Agrisem BOSS Series User manual

USER MANUAL

BOSS SEED DRILL

Telephone : +33 (0) 2 51 14 14 40

AGRISEM

535 Rue Pierre Levasseur

CS 60263

44158 ANCENIS - FRANCE

2

Table of contents

1Introduction .................................................................4

1.1 Preface ...............................................................4

1.2 Service................................................................4

1.3 Damages ............................................................4

1.4 Description of warning terms..............................4

2Safety and responsibility ...........................................4

2.1 Intended use .........................................................5

2.2 Spare parts.........................................................5

2.3 User manual .......................................................5

2.4 Personnelqualication .......................................5

2.5 User groups........................................................6

2.6 Children at risk ...................................................6

2.7 Personal protection equipment ..........................6

2.8 Road safety ........................................................6

2.9 Operational safety .............................................7

2.9.1 Commissioning.................................................7

2.9.2 Damage to the machine ...................................7

2.9.3 Coupling and uncoupling..................................7

2.9.4 Hydraulic system..............................................8

2.9.5 Pneumatic circuit and connections ..................8

2.9.6 Pressure accumulator ......................................8

2.9.7 Brake system....................................................8

2.9.8 Overhead lines .................................................8

2.9.9 Action in the event of a voltage discharge

..........................................................................9

2.9.10 Technical limit values...................................... 9

2.9.11 Useintheeld................................................ 9

2.9.12 Replacement of worn parts ............................9

2.9.13 Transportation on public roads.......................9

2.10 Fertilisers and seeds treated with disinfectants

2.11 Environmental protection .................................10

2.12 Retrots ...........................................................10

2.13 Servicing and maintenance .............................. 11

2.14 Delivery............................................................. 11

2.15 Loading and unloading ..................................... 11

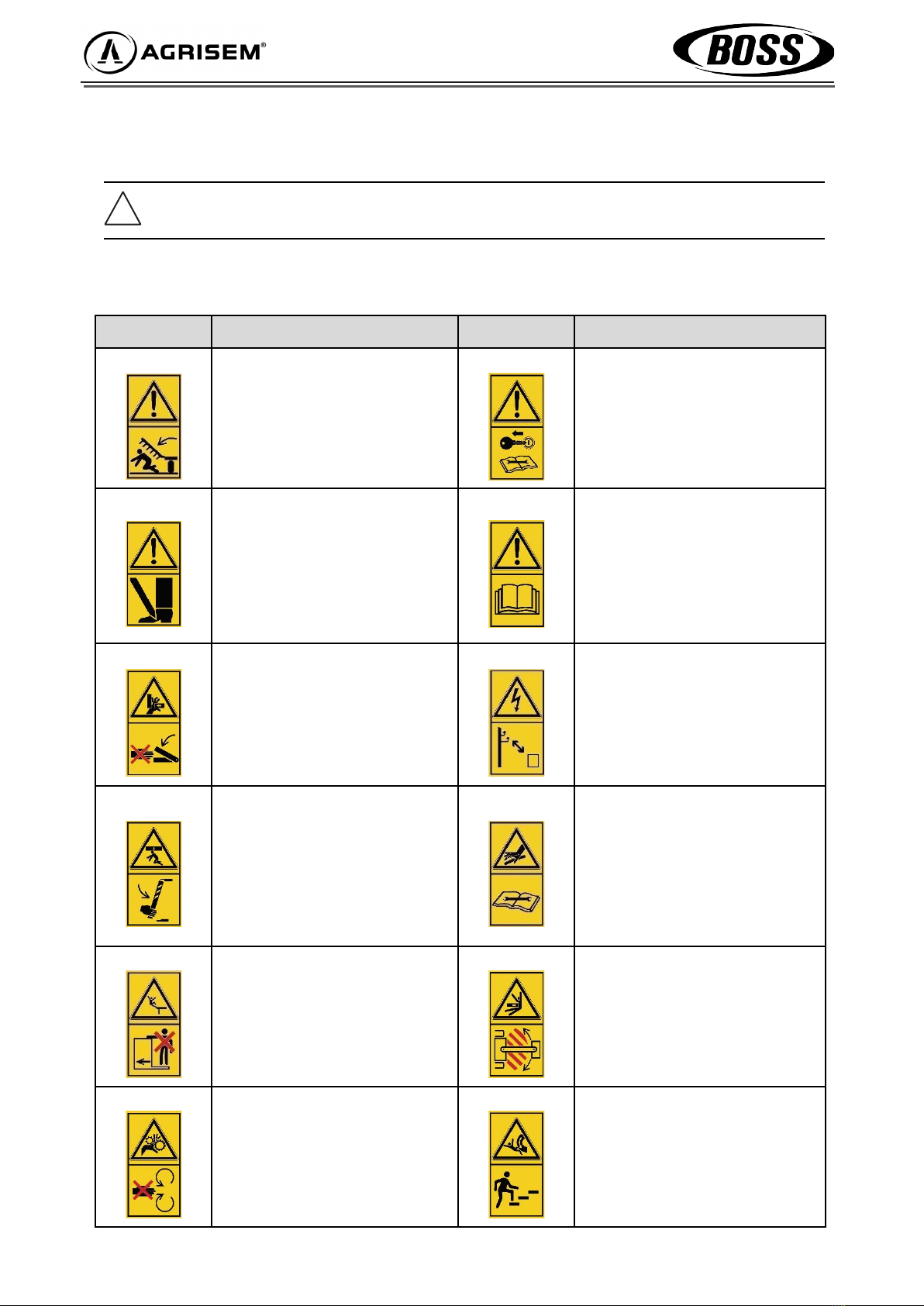

2.16 Safety stickers ..................................................12

2.16.1 Explanation of stickers : ...............................12

2.16.2 Placement of stickers : .................................13

2.16.3 Placement of stickers on Boss machines ....13

2.16.3 Placement of stickers on Big Boss machines ..

13

3Technical specications ...........................................14

3.1 Technical data .......................................................14

3.1.1 mBoss: ...........................................................14

3.1.2 Boss: ..............................................................14

3.1.3 Big Boss ........................................................15

3.2 Nameplate ........................................................15

3.3 Dimensions.......................................................16

3.4 Ballast calculation.............................................18

4Usage...............................................................19

4.1 Coupling ...........................................................19

4.2 Hydraulic connection ........................................19

4.3 Electrical connection.........................................19

5Starting up..................................................................20

5.1 Unfolding the seed drill.....................................20

5.1.1 Boss ..............................................................20

5.1.2 Big Boss ........................................................20

5.2 Hoppers 22

5.2.1 Accessing hoppers .........................................22

5.2.2 Filling..............................................................22

5.2.3 Emptying hoppers ..........................................23

5.3 Small seed hopper............................................23

5.4 Seed transportation ..........................................24

