4

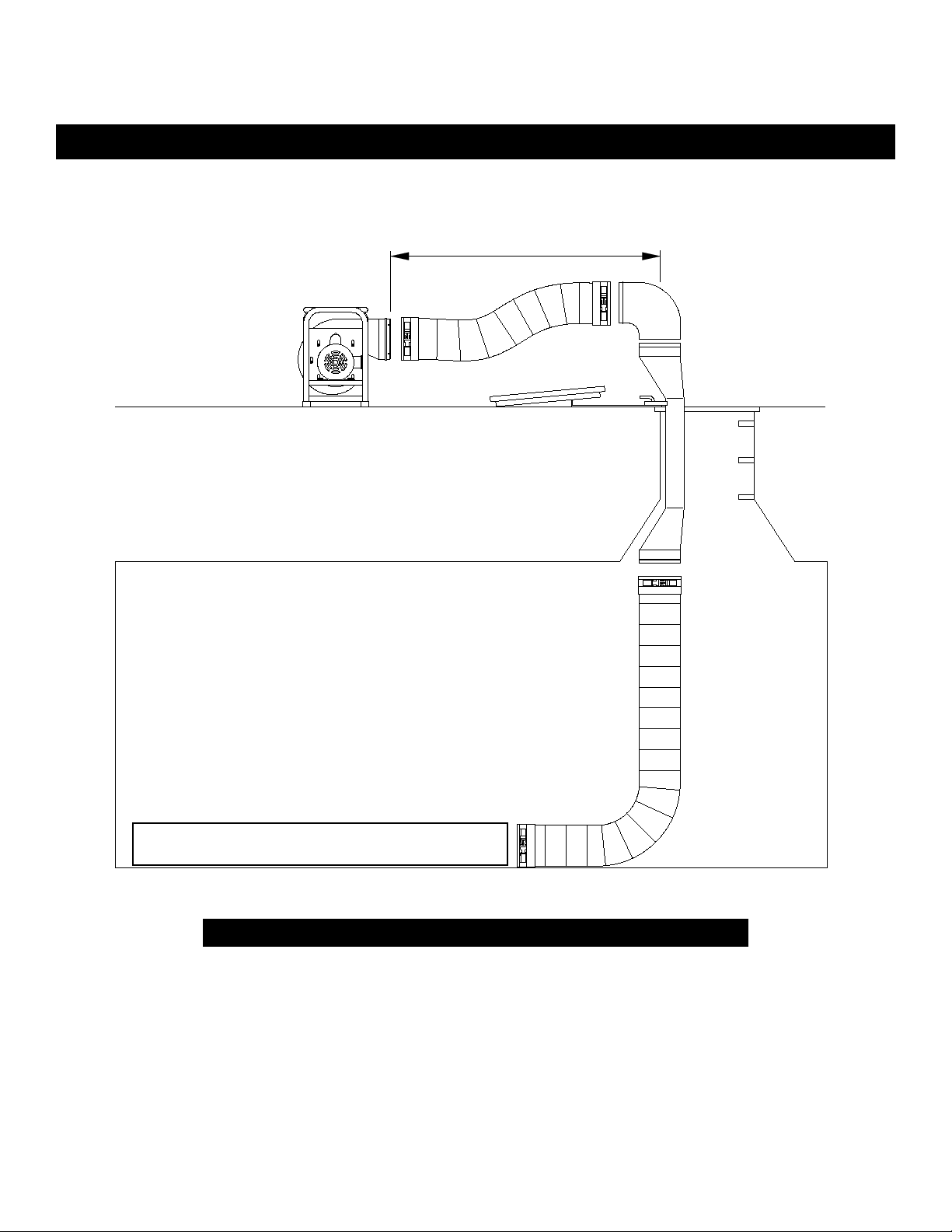

1) Place fan in a clean, fresh air environment.

2) Air quality of the conned space should be tested prior to ventilation. If air quality of the conned space is

unacceptable, consult a trained professional.

3) Inspect fan for damaged or worn parts, and inspect ducting for air leaks prior to fan operation.

4) Install duct cuff to exhaust ange and secure. Keep bends and kinks in ducting to a minimum to maximimize

air ow. If canister model is used, secure canister with connect straps, open lid and pull out ducting. Inspect

for air leaks.

NOTE: Maximum recommended duct hose length is 25 ft.

5) Set fan upwind from the work location and a minimum of 5 ft. from the manhole opening.

6) Connect fan to power source.

DC versions require 12 VDC. Attach the red connector to the positive (+) terminal and the black conector to

the negative (-) terminal. This unit must be run in the positive pressure mode as this model is not approved

for extracting (sucking) air. DO NOT REVERSE WIRING.

