6 7713402 R0

Dryer Model Number

D Series Model Numbers

The dryer model number provides information on the dryer length and capacity.

• The two digits after “D" are the dryer length.

• Multiply the remaining digits by 10 to determine the approximate bushel capacity for corn. In this example:

40 x 10 = 400 bushels

Example: D 16 60

•16 indicates this model is a 16 foot long dryer

•60 indicates this model has a capacity of 60 x 10 = 600 bushels

Using the same process, a model D32500 would be a 32 foot long dryer with an approximate capacity of 5,000

bushels.

K Series Model Number

The three digits after “K” indicate the nominal storage capacity. For example, a K600 holds approximately 600

bushels of grain.

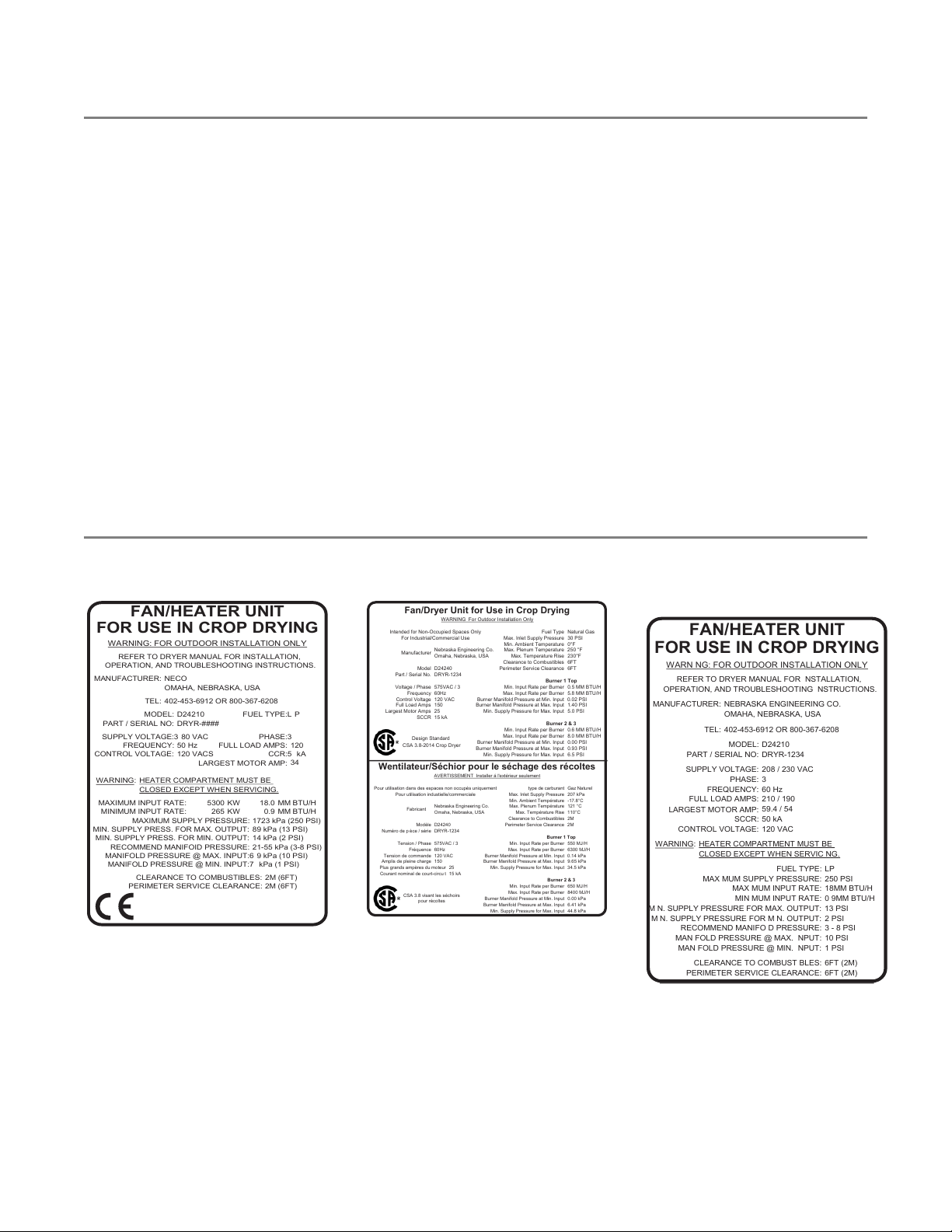

Dryer Rating Label

Figure 1. Dryer Rating Label — CE

MODEL: D24210 FUEL TYPE:L P

PART / SERIAL NO: DRYR-####

SUPPLY VOLTAGE:3 80 VAC PHASE:3

FREQUENCY: 50 Hz FULL LOAD AMPS:

CONTROL VOLTAGE: 120 VACS CCR:5 kA

LARGEST MOTOR AMP:

WARNING:

CLOSED EXCEPT WHEN SERVICING.

