.

CABLE

BRACKET

NOTCH

SMART-SHIFT

BRACKET

The OEM shift cable has an M6 screw preassembled

to it. This means the Smart Shift Nose Cone must be

drilled and tapped to M6 to accept it.

DRILL & TAP

FOR M6 SCREW

Slide the OEM shift cable over the Smart Shift cable

bracket. Secure the OEM shift cable to the Smart

Shift Cable Bracket with the preassembled OEM

hardware and a small amount of Blue Loctite®.

9

SMART-SHIFT INSTALLATION

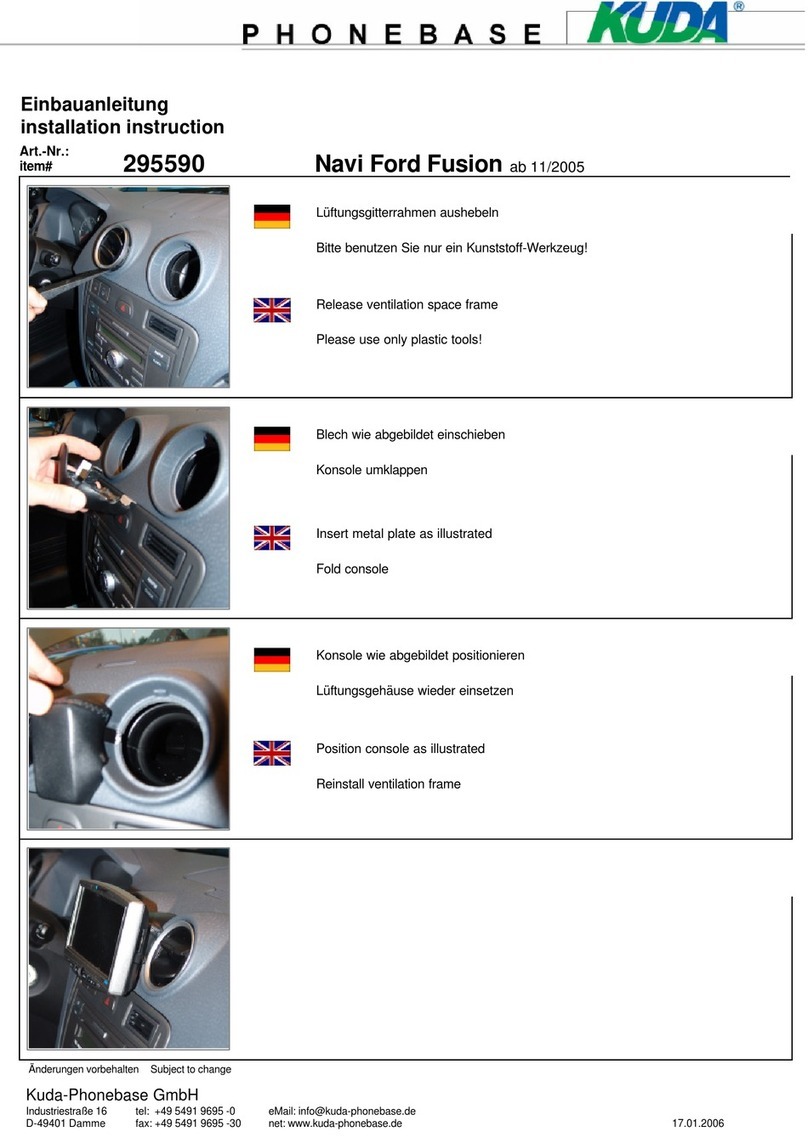

Each vehicle is dierent, depending on the vehicle type, amount of body lift and length of the shift cable.

Start by pulling the shift cable into the engine bay and seeing where it will reach without contacting anything

hot or needing sharp bends.

More often than not, the best location to mount the actuator bracket is above the engine on the wiper tray or

lower cowl panel. Both ends of the bracket must be attached to something rigid, not something connected

to the motor where there is ex. Some vehicles have threaded studs for hoses or wire looms that the actuator

bracket can be hung from. EMC includes small steel brackets that can be bent or drilled to hold either end of

the actuator bracket. Rivnuts or thru-bolts are also options.

Below are pictures of installed actuator brackets showing possible attachment methods.

Once securely attached, loop the shift cable around and over parts as needed to avoid kinks and hot surfaces.