5.5 Calibration of metering units.............................24

5.6 Dismantling the rotor in the metering units ......25

5.7 Changing the rotors .........................................25

5.8 Folding the seed drill ........................................26

5.8.2 Big Boss ........................................................26

6Settings ...........................................................28

6.1 Setting the seeding depth and the angle of the

of the seed wheel..................................................28

6.1.1 Quick rear adjustment system without

tools................................................................28

6.1.2 Quick adjustment system for the side wheel

(optional) ....................................................... 28

6.2 Hydraulic pressure setting................................28

6.3 Turbine setting..................................................29

6.4 Debris catcher setting (optional) ......................29

6.5 Skimmer setting................................................30

6.6 Side wheel setting ..........................................230

6.7 Metal ring for cleaning wheels 31

6.8 Disc cleaning scraper ......................................31

3

6.9 Setting the side markers (optional) 32

7Brakes 33

7.1 Hydraulic brake.................................................33

7.2 Pneumatic brake...............................................34

7.3 Parking brake ...................................................35

8Hydraulics 35

8.1 Boss .....................................................................35

8.1.1 Drawbar suspension .....................................35

8.1.2 Folding / turbine circuit..................................36

8.1.3 Circuit with CETOP.......................................37

8.1.4 Circuit elements ............................................38

8.2 Big Boss ...............................................................39

9 Operating instructions for the control system ......40

9.1 User manual for the control unit

RDS ISOCAN ARTEMIS .................................40

9.2 User manual for theSeedXconnect... touch tablet

40

9.3 User manual for A-Touch 800 / 1200 ................ 40

10 Servicing and maintenance....................................40

10.1 Disc and hub assembly ....................................40

10.1.1 18’’ disc ...........................................................40

10.2 Safety reminder. ...............................................41

10.3 Cleaning ...........................................................41

10.4 Immobilising the tractor unit and machine........ 41

10.5 Storage.............................................................41

10.6 Maintenance.....................................................42

10.6.1 Daily maintenance and care. ......................42

10.6.2 Annual maintenance ...................................42

10.6.3 Lubrication point plan..................................43

11 Problems and troubleshooting ..............................43

12 Annexes....................................................................45

12.1 Tightening torques............................................45

12.2 Choosing the rotors .........................................46

12.2.1 Rotor models................................................46

. 2 12.2 .......................................Rotorcongurations

47

12.3 Table for choosing rotors ..................................50

12.4 SeedXconnect manual .....................................59

12.4.1 Description..................................................59

12.4.2 Usage .........................................................60

12.4.3 Conguration ..............................................64

12.5 A-Touch 800 / 1200 manual.............................70

12.5.1 Description..................................................70

12.5.2 Usage .........................................................72

12.5.3 Calibrating the radar ..................................81

12.5.4 Calibrating the motors ...............................82

12.6 Using the equipment's diagnostic mode .............83

4

!

Read and observe the following safety

instructions before using the machine!

1 Introduction

1.1 Preface

Before commissioning the machine, the instructions in this

manual must be carefully read and strictly followed. This will

help to eliminate hazards, reduce repair costs and downtime

and increase the reliability and service life of your machine.