WARNING: Vehicle electrical systems must be able to handle 15 amp service or electrical damage may occur.

AC versions require 115 VAC/60Hz (SVF-8AC), 15 amp service or 220 VAC/50Hz (SVF-8AC50).

NOTE: If an extension cord is required, the minimum recommended size is 14 AWG up to

25 ft. For further information refer to the National Electric Code Tables, Article 400.

7) Push ON/OFF switch to “I” position.

General Set-Up And Operation

For SVF-8AC And SVF-8DC Models

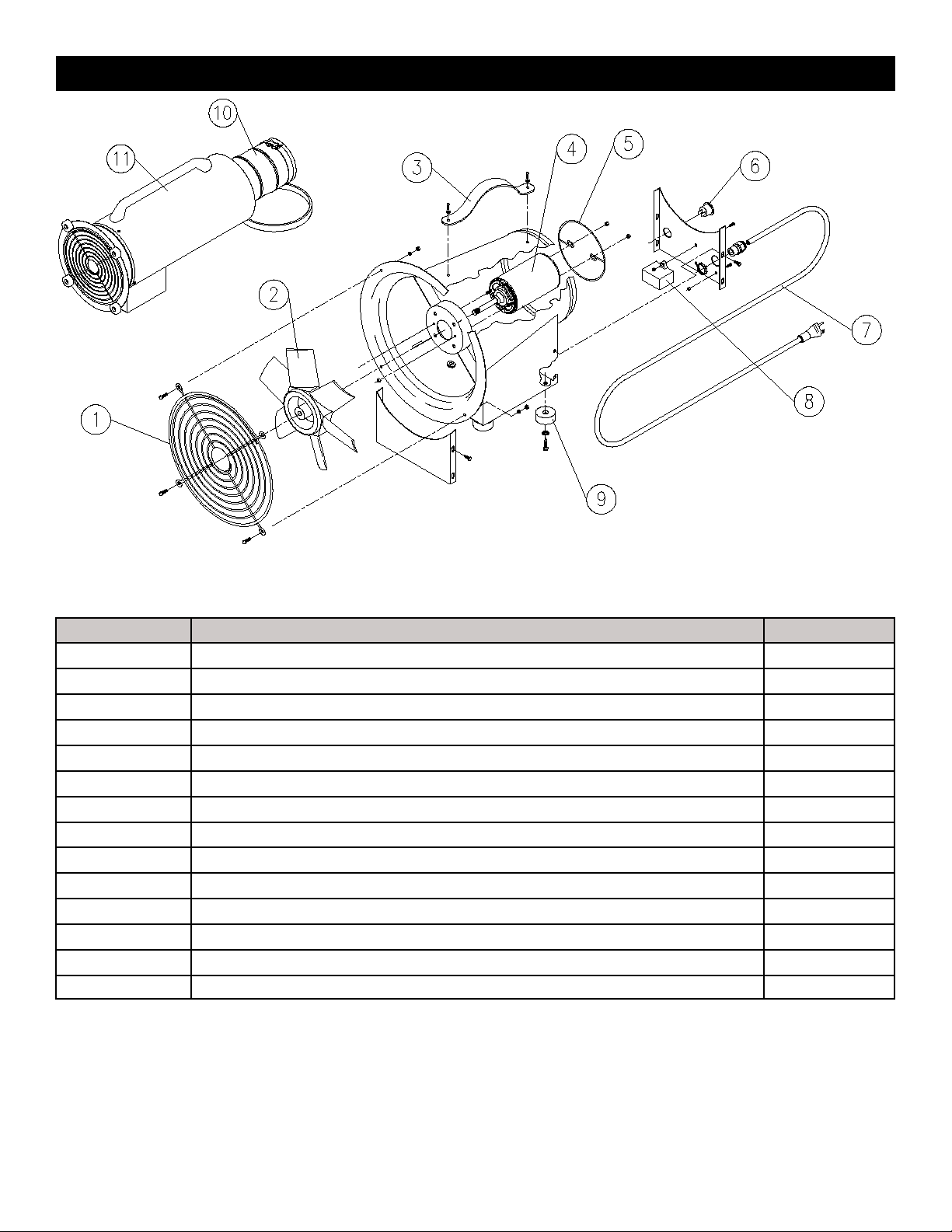

MOTOR TYPE 1/3 HP, 115 VAC/60 Hz (SVF-8AC), 2.6 amps, or 220VAC/50 Hz (SVF-8AC50)

Capacitor Start, Single Speed, 3200 RPM, CSA Approved

OUTLET SIZE 8” Diameter (203mm)

