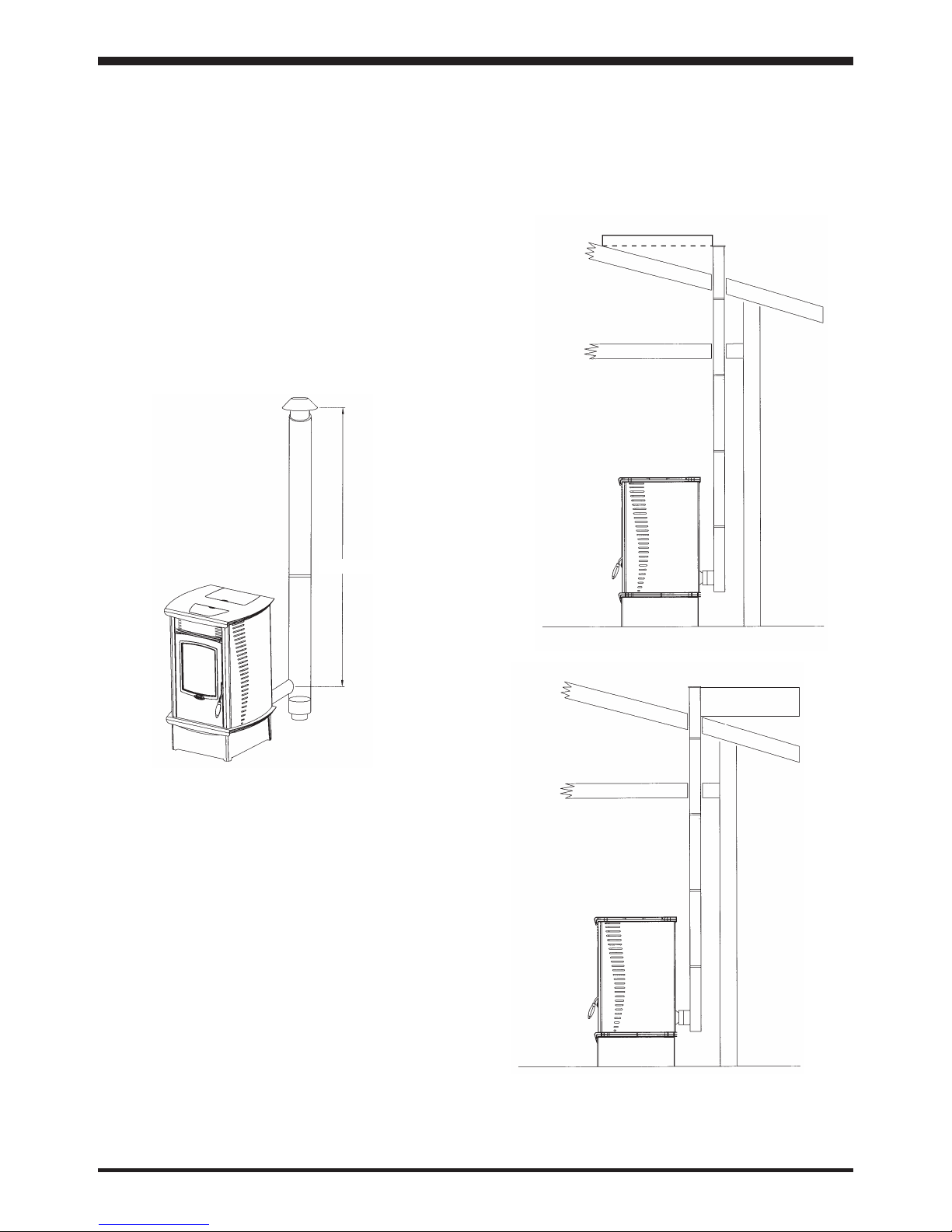

Where it is necessary to have a horizontal length of

pipe, there must be a minimum positive gradient of

3% along its length.

Do not run flue pipe in a totally horizontal plain or in

a reverse gradient.

Do not install the smoke outlet at pavement level,

on public streets, car-parks or anywhere that might

cause annoyance to people and/or animals.

The flue must be installed with the outlet above roof

level complying with current building regulations. A

maximum flue length of 8 metres is allowed. For

each 90° bend or T fitting, reduce the length by one

metre. A minimum flue draught of 10 Pascals is

required.

IMPORTANT: All sections of the flue pipe must be

accessible for inspection, and allow for internal

cleaning, removal or substitution.

Do not place a net or grill over the flue outlet. When

they become dirty they will obstruct the outlet and

cause poor combustion, and the stove may be

blocked with soot.

COMBUSTION AIR

The process of combustion requires oxygen, and

therefore air. When in operation, the stove draws air

from the room in which it is installed; poor

combustion may therefore result if the room is

insufficiently ventilated.

To resolve this problem, a suitable vent hole must

be provided to allow a permanent supply of fresh air

from the outside. The cross-section of the vent must

be 6cm² for each kW of energy consumed at

maximum input therefore the ventilation hole must

have a cross-sectional area of 83cm² if a flue

draught stabiliser is fitted.

If no flue draught stabiliser is fitted the ventilation

requirement is 44cm².

If the stove is located in a room containing another

appliance cooker hood or extractor fan, it is

essential to provide ventilation equivalent to the

sum of the air requirement for all appliances.