Observe the safety instructions!

AGRISEM accepts no responsibility for damage and

malfunctions resulting from failure to comply with this

manual.

This manual is intended to make it easier for the user to get

to know the machine and to exploit the potential applications

in accordance with the intended use.

This instruction manual must be read and observed by all

persons who have to work on or with the machine, e.g. :

- Operations (including preparation, troubleshooting

during work, maintenance)

- Maintenance (servicing, inspection)

- Transportation

The warranty period starts from the date of delivery.

We reserve the right to make changes to the illustrations,

technical data and weights shown in this manual for the

purpose of improvement.

Theillustrationsinthisusermanualshowdierentversions

of the mounted or coupled device as well as dierent

equipment.

1.2 Service

The AGRISEM Company wants you to be completely

satisedwithyourmachineandwithus.

If you have any problems, please contact the sales manager

for your area.

1.3 Damages

The machine has been carefully manufactured by AGRISEM-

SLY. However, even in the case of proper use, defects that

can lead to a complete breakdown can be caused by, for

example:

-Damageduetoexternalinuences

- Wear and tear of wearing parts

- Missing or damaged work equipment

- Incorrect driving speeds

- Incorrect setting of the equipment (incorrect assembly/

coupling, failure to follow the setting instructions)

- Non-compliance with the user manual

- Maintenance and servicing not carried out or not

carried out properly

Therefore, before each use of the machine and while it is in

operation, you should check whether it is working properly

andwhethertheowrateiscorrect.

Any claim for compensation for damage that has not

occurred directly on the machine is excluded. The company

cannot be held liable for damage caused by errors in

handling and use.

1.4 Description of warning terms

!

DANGER

This pictogram accompanies a risk situation for the user.

Consequences: death or unavoidable serious injury

!

WARNING

This pictogram accompanies a risk situation for the user.

Consequences: death or serious injury may occur.

!

CAUTION

This pictogram accompanies a risk situation for the user of

the equipment.

Consequences: minor injuries may occur to the user, minor

damage may occur on the equipment.

!

IMPORTANT

This pictogram provides mandatory information.

Consequences: equipment damage, physical risks, nancial

risks.

2 Safety and responsi-

bility

The following hazard and safety information applies to all

sections of this manual.

The machine is built according to the current state of the

art and the recognised technical safety regulations. Its use

may, however, present a danger of injury or death to the

user or third parties and/or cause damage to the machine

or other equipment.

5

2.1 Intended use

The machine is intended to be used for seeding and/or

normal tillage in accordance with the specic rules in the

agricultural sector.Any other use or use beyond the intended

purpose, e.g. as a means of transport, is not considered to

be in accordance with the intended use and may result in

injury or death to people.

AGRISEM accepts no responsibility for any claims that may

result from this. The user assumes full responsibility for this.

Comply with the accident prevention regulations of the

mutual agricultural insurance funds and other generally

recognised rules on safety, occupational health and road

safety.

Only use the machine if it is in perfect technical condition

for its intended purpose and with full knowledge of the risks!

Remove any potential safety hazards immediately.

The machine may only be used, maintained and repaired

by persons who are familiar with it and have been informed

of the dangers.

2.2 Spare parts

AGRISEM original spare parts and accessories are specially

designed for this machine.

Other spare parts or accessories are neither inspected nor

authorised by AGRISEM.

The installation or use of parts that are not of the AGRISEM

brand may, in certain cases, lead to adverse changes in the

characteristicsofthemachineandthusaectthesafetyof

people and the machine.

The AGRISEM Company cannot be held liable for damage

from the use of non-original parts and accessories.

Whensafetystickersareaxedtothecomponentthatisto

bereplaced,theymustalsobeorderedandaxedtothe

replacement component.

2.3 User manual

Intended use also includes complying with the instructions

in the user manual and the manufacturer's operating,

maintenance and servicing instructions.

The user manual is an integral part of the machine!

The machine should only be used in accordance with the

user manual. Failure to comply with the user manual may

result in serious injury or death to persons.

Before working, read and observe the relevant chapters of

the user manual.

Keep the user manual handy.

Give the user manual to subsequent users. To be submitted

in the local language in case of resale in a country where

another language is spoken.

2.4Personnelqualication

Improper use of the machine may result in serious injury or

death to persons. To avoid accidents, any person working

on the machine must meet at least the following general

criteria:

They must be physically able to control the machine.

They are capable of carrying out safe work on the machine

within the scope of this user manual.

They know how to operate the machine in the course of

their work and are aware of the hazards involved in the

work. They can assess and avoid work-related hazards.

They have understood the user manual and can apply the

information it contains.

They know how to drive vehicles safely.

For driving on the road, they are familiar with the respective

rules of the road and have a valid driving licence.

A trainee should always be supervised when working with

the machine.

The operator must:

- Regulate the scope of responsibilities, competence

and supervision of personnel.

!

6

It is forbidden to carry passengers on the

machine!

-Trainandinstructstaasrequired.

- Provide the operator with access to the user manual.

