(Vers. 05.02.2023)

Page 3 of 38

TrackBoss T28 Air Curtain Burner (HATZ 3H50TIC Diesel Engine)

OPERATING MANUAL

All of this is carefully engineered to provide the correct amount of air at the correct

velocity. It is sometimes thought that more air flow will actually increase the burn

rate. This is INCORRECT. Modifying the air flow will actually have the opposite

effect and reduce the machine’s throughput. Additionally, it will reduce the ma-

chine’s ability to meet air quality minimum standards. There is a maximum rate at

which wood can burn. Trying to exceed that rate by adding more air to an air cur-

tain burner causes two major problems:

1. It will cool the fire reducing combustion efficiency creating more smoke (carbon

dioxide and nitrogen enriched). This will begin a circular effect of further reduc-

ing the oxygen and further reducing combustion efficiency. The result is that

your throughput drops and smoke increases.

2. Increasing the air flow beyond design standards will over pressurize the firebox

causing significantly more particles (embers) to be ejected from the firebox.

Besides violating the EPA limits for PM (particulate matter) the larger hotter

embers ejected will pose a much greater fire hazard.

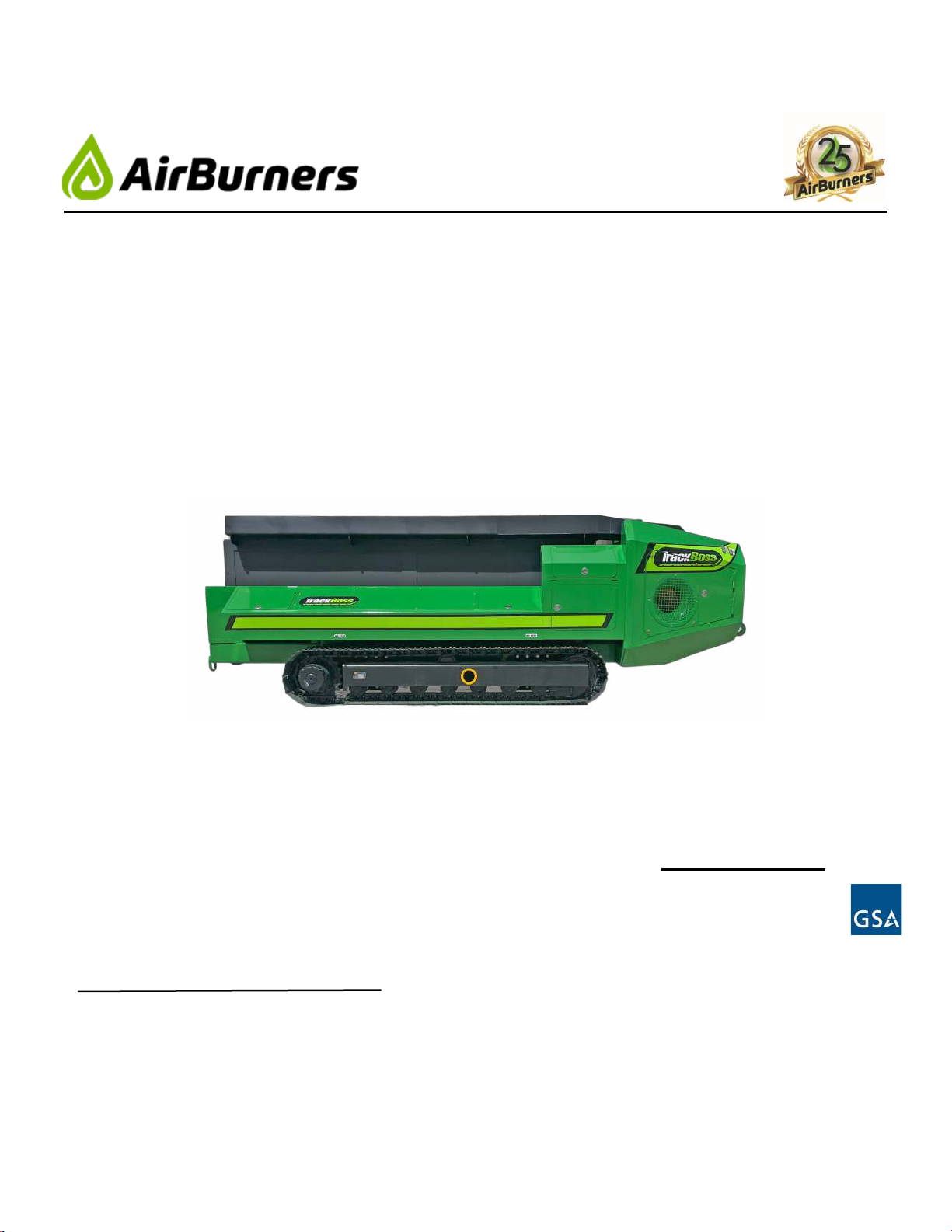

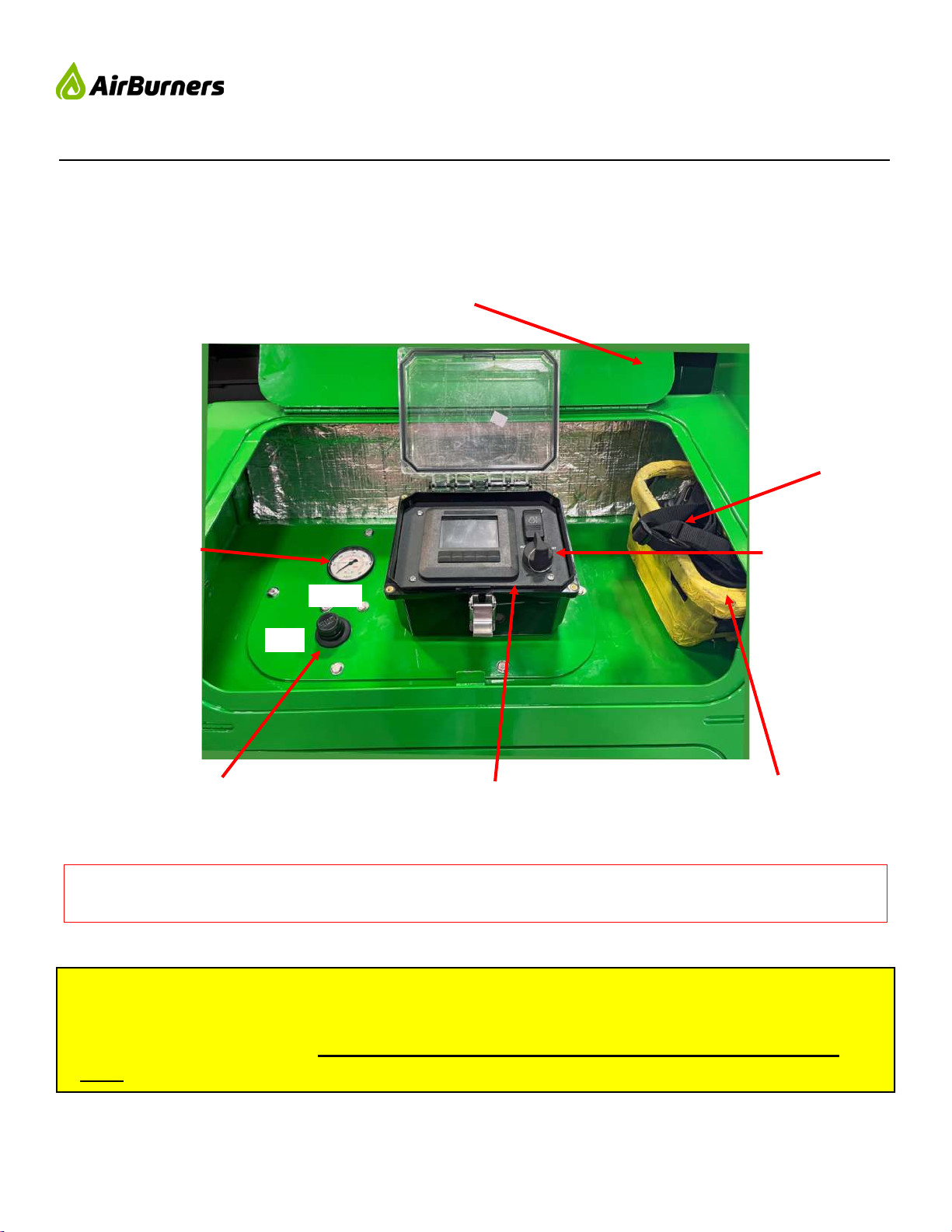

GENERAL DESCRIPTION OF TrackBoss

The TrackBoss is a proven design that adds self-propelled mobility at the workplace to the Air Burn-

ers FireBox line of above ground air curtain burners. When delivered to a job site, the machine is

ready for use as soon as it is off-loaded. The FireBox system is built on a patented frame that allows

the firebox to be raised and lowered for easy movement over the ground. The forward equipment

deck under the cowling supports a three cylinder Diesel engine, controls, the battery and the hy-

draulically-driven air fan. A 30 gallon fuel tank is mounted in a compartment above the tracks on the

manifold side. The tracks are controlled remotely by a portable remote control console. When

viewed from the front of the unit, the patented air disbursement manifold is mounted on the left top

side of the firebox.