The vent must not be placed directly beside the

appliance in order to avoid drawing in air that is too

cold: at certain times of the year when the

appliance is very cold, the stove may be locked out

when you first attempt to light it. If this occurs, the

situation should be considered absolutely normal,

and you can unlock the stove using the switch #4

located on the control panel. Then switch on again.

6

INITIAL COMMISSIONING

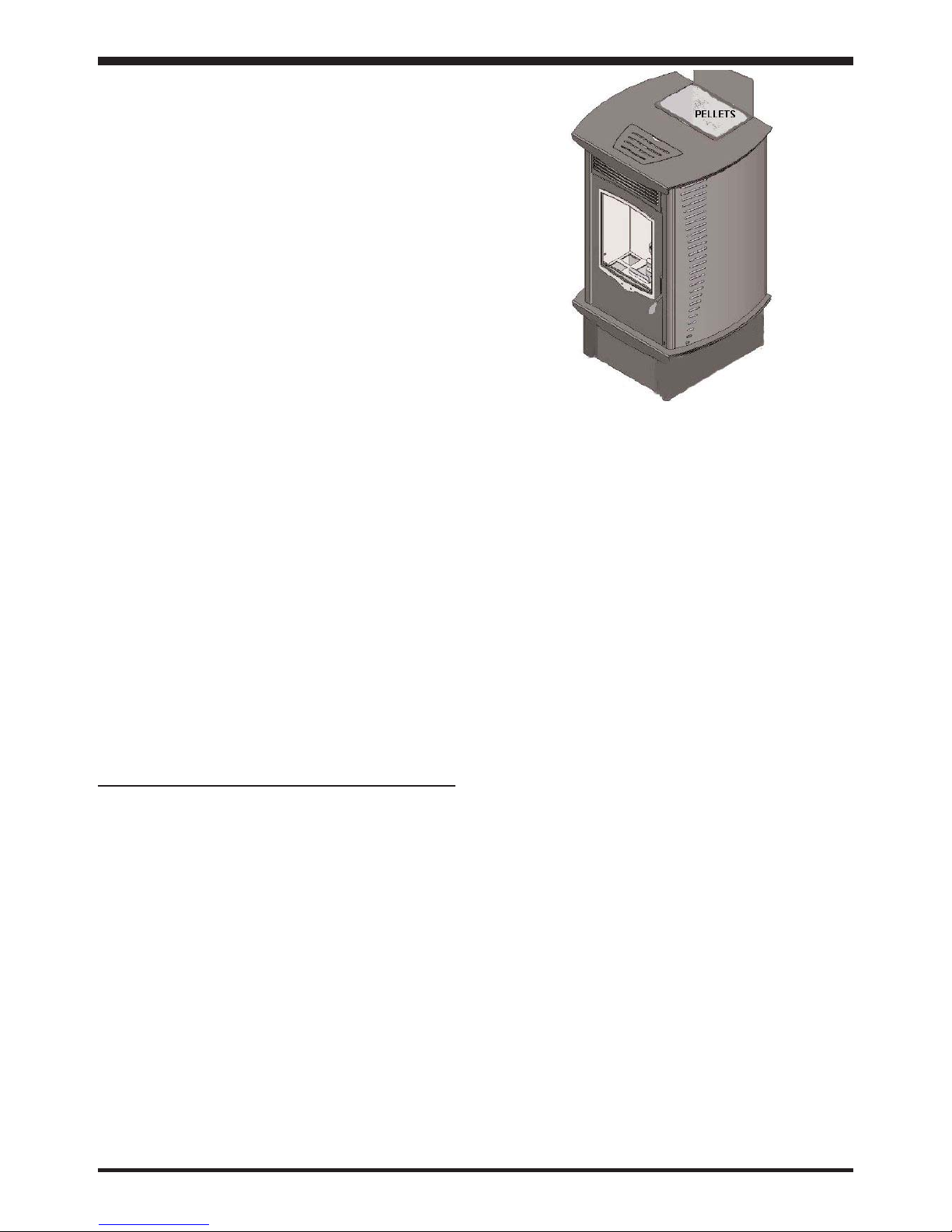

It is vital that the installation of the AGA Fusion

Pellet stove is in accordance to manufacturer’s

instructions.

On commissioning the appliance it is important

that the Auger is filled with pellets prior to firing.

To do this the fire door must be closed:

a) Fill the hopper with 6mm diameter pellets

taking care to keep sawdust in the bag.

b) Turn the power ON to the appliance and press

the power switch ON (located on the back of

the unit).

c) Press and hold button 4 for 4 seconds to turn

the unit ON (this will activate the fan required

to activate the air pressure switch), then re-

press button 4 for 4 seconds to turn the unit

OFF. Leave the mains power onto the

appliance.

d) Press buttons 5 and 6 together, this will

activate the Auger, hold the buttons until

pellets are seen to enter the burner from the

pellet chute, the Auger should now be loaded.

e) Remove pellets from the burner pot.

The stove has sequence settings which are

factory-set by the manufacturer and these should

not be altered.

However these must be checked during initial

commissioning before firing. To do this press

button 3 a number of times until UT01 shows. If

the lower display shows OFF then you will need to

set the correct day and time (See Page 10).

Day 1 - Monday

Day 2 - Tuesday

Day 3 - Wednesday

Day 4 - Thursday

Day 5 - Friday

Day 6 - Saturday

Day 7 - Sunday

1. Press button 3 until UT04 shows on the upper

display.

2. Press buttons 1 or 2 until A9 shows on the

lower display, then press button 3.