- Ensure that the operator has read and understood the

user manual.

2.5 User groups

Persons working with the machine must be trained

accordingly to perform the various tasks.

Trained operators

These persons must have been instructed by the owner

operator or suitably qualied personnel on the tasks to be

performed. This concerns the following tasks:

- Road transport

- Use and settings

- Operation

- Maintenance

-Faultndingandtroubleshooting

Skills and educational level

Activity Instructed

person

Person

with

specialised

training

Person specially

trained for this

activity

Transport loading

- x x

Commissioning

x x -

Installation and setting up the

equipment

- x -

Operation

x x -

Maintenance

x x -

Finding and resolving faults and

problems

x x -

Waste reprocessing/disposal

- - x

2.7 Personal protection

equipment

Missing or incomplete protective equipment increases the

risk of

injury. Personal protective equipment includes, for example:

Well-tting clothing / protective clothing, if necessary a

hairnet

Safety shoes, protective gloves

Protective glasses to protect against dust or splashes when

handling fertiliser and liquid fertiliser (observe the fertiliser

manufacturers' instructions )

Respiratory protection mask and protective gloves when

handling disinfectants or seeds treated with disinfectants

(observe the disinfectant manufacturers’ instructions)

Determine the personal protective equipment for the

respective task.

Makesureeectiveprotectiveequipmentisavailableandin

good condition.

Never wear rings or other jewellery.

2.8 Road safety

Observe the permitted transport widths and heights. Take

into account the vehicle height, especially when passing

under bridges and low power lines.

Axle loads, tyre load capacities and permissible total weights

must be observed so that sucient steering and braking

precision is maintained. The front axle must always have a

load of at least 20% of the tractor's empty weight.

For road transport, the machine must be in the transport

position. The machine must be folded and locked.

Before folding, soil must be removed from the folding areas.

This is to avoid damage to the mechanical system.

Install lighting and signalling and protective devices and

check their functioning.

Before driving on the road, clear any dirt that has accumulated

on the machine.

2.6 Children at risk

Children are not able to assess dangers and behave

unpredictably. They are therefore particularly at risk:

Keep children away.

In particular, make sure that there are no children in the

danger area before starting the machine and initiating its

movements.

Immobilise the tractor before getting out.

!Children may trigger dangerous movements

if they are able to access on the machine. An

insuciently secured and unattended machine is a

danger to children playing nearby!

7

Drivingisinuencedbymounted/coupledimplements.

Particularly when cornering, take into account the large

overhang and the mass of inertia of the attachment/coupling

aswellasthedegreeoflling.

Raised machines (three-point hydraulic system):

Consider the lack of stability and manoeuvrability of the

tractor.

!

When travelling on public roads, observe the

maximum speed allowed!

Always adapt driving to road conditions to avoid accidents

and damage to the frame and transport wheels. Take into

accountpersonalabilities,roadconditions,trac,visionand

bad weather.

2.9 Operational safety

2.9.1 Commissioning

Without correct commissioning of the machine, its operational

safety cannot be guaranteed. This can lead to accidents and

serious injury or death.

Use the machine only after receiving the necessary

instructions from the authorised dealer, factory

representatives or AGRISEM employees.

The completed acknowledgement of receipt must be

returned to AGRISEM.

The machine may only be used if all protective devices and

safety-related devices, e.g. removable guards (chocks, etc.),

are in place and functioning properly.

Regularly check that nuts and bolts are tight, especially those

on wheels and work tools, and retighten them if necessary.

Check tyre pressure regularly.

2.9.2 Damage to the machine

Damage to the machine can impair its operational safety and

cause accidents. This can result in serious injury or death.

The following parts of the machine are particularly important

for safety:

- Hydraulic system

- Brakes (where applicable)

- Connecting devices

- Protection devices

- Lights

If there is any doubt as to the safe condition of the machine,

e.g. if consumable parts are leaking, if there is visible damage

or if the machine's behaviour has changed unexpectedly:

stop the machine immediately and secure it.

If possible, determine the damage with the help of this user

manual and eliminate it.

Eliminate possible causes of damage (e.g. coarse dirt or

loose screws).

Havethedamagerepairedataqualiedspecialistworkshop

if it may compromise safety and if you cannot repair it

yourself.

2.9.3 Coupling and uncoupling

!

WARNING

If the tractor does not correspond to the coupled machine,

the following risks apply:

- Breakage of coupling

- Instability under load

- Instability when manoeuvring

- Insucient braking capacity

There is only a single operator, with drivers coupling and

uncoupling the machine on their own. Use the external lift

controls.

Ensure that no one is standing between the tractor and the

machine or in the immediate vicinity of the machine when

coupling or uncoupling.

Before getting out of the tractor to couple or uncouple, apply

the parking brake, stop the engine and remove the ignition

key from the tractor.

Before coupling your machine, make sure that there are no

signs of wear, breakage or incompatibility with your tractor in

the coupling pins, drawbar couplings or ball joints.

