PDZ-128-160-200 OI-vers. 3.2 gb. 03.07.2018 3

Table of contents

1.0.0 EC Declaration for Incorporation (Document original) ....................................... 5

1.1.0 According to: 2006/42/EC .............................................................................. 5

2.0.0 Module Information ............................................................................................ 6

2.1.0 Transport and storage (packing and unpacking) ............................................ 6

2.1.1 Overview for gantry module PDZ ................................................................... 7

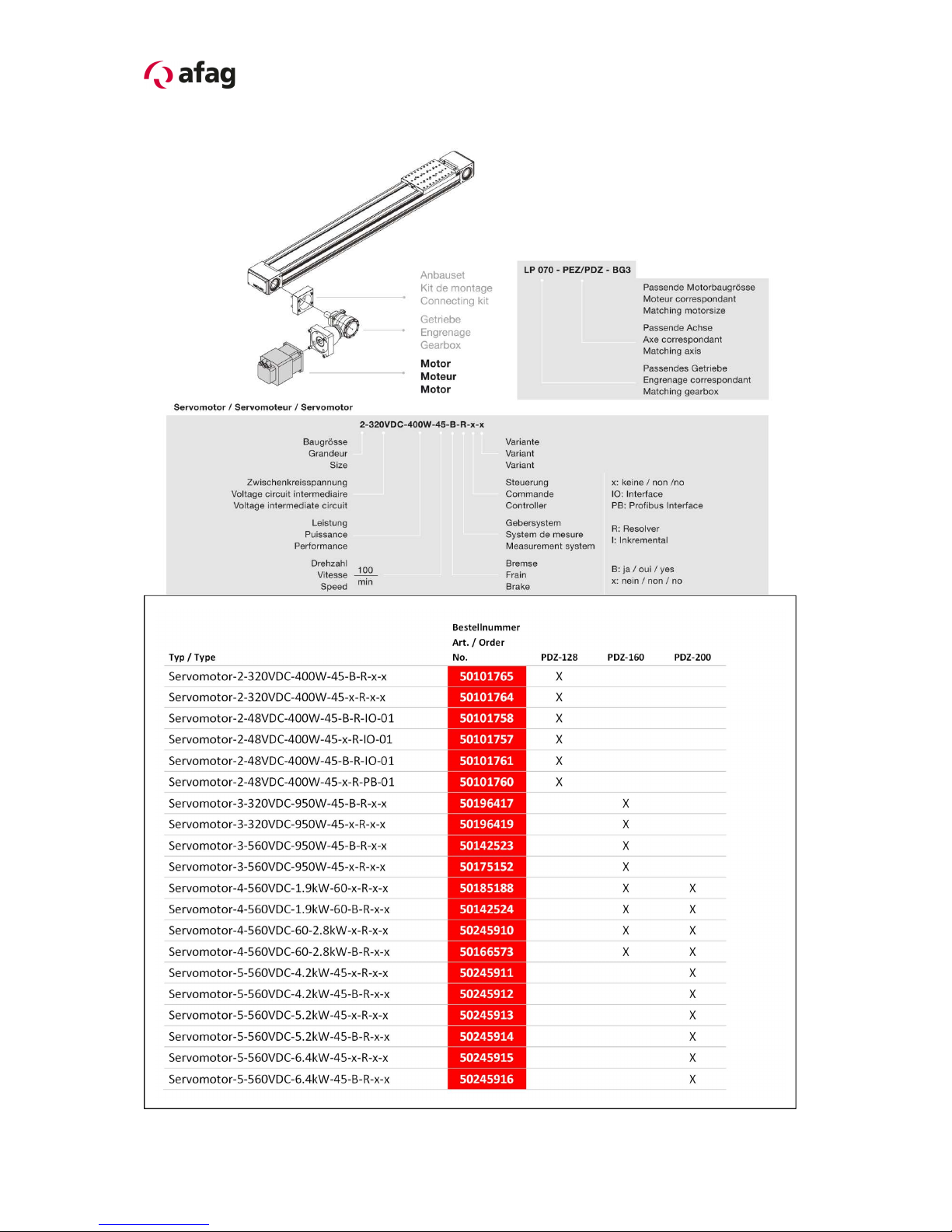

2.1.2 Overview for motor and gear .......................................................................... 8

2.1.3 Regulation for the connection gantry axis. ..................................................... 9

2.1.4 Assembly possibility in annex slide .............................................................. 10

2.1.5 Centering bushings and assembly raster ..................................................... 10

2.1.6 Tightening torques for screw ........................................................................ 11

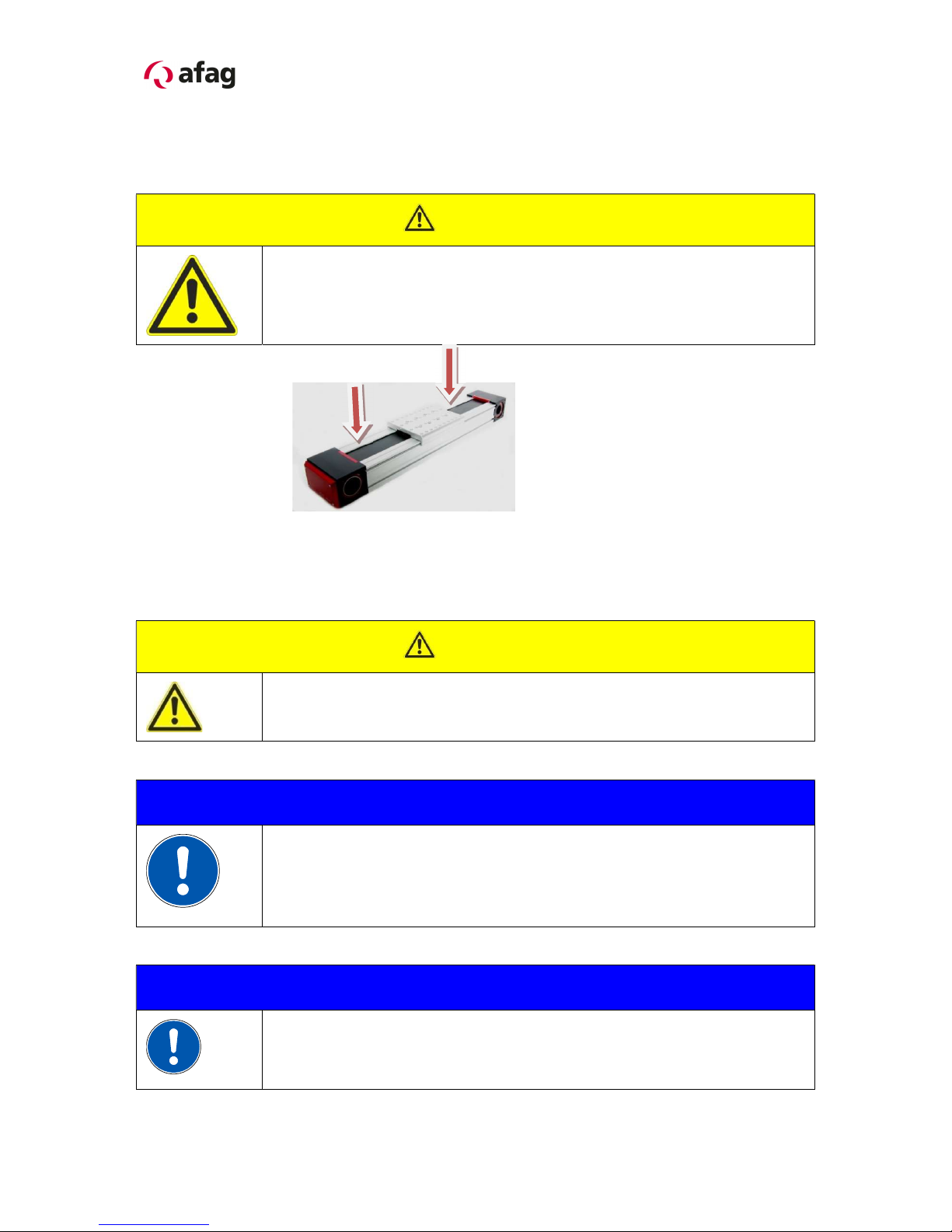

2.1.7 Safety tips .................................................................................................... 11

2.1.8 Redesign for the gear annex side ................................................................ 12

2.1.9 Go forward with gear redesign and motor .................................................... 13

2.2.0 Mounting third-party gears ........................................................................... 15

2.2.1 Preferred combinations to PDZ-128 ............................................................. 16

2.2.2 Preferred combinations to PDZ-160 ............................................................. 17

2.2.3 Preferred combinations to PDZ-200 ............................................................. 18

2.2.4 Installation of the gantry axis in a system ..................................................... 19

2.2.5 Tip for annex module ................................................................................... 19

2.2.6 Motor connection.......................................................................................... 21

2.2.7 Electrical interfaces ...................................................................................... 21

2.2.8 Technical connection data servo motor ........................................................ 22

2.2.9 Programming of the gantry axis ................................................................... 23

2.3.1 Noise Emission ............................................................................................ 24

2.3.2 SE-Power control and technical data ........................................................... 25

3.0.0 Montage Instructions ....................................................................................... 26

3.1.0 Manufacturer address: ................................................................................. 26

3.1.1 General description ...................................................................................... 27

3.1.3 Included in the delivery ................................................................................ 28

3.1.4 Warranty ...................................................................................................... 29

3.1.5 Areas of application ...................................................................................... 29

3.1.6 Module description and construction ............................................................ 30

3.1.7 Module description ....................................................................................... 31

3.1.8 Dimensions PDZ-128 ................................................................................... 33

3.1.9 Technical data PDZ-128 .............................................................................. 34