FLOW RATES

Free Air: 1275 cfm (2166 cm/hr)

15 ft. duct with one 90° bend: 797 cfm (1354 cm/hr)

15 ft. duct with two 90° bends: 677 cfm (1150 cm/hr)

Specications - AC Voltage Fans

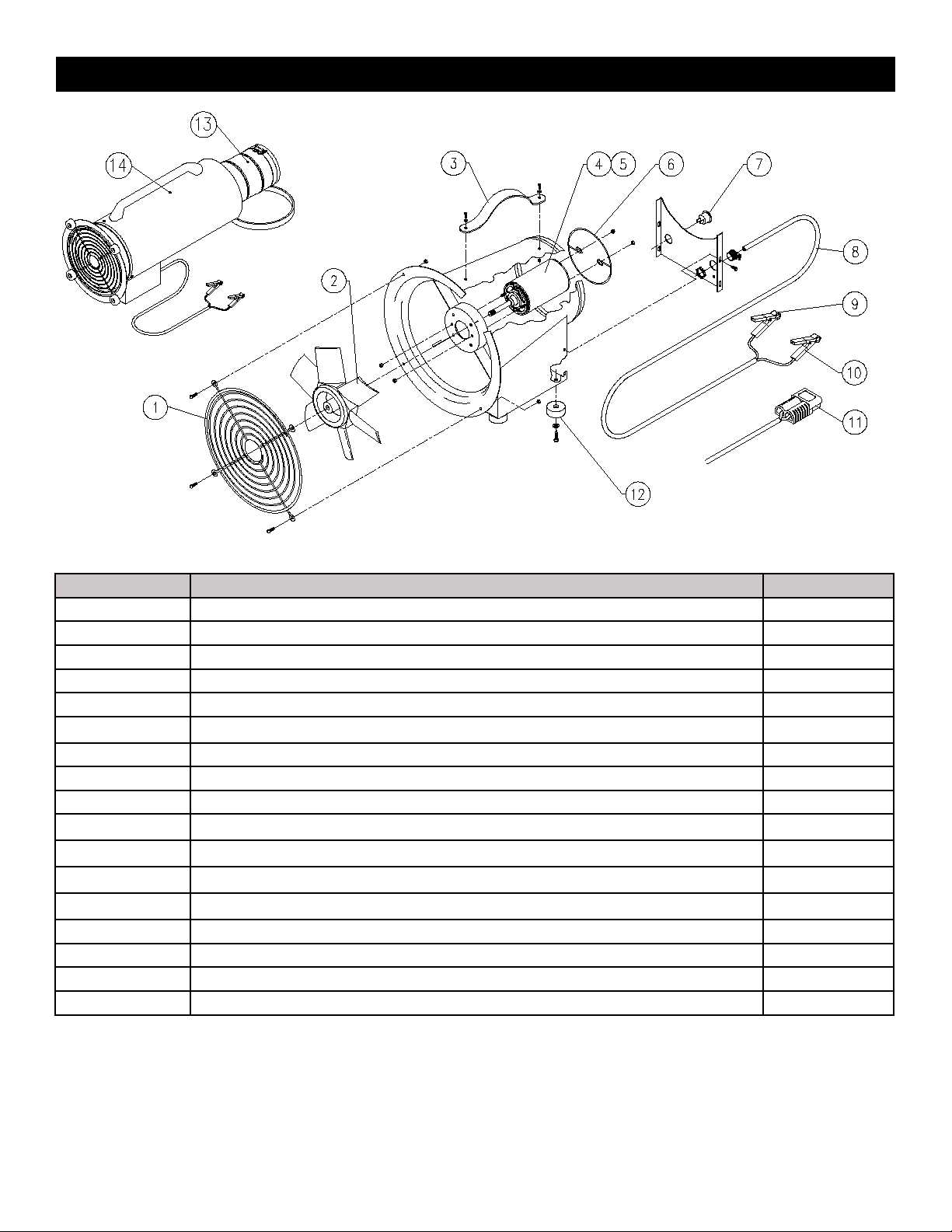

MOTOR TYPE 1/6 HP, 13.5 VDC, 15 amps, Single Speed, 4200 RPM,

20 amp/32 VDC Slow Blow Fuse

OUTLET SIZE 8” Diameter (203mm)

FLOW RATES

Free Air: 1275 cfm (2166 cm/hr)

15 ft. duct with one 90° bend: 797 cfm (1354 cm/hr)

15 ft. duct with two 90° bends: 677 cfm (1150 cm/hr)

Specications - DC Voltage Fans