P-clamp it periodically to hold it in place. Route the actuator harness back into the cabin through an open

grommet or the through the hole used for the shift cable. Seal around the harness to prevent water and fumes

from entering back into the cabin.

2.2 MOUNTING THE SMARTSHIFT ACTUATOR BRACKET

10

SMART-SHIFT INSTALLATION

OTHER APPLICATIONS

If your particular vehicle uses a cable operated shift mechanism, or a mechanical “rod style”, one of the bracket

kits can likely be modied to t your application, or you can fabricate your own. The actuator has a total stroke

of 2-1/4”. You must weld or bolt a bracket to the shift arm on the transmission such that the arc of travel from

Park to Low gear is approximately 2-1/4”. This will be the connection point of the actuator. Other optional

mounting techniques could involve purchasing a Ford or Chrysler shift cable and adapting it to your particular

vehicle. You could also mount the actuator inside the vehicle with this sort of cable control. Feel free to contact

EMC Service with your particular applications should you encounter installation problems.

The remaining modules - Controller Module and Touchpad - will be located inside the cabin of the vehicle.

The Controller Module can be attached under the dash in a convenient location, provided it is within reach of

the actuator harness and the electrical connections described in the next section. Avoid locating the module

next to a heat source.

The Touchpad will be mounted according to the users range of motion, needs or preference. On back of the

Touchpad you will nd (2) 1/4-20 threaded studs to help facilitate attaching the Touchpad to something suit-

able.

IMPORTANT NOTE: DO NOT CUT THE CONNECTOR END OFF OF THE ACTUATOR TO ROUTE YOUR

CABLE AS IT IS A SPECIAL SHIELDED,TWISTED PAIR CABLE WITH THREE BLACK WIRES.

There is only (1) harness that will interface with the vehicle. The other connections are the telco cord from the

touchpad to the controller and the actuator connector to the controller. If you are routing the actuator cable

through the oorboard of the vehicle, DO NOT cut the connector o of the harness. This connector contains

shielded twisted pairs with three black wires. If this cable is cut and wired back incorrectly, damage to the

actuator will result which is not covered under warranty. Make sure you drill a large enough hole to accommo-

date the connector.

Locate the power cable which plugs into the Smart-Shift Harness port and connect the four wires as depicted

and explained in FIGURE 2.

RED - Connect to 12V dc source, through a 15 AMP circuit breaker that is hot only with the ignition of the

vehicle On.

BLACK - Connect to Chassis Ground.

WHITE - Connect to the brake light switch wire that has 12V dc only when the brake lights are “On”. The Smart-

Shift will not work if this wire is not connected to a brake light feed.

GREEN - Connect to a wire that supplies the dash lamp with 12V dc when the dash lights are “On”. This wire

provides backlight illumination to the touchpad.

2.3 MOUNTING THE CONTROLLER AND TOUCHPAD

2.4 ELECTRICAL CONNECTIONS

11

SMART-SHIFT INSTALLATION

FIGURE 2

12

SMART-SHIFT INSTALLATION

To calibrate the Smart Shift for your vehicle you will use the four gear selector keys and the two actuator control

