i

Table of Contents

ABOUT LOADMAXX FOR CAMELBACK SUSPENSIONS......................1

ABOUTINSTALLATION.............................................................................1

Overview..........................................................................................1

TOOLS REQUIRED...................................................................................2

Optional Tools................................................................................2

INSTALLING THE STEER AXLE SENSOR BRACKET............................3

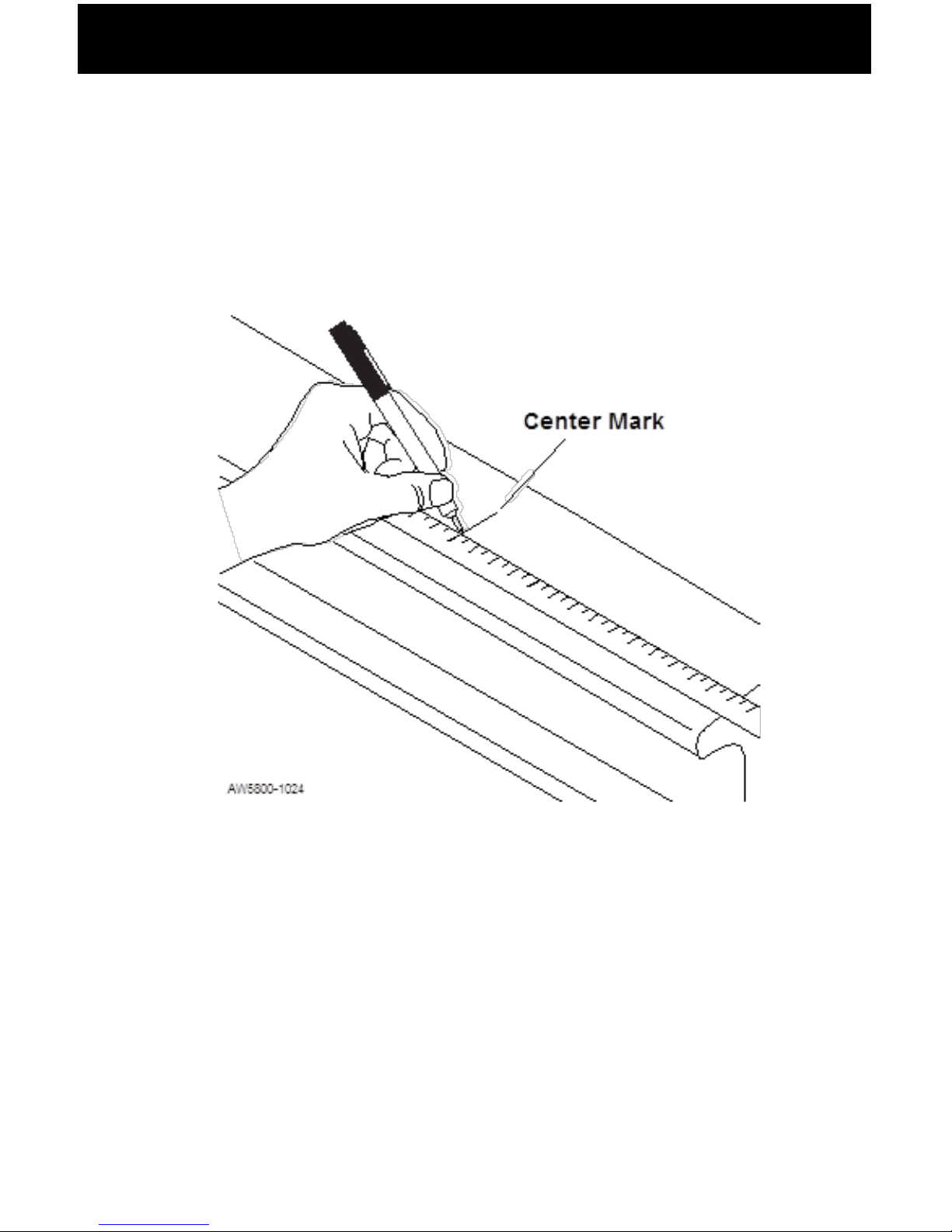

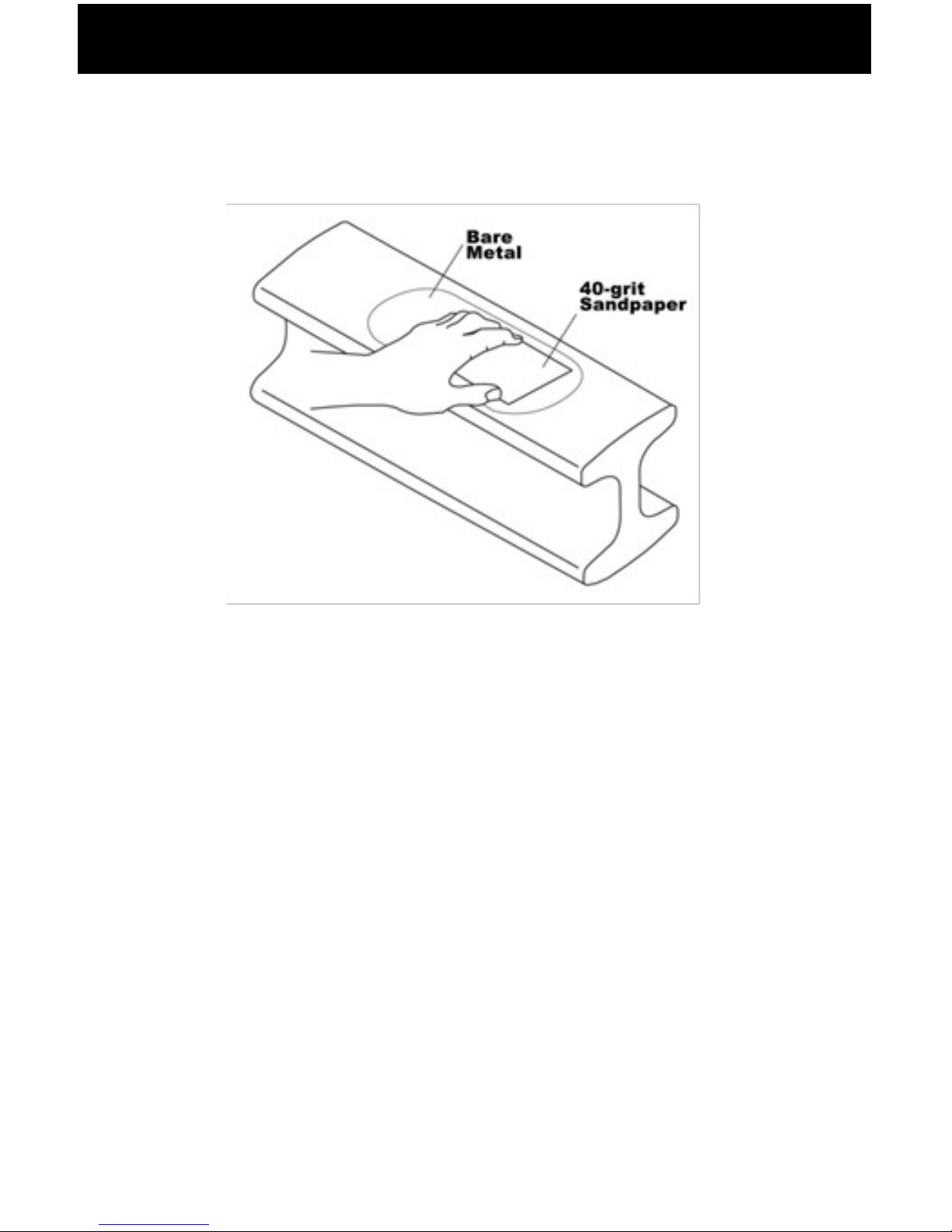

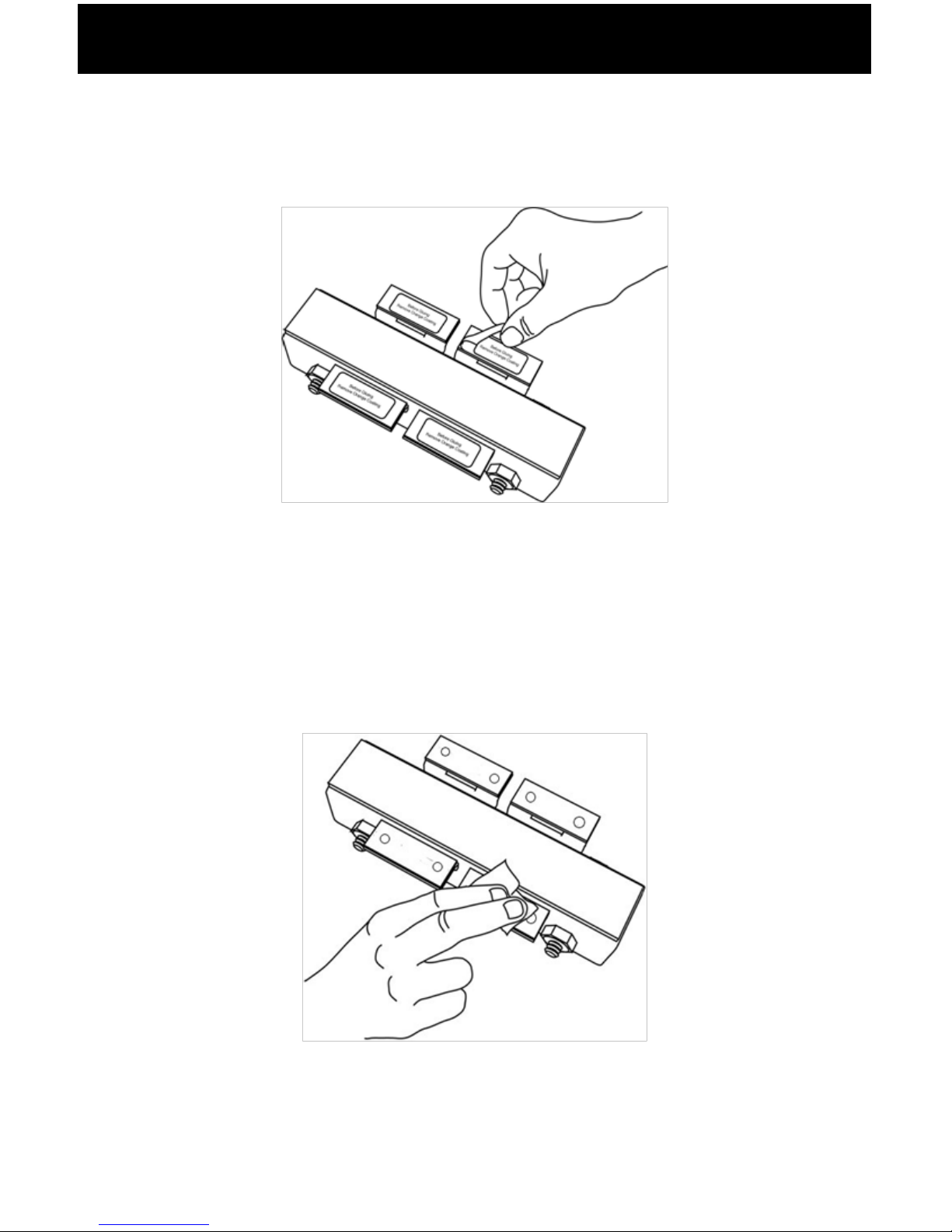

Preparing the Steer Axle Sensor Brackets...............................3

Welding the Bracket......................................................................6

