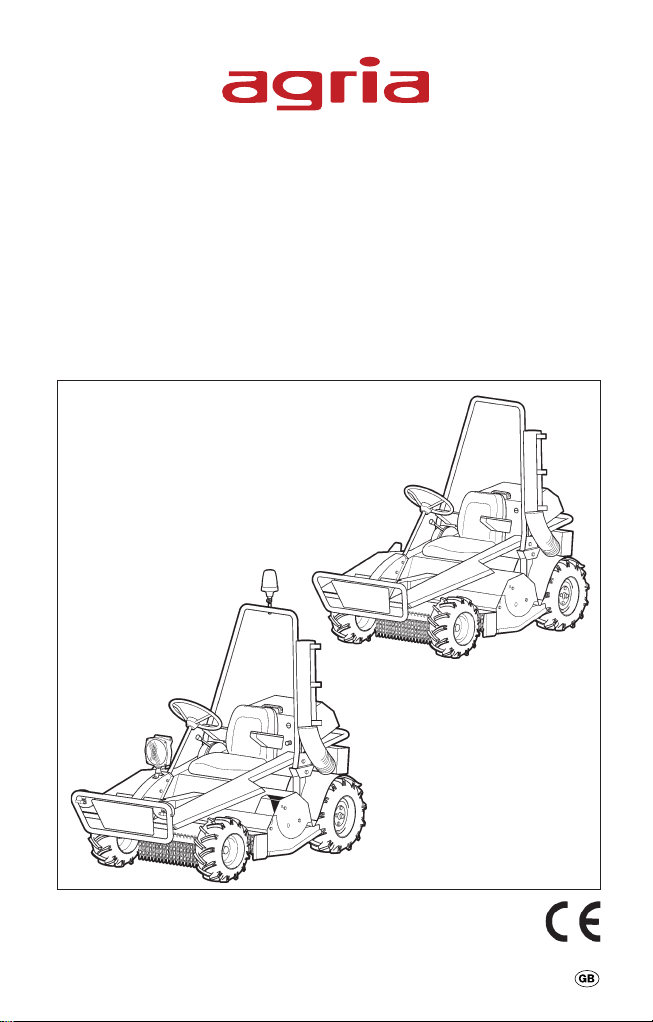

Ride-on Brushcutter Sitting Bull 5

Index

3

5

6

2

1

4

Recommendations

Fuel ............................................ 6

Maintenance and Repair ........... 6

Designation of Parts

....................................... 3, 50

1. Safety Instructions....7-12

2. Specifications

Dimensions .............................. 12

Machine ................................... 14

Vibration Acceleration Value.... 14

Petrol Engine ........................... 15

Diesel Engine........................... 16

Noise Levels ...................... 15, 16

Operation on Slopes................ 15

3. Devices and Operating

Elements

Engine...................................... 17

Safety Circuit ........................... 18

Start Switch ............................. 18

Warning Signal ........................ 18

Speed Adjusting Lever............. 19

Choke....................................... 19

Driving Control ......................... 19

Park Brake............................... 19

Coasting Operation.................. 20

Differential Lock....................... 21

Cutting Height Adjustment....... 21

Cutter Switching ...................... 21

Driver's Seat Adjustment ......... 22

Guard bow............................... 22

Drive-Wheels ........................... 22

Engine Cover ........................... 22

Fixing/Jacking Points ............... 23

Battery..................................... 23

4. Commissioning and

Operation

Commissioning the Machine ... 24

Starting the Engine ........... 25 - 26

Driving...................................... 27

Mowing..................................... 27

Danger Zone............................ 28

Working on Slopes................... 28

Switching off the Engine .......... 29

5. Maintenance

Engine Oil .......................... 30, 31

Engine Oil Filter ................. 30, 31

Air Filter (Diesel engine) .......... 31

Cooling System........................ 32

Battery, Fuse............................ 33

Hydrostat Gear ....................... 34

Angle Gear............................... 34

Hydrostat Cooling Fan ............. 34

Steering, Front Axle ................. 35

Blade Shaft .............................. 35

Drive-wheels ............................ 36

Park Brake............................... 36

Safety Circuit ........................... 36

Engine Shut-off Switch ............ 36

V-Belt ....................................... 37

Chain Guard ............................ 39

Driving Chains ......................... 38

Flail Knives............................... 39

General Maintenance, Cleaning . 40

Storage .................................... 41

Varnishes, Wear Parts...... 42

Electrical Wiring ............... 43

6.Troubleshooting.....44 - 45

Lubrication Chart............. 46

Maintenance Schedule .... 47

Inspection and Maintenance

Chart.................................. 48

Conformity Declaration ... 51

Note fold-out pages!

Fig. A ................................... 3

Fig. B (Engine) .................. 50