8

SKP 20

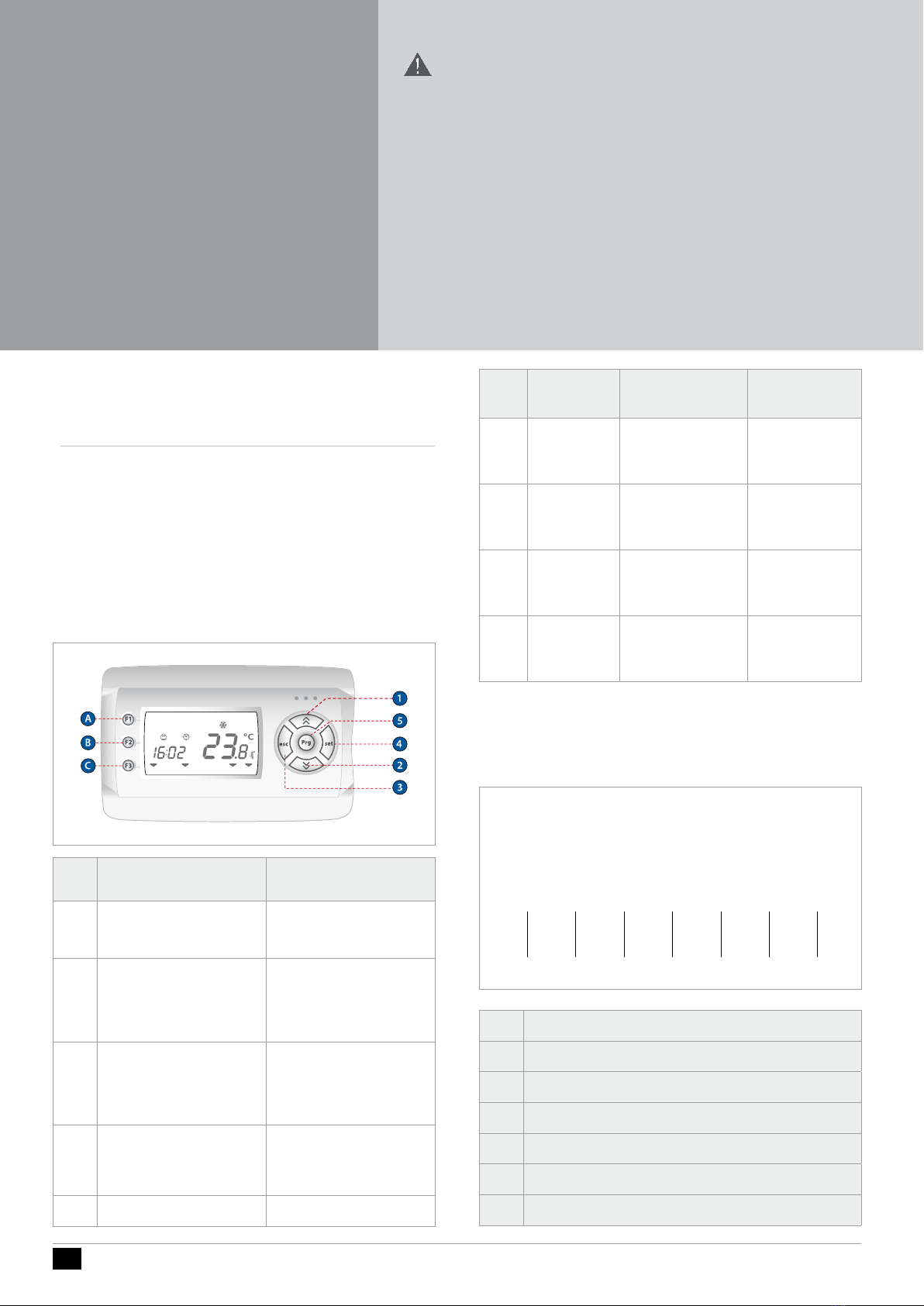

1.3.5 Alarm Display (AL)

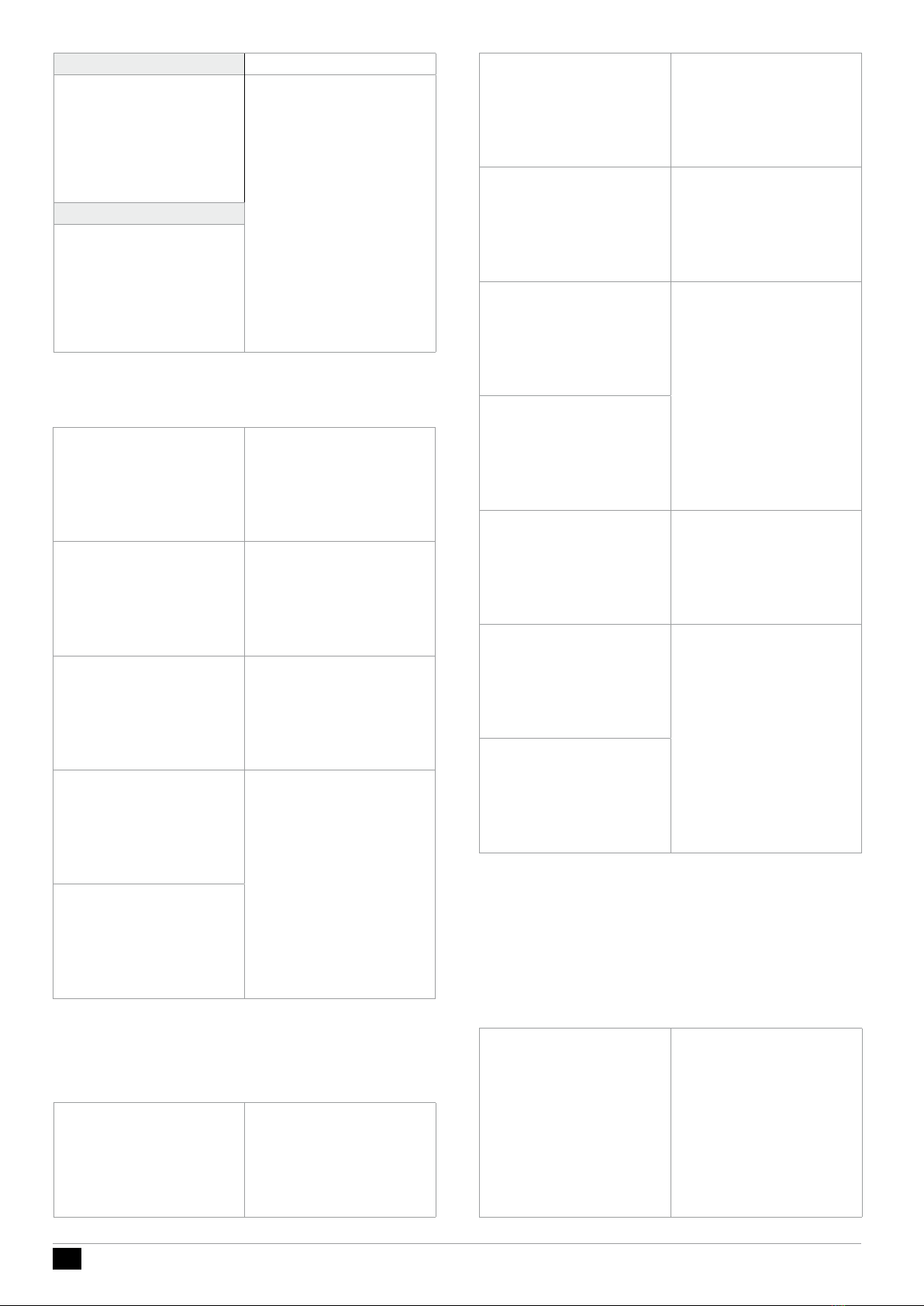

1.3.6 Example of how to set the setpoint (SP)

Forexample,wewillmodifythesetpointinCOOLmodefrom12.0degreescentigradeto12.5de-

grees centigrade.

Setpoint edit function enable from main screen

Parameter Ui25 allows you to enable Set Point modication on the main display with the UP and

DOWNkeys.Forexample,wewillmodifythesetpointinCOOLmodefrom12.0degreescentigrade

to 12.5 degrees centigrade.

Parameter UI25=1 (folder Par/Ui/UI25) must be set.

See Parameters section (folder PAr)

Press the set key from the main display.

Label Ai appears on the display.

UsetheUPandDOWNkeysto

browse the other labels until you nd

the AL label.

Press the set key to view the label of

the rst active alarm (if it exists).

Inthiscase,therstalarmisEr01.

Scroll using the“up”and“down”keys

to nd other active alarms.

-------------------------------------

N.B.: the menu is not cyclical.

Forexample,iftheactivealarmsare

ER01,Er02andEr03,thedisplaywillshow:

Er01 ->Er02->Er03 <-Er02<-Er01

NOTE:->UP,<-DOWN

Press the esc key to go back to the

main display.

Tochangethesetpointonyour

machine,startingfromthemain

display,pressthesetkey.

Let’ssaywewanttochangetheCOOLmode

setpoint.

ThedevicemustbeinCOOLmode

(or in StdBy mode from COOL).

TochangethesetpointoftheHEATmode,

proceed in the same way by rst changing the

device”smodefromCOOLtoHEAT

See Operating Mode Menu chapter.

Tochangethesetpointonyourmachine,press

theUPorDOWNkeyinthemaindisplay

Label Ai appears on the display.

UsetheUPandDOWNkeysto

scroll the other labels until you

nd the SP label

Press the set key to open the SP

menu.

TherstdisplaywillbeCOOL

mode,andthenscrollingwiththe

UPandDOWNkeys,theHEAT

mode (the various displays are

shown at the side).

