aircom.it .13

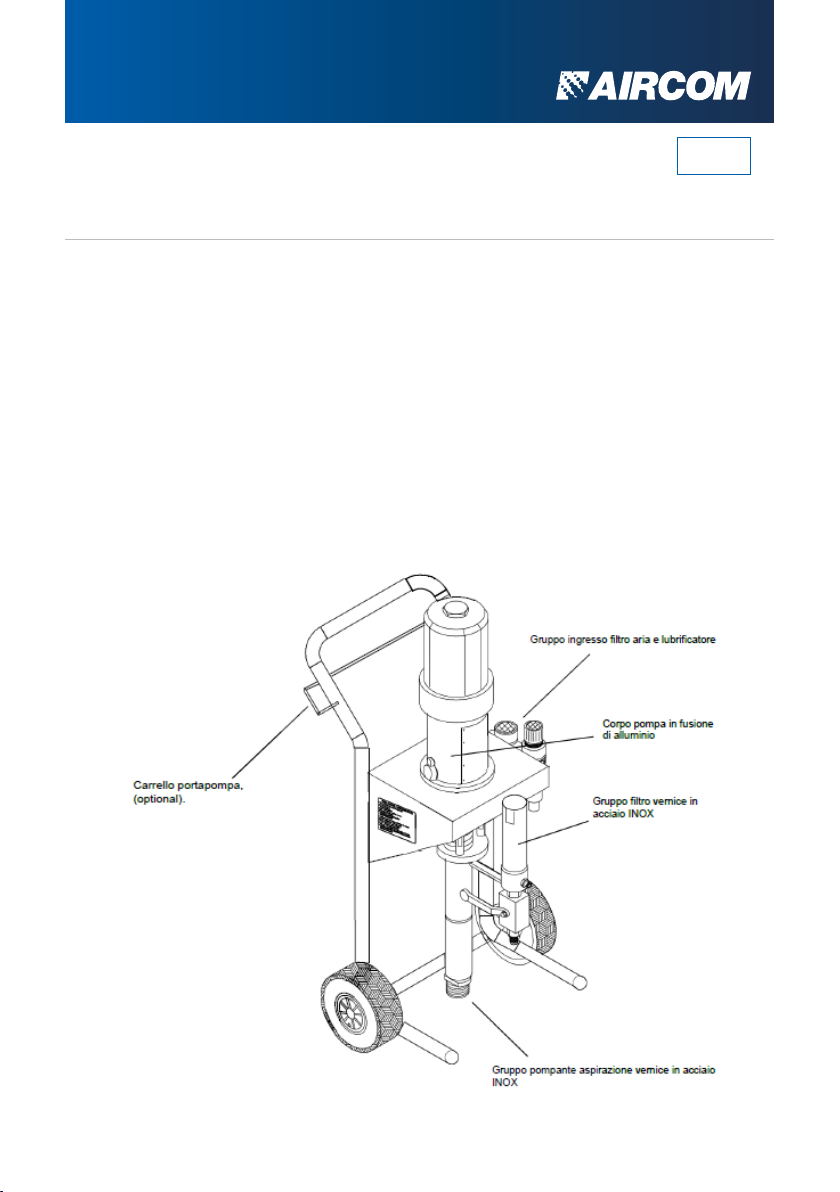

MAINTENANCE

Adequate maintenance is a determining factor for a longer life of the

equipment in optimal operating conditions and performance, and ensures

functional safety over time. It is recommended to have the maintenance

operations carried out by trained personnel. Personnel must be provided

with personal protective equipment commonly used for similar operations,

and follow the safety procedures prescribed in the following chapter.

Routine maintenance of the AST30 system is very simple and does not

require particular interventions as the mechanical components of the

system are lubrication-free. During operation, the friction of the stem on

the seals can cause product leakage into the cup (when the system is new

this occurs after about 30/40 hours of operation). These leaks are minor at

the origin, but, if neglected, they can irreparably damage the pumping

element. The leak is due to settling of the gasket pack. It is important to

intervene immediately by adjusting the gasket pack with the special key

supplied with the system.

