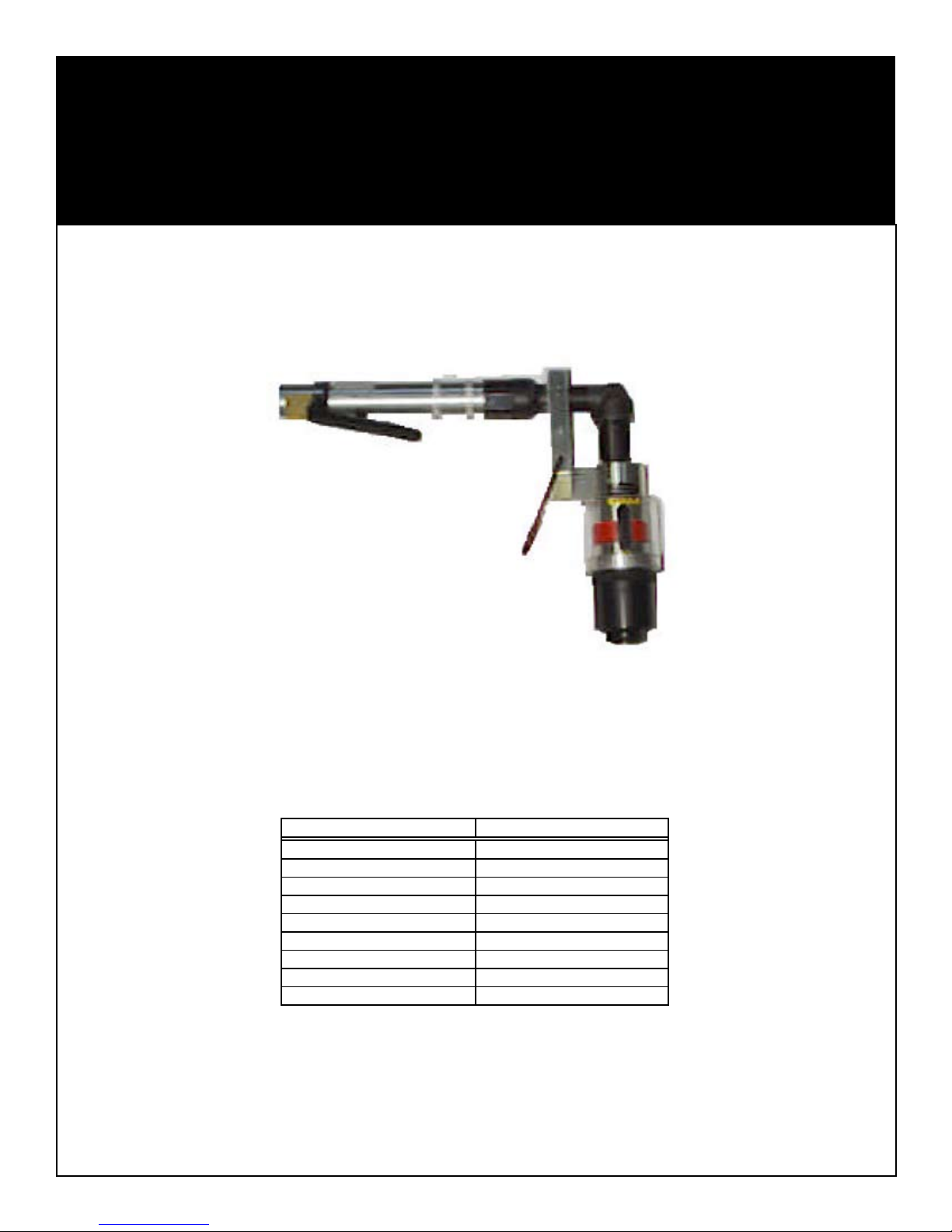

Airetool FPT-9800-C-162 Instruction and safety manual

For additional product information visit our website at http://www.apextoolgroup.com

Operating & Service Manual

90109-IM

05/25/2011

FPT-9800 Series

Freeze Plug Removal Tool

Model Number Part Number (Order)

FPT-9800-C-162 5525147

FPT-9800-F-150 5524842

FPT-9800-GM 5524792

FPT-9800-M-175 5524844

FPT-9800-7-GC-44

FPT-9800-7-GM-134 5525135

FPT-9800-7-GM-162 5525177

FPT-9800-7-GM-150 5525192

FPT-9800-7-GM-35M 5525418

Airetool®

Page 2

Safety Recommendations

Some individuals are susceptible to disorders of the hands

and arms when exposed to tasks which involve highly

Tools with clutches can stall rather than shut-off if ad-

justed over the maximum power output of the tool, or if

there is a drop in air pressure. Operator must then resist

the stall torque until the throttle is released.

