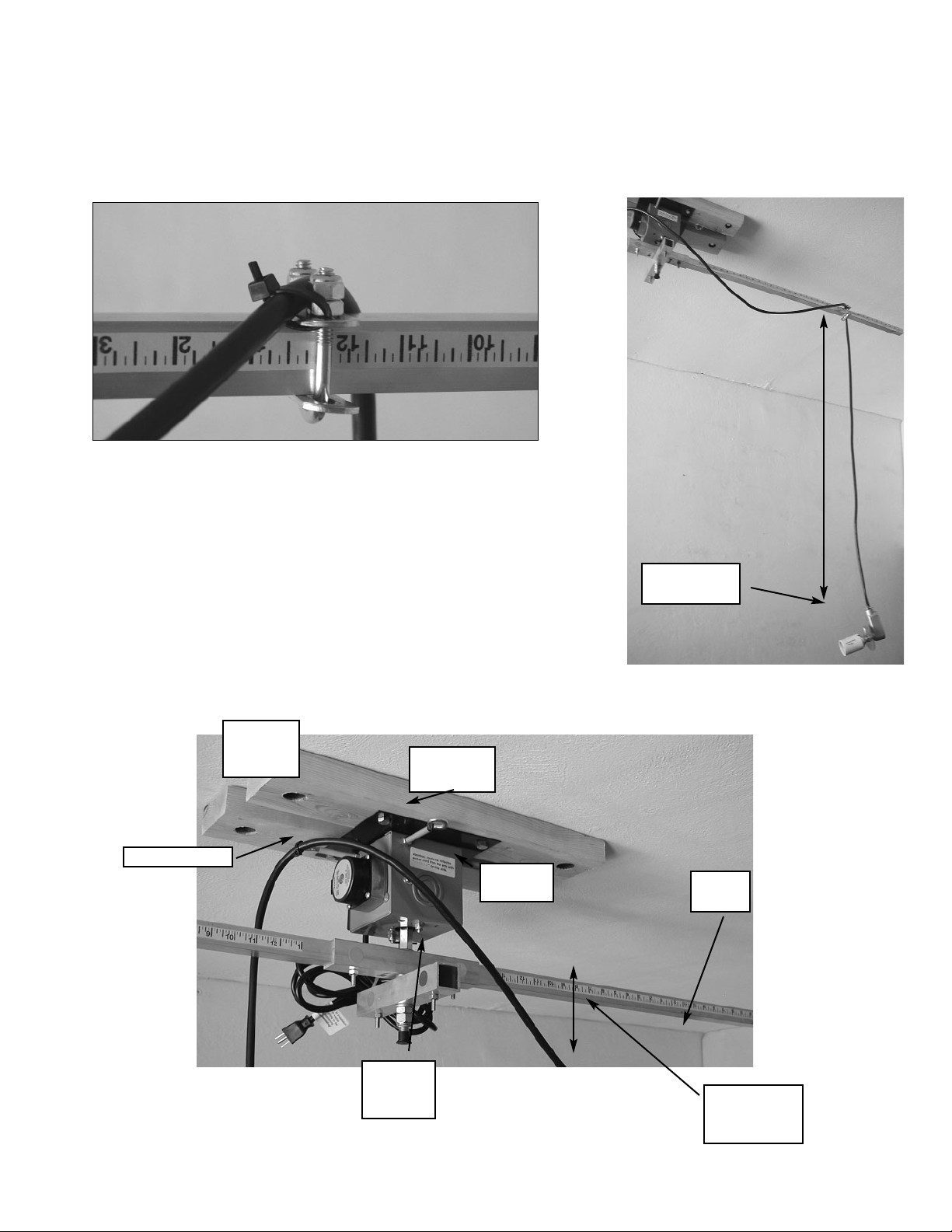

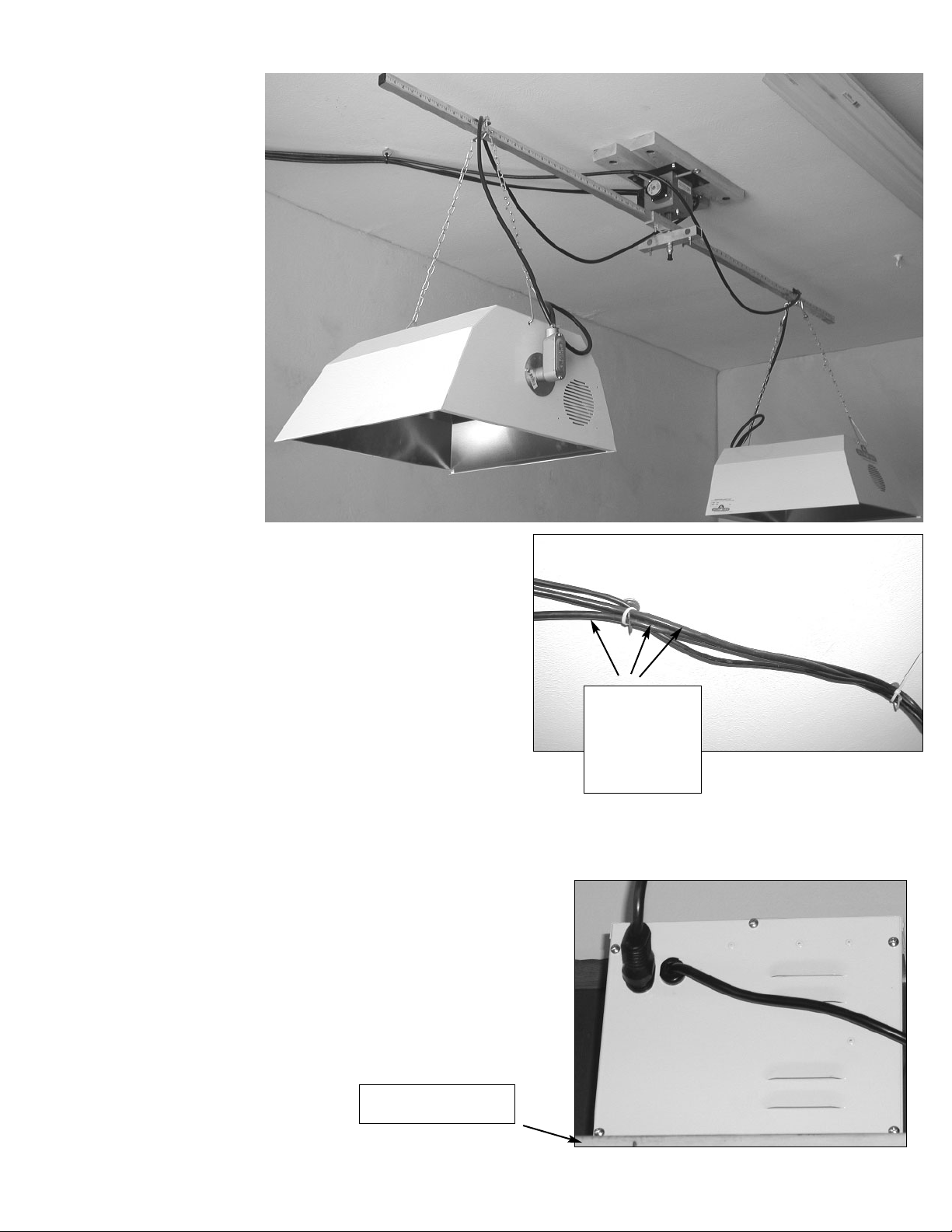

The photos on the previous page show the socket cord configuration for four reflectors.