Depressurise your hydraulic system before connecting or

disconnecting hydraulic connections.

Connect or disconnect the electrical connections.

Lower the machine completely to the ground before

uncoupling.Checkthatthesurfaceislevelandrmenough

to ensure that the machine is stable when stored.

8

When your machine is parked, make sure it is stable so as

not to cause personal injury or damage to equipment.

2.9.4 Hydraulic system

The machine's hydraulic system has a number of functions

that can cause injury and equipment damage in the event of

operating errors.

Do not connect the hydraulic hoses to the tractor until both

the tractor and the machine are depressurised.

The hydraulic system is under high pressure.

Regularly check all pipes, hoses and connections for leaks

and externally visible damage!

Only use appropriate means to search for leaks. Repair

damage immediately! Oil splashes can cause injuries and

res!

To prevent operating errors, mark the plugs and sockets of

the hydraulic connections.

Consult a doctor immediately in the event of injury!

Secure or lock the tractor's valves when not in use!

Replace the hydraulic hoses after a maximum of six years.

2.9.5 Pneumatic circuit and connections

Observe the assembly order of the pneumatic connections.

Before connecting the pneumatic system, clean the

connections on the tractor and on the machine and check

that the pressure is zero on the tractor and on the machine.

Replace damaged or worn pneumatic hoses and observe

thedimensionalspecications.

For all operations on the pneumatic system, place the

machine on the ground and depressurise the pneumatic

circuit.

2.9.6 Pressure accumulator

There may be pressure accumulators in the hydraulic

system.

!Do not open the pressure accumulators or do

any work on them (welding, drilling). Even after

emptying, the tanks are still under gas pressure.

The hydraulic system must be depressurised

before maintenance work is carried out!

!Never get on or o the machine under overhead

lines to avoid the risk of electric shock from voltage

discharges.

!The hydraulic system is under high pressure.

Splashed liquid can penetrate the skin and cause

serious injury. Consult a doctor immediately in the

event of injury.

Never unfold or fold the side sections in the vicinity

of power pylons and overhead lines.

2.9.7 Braking system

Depending on the equipment, the machines can be tted

with a pneumatic or hydraulic braking system.

The braking system must always be connected and

functioning properly when driving on the road.

After coupling the machine and before any kind of transport,

always check the condition and functioning of the braking

systemrst.

Check the setting on the brake force regulator.

Alwaysreleasetheparkingbrakerstbeforemoving.

Before uncoupling, always secure the machine against

rolling and apply the parking brake.

2.9.8 Overhead lines

When the side sections are unfolded and folded, the

machine can reach the height of overhead lines. The voltage

can then be discharged onto the machine and cause a fatal

electricshockorre.

Ensure that sucient distance is maintained from high

voltage power lines when the side sections are folded and

when unfolding and folding.

!

9

!Protruding parts (ploughshares, etc.) can cause

injury!

2.9.9 Action in the event of a voltage

discharge

Voltage discharges cause high electrical voltages on the

outside of the machine. Large voltage dierences appear

ontheooraroundthemachine.Takingbigsteps,lyingon

theoorortouchingthegroundwithyourhandscancause

deadly electric currents (step voltage).

Do not leave the cab.

Do not touch metal objects.

Do not make any conductive connection with the ground.

Warn people: NOT to go near the

machine. Electrical voltages on the ground can cause

powerful electric shocks.

Wait for professional help. The overhead line must be cut.

If people have to leave the cab despite voltage discharges,

e.g.whenthereisimmediatedangerofdeathfromre:

Jump out of the machine. Be careful to maintain stability

while jumping. Do not touch the outside of the machine.

Move away from the machine taking small steps.

2.9.10 Technical limit values

If the technical limits of the machine are not respected, the

machine may be damaged. This can lead to accidents and

serious injury or death.

The following technical limit values are particularly important

for safety:

• total permissible weight

• maximum axle loads

• maximum load transfer

• maximum speed

Also observe the maximum tractor loads.

To calculate the permissible loads and weights, refer to

section ‘3.4 Ballast calculation’.

2.9.11 Useintheeld

Before start-up and commissioning, make sure that no one

isnearthemachine(children).Ensurethatthereissucient

visibility.

Ensure sucient stability of the machine in case of

longitudinal and transversal slopes on uneven ground.

Observe the permitted limit values for the tractor.

None of the prescribed and supplied protective devices may

be removed.

Ensure that no one is in the pivoting range of hydraulically

operated machine parts.

Do not reverse the machine when it is lowered. The

componentsareonlydesignedtomoveforwardsintheeld

and could be damaged when travelling in reverse.

2.9.12 Replacement of worn parts

Secure the machine so that it does not move unexpectedly!

The raised frame sections under which you are positioned

must be secured with suitable supports!

Never climb on rotating parts to get on the machine. These

could spin and you could be seriously injured if you fall.

2.9.13 Transportation on public roads

Machines must always be used in accordance with the

applicable guidelines and regulations concerning accident

prevention, road safety and occupational health.