Higher torqueAiretrols, inline and right angleare supplied

with a torque reaction bar designed to work with the torque

of the tool it is for, be equipped with splined torque reac-

tion mounting plates which accept torque reaction bars.

These bars can be braced against the work or other suit-

able points to absorb and relieve the operator of the torque

reaction transmitted by the tool. Tool balance arms are

also available to absprb the torque reaction of the tool while

balancing the weight of the tool for improved ergonomic

applications.

When using right angle Airetrols with lever type throttles,

be sure the throttle is positioned relative to the angle head

so that the throttle will not become wedged against an

adjacent object in the “ON” position due to the torque reac-

tion. The angle head may be repositioned with the respect

to the lever to accommodate proper location foe the task. If

tool is to be reversed, locate the throttle lever in a neutral

position that will prevent entrapment. Refer to operating

instructions for additional information.

Hearing protectors are required in high noise areas, 85

dBA or greater. The operation of other tools and equipment

in the area, reflective surfaces, process noises and reso-

nant structures can substantially contribute to, and increase

the noise level in the area. For additional information on

hearing protection, refer to Federal OSHA Regulations, 29

Code of Federal Regulations Section 1910.95, Occupa-

tional Noise Exposure, and American National Standard

Institute, ANSI S12.6 Hearing Protectors.

HEARING PROTECTION

EYE AND FACE PROTECTION

For additional information on eye and face protection, refer

to Federal OSHA Regulations, 29 Code of Federal Regula-

tions, Section 1910.133., Eye and Face Protection, and

American National Standards Institute, ANSI A87.1, Oc-

cupational and Educational Eye and Face Protection. Z87.1

is available from the American National Standards Insti-

tute, Inc., 1430 Broadway, New York, NY 10018.

For your safety and the safety of others, read and under-

stand the safety recommendations and operating instruc-

tions before operating this tool.

ALWAYSWEARPROTECTIVEEQUIP-

MENT

Follow good machine shop practices. Rotating shafts and

moving components can entangle and enwrap, and can

result in serious injuries. Never wear long hair, loose fitting

clothes, gloves, ties or jewelry when working with or near

any power tool with an exposed rotating shaft or spindle.

Page 3

Use of this tool may produce hazardous fumes, particles,

and/or dust. To avoid adverse health effects utilize adequate

ventalation and/or a respirator. Read the material safety

data sheet of any materials involved in the tube expansion

process.

Safety Recommendations

This Airetool product is designed to operate on 90 psig

(6.2 bar) maximum air pressure. If the tool is properly sized

and applied, higher air pressure is unnecessary. Excessive

air pressure increases the loads and stresses on the tool

parts, mandrels, rolls and cages and may result in break-

age. Installation of a filter-regulator-lubricator in the air sup-

ply line ahead of the tool is required.

Before the tool is connected to the air supply, check the

throttle for proper operation (i.e., the throttle moves freely

and returns to the closed “OFF” position when released).

Clear the air hose of accumulated dust and moisture. Be

careful not to endanger adjacent personnel. Before remov-

ing a tool from service or changing sockets, make sure the

air line is shut off and drained of air. This will prevent the

tool from operating if the throttle is accidently engaged.

repetitive motions and/or vibrations. Those individuals pre-

disposed to vasculatory or circulatory problems may be

particularly susceptibly. Cumulative trauma disorders such

as carpal tunnel syndrome and tendonitis can be caused

or aggravated by repetitions, forceful exertions of the hands

and arms. These disorders develop gradually over periods

of weeks, months, and years.

