~ 3 ~

Frostguard - Operating & Maintenance Instructions –www.agrofrost.eu

1INTRODUCTION .......................................................................................................................................4

1.1 Intended conditions of use of the FrostGuard ..................................................................................................4

1.2 Improper use of the FrostGuard .......................................................................................................................4

1.3 Positioning the FrostGuard in the orchard, vineyard or field...........................................................................4

1.4 When to start? –When to stop? .......................................................................................................................4

2SAFETY........................................................................................................................................................5

2.1 Important: not to be used in closed areas .........................................................................................................5

2.2 Safety and health risks: residual risk................................................................................................................5

2.3 Safety precautions............................................................................................................................................6

2.4 Safety advice on maintenance, repairs and storage..........................................................................................6

2.5 Explanation pictograms....................................................................................................................................7

3TRANSPORT AND STORAGE.................................................................................................................8

3.1 Transport..........................................................................................................................................................8

3.2 Storage .............................................................................................................................................................8

4FIRST USE AND PREPARATION...........................................................................................................9

4.1 First use............................................................................................................................................................9

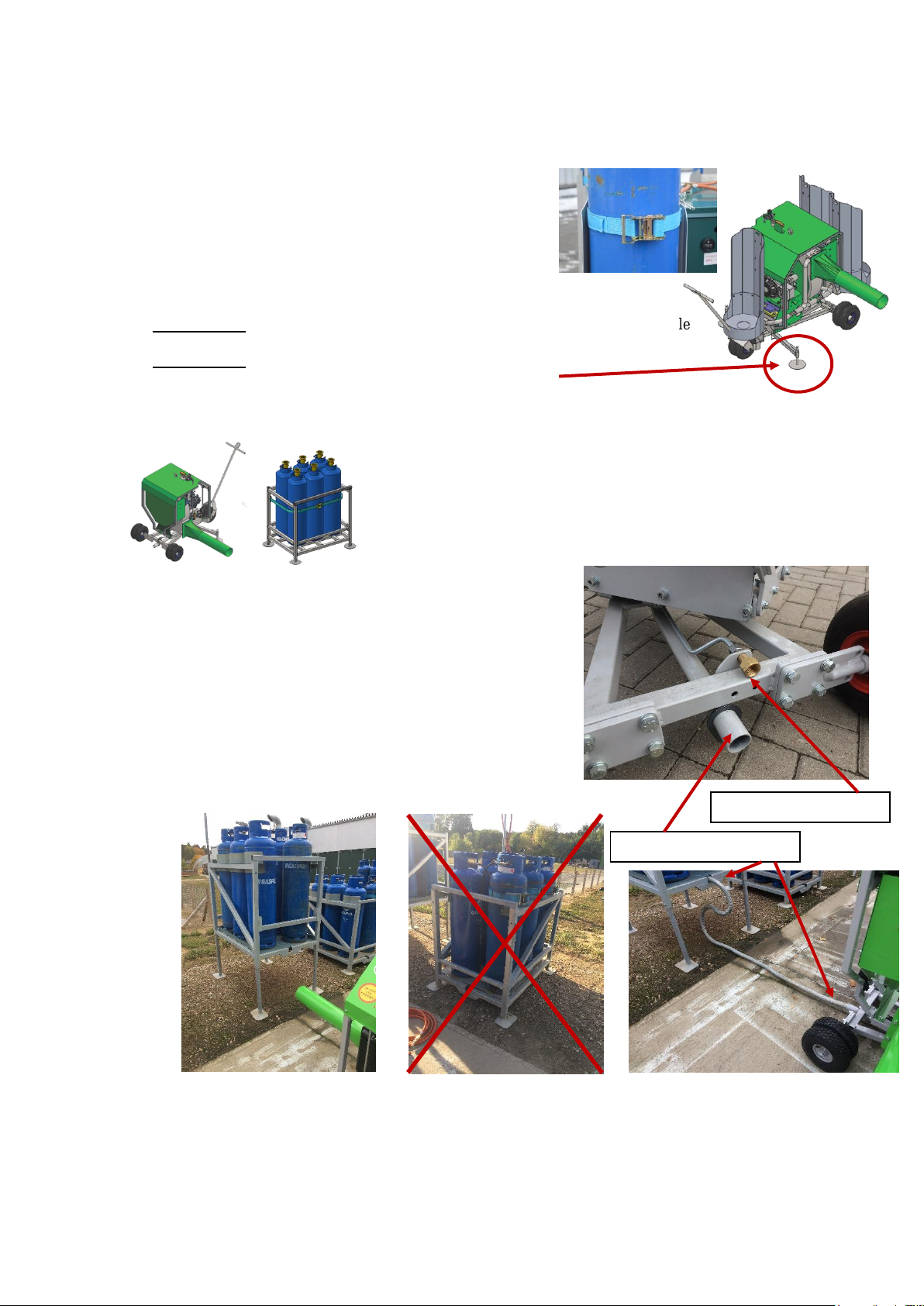

4.2 Set up the FrostGuard with 3 gas cylinder holders on the machine –B25 only.............................................10

4.3 Set up the FrostGuard with container for 5 or 6 gas cylinders –B20 only. ...................................................10

4.4 Set up the FrostGuard with support for 5 or 10 gas cylinders –B20 only. ....................................................11

4.5 Set up the FrostGuard with a gas tank of 300 kg, 500 kg or bigger. ..............................................................11

4.6 Setting the gas pressure..................................................................................................................................11

5OPERATING THE FROSTGUARD BASIC..........................................................................................12

5.1 The controls....................................................................................................................................................12

5.2 Start up and stop Procedure............................................................................................................................12

5.2.1 The Main Control Box..........................................................................................................................12

5.2.2 Starting Procedure. ...............................................................................................................................13

5.2.3 Stopping Procedure...............................................................................................................................14

5.3 During operation ............................................................................................................................................14

5.4 Replacing the gas cylinders during operation ................................................................................................14

6MAINTENANCE –CLEANING .............................................................................................................15

6.1 Cleaning.........................................................................................................................................................15

6.2 Maintenance...................................................................................................................................................15

6.2.1 Burner...................................................................................................................................................15

6.2.2 Engine...................................................................................................................................................15

6.3 Warranty –Scrapping –Spare parts list.........................................................................................................15

6.3.1 Warranty...............................................................................................................................................15

6.3.2 Scrapping..............................................................................................................................................15

6.3.3 Parts list ................................................................................................................................................15

7EC DECLARATION OF CONFORMITY .............................................................................................16