Before any movement:

-Checkthewheelstudsandtandemmountingbolts(iftted)

for tightness.

- Check the functioning of the lighting equipment.

- Check tyre pressure and condition:

• Do not drive with low pressures or damaged tyres or

rims.

When driving, use all the lighting and signalling devices

required by law in the country of use. If necessary, they can

beremovedduringeldworktopreventdamage.

It is forbidden to carry passengers on the

machine!

!

10

The user is responsible for ensuring compliance with the

applicable regulations and for monitoring developments.

Regularlychecktheconditionandxingofthecouplingpins;

do not hesitate to change them if they are worn.

The tractor's ball joints may also show signs of wear, so do

not hesitate to replace them with new ones.

Drive at a reasonable speed in accordance with the law so

that you always have control of the coupled unit.

Take particular care on uneven or sloping ground. Before

starting a descent, drop down to a lower gear.

The tractor used to move the machine on the road must have

thesameweightandpowerastheoneusedforeldwork.

Never manoeuvre when a person is near the machine or the

tractor.

For machines equipped with a folding system for transport,

make sure that there are no people or obstacles in the

scanning area when folding the parts.

Observe all safety rules when driving, especially on bends

and narrow roads.

Take all precautions before getting out of the tractor.

Engage the parking brake, stop the engine, remove the

ignition key.

When travelling on the road, do not allow anyone to ride on

the machine or between the machine and the tractor.

2.10 2.10 Fertilisers and seeds

treated with disinfectants

Improper handling of fertilisers and seeds treated with

disinfectants can lead to poisoning and death.

Observe the product manufacturer's safety data sheet. If

necessary, ask the dealer for the safety data sheet.

Determine the required personal protective equipment

according to the manufacturer's instructions and ensure its

availability.

2.11 Environmental protection

Consumables such as hydraulic oil, lubricants, etc., can

harm the environment and people's health.

Do not allow consumables to pollute the environment.

Soak up spilled consumables with absorbent material

or sand, collect them in a sealed, marked container and

dispose of them in accordance with legal requirements.

2.12Retrots

Constructional changes and additions can impair the proper

functioning and operational safety of the machine. This can

result in serious injury or death.

Do not make any constructional changes or additions that

are not authorised by AGRISEM.

Conversions or additions to the machine may only be carried

out by a specialised workshop or by an operator trained for

this purpose by AGRISEM.

Observe national regulations for weights, weight distribution

and dimensions.

For equipment aecting weight or weight distribution, the

specicationsforthecouplingdevice,loadtransferandaxle

load must be checked and observed.

For machines without brakes, a braking system may have to

beretrottediftheweightlimitsareexceeded.

For all changes to the data on the nameplate, a new

nameplate with the current data must be installed.

If there are any changes to the information on the road

permit, it must be renewed.

11

2.13 Servicing and maintenance

Observe the prescribed intervals for periodic checks and

inspections.

Maintain the machine according to the maintenance plan;

see chapter ‘Servicing and maintenance’.

Only carry out the work described in this user manual.

Carry out maintenance and servicing work after placing the

machineonastableoorandsecuringittopreventitfrom

moving.

Depressurise the hydraulic system and lower the work

equipment or support it with appropriate means.

Before carrying out any work on the electrical system,

disconnect it from the power supply.

Before performing welding work on the machine, disconnect

cables from computers and other electronic components.

Mount the grounding terminal as close as possible to the

weld.

Before cleaning the machine with a high-pressure cleaner,

cover all the openings, which for safety and functional

reasons must not be penetrated by water, steam or cleaning

agents. Do not direct the water jet directly at electrical or

electronic components, bearings or the fan. When cleaning

with high pressure or steam, always keep a distance of at

least 50 cm from the machine parts.

After cleaning, check all hydraulic lines for leaks and loose

connections.

Inspect for wear from friction and abrasion. Immediately

remedy any defects found!

Tighten all loose screw connections during servicing and

maintenance work.

Do not wash new machines with steam or high-pressure

cleaners. The paint only hardens after about 3 months and

could be damaged before that.

2.14 Delivery

As a rule, the machine and tools are delivered fully

assembled on a low loader. If parts or subassemblies have

been disassembled for transport, they will be reassembled

onsitebyourdealerorbyourtters.

Depending on the model of low loader used, the machine

can be lowered by pulling it behind a tractor or must be

unloaded with appropriate lifting equipment (hoist or crane).

Only use lifting equipment and tools with sucient

load-bearing capacity and approval!

2.15 Loading and unloading

Loading and unloading with a tractor.

The machine should be coupled to or uncoupled from the

tractor for loading onto or unloading from a truck.

An assistant is needed to guide the manoeuvre.

Attach or remove the transport locks.

!Incorrect maintenance and servicing jeopardises

the operational safety of the machine. This can

lead to accidents and serious injury or death.

12

!

Take care not to damage the safety stickers when washing the machine. Change or replace any

damaged or missing stickers.