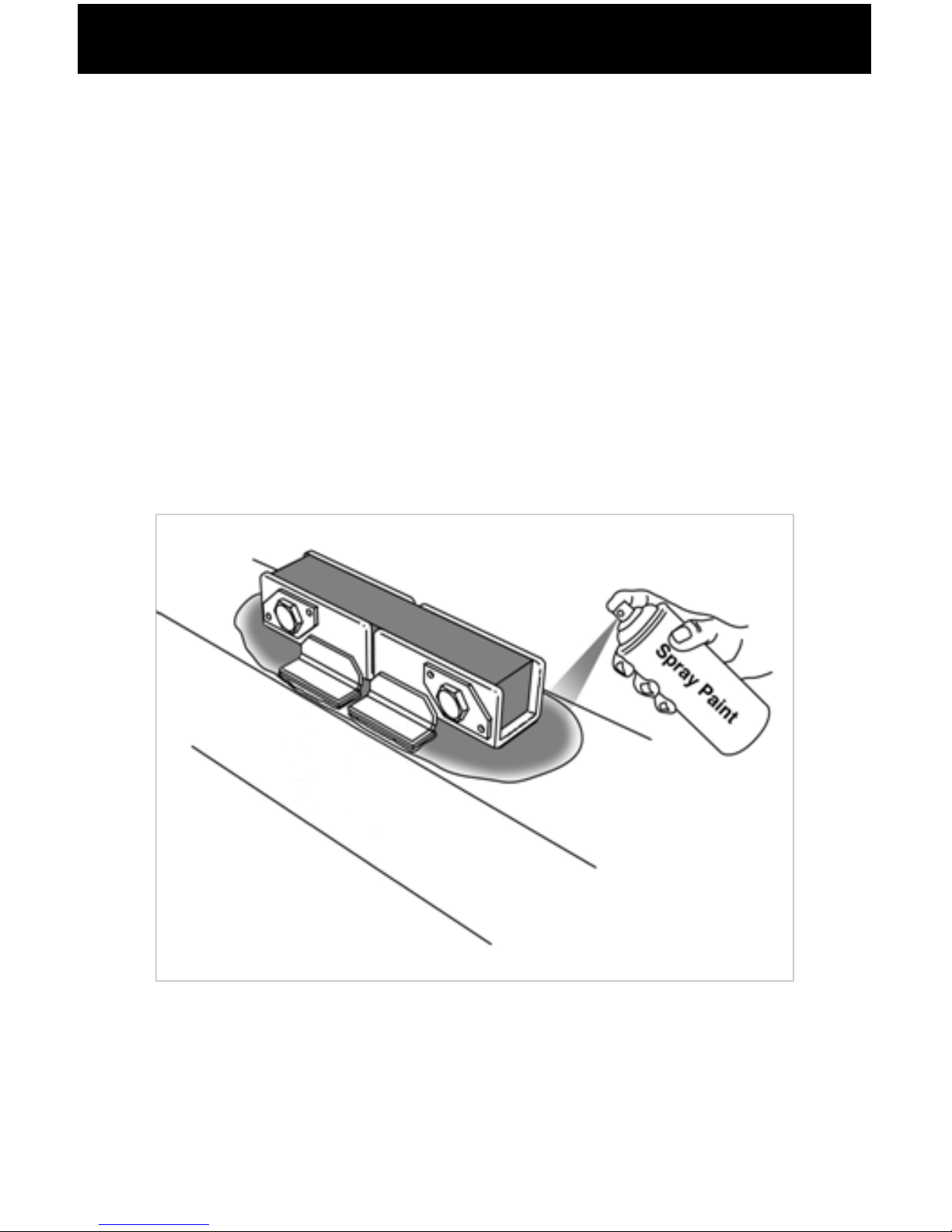

Adding a Protective Spray Paint Coating..................................7

INSTALLING THE DRIVE AXLE SENSOR BRACKET.............................8

Preparing the Camelback Suspension......................................8

Welding the Bracket.....................................................................9

Adding a Protective Spray Paint Coating................................10

ROUTING CABLES..................................................................................11

INSTALLING THE COMLINK AND DISPLAY..........................................12

Preparing the Cab Display for Installation...............................12

Installing the Cab Display...........................................................12

Mounting the ComLink...............................................................13

CONNECTING CABLES...........................................................................14

Power and Ground Table....................................................14

Securing Cables and Reassembling the Dash......................14

INSTALLING AND ADJUSTING THE STEER AXLE SENSOR..............15

INSTALLING AND ADJUSTING THE DRIVE AXLE SENSOR...............17

Setting A/D Values.....................................................................18

Adjusting the A/D Reading.....................................................19

Final Sensor Torque...................................................................20

COVER INSTALLATION..........................................................................21