MALUX GHG 791 02 User manual

Cooper Crouse-Hinds GmbH 77

77

7

Explosion protected terminal boxes GHG 791 01 and

GHG 791 02

1 Technical data

Terminal box GHG 791 01/GHG 721 02

Marking acc. to 94/9/EC and directice: II 2 G Ex e d m ia IIC T6

II 2 D Ex tD A21 IP 66 T80 °C

EC type examination certificate: PTB 00 ATEX 3108

Rated voltage: up to 690 V

Rated current: acc. to table an the inside of the enclosure cover

Perm. ambient temperature: -20° C up to +40° C (catalogue version)

Special versions permit deviating temperature ranges.

Perm. storage temperature in original packing: -40° C up to +80° C

Schutzart nach EN/IEC 60529: IP 66 (catalogue version)

Insulation class acc. to EN/IEC 61140: I - is complied with by the terminal boxes

II - with internal earth plate

Supply terminal: acc. to customers specification and as certificate

GHG 791 01 max. 4mm²

GHG 791 02 max. 6mm²

Cable entries: acc. to customers specification and as certificate

Test torques:

Cover screws 1.20 Nm

Cap nut of the M12 entry 1.65 Nm

Cap nut of the M16 entry 2.50 Nm

Cap nut of the M20 entry 2.50 Nm

Cap nut of the M25 entry 3.50 Nm

Cap nut of the M32 entry 5.00 Nm

Weight GHG 791 01:

empty weight approx. 0.25 kg

with internal earth plate approx. 0.30 kg

Weight GHG 791 02:

empty weight approx. 0.45 kg

with internal earth plate approx. 0.52 kg

Intrinsically safe circuits:

Max. safe voltage Um690 V eff

Safe galvanic isolation from all other circuits

and earth

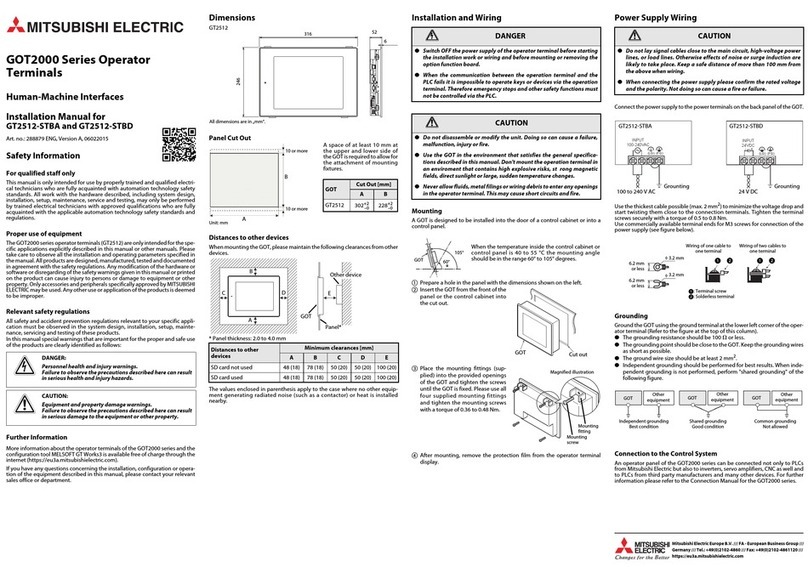

Terminal box GHG 791 02

Terminal box GHG 791 01 Terminal box GHG 791 02

Dimensions in mm

X = fixing dimensions

www.malux.se

Cooper Crouse-Hinds GmbH

88

88

8

2 Safety instructions

The terminal boxes GHG 791 are

not suitable for Zone 0 and Zone

20 hazardous areas.

The operations must be carried out by

electrical suitably trained in hazardous

areea with knowledge of increased safety

explosion protection.

The temperature class and explosion

group marked on the terminal boxes shall

be observed.

The requirements of the EN 61241-0 and -1

regarding excessive dust deposits and

temperature to be considered from the

user.