2.16 Safety stickers

2.16.1 Explanation of stickers :

Sticker Description Sticker Description

380135

ETIQ01-627

Stay clear when unfolding.

Keep a safe distance

from any moving parts when

unfolding.

305021

ETIQ01-601

Stop the engine and remove the key.

Stop the engine and remove the

ignition key before carrying out any

maintenance or servicing.

305016

ETIQ01-633

Feet-crushing danger area.

Keep a safe distance from any

moving parts.

355001

ETIQ01-603

Read the user manual.

Read the user manual and safety

instructions before commissioning

and observe them during operation.

355054

ETIQ01-625

Crushing danger area.

Never work in an area where there

is a risk of crushing while parts are

still moving.

355063

ETIQ01-643

Keep a safe distance from power

lines.

Keep a safe distance from high-

voltage

power lines.

355049

ETIQ01-617

Locking device.

Apply the locking device before

any work is carried out.

305064

ETIQ01-641

Hydraulic leakage.

Follow the instructions in the user

manual for maintenance work.

355062

ETIQ01-651

Transporting on the machine.

Never carry passengers on the

machine.

355048

ETIQ01-609

Scanning area.

Stay out of the scanning area.

355035

ETIQ01-655

Rotating parts.

Never put your hands in the area

where the bolt is rotating.

380299

ETIQ01-649

Moving parts.

Never climb on parts that can

rotate. Only use the equipment

intended for climbing.

13

002

Sticker Description

Wheel tightening.

Check the tightness of the wheels after 8 hours of use.

355001

355021

355064

355062

355065

355048

355016

355049

355054

380135

355063 x 2

x 2 355062 380299

305035 x 2

002 x 2

2.16.2 Placement of stickers on the mBoss

2.16.3 Placement of stickers on the Boss

2.16.4 Placement of stickers on Big Boss machines

The safety stickers with the supplement ‘x 2’ are located on both sides of the machine.

Stickers

Stickers

Stickers

Stickers

14

3 Technical specications

3.1 Technical data

3.1.1 mBoss

3.1.2 Boss

Operating width (m) 3 4

Transport width (m) 3 4

Transport height (m) 2.96 3.96

Length (m) 5.60

Weight (kg) 4,150 5,400

Single hopper capacity (l) 1,600

Double hopper capacity (l) 3,200

Triple hopper capacity (l) (+1200 or 2000) 4400 or 5200

Open,lledhopperdims.(m) 0.77 x 0.91

Number of seeding ploughshares 18 16 24 22

Row spacing (cm) 16.7 18.75 16.7 18.75

Transport wheels dims. 500/60R-22.5

Transport wheels dims.

(optional) 710/50R-26.5

Working speed (km/h) 16.7

Max. transport speed

(km/h) 25

Operating width (m) 3 4 4.5 6 7

Transport width (m) 2.99

Transport height (m) 3.23 3.29 3.97 4.45

Length (m) 7.18 – 7.80 (triple hoppers)

Weight (kg) 4,850 5,310 6,240 6,650 7,200

Single hopper capacity (l) 1,200 or 2,000

Double hopper capacity (l) 2,400 or 4,000

Triple hopper capacity (l) 3,600 or 6,000

Open,lledhopperdims.(m) 0.77 x 0.91

Heightoflledhopper(m) 2.63 (1200L hopper ) or 3.12 (2000L hopper)

Number of seeding ploughshares 12 - 16 - 18 16 - 20 - 22

- 24 24 24 - 30 - 32

- 36 28

Row spacing (cm) 16.7 - 18.75

- 20 - 25

16.7 - 18.75

- 20 - 25 18.75 16.7 - 18.75

- 20 - 25 25

Transport wheels dims. 500/60R-22.5

Transport wheels dims.

(optional) 710/50R-26.5

Working speed (km/h) 6 - 15

Max. transport speed

(km/h) 25

15

NOTE:

We reserve the right to make changes as a result of technical developments.

The weight of the coupled implement depends on the equipment; indication with minimum

equipment.

The permitted transport heights and widths on public roads may vary from country to country.

Observe national registration requirements.

3.2 Nameplate

The nameplate with the CE label is located on the machine frame.

3.1.3 Big Boss

Operating width (m) 8 9 10 12

Transport width (m) 2.99

Transport height (m) 4.45

Length (m) 12.5

Weight (kg) 16,900 17,500 18,100 19,500

Single hopper capacity (l) 1,200 or 2,000

Double hopper capacity (l) 2,400 or 4,000

Triple hopper capacity (l) 3,600 or 6,000

Open,lledhopperdims.(m) 0.77 x 0.91

Heightoflledhopper(m) 2.63 (1200L hopper ) or 3.12 (2000L hopper)

Number of seeding ploughshares 32 - 40 - 44 - 48 36 - 46 - 48 - 54 40 - 50 - 56 - 60 48 - 60

Row spacing (cm) 16.7 - 18.75 - 20 - 25 20 - 25

Transport wheels dims. 500/60R-22.5

Transport wheels dims.