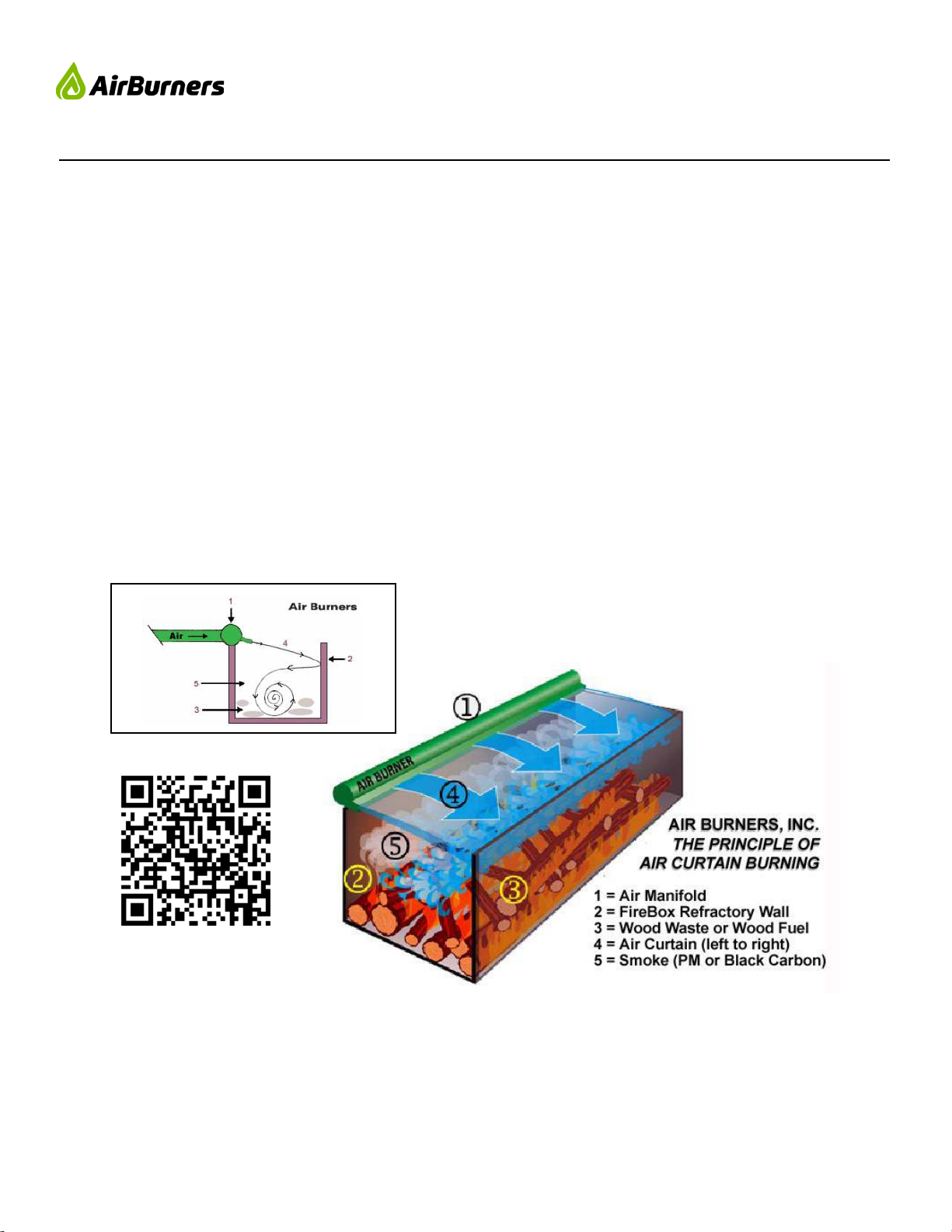

The Diesel engine powers a hydraulic pump that serves the air fan, firebox lift system and the

tracks. The high velocity air is sent down the manifold through the vanes and directed to the outlet

nozzles. A balanced and distributed air flow is directed across the top of the firebox and then reflect-

ed down into the combustion zone.

The curtain of air acts as a top over the firebox, trapping a large percentage of the escaping particu-

late matter (smoke) and causing it to burn down even further under the curtain before finally escap-

ing through the curtain as a hot gas. The air from the nozzles travels across the firebox creating the

air curtain effect, then it reflects off the far side thermo-ceramic wall adding oxygen to the combus-

tion zone helping to generate a hotter more complete fire. This additional agitation helps prevent the

fire from starving for oxygen as the ash builds up during burning operations.