9

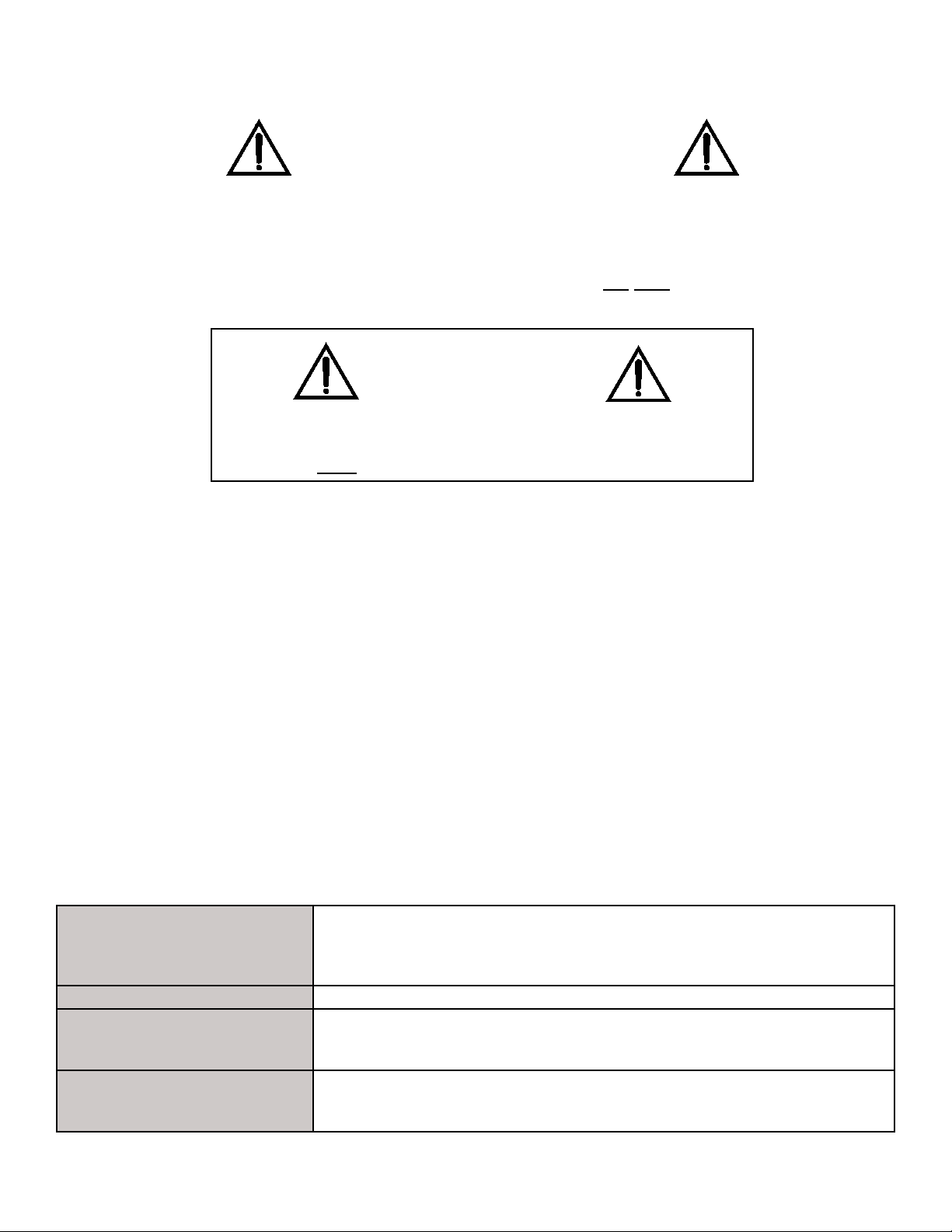

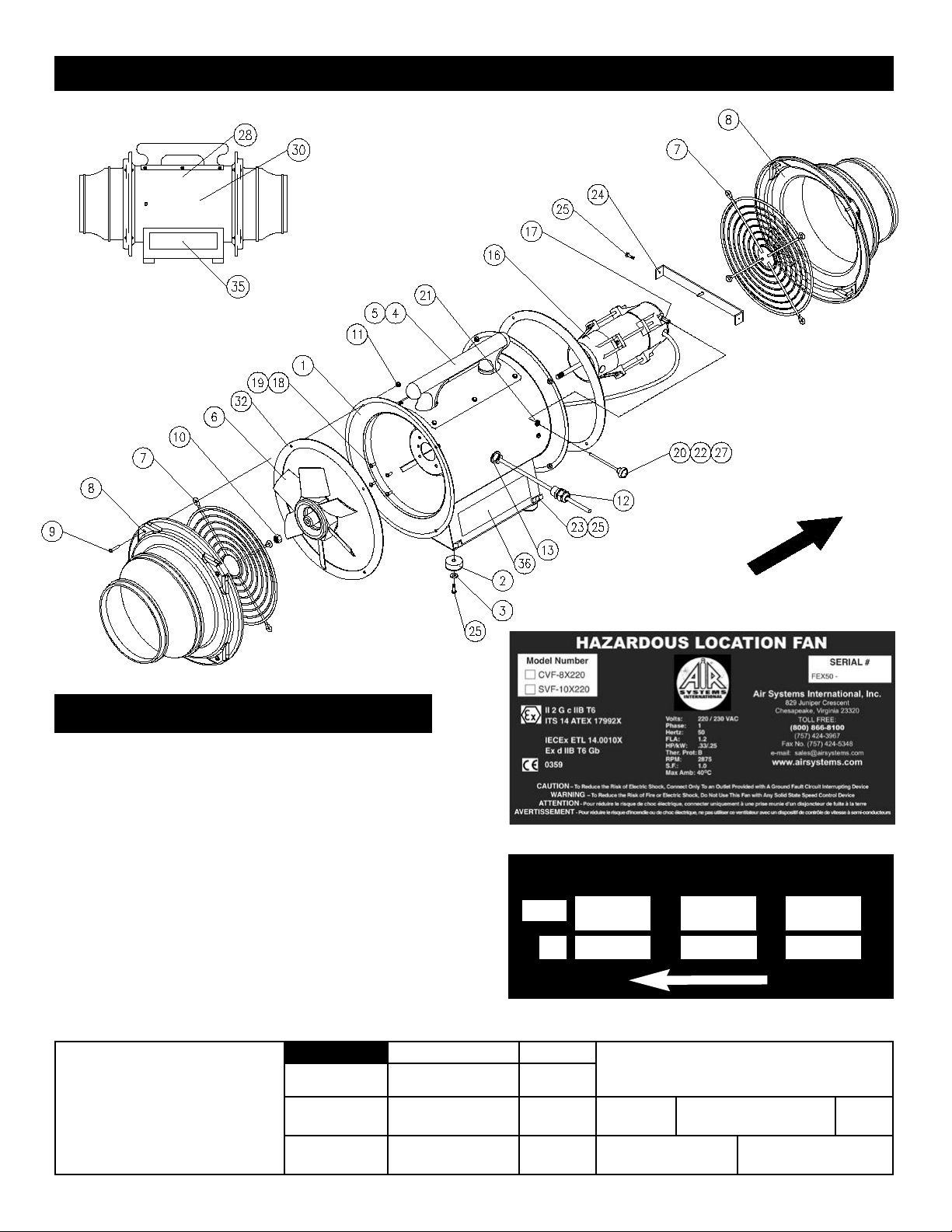

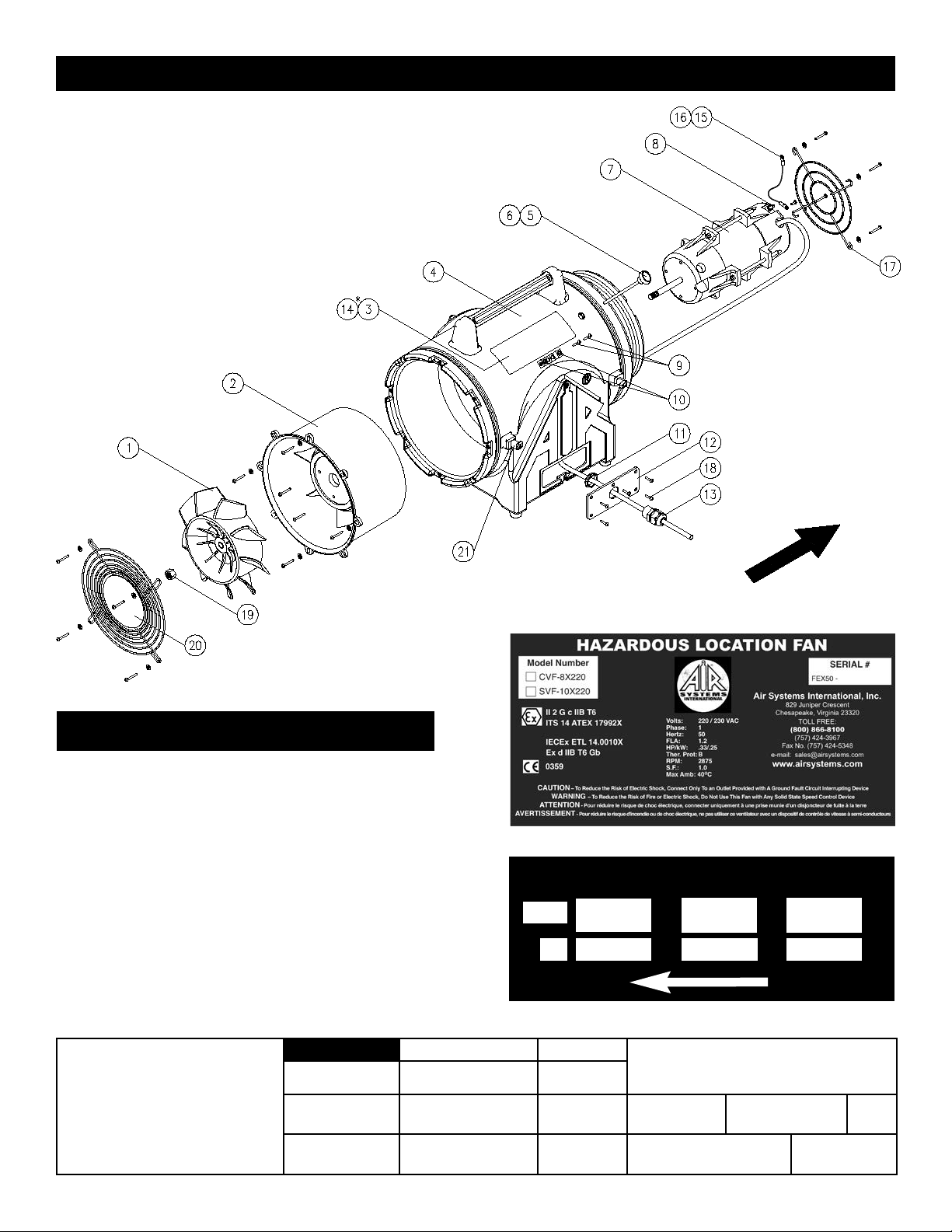

System Components: Model SVF-10X220

SEQ. # ITEM # DESCRIPTION BOM QUANTITY

1 MILF-10BR 10” STEEL BASE - RED, AXALTA, P/N RED RIVER HP II 1

2 HDWR026 RUBBER FEET FOR SVF FANS - 70 DURO SBR 4

3 FW3/16 3/16 USS FLAT WASHER ZINC COATED STEEL 4

4 FS10X050W 10-24 X 1/2 HEX WASHER, ZINC COAT STEEL 6

5 SVF-10HNDL HANDLE, BLACK, LLDPE, EXXON P/N LL8555 1

6 SVF-FAN AXIAL FAN, REINFORCED FIBER, WINGFAN P/N PACAS 1

7 MGDAXFAN1 FINGER GUARD, ZINC COATED STEEL 2