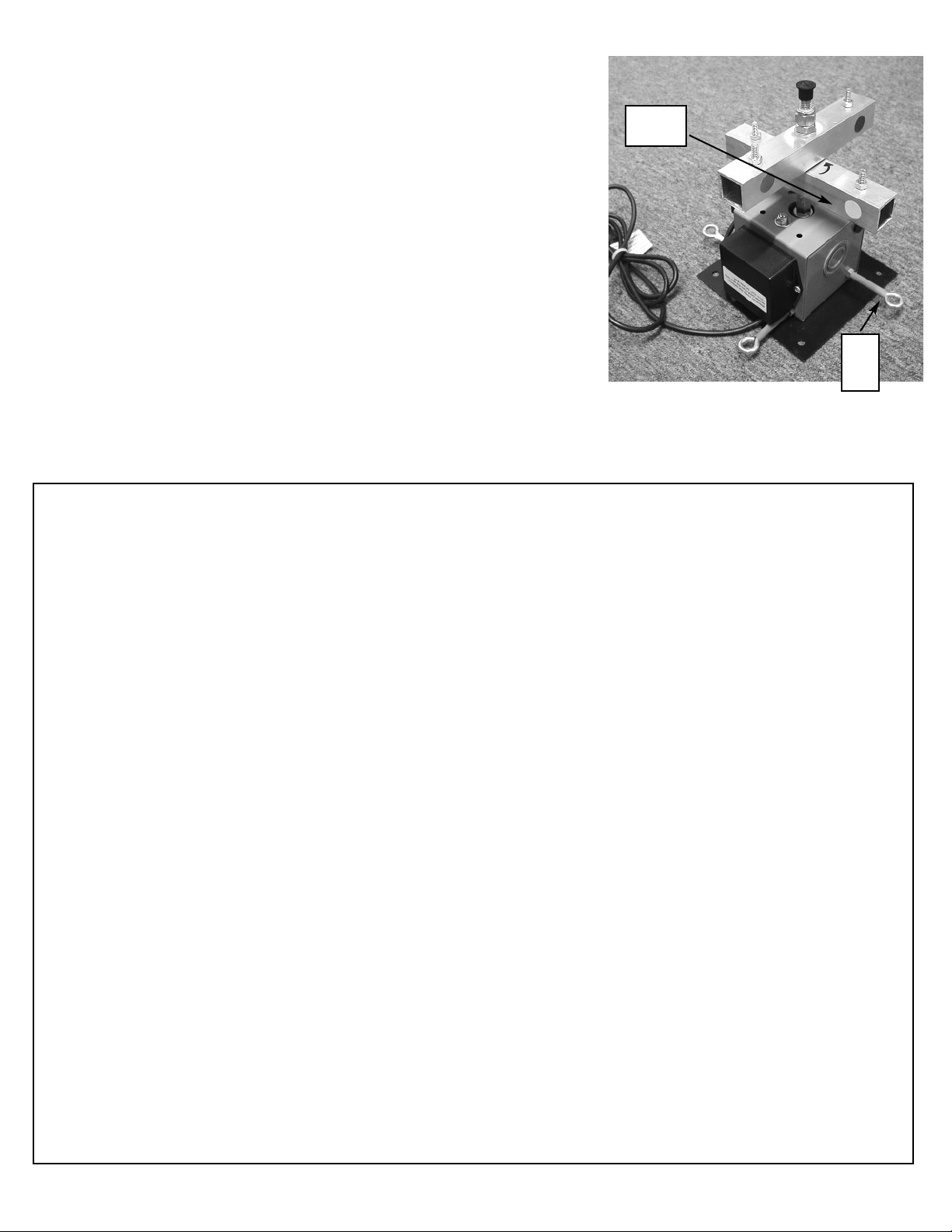

Two additional extender arms will slide into the lower center bar-the one with the blue and

green dots. The cord from the reflector on the side of the center bar with the blue dot ought

to attach to the U-bracket, go over the extender arm perpendicular while passing on the

side of the motor with the yellow eye bolt, and attach to the blue eye bolt. The cord from

the reflector on the side of the center bar with the green dot ought to attach to the U-brack-

et, go over the extender arm perpendicular while passing on the side of the motor with the

pink eye bolt, and attach to the green eye bolt. The same principle applies for each exten-

der arm. The cord comes up from the socket, attaches securely to the U-bracket assembly,

passes on the left of the motor, and attaches securely to the eyebolt opposite, leaving about

six inches hanging slack. Also, it is very important when using four extender arms that the

cord goes OVER the extender arm situated cross-wise to the original.

LIMITED WARRANTY

AHL inc. (company) warrants to the original purchaser that said product (Solar Revolution TM) will be free

rom defect in workmanship and materials for a period of two (2) years, one (1) year on all motors from the

date of purchase. If there is a perceived problem with the Solar Revolution, contact AHL inc. (505)-255-

3677 with a description of the problem. If necessary, AHL will issue a warranty return authorization num-

ber. Once received, AHL inc. will inspect the unit and repair or replace any defective part. AHL inc.

eserves the right to refuse warranty service if the unit has been opened, misused, damage or modified in

any way. If sending the unit, customer is responsible for initial postage, and AHL inc. will cover the postage

back within the continental United States. Under no circumstance will AHL inc. accept warranty work with-

out the return authorization number printed on the OUTSIDE of the box! If there is a failure, please contact

AHL inc. prior to sending.

Limitations:

mplied warranties, including those of fitness for a particular purpose and merchantability (an unwritten war-

anty that the product is fit for ordinary use), are limited to Two (2) years from the date of purchase on

workmanship and materials, one (1) year on the drive motor. We will not pay for loss of time, inconve-

nience, loss of use of your Solar Revolution TM or property damage caused by your Solar RevolutionTM or

ts failure to work, or any other incidental or consequential damages.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of

ncidental or consequential damages, so the above exclusion or limitations may not apply to you.

AHL

Albuquerque Hydroponics & Lighting

1051 San Mateo Blvd SE

Albuquerque,NM 87108

phone 505.255.3677

fax 505.255.7417