TASKS SHOULD BE PERFORMED IN SUCH A MANNER

THAT THE WRISTS ARE MAINTAINED IN A NEUTRAL

POSITION WHICH IS NOT FLEXED, HYPEREXTENDED,

OR TURNED SIDE TO SIDE.

STRESSFUL POSTURES SHOULD BE AVOIDED AND

CAN BE CONTROLLED THROUGH TOOL SELECTION

AND WORK LOCATION.

Any user suffering from prolonged symptoms of tingling,

numbness, blanching of the fingers, clumsiness or weak-

ened grip, nocturnal pain in the hand, or any other disorder

of the shoulders, arms, wrists, or fingers is advised to con-

sult with a physician. If it is determined that the symptoms

are job related or aggravated by movements and postures

dictated by the job design, it may be necessary for the

employer to take steps to prevent further occurrences. These

steps might include, but not limited to, repositioning the

work piece or redesigning the workstation, reassigning

workers to other jobs, rotating jobs, altering work pace,

and/or changing the type of tool used so as to minimize

stress on the operator. Some tasks may require more than

one type of tool to obtain the optimum operator/tool/task

relationship.

The following recommendations will help reduce or mod-

erate the effects of repetitive work motions

•Use a minimum hand grip force consistent with

proper control and safe operation.

•Keep wrists as straight as possible.

•Keep body and hands warm and dry.

.

It is essential for safe operation that any operator of an

Airetrol use good balance, sure footing, and proper posture

in anticipation of a torque reaction. Insure that the opera-

tors hand will not be wedged or pinched between the work

and the tool when operating.

•Avoid anything that inhibits bloodcirculation

- Smoking tobacco

- Cold temperatures

- Certain drugs

• Avoid highly repetitive movements of the

hands and wrists, and continuous vibration ex

posure.

NOTE : ANY USE OF THIS TOOL OTHER THAN ITS

DESIGNED PURPOSE COULD CAUSE MAJOR

DAMAGE TO THE TOOL AS WELL AS POSE A RISK

TO THE OPERATOR.

Page 4

NOTE :

1. First, read and fully understand the Cleco nutrunner ser-

vice manual. The nutrunner used in this application has the

“M” right angle head, -5 gear train, stall -5 motor and modi-

fied 35TNAL backhead ( the 204172 reversing valve is re-

placed with Airetool valve spool part # 8567519.

2. The tool is controlled by a two position lever throttle. The

tool runs in the

PULL direction when the lever is fully de-

pressed (PULL = FULL). The tool runs in the RESET di-

rection when the lever is depressed about half way (touch-

ing but not shifting the reverse valve). Approximate pulled/

reset points are marked with the red stripe. We recom-

mend that you become comfortable with the throttle action

before pulling a freeze plug.

3. There is generally no need to have the center of the

rollers go beyond the edges of the red strip. Avoid bottom-

ing out the guide rollers in the reset direction as this could

bend or break the guide rollers shoulder screws.

4. If the tool should bottom out in the reset direction, im-

mediately FULLY DEPRESS the throttle lever to correct.

TO PULL A FREEZE PLUG :

1. Insert the gripper into the plug.

2. With the end of the cam held against the bottom of the

plug, FULLY DEPRESS the lever throttle.

3. Guide the gripper into the plug (with the thrust collar

held square to the block face) as it expands to grip the

plug.

4. When the plug is gripped and starts to pull out, pull back

slightly on the tool so you can tell when the plug pulls free.

5. When the plug is free, move the throttle lever to the

RESET position until the plug is released. PLEASE NOTE

that the plug is fully released when the center of the roller

reaches the edge of the red stripe - DO NOT RUN THE

ROLLER TO THE END OF THE SLOT.