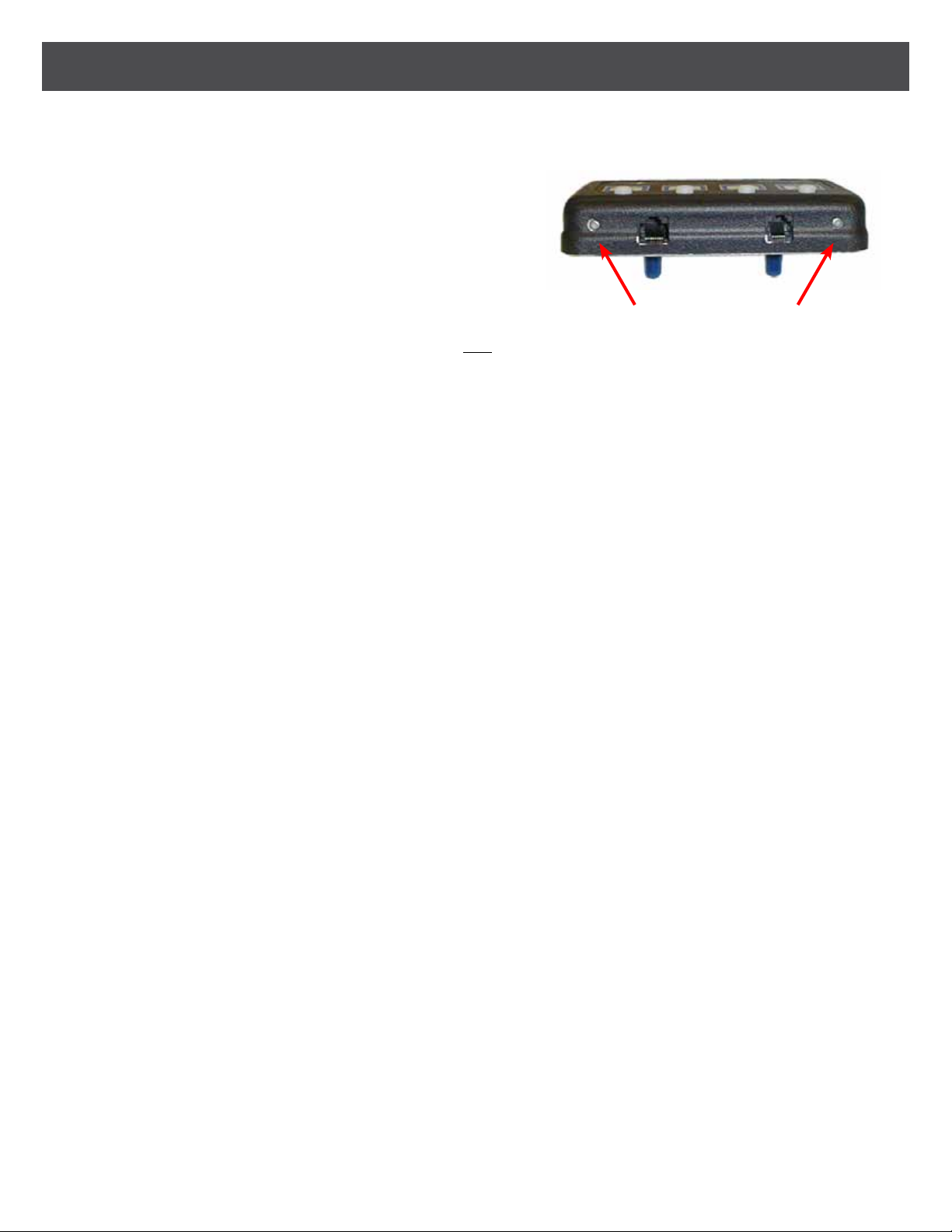

buttons. The actuator control buttons are located on the front side of the controller on the left and right edges as

shown below. These two buttons are used to move the actuator in either direction when they are depressed, as

long as the ignition is “ON”and the brakes are applied. Once one of

the actuator control buttons is depressed, the actuator will move

in one direction and all four of the indicator lights on the touchpad

will illuminate to signify that you are in calibration mode. Use both

buttons to move the actuator to the desired position. Once the

actuator is positioned correctly, depress the corresponding button

on the touchpad.

IMPORTANT NOTE: If your vehicle is unable to reach all four of the Drive positions, program the un-used Drives for

the same setting as Drive. This way if the“D” key is pressed in error the actuator will still travel to the Drive position.

CALIBRATION PROCEDURE

Step 1: As discussed in the Actuator Installation section, in most installations the actuator will not meet the OEM

shift cable when the actuator is installed. For those cases you must rst adjust the actuator to meet the OEM

shift cable. Conrm that the Electronic Connections section has been completed, and the vehicle’s transmis-

sion is in Park. Turn on the ignition, start the vehicle, and apply and hold the brakes. (Remember the Smart-

Shift must receive a brake light input in order for the actuator to move.) Using the actuator control buttons,

position the actuator so that the OEM shift cable can attach to the actuator. Now, with the brake pedal de-

pressed, have someone attach the cable to the actuator according to the Installation section for your vehicle

type.

Step 2: With the engine still running and the brake depressed, use the Actuator Control Buttons to conrm that the

actuator can travel to the four main gears of the transmission (Park, Reverse, Neutral, & Drive). If not, some

adjustments to the placement of the OEM cable in relation to the bracket, or the OEM cable to the transmis-

sion will need to be made. If you are unable get the actuator to travel to these four positions, contact EMC

Service for assistance.