MAXIMUM INPUT RATE: KW MM BTU/H

MINIMUM INPUT RATE: KW MM BTU/H

MAXIMUM SUPPLY PRESSURE: 1723 kPa (250 PSI)

MIN. SUPPLY PRESS. FOR MAX. OUTPUT: 89 kPa (13 PSI)

MIN. SUPPLY PRESS. FOR MIN. OUTPUT: 14 kPa (2 PSI)

RECOMMEND MANIFOID PRESSURE: 21-55 kPa (3-8 PSI)

MANIFOLD PRESSURE @ MAX. INPUT:6 9 kPa (10 PSI)

MANIFOLD PRESSURE @ MIN. INPUT:7 kPa (1 PSI)

CLEARANCE TO COMBUSTIBLES: 2M (6FT)

PERIMETER SERVICE CLEARANCE: 2M (6FT)

402-453-6912 OR 800-367-6208

HEATER COMPARTMENT MUST BE

120

34

FAN/HEATER UNIT

FOR USE IN CROP DRYING

WARNING: FOR OUTDOOR INSTALLATION ONLY

REFER TO DRYER MANUAL FOR INSTALLATION,

OPERATION, AND TROUBLESHOOTING INSTRUCTIONS.

MANUFACTURER:

TEL:

NECO

OMAHA, NEBRASKA, USA

0.9

18.0

5300

265

Figure 2. Dryer Rating Label — CSA

Intended for Non-Occupied Spaces Only

For Industrial/Commercial Use

Max. Inlet Supply Pressure 30 PSI

Min. Ambient Temperature 0°F

Nebraska Engineering Co. Max. Plenum Temperature 250 °F

Omaha, Nebraska, USA Max. Temperature Rise

Clearance to Combustibles 6FT

Model D24240 Perimeter Service Clearance 6FT

Part / Serial No. DRYR-1234

Voltage / Phase 575VAC / 3 Min. Input Rate per Burner 0.5 MM BTU/H

Frequency 60Hz Max. Input Rate per Burner 5.8 MM BTU/H

Control Voltage 120 VAC Burner Manifold Pressure at Min. Input 0.02 PSI

Full Load Amps 150 Burner Manifold Pressure at Max. Input 1.40 PSI

Min. Supply Pressure for Max. Input

Min. Input Rate per Burner 0.6 MM BTU/H

Max. Input Rate per Burner 8.0 MM BTU/H

Burner Manifold Pressure at Min. Input 0.00 PSI

Burner Manifold Pressure at Max. Input 0.93 PSI

Min. Supply Pressure for Max. Input

Pour utilisation dans des espaces non occupés uniquement type de carburant

Pour utilisation industielle/commerciale Max. Inlet Supply Pressure

Min. Ambient Température -17.8°C

Nebraska Engineering Co. Max. Plenum Température 121 °C

Omaha, Nebraska, USA Max. Température Rise 110°C

Clearance to Combustibles 2M

Modèle D24240 Perimeter Service Clearance 2M

Numéro de p èce / série DRYR-1234

Tension / Phase 575VAC / 3 Min. Input Rate per Burner 550 MJ/H

Fréquence 60Hz Max. Input Rate per Burner 6300 MJ/H

Tension de commande 120 VAC Burner Manifold Pressure at Min. Input 0.14 kPa

Amplis de pleine charge 150 Burner Manifold Pressure at Max. Input 9.65 kPa

Plus grands ampères du moteur 25 Min. Supply Pressure for Max. Input 34.5 kPa

Courant nominal de court-circu t 15 kA

Min. Input Rate per Burner 650 MJ/H

Max. Input Rate per Burner 8400 MJ/H

Burner Manifold Pressure at Min. Input 0.00 kPa

Burner Manifold Pressure at Max. Input 6.41 kPa

Min. Supply Pressure for Max. Input 44.8 kPa

Fan/Dryer Unit for Use in Crop Drying

WARNING For Outdoor Installation Only

Wentilateur/Séchior pour le séchage des récoltes

AVERTISSEMENT Installer á l'extérieur seulement

CSA 3.8 visant les séchoirs

pour récoltes

Design Standard

CSA 3.8-2014 Crop Dryer

Figure 3. Dryer Rating Label —

Domestic

MODEL: D24210

PART / SERIAL NO: DRYR-1234

SUPPLY VOLTAGE:

PHASE: 3

FREQUENCY: 60 Hz

FULL LOAD AMPS:

LARGEST MOTOR AMP:

SCCR: 50 kA

CONTROL VOLTAGE: 120 VAC

CLOSED EXCEPT WHEN SERVIC NG.