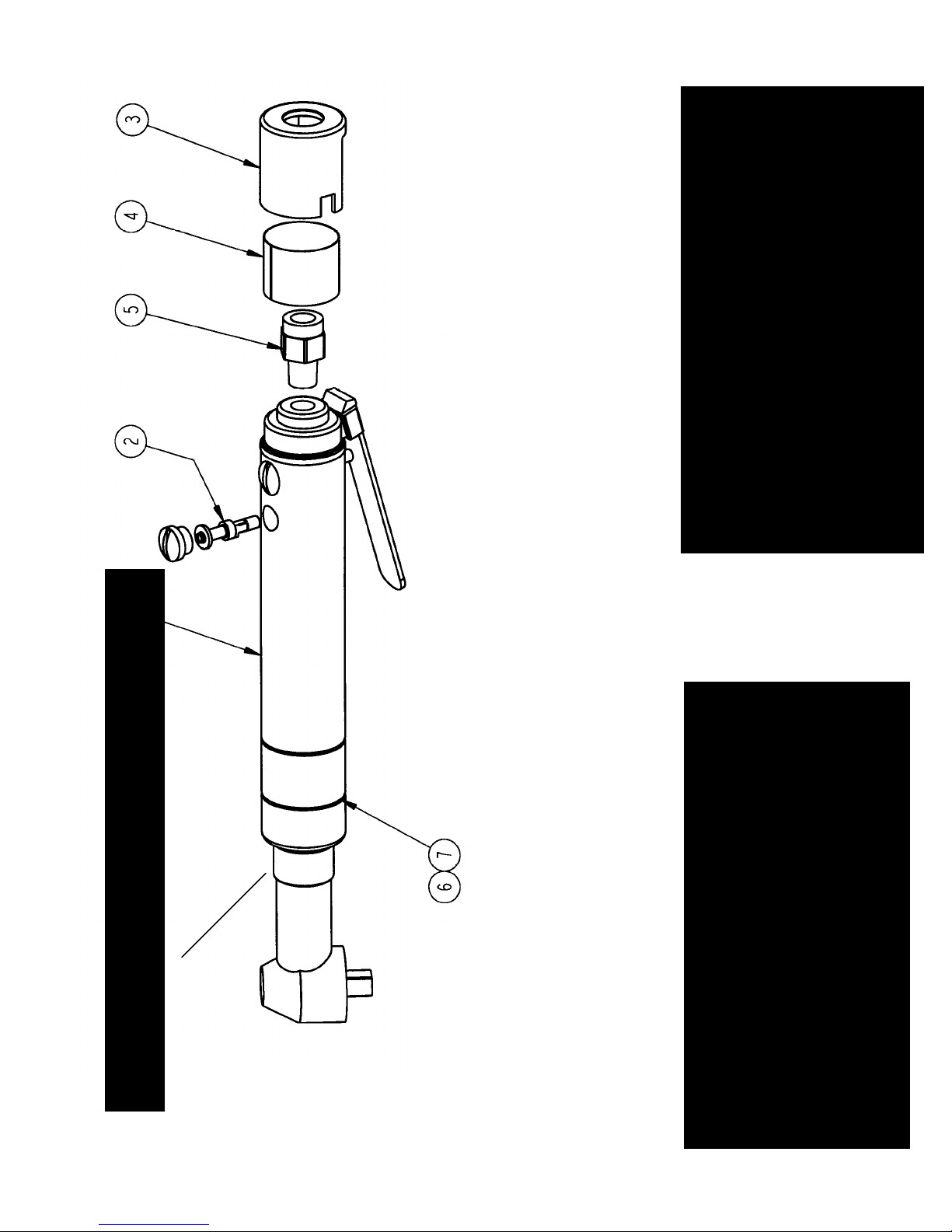

TO CHANGE THE GRIPPER SET :

OPERATING INSTRUCTIONS

Model FPT-9800-7-GM-35M (5525418)

FREEZE PLUG REMOVAL TOOL

1. Have the tool in the RESET position and unscrew the

thrust sleeve (4).

2. Remove the front O-ring (25) and pull the gripper seg-

ments (3) out of engagement with the pins (24).

3. Rotate one of the segments out from under the back O-

ring and slide the rest off over the cam (2).

4. Reverse the order to install a new gripper set. Make sure

that the cam segments are between the pins before install-

ing the thrust sleeve.

LUBRICATION :

The thrust bearing and screw should be kept well lubri-

cated with NLGI-2-EP or a teflon Grease such as Carlton-

Stuart Magnalube-G. The cam surface should be lightly

greased.

