-3-

OVERVIEW

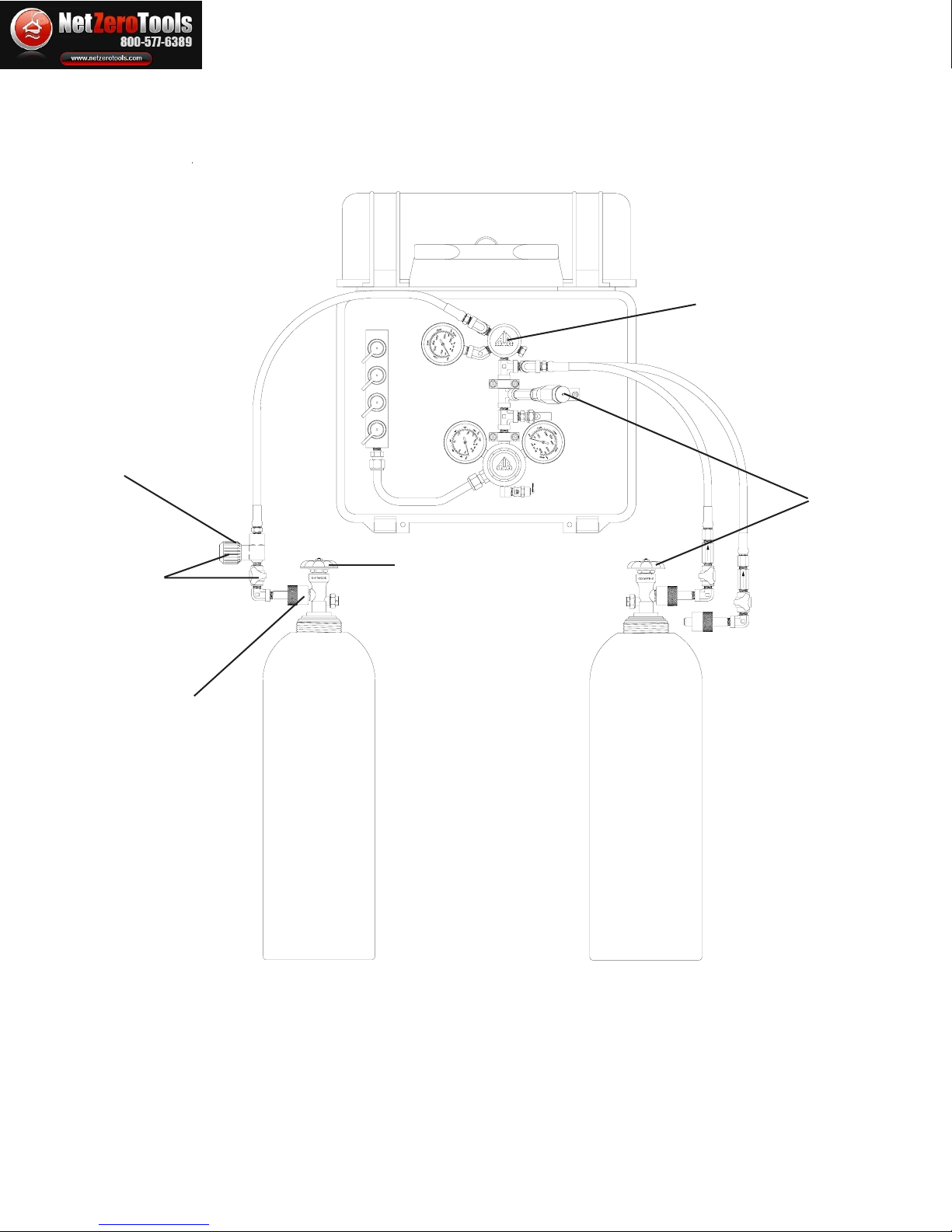

The MACK series has been designed as a portable multifunctional air distribution system. All

MACK units are rated for 5000psi.

MACK-1

This version allows for one or two high pressure cylinders to be attached to the supply inlet

whips. A CGA-347 male inlet is provided for direct attachment to a bank of air cylinders. All

MACK series units have at least one air outlet manifold with pressure adjustments from 0-125psi.

MACK-2

This version has the same features as the MACK-1, with the addition of an adjustable fill regula-

tor, pressure gauge, and fill whip. An optional second fill whip is available.

MACK-3

The MACK-3 contains two independent low pressure manifolds and regulator systems that each

have their own cylinder supply hoses. An isolation valve is located between the regulators to

isolate the systems, as well as provide common air flow from a single bottled air source. One

regulator is set to provide low pressure air (0-125psi) for respirators, and one for medium pres-

sure air (0-250psi) for air shores and other rescue tools. This medium pressure manifold has an

additional low pressure regulator/manifold system for additional respirators and tools. A total of

eleven outlets are provided. The MACK-3FA version contains all of the above items, with the

addition of a complete bottle fill assembly, model number MACK-FA.

MACK-NFPA1

This version contains two in dependent MACK-1 manifold and regulator systems, so that each

one has its own cylinder supply hoses and low pressure whistle. A total of 6 low pressure outlets

are provided.

MACK-NFPA3

This version of the MACK-NFPA1 contains two independent low pressure manifold and regula-

tor systems, so that each has its own cylinder supply hoses. An isolation valve is added between

the systems to isolate the regulators, as well as provide common air flow from a single bottled air

source. A CGA-347 high pressure inlet is provided on this version to allow for an external bank

of air cylinders to operate the unit.