NOTICE!

This instruction manual is also available on www.afriso.pl.

WARNING!

The product may only be mounted, commissioned and disposed of by qualied, specially trained

staff.

Alterations performed by unauthorized staff may cause a threat and are forbidden for safety

reasons.

APPLICATION

DESCRIPTION

APPROVALS AND CERTIFICATES

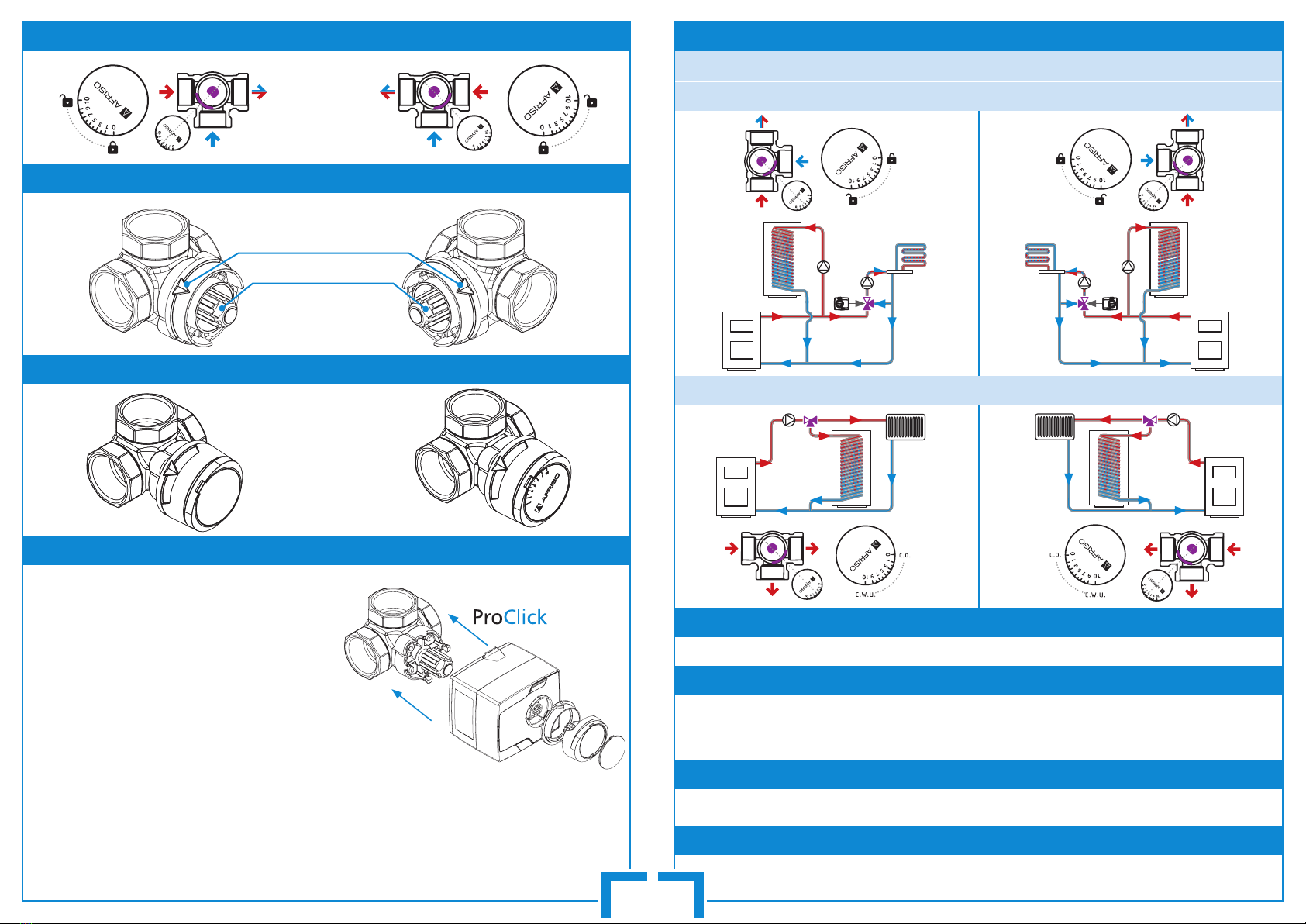

Drawing 1. Construction

3-way rotary valves are mainly used as mixing valves, where the desired temperature is achieved by mixing the hot

water from the boiler and the cold water from the system return, in appropriate proportions. 3-way valves can also

be used as switching or separating valves, when changing the ow direction between two outlets (e.g. central he-

ating and domestic hot water preparation) is required. The 3-way ARV ProClick valves can be utilized in cooling and

d.h.w. systems.