FUEL TYPE: LP

MAX MUM SUPPLY PRESSURE: 250 PSI

MAX MUM INPUT RATE:

MIN MUM INPUT RATE: 0 9MM BTU/H

M N. SUPPLY PRESSURE FOR MAX. OUTPUT: 13 PSI

M N. SUPPLY PRESSURE FOR M N. OUTPUT: 2 PSI

RECOMMEND MANIFO D PRESSURE: 3 - 8 PSI

MAN FOLD PRESSURE @ MAX. NPUT: 10 PSI

MAN FOLD PRESSURE @ MIN. NPUT: 1 PSI

CLEARANCE TO COMBUST BLES: 6FT (2M)

PERIMETER SERVICE CLEARANCE: 6FT (2M)

WARN NG: FOR OUTDOOR INSTALLATION ONLY

REFER TO DRYER MANUAL FOR NSTALLATION,

OPERATION, AND TROUBLESHOOTING NSTRUCTIONS.

402-453-6912 OR 800-367-6208

HEATER COMPARTMENT MUST BE

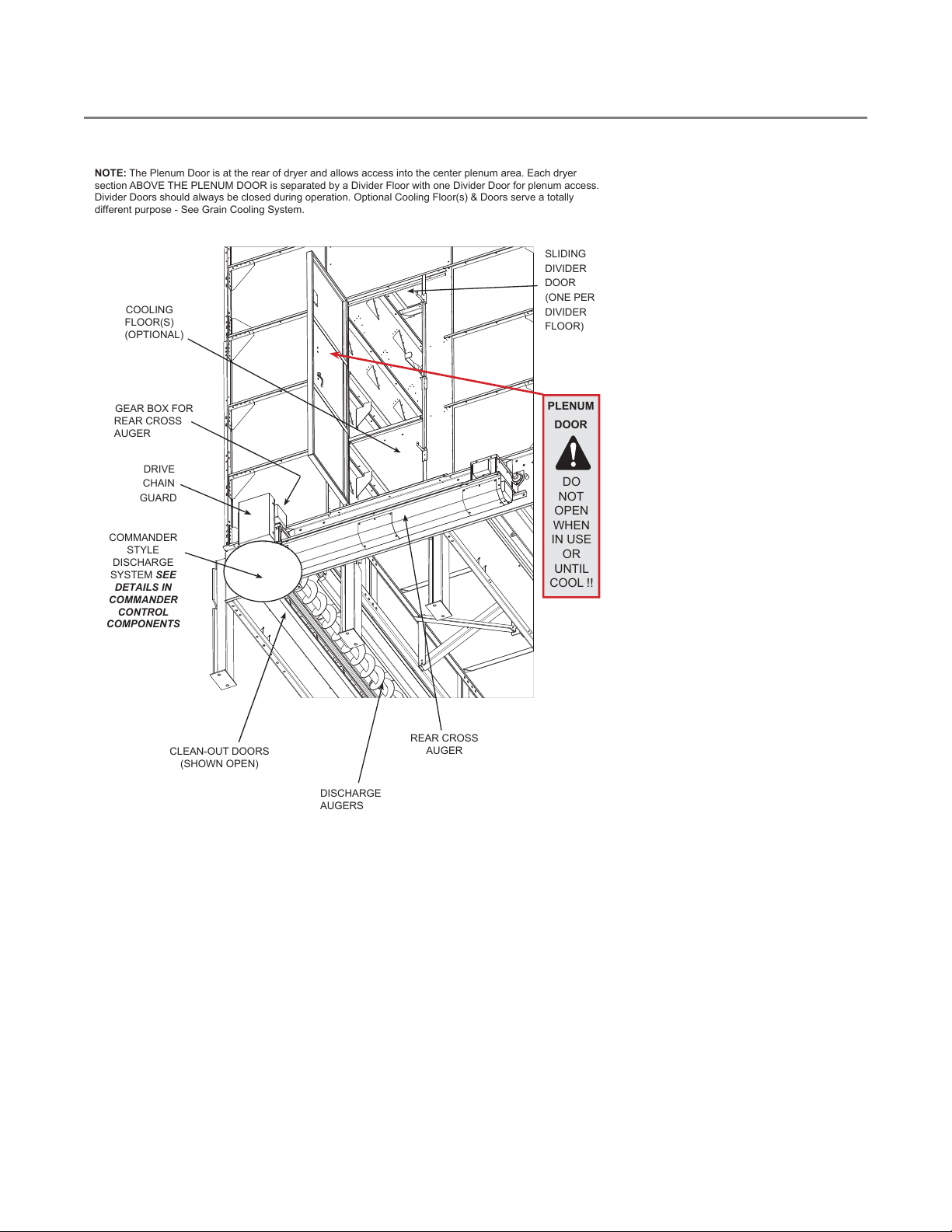

1. GENERAL DESIGN CRITERIA CONTINUOUS MIXED-FLOW GRAIN DRYER – GRAIN DRYER