Let’ssaywewanttochangethe

COOL mode setpoint.

Press the set key beside the COOL

label.

Thedevicewillshowthecurrent

setpointofthemachine,whichis

12.0 degrees centigrade in this case).

- - -

Toincreaseordecreasethis,press

the“up”and“down”keys. For

example,ifyouwanttochange

thesetpointto12.5degrees,press

the“up arrow”key until you reach

therequiredvalue.

- - -

Torepeattheprocedurein

reverse until you get back to the

maindisplay,presstheesckeyor

wait for the 15-second timeout to elapse.

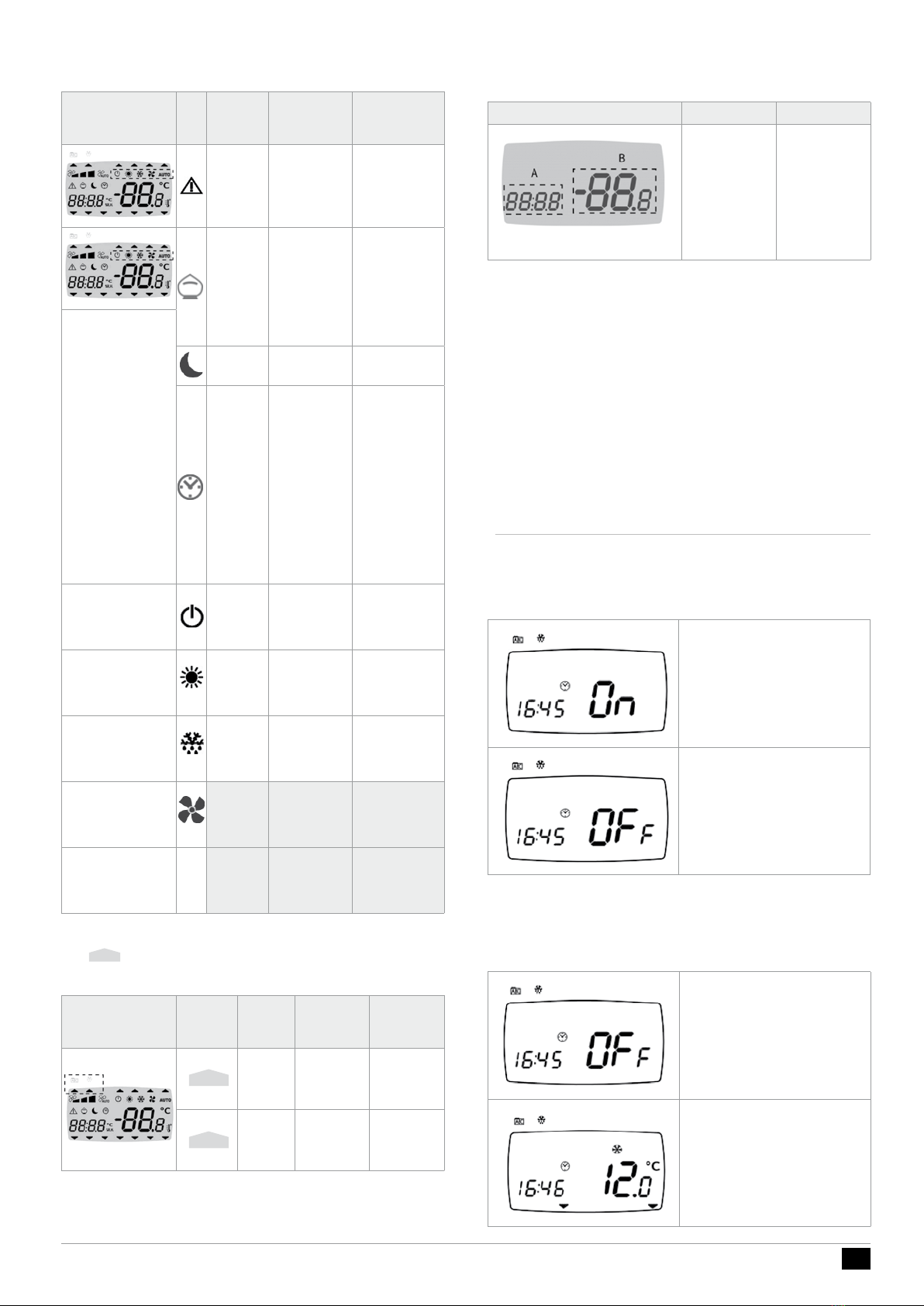

Change time/date/day menu

Note: Display A blinks.

Usethe“UP”and“DOWN”keys

toselectthetime,dateoryear.

Once you have decided what you

want to set (for example the

time),pressthesetkeyagainto

open the modication menu for

the variable selected.

- - -

Tosetthetime(thesame

procedure applies to the date

andyear),usethe“UP”and

“DOWN”keystoenterthe

requiredvalueandpressthe

- - -

Toexitthesettimemenu,press

the esc key until you are returned

to the main display.

Change time