(optional) n/a

Working speed (km/h) 6 - 15

Max. transport speed

(km/h) 25

Reference

marker

Description

1 Brand

2 Model / variant / version

3Serialidenticationnumber

4 Date of receipt

5Issueofapprovalbycertication

bodies

6 Total loaded weight

7 Tare weight

8 - 9 Not used

mBoss seed drill 4 m:

16

3.3 Dimensions

BOSS seed drill 4.5m :

BOSS seed drill 3m:

mBoss seed drill 3 m:

17

BOSS seed drill 6m :

BOSS seed drill 7m:

Big Boss seed drill 8 / 9 / 10 / 12m :

Dimensions, see table ‘3.1 Technical data’ 3.1.3 Big Boss

12,500 2,990

4,450

18

Actual value obtained

from the calculation

Permissible value

according to the

user manual

Value x 2 of the permissi-

ble tyre load

MAV

CAV CAR

RAR

3.4 Ballast calculation

The mounting or coupling of implements must not lead to the tractor's permissible gross vehicle weight, permissible

axleloadandtyrespecicationsbeingexceeded.

PV Tractor empty weight.

CAV Empty tractor front axle load.

CAR Empty tractor rear axle load.

MAV Front mass (if present).

RAR Load transfer from the coupled machine

a Distance between the centre of gravity of the front implement or front ballast and the centre of the front axle.

b Tractor wheelbase.

c Distance between the centre of the rear axle and the centre of the rear lower coupling point.

All weight data in (kg)

All measurement data in (m)

Calculation of the minimum ballast at the front :

Calculation of the actual front axle load :

Calculation of the actual total weight :

Calculation of the actual rear axle load :

The calculated values must not exceed the permissible values.

Mini ballast

front

Total weight

Load on front

axle

Load on rear

axle

≥

≥

≥

≥

≥

MAV (min)=

P(total)=

CAV (total)=

CAR (total)=

19

4 Usage

4.1 Coupling

Before coupling the machine, ensure that it has been correctly immobilised.

1. Check the machine and tractor couplings for wear and cleanliness.

2. Move the tractor up to the machine.

3. Couple the machine.

a) Machines with coupling on the lifting arms :

Couple the machine

Lock the catch hooks Tension the stabilisers to prevent lateral movement

Ensure that the level of the linkage is set so that the machine frame is in a horizontal position

Connect the hydraulic brake connector

b) Machines with hitch ring :

Adjust the height of the drawbar so that the machine can be coupled.

Couple the machine.

Insert the bolt and lock it.

Connect the hydraulic brake connector

c) Machines with ball coupling :

Lower the drawbar or cap onto the ball and raise the machine slightly.

Position the clamping frame.

Check and adjust the size of the gap between the clamping frame and the cap.

4. Fold in the support legs and lock them in place with the pin provided.

4.2 Hydraulic connection

The operation of the seed drill requires :

- 1 double-acting hydraulic valve for folding and unfolding the machine's wings.

-1double-actinghydraulicvalvetoraiseandlowertheseedingunitsintheeld.

- 1 double hydraulic valve for the use of markers (optional).

- 1 single-acting to power the hydraulic turbine.

-1freereturn(malein3⁄4)tothetractor'shydraulicoiltankforturbineoilreturn.

Whenusingatractorwithavariableowpumpandintegratedregulators(closedcircuit),thetractor'sregulatormust

be used to adjust the fan speed.

Theoilowraterequiredforaturbinespeedofapproximately4,500rpmis45l/min.

Clean the hydraulic connections before connecting.

Connect the hydraulic hoses that supply the folding system to a double-acting valve.

Connect the hydraulic hoses required to supply the markers to a double-acting control valve.

Connect the free return of the turbine (photo).

Connect the turbine supply to a single-acting valve.

4.3 Electrical connection

1. Plug in the road signal electrical socket.

2. Connect the power supply plug of the regulator (photo)

3. Connect the cigarette lighter socket to the power supply of the touch pad.

!Never operate the valve controlling the turbine without having correctly connected the free return,

otherwise the turbine motor may be damaged.

20

!Do not position yourself under the wing of the seed drill

when removing the pins

Starting up

5.1 Unfolding the seed drill

5.1.1 Boss

1. Remove the safety pins from the wings

2. Activate the corresponding hydraulic control valve until the wings are completely unfolded

!Before unfolding the wings, make sure that the seeding units are in the upper position

5.1.2 Big Boss

1. Manually unlock the wings by removing the locking pins on the main base brackets.

This manual suits for next models

3

Table of contents

Other Agrisem Seeder manuals

Popular Seeder manuals by other brands

Amazone

Amazone Centaya 3000 Special Original operating manual

Billy Goat

Billy Goat OS901SPS owner's manual

Meridian

Meridian 112BST Operator's manual

Maschio

Maschio Gaspardo SP Series Use and maintenance

GREAT PLAINS

GREAT PLAINS 2SNG24 Original instructions

GREAT PLAINS

GREAT PLAINS YP2425F-2470 Feature supplement manual