Motor Type

Models: CVF-8EXP and SVF-10EXP

115 VAC, 60 Hz, 1/3 HP, 2.2 amps, .25 kw, Temp. Code T-4

Class I & II, Group C,D,E,F,G

Motor Type

Model: CVF-12EXP

115 VAC, 60 Hz, 1.5 HP, 9.6 amps, 1.1 kw, Temp. Code T-4

Class I & II, Group C,D,E,F,G

Outlet Size

Models: CVF-8EXP and SVF-10EXP

8” Diameter (203 mm)

(SVF-10EXP will accommodate 8” duct as well as 10” duct)

Outlet Size

Model: CVF-12EXP 12” Diameter (305 mm)

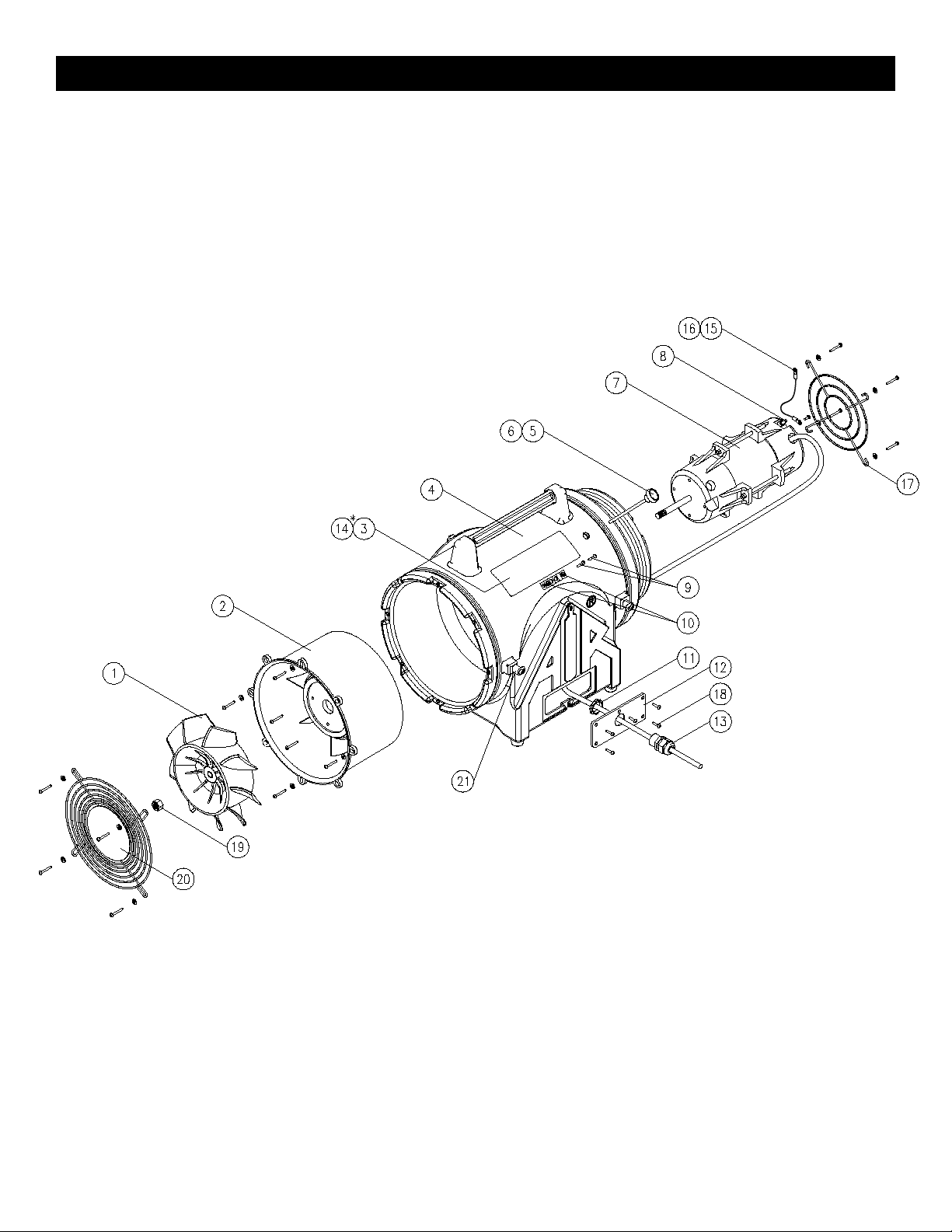

CVF-8EXP

Flow Rates

Free Air: 987 CFM (1677 cm/hr)

15 ft. of duct with one 90° bend: 730 CFM (1246 cm/hr)

15 ft. of duct with (2) 90° bends: 648 CFM (1101 cm/hr)

