8

ENGLISH

CONTRACOR® Version 5.0

5. Set-Up and Operation

5.1 Set-Up

An air lter is recommended in the air supply to remove condensed moisture from the air

line.

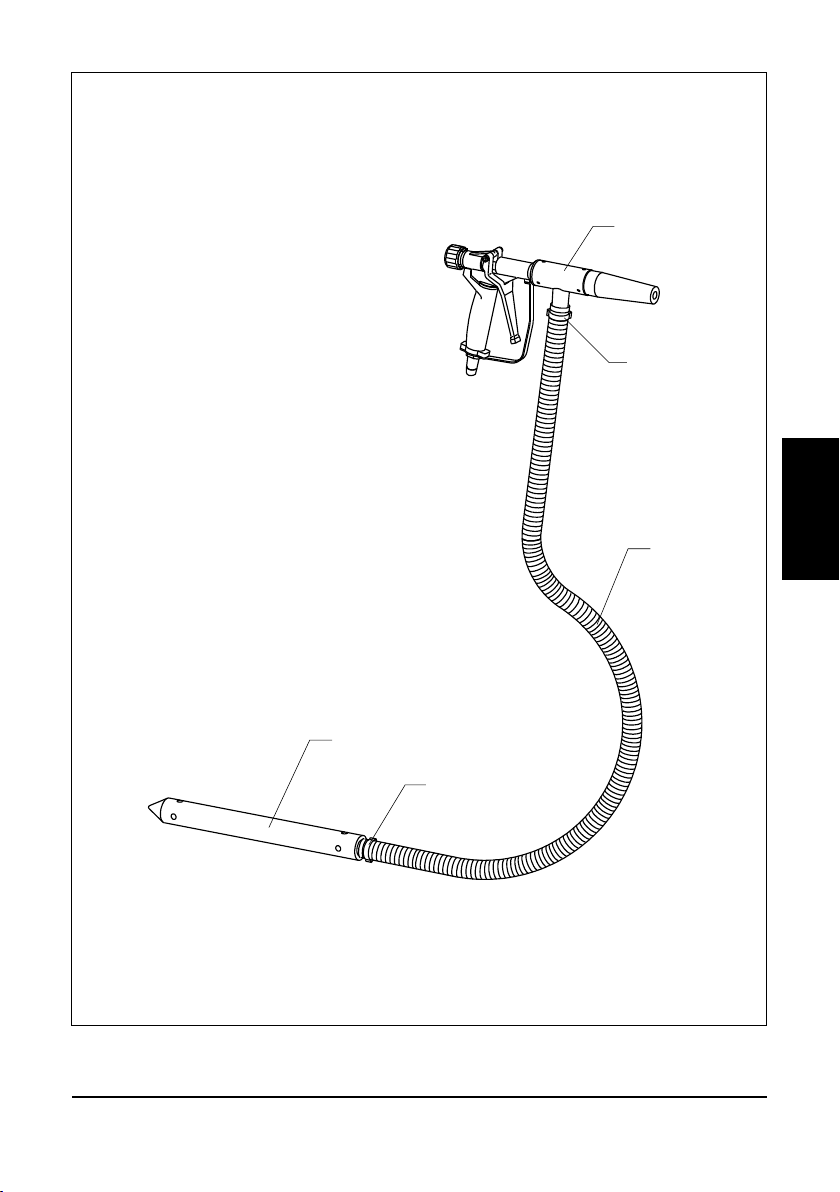

Connect POWER GUN to a 25mm (1") ID air hose. An isolation valve is required at the air

source to enable depressurization.

Secure all compressed-air supply hose connections with safety lock pins to prevent

accidental disconnection.

5.2 Operation

Use the pointed end of the lance to pierce the bag of abrasive. Insert the lance into the

abrasive. The upper (air-intake) holes must remain open, and outside of the abrasive.

Pressurize the air supply line.

Put on the appropriate protective gear, including supplied-air respirator, abrasive resistant

clothing, leather gloves, and hearing protection as required.

Hold the gun approximately 150mm from the blast surface, and squeeze the trigger lever.

Adjust the stand off distance and angle for optimum performance.

5.3 Shutdown

When nished blasting, remove the lance from the abrasive and shake abrasive from the

material hose. If conditions are safe to do so, pull the trigger to further empty the hose.

When nished blasting, and after cleanup is completed, remove the respirator outside the

blasting area, where the air is safe to breathe.

Depressurize the air supply line and shutdown the compressor.