3-way rotary mixing valves ARV ProClick with inner threads are made out of brass. The connections have octagonal sha-

pe. The valves have knobs for manual operation and rotation angle limiters. The scale on top of the knob is printed with

“from 0 to 10” on one side and on the other “from 10 to 0”, so one can mount the valve in various positions. The thicker

knob part shows the sleeve position inside the valve. The knob itself is made from a non-slip material. The durable

plastic parts under the knob are used to mount the ARM ProClick actuator on the valve. The ProClick system does not

require any tools. ARV ProClick valves require low torque.

The rotary mixing valves ARV ProClick comply with the Pressure Directive PED 2014/68/EU and according to artic-

le 4.3 (sound engineering practice) must not wear the CE mark.

DN15 ÷ DN25

DN32 DN40 ÷ DN50

3-way rotary mixing valves

ARV ProClick

Art.-No 13 381 10, 13 388 10, 13 382 10,

13 384 10, 13 385 10, 13 386 10,

13 387 10

INSTRUCTION MANUAL 953.001.0063 1

TECHNICAL DATA

Parameter / piece Value / description

Working temperature 5-110˚C

Working pressure max 10 bar

Differential pressure max 1 bar

Body brass CW617N

Sealing EPDM

Leak rate (Δp=100 kPa) max 0,2% for DN15-DN32

max 0,5% for DN40-DN50

Rotation angle 90˚

Required torque max 0,5 Nm for DN15-DN25, max 2 Nm for DN32,

max 3 Nm for DN40-DN50

Glycol concentration max 50%

MOUNTING

Notice! The attening on the spindle of the valve and on the adapter mounted on it (Drawing 1) indicates the posi-

tion of the sleeve inside the valve (Drawing 2).

The ARV ProClick valve is delivered with mounted knob, blue ring and scale. Not to damage the plastic elements,

we suggest to disassemble the scale, knob and blue limiting ring before mounting the valve. These parts are moun-

ted on latch. When having trouble with dismounting the knob, one can gently pry it up with a at screwdriver.

Next mount the valve in the system. When the valve is in place, set it and assemble the plastic components,

as follows:

1. Determine the working range of the sleeve inside and the closing direction (Drawing 2). First determine

the hot and cold water inlets after the valve is mounted. The sleeve should rotate by 90˚ between these two

inlets. Next set the sleeve exactly in the middle between the hot and cold water inlet (Drawing 2). Learn also

the direction of closing (closing the hot water inlet) and opening (opening the hot water inlet) of the valve.

2. Choose the right side of the scale. A double-sided scale is delivered with the ProClick valves. It is printed “from

0 to 10” on one side and “from 10 to 0” on the other. Apply the scale to the vale and choose the side on which

“0” will coincide with the cold water inlet and simultaneously “10” will coincide with the hot water inlet,

as shown on Drawing 2.

You can follow also another simple rule:

- if the valve is closed turned right (clockwise) choose the scale “from 0 to 10”,

- if the valve is closed turned left (counter-clockwise) choose the scale “from 10 to 0”.

3. Put on and latch the blue limiting ring on the valve, which was set according to point 1. The indicator should

point directly on the middle of the sleeve inside the valve (Drawing 3a or 3b), as well as the attening on the

spindle and adapter. The indicator should nd itself between the hot and cold inlets.

4. Lock the knob on the adapter. It ts only in one position (Drawing 4).

5. Put the lid with the chosen scale (Drawing 5) on the knob. To lock the lid rst put the smaller inset in the hole

inside the knob and then press the lid down.

6. Check if the valve works properly.

valve body DN40-50

valve body DN32

valve body DN15-DN25 with plastic part for ProClick actuator

adapter with attening, for ARM ProClick actuators

adapter xing screw

knob with a thicker part showing the valve sleeve position

double-sided scale

limiting ring with indicator

attening on the valve spindle

AFRISO Sp. z o.o.

Szałsza ul. Kościelna 7

42-677 Czekanów

Poland

www.afriso.pl

Customer service

Tel. +48 330 33 55

Fax: +48 330 33 51

1 2