Modifications to the terminal boxes or

changes of their design are not

permitted.

They shall be used for their intended

purpose and in perfect and clean

condition.

For replacement and repair only genuine

COOPER CROUSE-HINDS spare parts

shall be used. Repairs that affect the

explosion protection, may only be carried

out by COOPER CROUSE-HINDS or a

qualified electrician in compliance with

the respective national regulations.

Prior to taking the terminal boxes into

operation, they shall be checked in

accordance with the instruction as per

section 6.

Before the initial operation, any foreign

matter shall be removed from the

terminal boxes.

Observe the national safety rules and

regulations for prevention of accidents as

well as the safety instructions included in

these operating instructions and set in

italics the same as this text!

Explosion protected terminal boxes GHG 791 01 and

GHG 791 02

3 Conformity with standards

The apparat is conform to the standards

specified in the EC-Declaration of conformity,

enclosed separately.

It has been designed, manufactured and

tested according to the state of the art and to

DIN EN ISO 9001.

94/9 EC: Equipment and protective systems

intended for use in potentially explosive at-

mospheres.

The apparats fulfil further requirements, such

as the EC directive on electromagnetic

compatibility (2004/108/EEC).

5 Use/Properties

The terminal boxes are intended for the

distribution of electrical energy e.g. light

circuits, heater circuits, control circuits,

intrinsically safe circuits etc. in hazardous

areas (see technical data). The temperature

class, explosion group and permissible

ambient temperature, see technical data.

The electrical limiting values that are

decisive for the intrinsic safety shall be

observed.

The terminal boxes can also be used in a

„normal industrial area“.

The data as per point 3 and 4 shall be

taken into account with the use.

Applications other than described are not

permitted without COOPER CROUSE-

HINDS’s prior written consent.

For the operation, the instructions stated

in section 7 of the operating instructions

shall be observed.

The user alone is responsible for the

appropriate use of this terminal box in

consideration of the basic conditions

existing at the plant (see technical data).

6 Installation

For the mounting and operation, the

respective national regulations (e. g. Betr.Si.V,

equipment safety law for Germany) as well as

the general rules of engineering shall be

observed.

4 Field of application

The terminal boxes GHG 791 01 and GHG

791 02 are suitable for use in Zone 1 and 2

as well as in Zones 21 and 22 hazardous

areas acc. to IEC 60 079-10 and

IEC 60 079-14!

The enclosure materials employed, including

the exterior metal parts, are made of high-

quality materials which ensure a corrosion

protection and resistance to chemical

substances corresponding to the

requirements in a “normal industrial

atmosphere”:

- impact resistant polyamide

- special steel AISI 316 L

In case of use in an extremely aggresive

atmosphere, please refer to manufacturer.