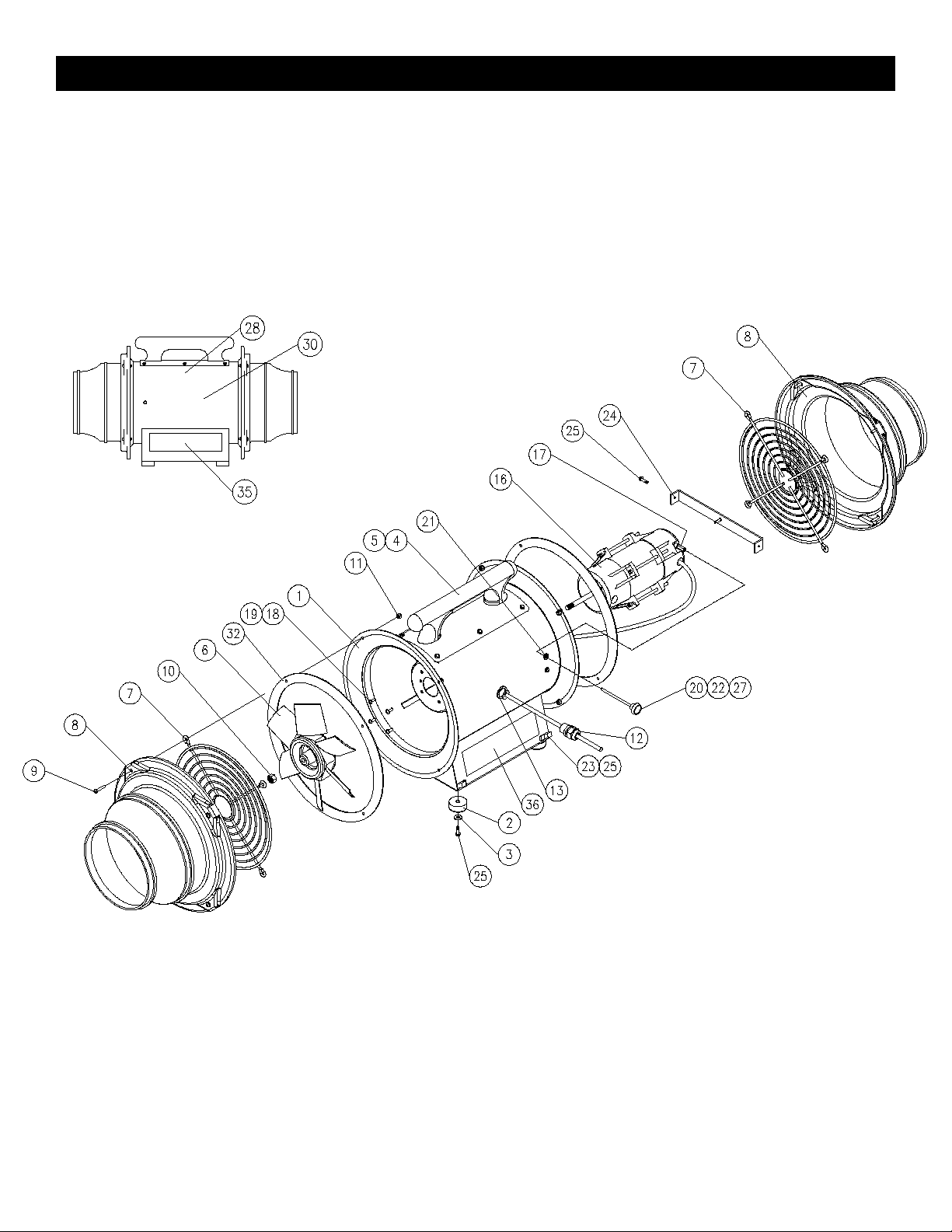

SVF-10EXP

Flow Rates

Free Air: 1390 CFM (2362 cm/hr)

15 ft. of duct with one 90° bend: 870 CFM (1478 cm/hr)

15 ft. of duct with two 90° bends 858 CFM (1458 cm/hr)

CVF-12EXP

Free Air: 2400 CFM (4078 cm/hr)

15 ft. of duct with one 90° bend: 2334 CFM (3967 cm/hr)

15 ft. of duct with two 90° bends 1598 CFM (2715 cm/hr)

4

-Approved for outdoor use.

-Thermally protected.

-Use only a plug certied and/or listed as explosion-proof for both Canada and the U.S., type suitable for the area of clas–

sication that it is used in.

-Caution! To reduce the risk of electric shock, connect only to an outlet provided with a ground fault interrupting device.

Important - Please Read!

Specications

All ventilation procedures should comply with federal, state, and local regulations. Air quality should be tested prior to

ventilating a con ned space. A purge chart is provided on our website, www.airsystems.com, help assist in estimating the

approximate time needed to ventilate con ned spaces. Air quality should be tested continuously during con ned space

occupancy to ensure a stable atmosphere and worker safety because atmospheric conditions can change rapidly. Addi-

tional procedures and recommendations are available from federal, state, and local agencies. DO NOT operate these fan

unit in a vertical position or with the ange or guards removed.

SAFETY PRECAUTIONS

READ AND FOLLOW ALL INSTRUCTIONS BELOW

WARNING

Fan and blower models with the “EX” or “X” designation are the

only models approved for use in hazardous locations. These

models are NOT approved for use in mines.