8 SVF-108ADP 10” TO 8” SHROUD, BLACK, LLDPE, EXXON P/N LL8555 2

9 FS1032X78T 10-32 X 7/8 TRUSS,PHILLIPS, ZINC COATED 8

10 FNM8X1ESN M8 X 1.0 ELASTIC STOP NUT, ZINC COATED 1

11 FN1032ESN 10-32 ELASTIC STOP NUT ZINC COATED 8

12 ELA001 CABLE GLAND, 5-12mm, ALTECH P/N 5308921 1

13 ELA007 1/2 CONDUIT LOCK NUT, ZINC COATED STEEL 1

16 MTR043EX22 ATEX APPROVED MOTOR,220-230 VAC,50 HZ 1

17 HDWR068 COUPLING NUT 10-24 X 3/4 LONG,GRADE 2 1

18 FS1032X050 10-32 X .5, ROUND PHILLIPS HEAD, ZINC 4

19 FW10LOCK #10 LOCKWASHER ZINC COATED 4

20 FS10X350TS 10-24 X 3-1/2 FULLY THREADED STEEL STUD 1

21 HDWR027 GROMMET FOR SV FANS-60 DURAMETER, SBR 1

22 HDWR070 BLACK ABS KNOB WITH 10-24 THREADS, SVF 1

23 ELA051 ALUMINUM GROUNDING LUG, 6-14 AWG (6.35mm MAX) 2

24 MBSVF10EXP STABILIZER BRACKET FOR SVF-10EX SERIES, STEEL 1

25 FS10X075W 10-24 X 3/4 HEX WASHER, ZINC COATED 6

27 ELA039 1/4” DIAMETER SHRINK TUBING, PVC 0.25

28 DECAL045 MOTOR ROTATION DECAL, PERMANENT OUTDOOR 2

30 DECAL043 AIR SYSTEMS WORLD LOGO DECAL - 4” DIA. 1

32 ILF-G GASKET, ROUND, 8 HOLES, FOR SVF FANS, SBR 2

35 DECAL168 SERIAL NO. DECAL,CVF-8X220,SVF-10X220 1

36 DECAL169 PERF. SPEC. DECAL, CVF-8X220, SVF-10X220 1