Terminal box GHG 791 01

Fig. 1

www.malux.se

Cooper Crouse-Hinds GmbH 99

99

9

Explosion protected terminal boxes GHG 791 01 and

GHG 791 02

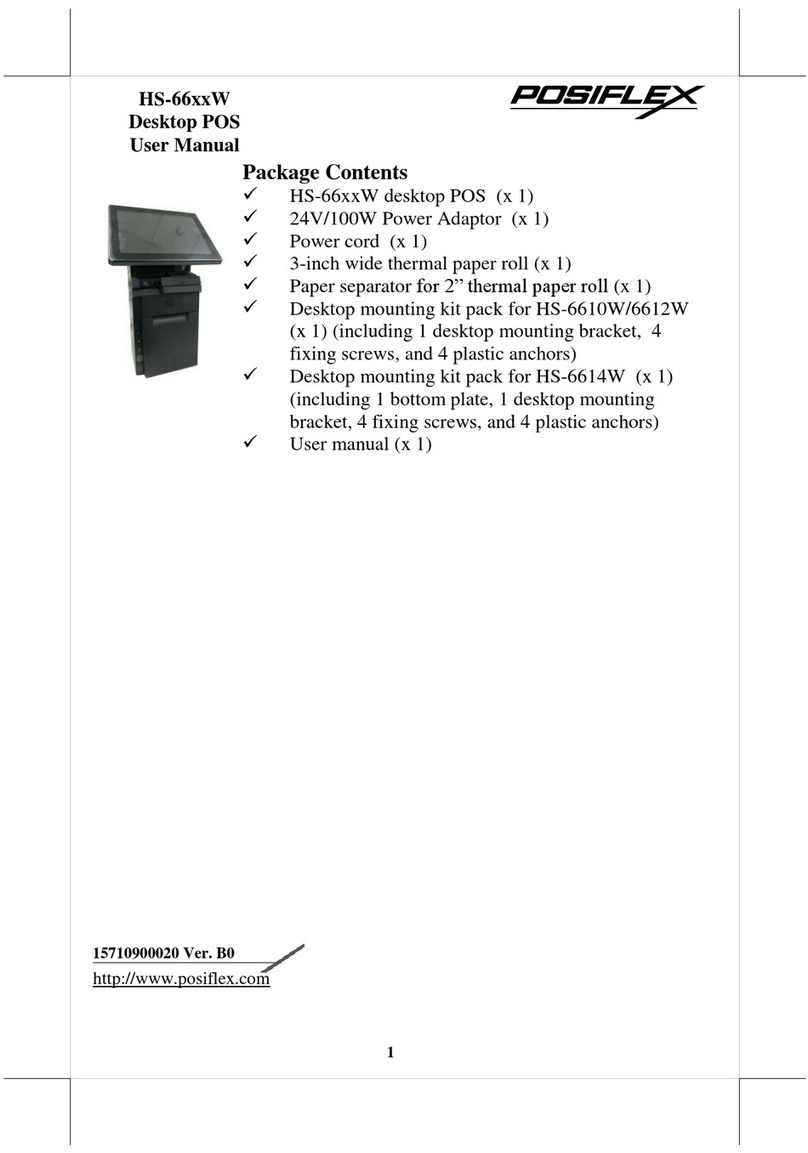

6.1 Mounting

The terminal boxes can be mounted without

opening their enclosure.

In case the terminal boxess are mounted

directly onto the wall, they may rest evenly

only at the respective fastening points. The

chosen screw shall match the fastening hole

(see dimensional drawing) and it must not

damage the hole (e. g. use of a washer).

The device shall be fastened diagonally with

at least 2 screws.

If the screws are overtightened, the

apparatus can be damaged.

The terminal boxes are suitable for fixing onto

COOPER CROUSE-HINDS apparatus holders

size 1+ 2 by means of self-cutting screws (see

fig. 2, fixing point "B").

The respective mounting instructions

shall be observed.

6.2 Opening the device/

Electrical connection

Before opening the apparatus, it is

necessary to ensure that there is no

voltage or to take suitable protective

measures.

The electrical connection of the device

may only be carried out by skilled staff ina

acc. to 60 079-14.

The insulation of the conductors shall

reach up to the terminal. The conductor

itself shall not be damaged.

The properly bared conductors of the cables

shall be connected, taking into account the

respective regulations.

The connectible min. and max. conductor

cross-sections will have to be observed (see

technical data).

All screws and/or nuts of the supply

terminals, also of those remaining unused,

shall be tightened down.

The conductors shall be connected with

special care in order to maintain the

explosion category.

The supply terminals are designed for the

connection of copper conductors. If multi- or

fine-wire connecting cables are used, the

wire ends will have to be handled in acc. with

the applicable national and international rules

(e. g. use of ferrules).

The table indicating the current load

values which is provided on the cover

inside of the terminal boxes is to be

observed.