Step 3: After you have attached the cable and conrmed that the cable can travel to the required gear positions,

your ready to program the positions into memory. Remember, while in calibration mode all four LED’s will

illuminate. Using the Actuator Control Buttons, place the vehicle in Park and press the “P” key to set the

position. The Park LED should now be the only LED illuminated. Park has now be set. Each time the “P” key is

depressed, the actuator will track to Park.

Step 4: Using the Actuator Control Buttons, place the vehicle in Reverse and press the “R” key. Again the LED above

the Reverse icon will illuminate. Repeat this same step for Neutral and Drive.

Step 5: For Drive2 follow the same procedure to set the position, except you will need to press and hold the “D” key

to set Drive2. Once Drive2 is set the “D” LED indicator will ash continuously. Press the “D” key or any other

key to change out of Drive2 and to move to the selected position.

Step 6: Once all gear positions have been adjusted, you will need to check the operation from both directions, that

is, from Park to Drive (or Drive1) and Drive to Park. The reason for this is that each shift position has an area

or “window” in which it will operate or “drop into” a gear. When you set the positions from Park to Drive you

positioned it on the high side of this area or “window”. You must check to make sure that your high side ad-

justments are low enough to be activated from the low direction. If you are unable to“drop into” a gear from

the low side direction, use the actuator control buttons to reset the gears position slightly further to the low

side.

M11

3. CALIBRATION

13

Actuator Control Buttons

SMART-SHIFT INSTALLATION

14

When delivering the vehicle, be sure to go over the OEM operation of the transmission. Some vehicle’s utilizes

a lockout feature for Lower gears to prevent the transmission from entering if the vehicle is above a

certain speed. An example of this situation is if the operator of the vehicle is traveling at 30 mph and de-

cides that the grade is extremely long and steep or that the road conditions require a lower gear to save

on wear and tear of the vehicle, the operator only needs to depress the Drive key and the transmission

linkage will move to the low Drive position. The transmission, however, will only shift into low gear if the

vehicle slows down below the maximum speed allowable to access that gear. Therefore, no matter what

the driver selects below the Drive (D) position, the vehicle’s transmission will dictate when and if these

lower gears can be accessed.

CAUTION: THE EMC SMARTSHIFT ACTUATOR MUST BE EITHER PLACED IN NEUTRAL OR THE OEM

SHIFT CABLE DISCONNECTED FROM THE ACTUATOR BEFORE ATTEMPTING TO TOW THE VEHICLE.

Table of contents

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 285690 Assembly and Safety Advice

Rockford Fosgate

Rockford Fosgate Polaris PMX-P2 Operation manual

InPOWER

InPOWER ITM131 owner's manual

Front Runner

Front Runner JADA010 quick start guide

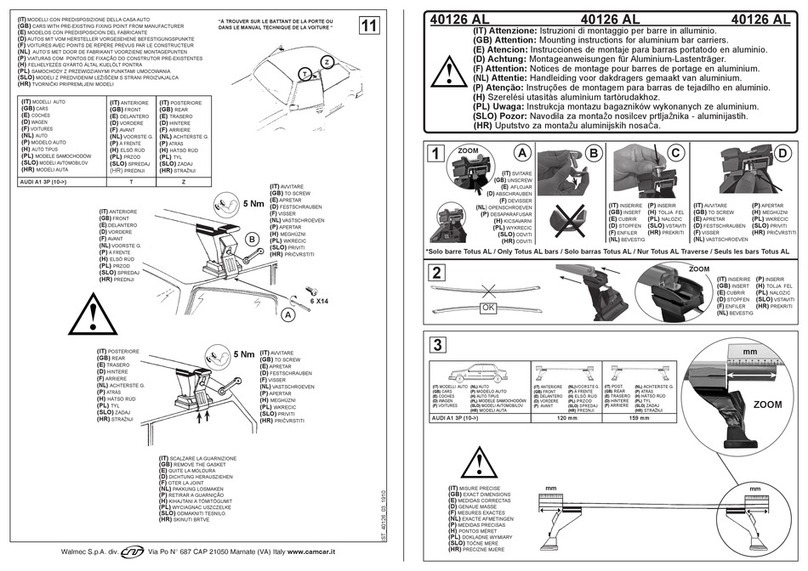

WALMEC

WALMEC 40126 AL Mounting instructions

Audison

Audison FORZA AFBMW ReAMP 3 owner's manual