CONTINUOUS MIXED-FLOW GRAIN DRYER WITH COMMANDER CONTROL SYSTEM

4 7713395 R2

4. Operation .............................................................................................................................................. 60

4.1 Operation Safety ..................................................................................................................... 60

4.2 Equipment Pre-Check.............................................................................................................. 60

4.3 Commander Control Setup ..................................................................................................... 63

4.3.1 Log In ........................................................................................................................ 63

4.3.2 SETUP Main Screen .................................................................................................. 68

4.3.3 NECO Entered Setup Data........................................................................................ 70

4.3.4 Dealer or Customer Entered Setup Data ................................................................. 73

4.4 Operation Overview ................................................................................................................ 77

4.4.1 Example A: Batch Drying .......................................................................................... 78

4.4.2 Example B: Auto Drying ........................................................................................... 78

4.4.3 Plenum Door Safety Switch...................................................................................... 79

4.5 Fill/Empty Dryer ...................................................................................................................... 80

4.6 Start Dryer - Main.................................................................................................................... 83

4.6.1 Start Dryer Overview................................................................................................ 83

4.6.2 Completion of Dryer Setup ...................................................................................... 89

4.6.3 To Start Batch Drying ............................................................................................... 89

4.7 Batch Drying Mode.................................................................................................................. 90

4.7.1 Batch Drying Overview............................................................................................. 90

4.8 Auto Drying Mode ................................................................................................................... 94

4.8.1 Auto Drying Pre-Conditions ..................................................................................... 94

4.8.2 Auto Drying Overview .............................................................................................. 95

4.8.3 Slide Gate Adjustment ........................................................................................... 102

4.8.4 Moisture Calibration .............................................................................................. 105

4.9 Data and Graphs Screens ...................................................................................................... 107

4.9.1 Data Screen ............................................................................................................ 107

4.9.2 Performance Data Graphs...................................................................................... 108

4.10 Emergency Shutdown Procedure........................................................................................ 110

5. Maintenance ....................................................................................................................................... 112

5.1 Maintenance Safety .............................................................................................................. 112

5.2 Maintenance Overview ......................................................................................................... 112

5.3 Burner Gas Ports ................................................................................................................... 113

5.4 Solenoid Valves ..................................................................................................................... 113

5.5 Lubrication............................................................................................................................. 114

5.6 Motors ................................................................................................................................... 114

6. Troubleshooting.................................................................................................................................. 115

6.1 Solutions Table ...................................................................................................................... 115

6.2 HMI Troubleshooting Screens............................................................................................... 119

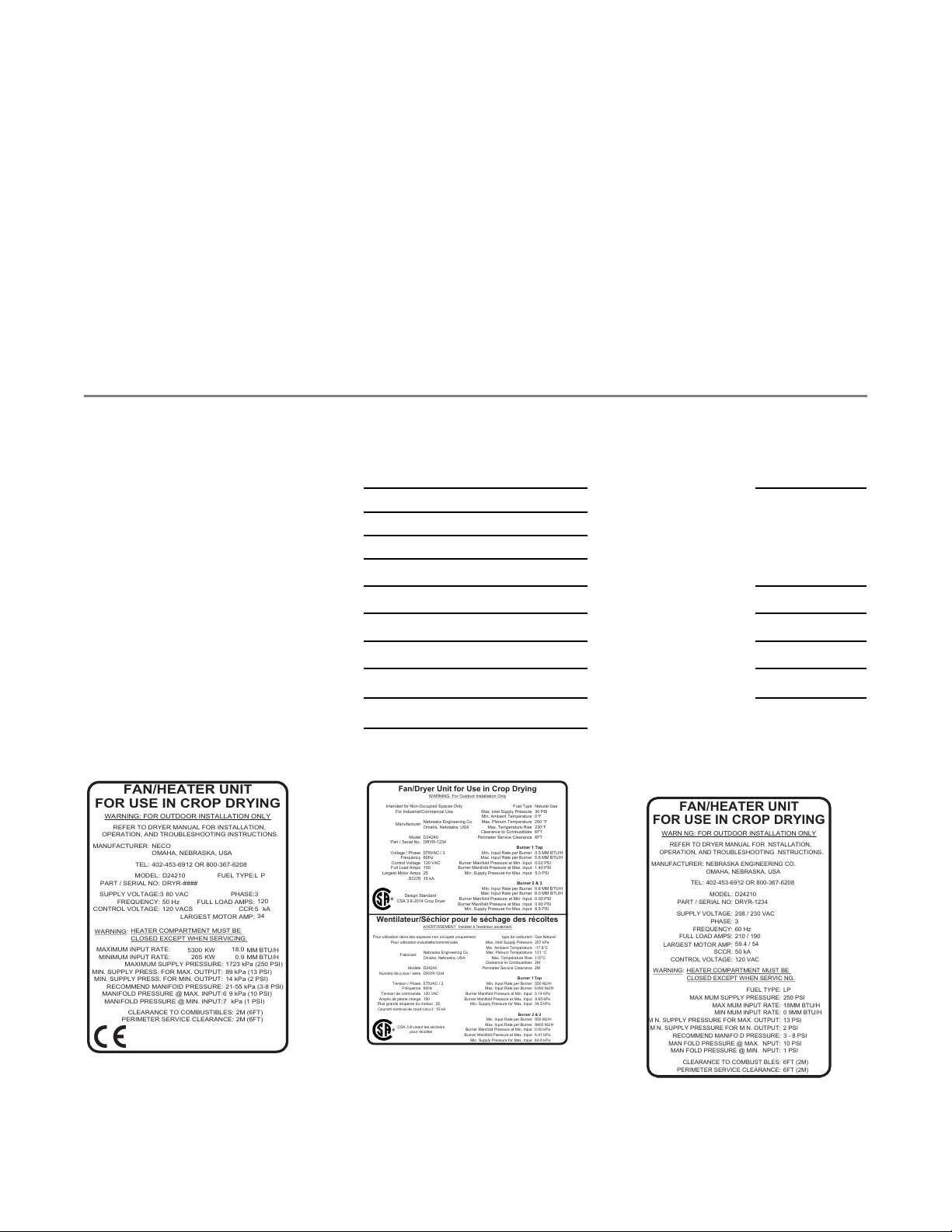

7. Specifications ...................................................................................................................................... 125

7.1 Standard Model Specifications ............................................................................................. 125

8. Appendix ............................................................................................................................................. 127

8.1 Manual Dryer Speed.............................................................................................................. 127

8.2 Optional External Transport Configurations ......................................................................... 128

8.3 Wiring External Transports ................................................................................................... 132

8.4 Wiring NEMA Starters / IEC Starters / Air Systems............................................................... 133

8.5 PLC and HMI Recorded Data Sheet....................................................................................... 134

8.6 Updating the PLC and HMI Programs ................................................................................... 135

8.7 Main Control Box Terminal Strip........................................................................................... 138