B

for wall-

and

channel

fixing

for pipe

fixing

Size 1 apparatus holder for GHG 791 01

Fig. 2

Size 2 apparatus holder for GHG 791 02

B

for wall

and

channel

fixing

for pipe

fixing

6.3 Cable entries (KLE);

blanking plugs

Generally, only certified cable entries and

blanking plugs may be used.

Flexible cables are to be used with

trumpet-shaped cable glands or other

suitable entries with additional pull-relief.

The mounting directives applicable to the

fitted cable entries are to be observed.

When using cable entries with a lower IP

protection than that which applies to the

device (see technical data, page 9 + 10),

the IP protection of the whole device will

be reduced.

In order to establish the minimum protection

category, unused holes have to be closed

with a certified blanking plug.

Care has to be taken that when fitting the

cable entries, sealing inserts appropriate to

the cable diameter are used.

In case of sealing inserts that are cut out, it

will have to be ensured that the insert is

properly adapted to the cable diameter.

When using cable entries for fixed cables it is

necessary to ensure that no inadmissible

high mechanical stress is applied to the cable

entry or its seal.

Intrinsically safe circuits shall be fed through

cable entries that are colour-coded (light

blue).

All vacant metric COOPER CROUSE-HINDS

cable entries are to be closed with the

certified blanking plug for metric cable entries

(see page 8, fig. 1).

In case of mixed equipment Ex e / Ex-i, the

required minimum distances will have to be

kept (see e.g. EN 60079-11).

When apparatus is open, it is necessary to

ensure (disconnect voltage supply) that

no voltage is carried over into the

connected intrinsically safe circuits.

The installation instructions for intrinsically

safe electrical apparatus shall be observed.

It is necessary to ensure that the permissible

external capacitance and inductance of the

special intrinsically safe circuits are not

exceeded.

www.malux.se

Cooper Crouse-Hinds GmbH

1010

1010

10

6.6 Taking into operation

Prior to taking the apparatus into operation,

the tests specified in the relevant national

regulations will have to be carried out.

Apart from that, the correct functioning and

installation of the apparatus in accordance

with these operating instructions and other

applicable regulations will have to be

checked.

Incorrect installation and use of the

terminal boxes can invalidate the

guarantee.

Explosion protected terminal boxes GHG 791 01 and

GHG 791 02

8 Repairs / Overhaul /

Modification

Repairs may only be carried out with genuine

COOPER CROUSE-HINDS spare parts.

Repairs that affect the explosion

protection, may only be carried out by

COOPER CROUSE-HINDS or a qualified

electrician in compliance with the

applicable national rules (EN 60079-19).

Modifications to the apparatus or changes of

its design are not permitted, except for the

mounting of additional cable entries and the

installation of supply terminals in accordance

with the approval of the apparatus.

9 Disposal / Recycling

When the apparatus is disposed of, the

respective national regulations on waste

disposal will have to be observed.

In order to facilitate the recycling of individual

components, plastic parts have been

provided with the identification mark of the

plastic material used.

Subject to modifications or supplement of the

product range.

7 Maintenance/Servicing

The relevant national regulations which

apply to the maintenance/servicing of

electrical apparatus in explosive

atmospheres, shall be observed

(EN 60079-17).

Before opening the enclosure make sure

that the apparatus is disconnected from

the voltage, or take the appropriate

protective measures.

In case of intrinsically safe circuits, working is

permitted while voltage applies.

The required maintenance intervals depend

on the respective application and will

therefore have to be determined by the user

dependent on the conditions of use.

Cleaning:

Because of the risk of an electrostatic

charge, the junction boxes shall only be

cleaned with a damp, non fibrous cloth or

sponge!

When servicing the apparatus, particularly

those parts that are decisive for the type of

protection against explosion, will have to be

checked (e. g. intactness of enclosure, cable

glands, efficacy of the cover gaskets).

If during servicing repairs prove to be

necessary, section 8 of these operating

instructions will have to be observed.

6.5 Closing the device/

cover closure

Any foreign matter shall be removed from

the apparatus.

