7

Meganorm

f) Curves and accessories, when needed should be

designed and installed reducing pressure losses to a

minimum, i.e. always prefer long or medium radius

curves.

g) The suction line flange should fit to the pump suction

flange without any stress or tension and without applying

any kind of force to the casing. The pump should never

be an anchor point for the suction pipeline. If this

condition is not observed a misalignment may happen,

originating cracks on pump parts and/or other severe

damages.

h) On installations equipped with foot valve, observe that the

free passage area should be 1.5 times the cross sectional

area of the suction pipeline. Normally coupled to the foot

valve there should be a suction strainer with a free

passage area 3 to 4 times larger than the cross sectional

area of the suction pipeline.

i) When the liquid being pumped has large temperature

variations, expansion joints should be installed preventing

the effects of contractions and expansions of the suction

pipeline on the pump.

j) With positive suction, it is advisable to install an inlet

valve to close the flow to the pump when necessary.

During the pump operation it should stay totally open. A

suction with a common header for several pumps should

have an inlet valve for each pump and the connection

between the header and each suction line should be

made with line angle changes less than 45 degrees. In all

these applications of gate valves, the valve stems should

be directed either horizontally or vertically downwards.

k) To prevent turbulence, leakage of air, sand or mud at the

pump suction, all recommendations of the HYDRAULIC

INSTITUTE referred to the these types of installation

should be strictly observed.

l) Even if the coupling alignment has been checked before

tightening, it has to be repeated after the final tightening

of the suction pipeline.

