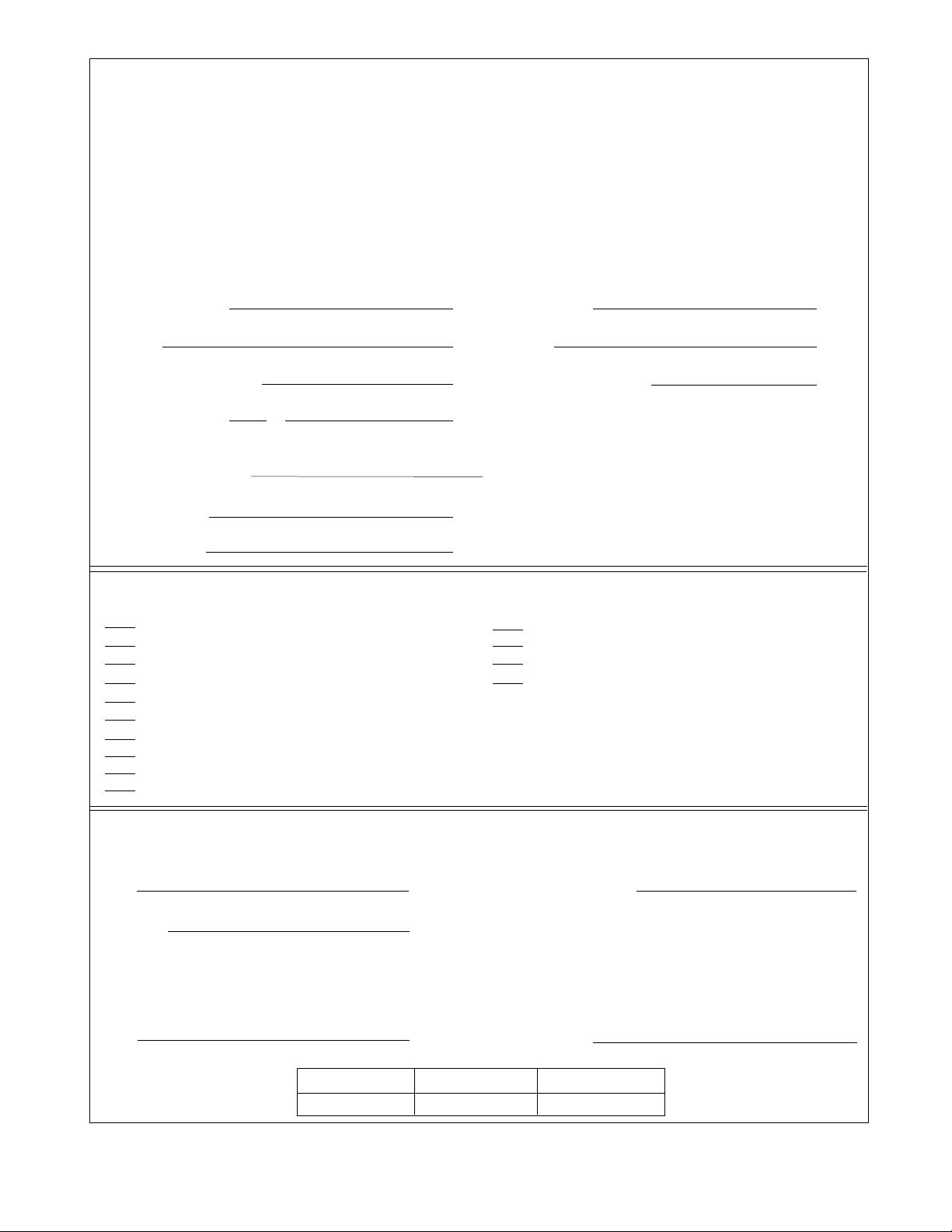

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1 Introduction ........................................................ 1

2 Safety.................................................................... 3

2.1 General Safety....................................................... 4

2.2 Equipment Safety Guidelines ................................ 5

2.3 Safety Training....................................................... 6

2.4 Safety Signs .......................................................... 6

2.5 Preparation ............................................................ 7

2.6 Maintenance Safety............................................... 7

2.7 Operating Safety.................................................... 8

2.8 Transport Safety .................................................... 9

2.9 Storage Safety....................................................... 9

2.10 Refuelling Safety ................................................... 9

2.11 Tire Safety ............................................................. 9

2.12 Gas Motor Safety................................................. 10

2.13 Sign-Off Form .......................................................11

3 Safety Sign Locations ....................................... 13

4 Assembling ........................................................ 15

4.1 Machine Assembly............................................... 15

5 Operation............................................................ 29

5.1 To the New Operator or Owner............................ 29

5.2 Machine Components.......................................... 30

5.3 Break-In ............................................................... 31

5.4 Pre-Operation Checklist ...................................... 31

5.5 Controls ............................................................... 32

5.6 Attaching/Unhooking ........................................... 34

5.7 Loading Greens Roller onto Trailer...................... 35

5.8 Field Operation .................................................... 36

5.9 Transporting......................................................... 44

5.10 Storage ................................................................ 45

6 Service and Maintenance.................................. 47

6.1 Service................................................................. 47

6.1.1 Fluids and Lubricants ........................................................... 47

6.1.2 Greasing............................................................................... 47

6.1.3 Servicing Intervals................................................................ 48

6.1.4 Service Record..................................................................... 53

6.2 Maintenance ........................................................ 54

6.2.1 Cleaning Air Cleaner ............................................................ 54

6.2.2 Changing Engine Oil ............................................................ 55

6.2.3 Changing Hydraulic Oil and Filter......................................... 56

6.2.4 Steering System Centering .................................................. 57

6.2.5 Rolling System Chain Drive Tension and Alignment ............ 58

7 Trouble Shooting ............................................... 59

8 Specications .................................................... 61

8.1 Mechanical .......................................................... 61

8.2 Hydraulic Fitting Torque ....................................... 62

8.3 Bolt Torque........................................................... 63

9 Index ................................................................... 65