In order to ensure the required minimum

protection category, the cover screws are to

be tightened down.

Overtightening might impair the

protection category.

In order to ensure the required minimum

protection category, the cable glands shall be

tightened down.

Overtightening might impair the

protection category.

Attention: The metal frame and metal

glands are to be integrated into the

potential equalization.

www.malux.se

This manual suits for next models

1

Popular Touch Terminal manuals by other brands

Sharp

Sharp UP-600D Operation manual supplement

Castles Technology

Castles Technology SATURN1000 S1F2 MOB user manual

AURES

AURES NINO II user manual

amber connect

amber connect Amber Govern T400-la quick start guide

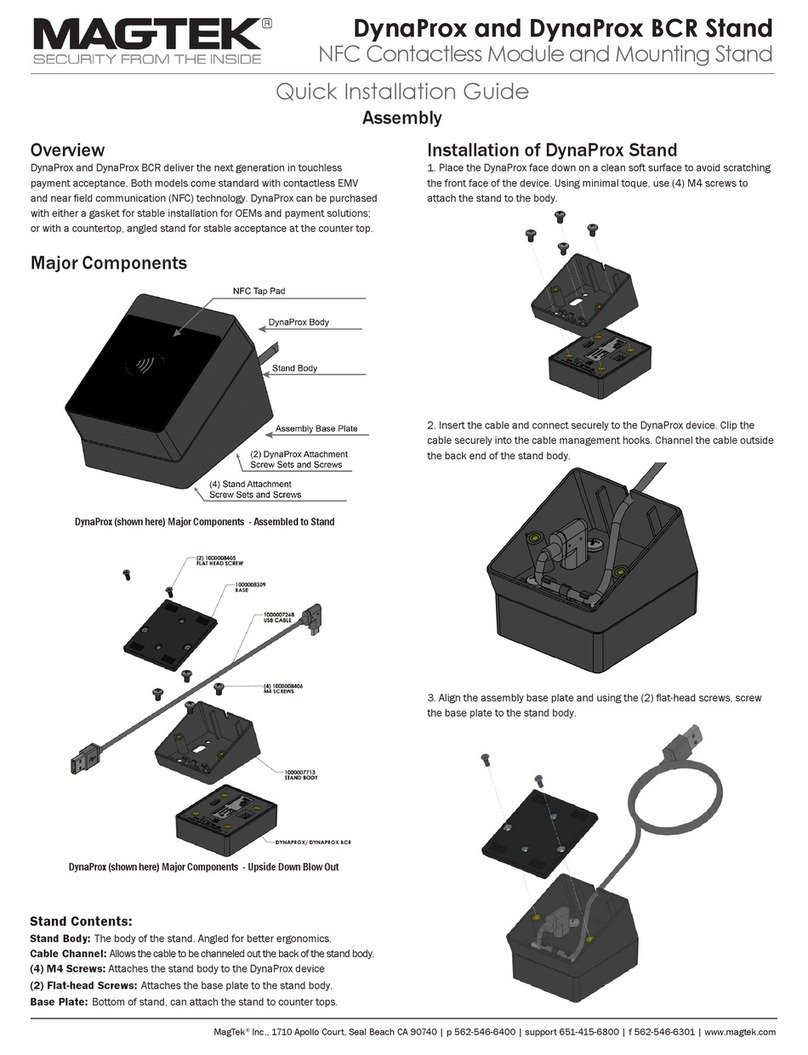

Magtek

Magtek DynaProx Quick installation guide

Allen-Bradley

Allen-Bradley PanelView 1200 user manual

Equinox Systems

Equinox Systems T4220 Quick reference guide

National Instruments

National Instruments TBX-2809 installation instructions

Acrel

Acrel ARTU Installation & operation instructions

Novatel

Novatel MT 1200 user guide

RedPort

RedPort Aurora Iridium Installation and setup guide

ToKViA

ToKViA T102 Quick reference manual