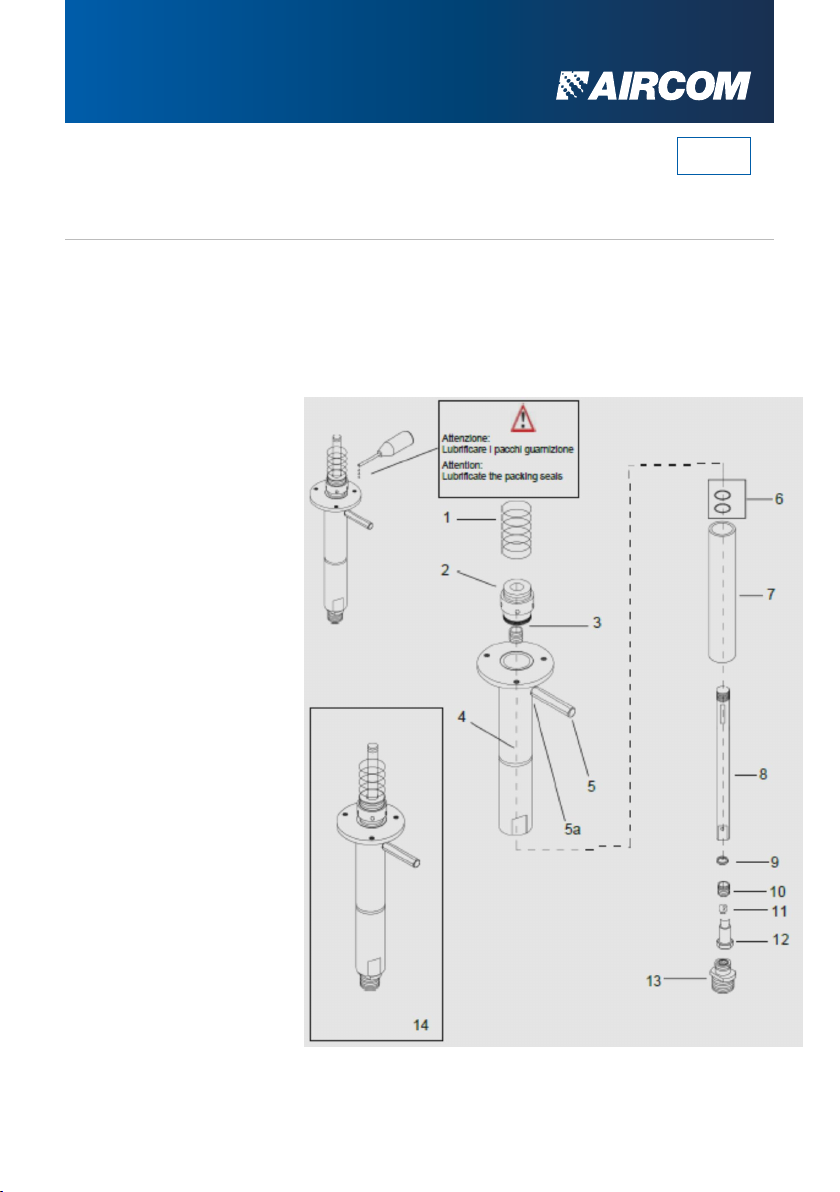

REGISTRATION OF THE GASKETS PACK

The seal pack adjustment must be carried out with the pumping rod in

motion, and in the absence of product. Open the recirculation tap, adjust

the supply air to 2 bar (the stem begins to move), with the special spanner

provided, rotate the cup clockwise. For minor leaks, it is sufficient to give a

small amount of pre-charge to the seal pack (AVOID BLOCKING THE ROD

WITH AN EXCESSIVE ROTATION OF THE CUP).

• Disconnect the air supply before removing any part of the unit or making

any replacement of components.

• Do not wear rings, watches, chains, bracelets, etc. during maintenance

operations.

• Always use personal protective equipment (gloves, goggles, safety

shoes).

• Use only original spare parts.

• Do not use open flames, sharp points or pins for cleaning.

• No smoking.

EN