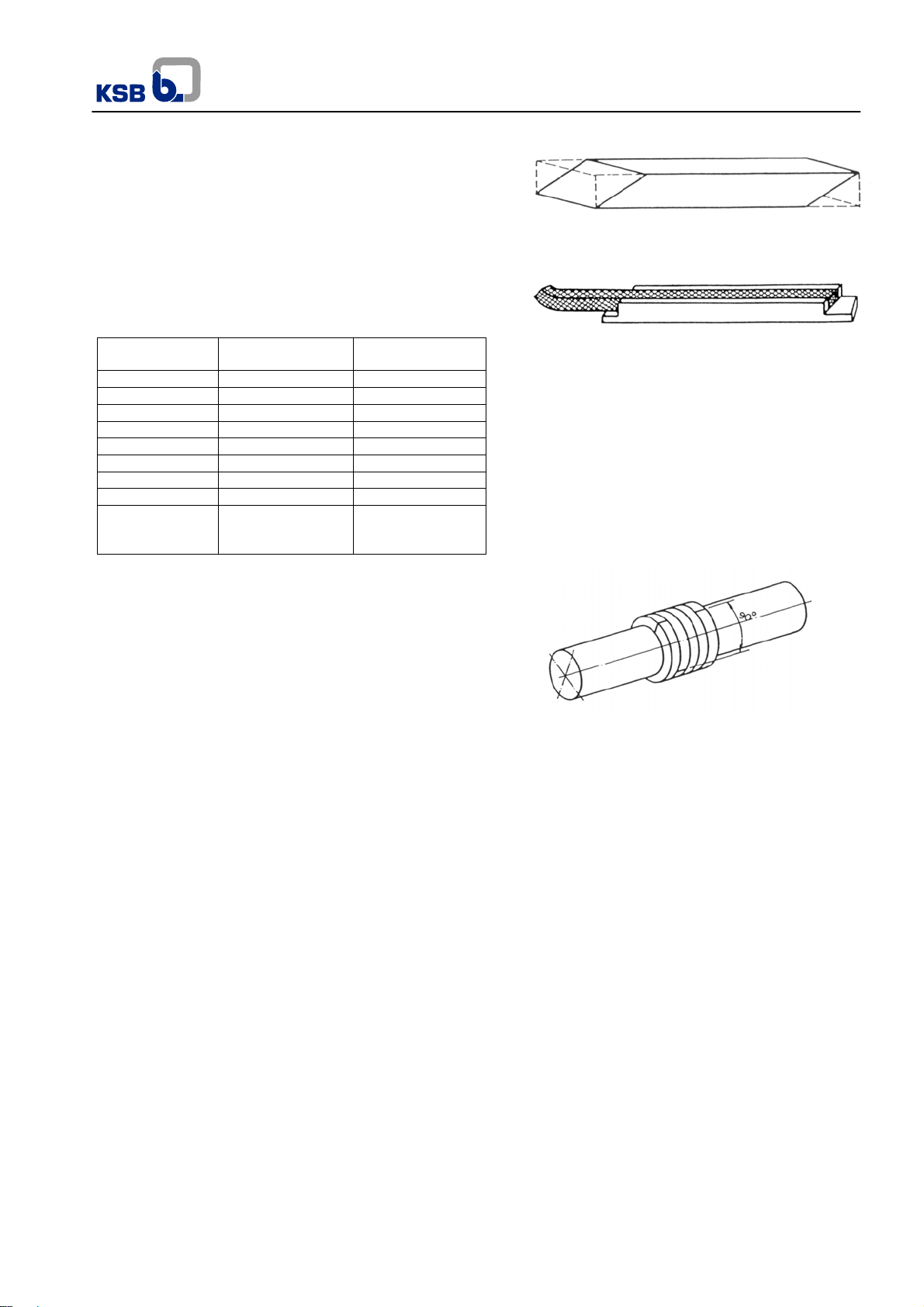

m) To facilitate the mounting of the suction pipeline and the

fitting of the parts, install as necessary, flexible joints of

the following types: Dresser, common or special with tie

bolts.

