*****TIPS*****

Before beginning, it is best to evaluate the condition of the lawn by cutting one or more core samples from area to be treated. A core can

be cut using a piece of PVC, or metal pipe. Hammer the pipe into the ground, remove it, push the core out of the pipe and inspect it to

determine the depth of thatch in your yard.

MOW

Mow the lawn to its normal cut height. Be sure grass is dry. Wet conditions can cause increased damage to healthy grass.

INSPECT

Check the lawn before beginning work. Remove all rocks, wire, string, or other objects that can present a hazard during work.

IDENTIFY

Mark all fixed objects to be avoided during work, such as sprinkler heads, water valves, buried cables, or clothes line anchors, etc.

THATCH

Thatch is a dense layer of dead grass, clippings, and roots that builds up over time at the base of the lawn preventing air, water, and

fertilizer from reaching the soil. This can cause shallow root development and make a lawn more susceptible to drought and disease.

Thatch also provides an ideal environment for insects to hide and multiply. Periodic removal of thatch will keep your lawn in good health.

HEAVY THATCH

Lawns with an excessive amount of thatch will require multiple treatments for effective removal. Trying to remove excessive thatch

(greater than 3/4"[19 mm] deep) in one treatment will damage or destroy the living part of the lawn. It is best to remove heavy thatch in

seasonal treatments (i.e. spring, and fall).

SLOPES

Rake slopes across not up and down the slope. This is much easier and safer for the operator and is better for the lawn. Raking across

will help to reduce runoff during watering and allow the sloped ground to hold more seed, fertilizer, and water. The unit’s maximum

operating slope is 35% or 19°.

DEPTH

The wide range of depth adjustment on your unit is provided to allow for blade wear. Setting the reel deeper will not produce better results.

The flail reel is intended to be set so it just touches the surface on flat ground. The slicing reel should be set even with the ground for verti-

slicing work, and set to a maximum 1/2" depth for overseeding. Setting the reel deeper will only result in premature wear on the unit (i.e.

failed belt). If you desire to work the ground deeper than the above guidelines, it should be done gradually in multiple passes.

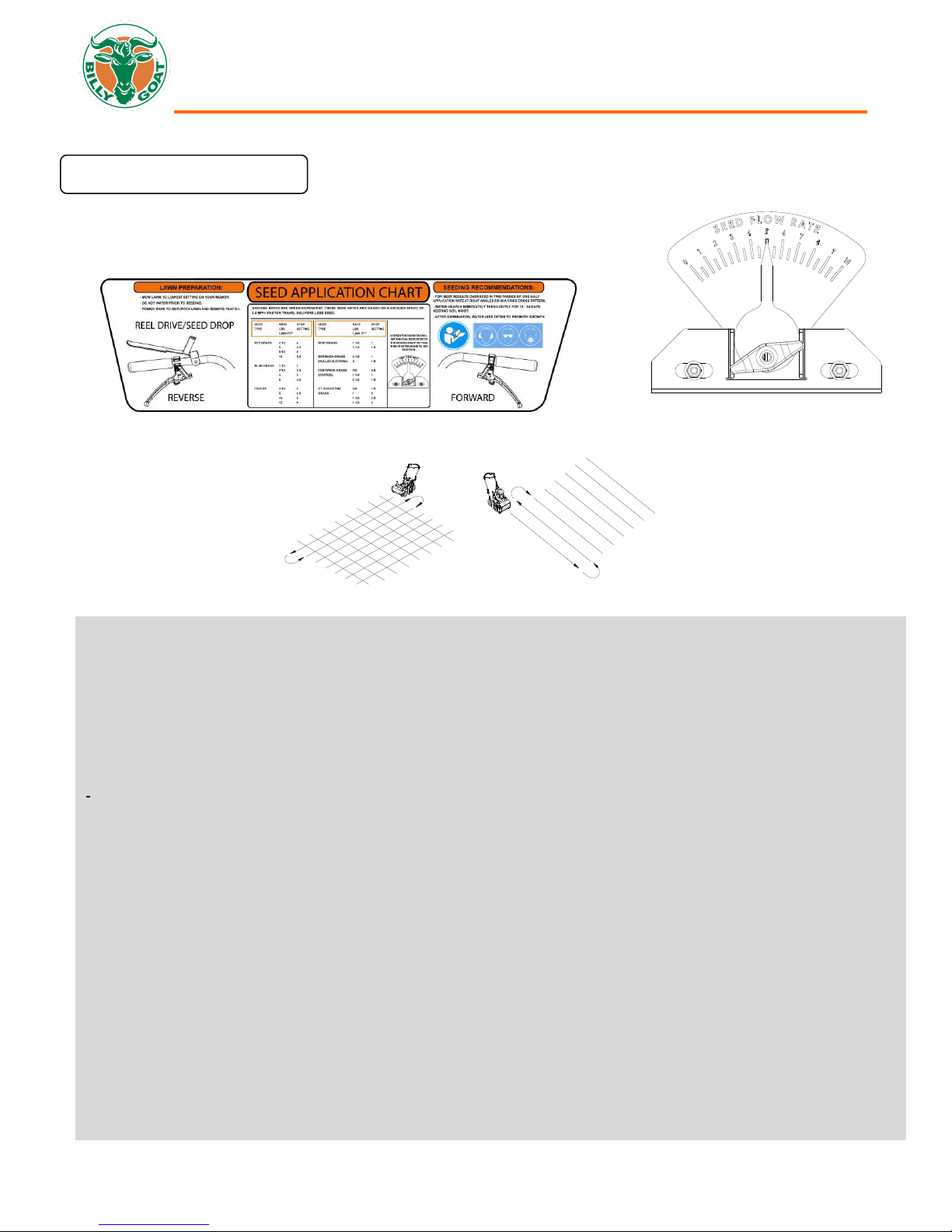

SLICING / OVERSEEDING: Mow the lawn to shorter than the normal cut height before starting (i.e. approximately 2" tall for fescue grass).

For the best result, slice/overseed in criss-cross pattern (See Fig. 5 & 6).