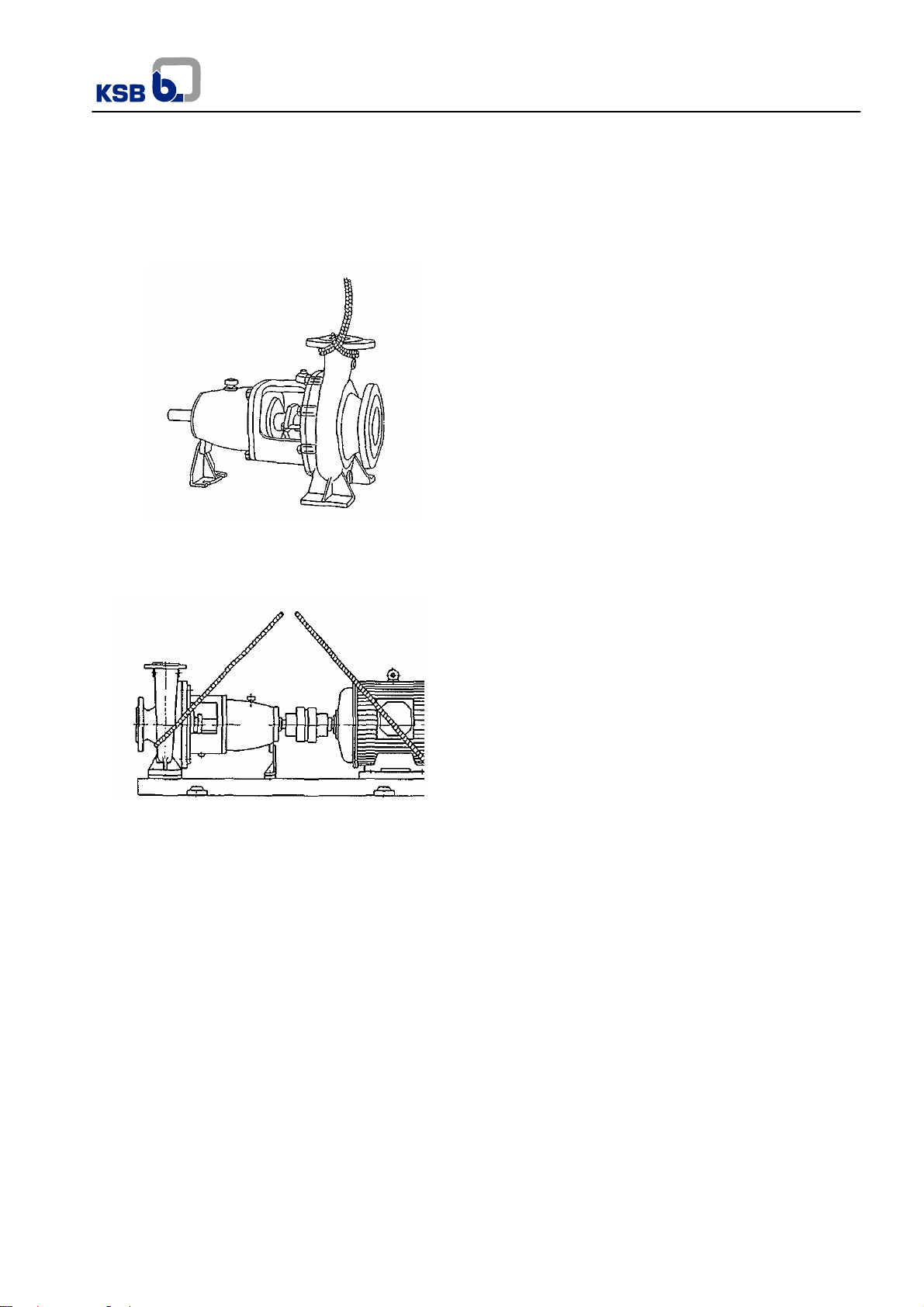

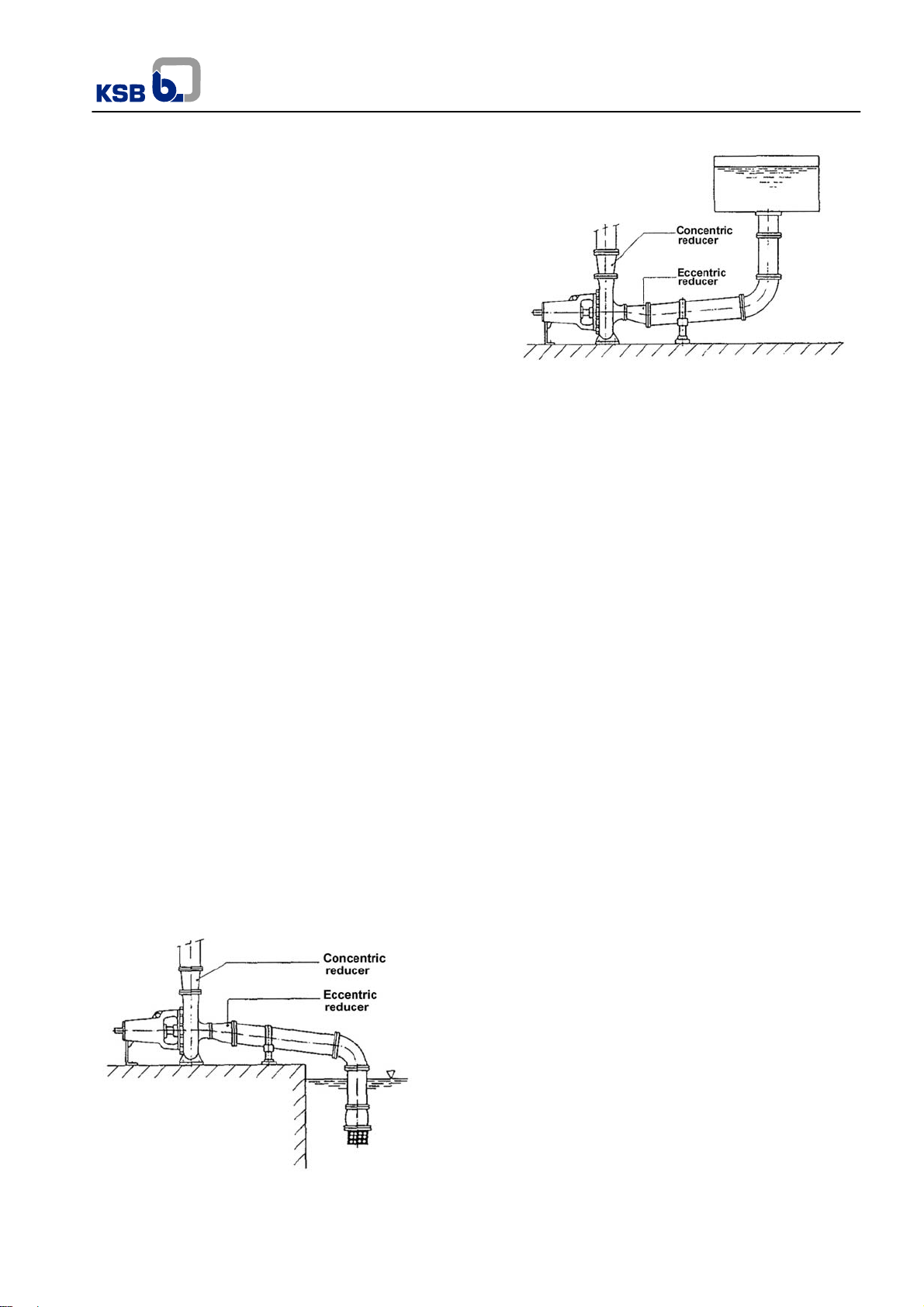

Fig.10 – Negative suction

Fig.11 Positive suction

9.6 Discharge pipeline – Recommendations

To install the discharge pipeline, please follow the instructions

below:

a) If the overpressures caused by the returning of the liquid

in long pipe lines, exceed the limits specified for the line

and the pump, water hammer control devices should be

installed on the discharge pipe line.

b) When the diameters of the pump and pipeline flanges are

different, the connections should be done through a

concentric reduction.

c) On the points where it is necessary to bleed the air in the

pipeline, vent valves should be installed.

d) Install a discharge valve, if possible immediately after the

discharge nozzle of the pump in order to properly control

the flow rate and pressure or to prevent driver overloads.

e) When a non-return valve is installed, it should be mounted

between the pump and the discharge valve, prevailing this

condition over item D.

f) Tie mounting joints should be installed to absorb the

system reaction forces, originated on the applied loads.

g) Safety valves, pressure relief devices and other

operational valves not included up to now, should be

installed as necessary for adequate operation of the

pipeline.

h) The recommendations for the suction pipeline described

on items A, B, F, G are also valid for the discharge

pipeline.