See the Cleco Manual for the nutrunner lubrication

recommendations.

Page 5

Model FPT-35-TNL-5m-1/8” (8405530)

Right Angle Nut Runner for Tool Numbers

5524792 - 5524842 - 5524844 - 5525147

Model FPT-35-TNL-7m-1/8” (8405536)

Right Angle Nut Runner for Tool Numbers

5525135 - 5525177 - 5525192 - 5525418

Page 6

P A R T S L I S T I N G F O R

GRIPPING MECHANISM

SERIES “FPT” FREEZE PLUG REMOVAL TOOL

Page 7

P A R T S L I S T I N G F O R

GRIPPING MECHANISM

SERIES “FPT” FREEZE PLUG REMOVAL TOOL

Page 8

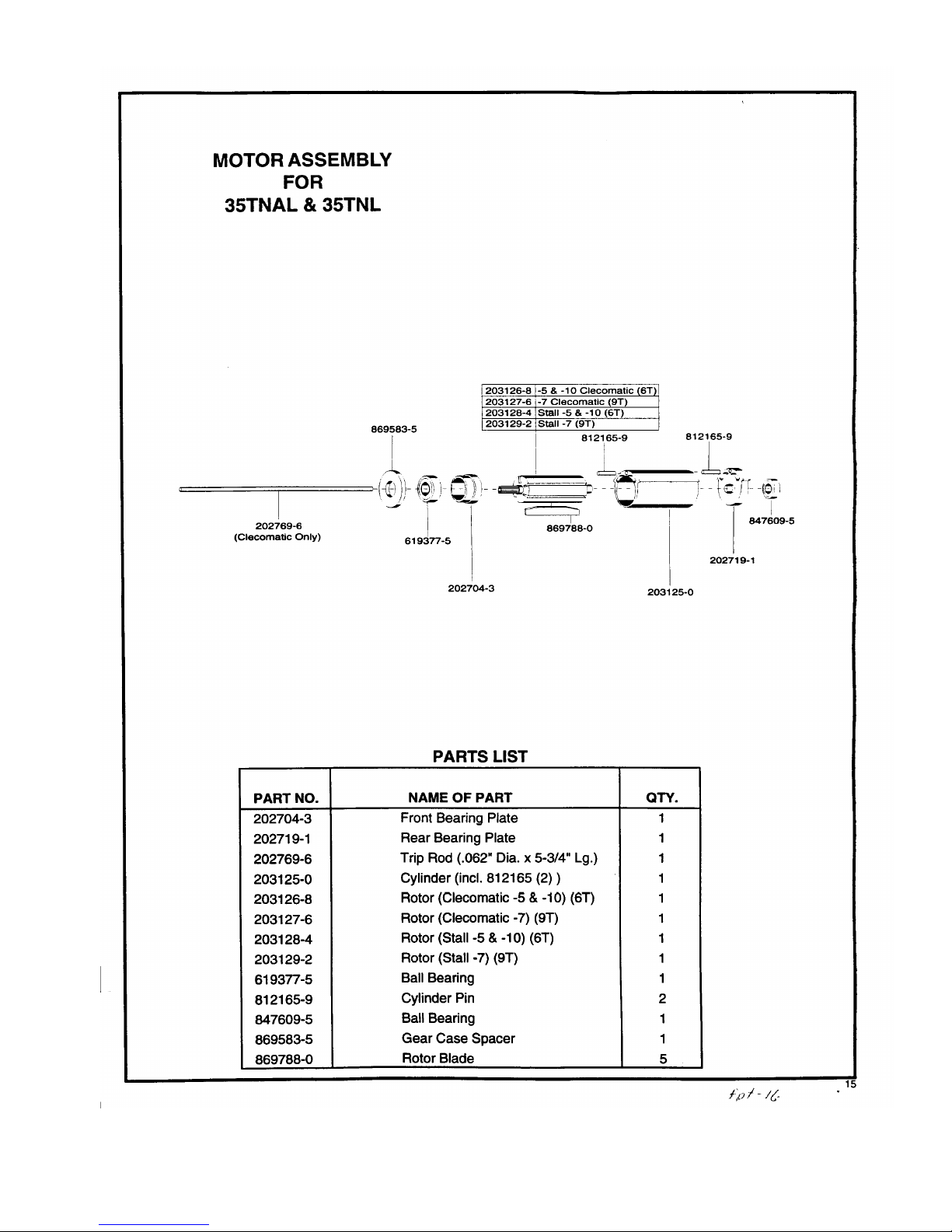

Page 9

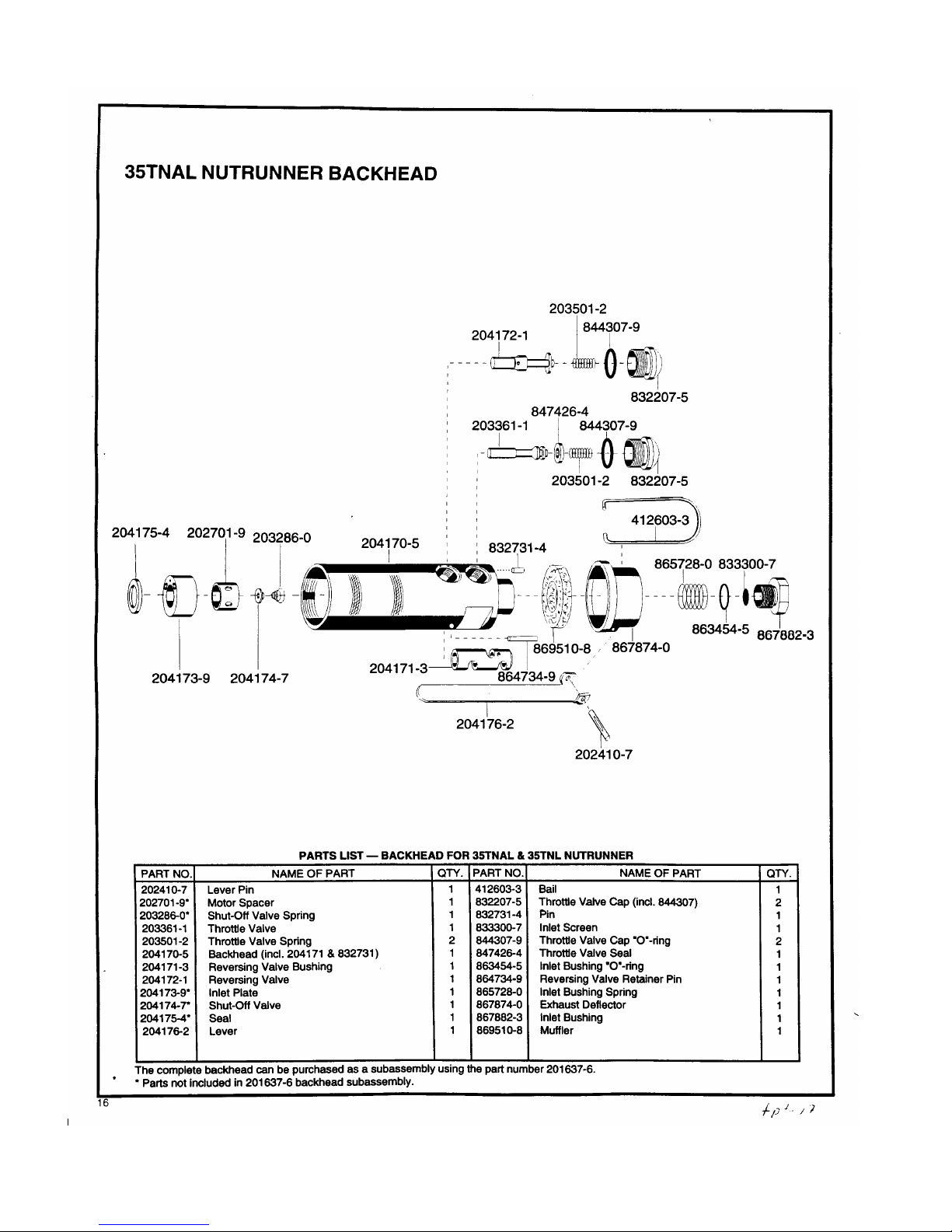

Page 10

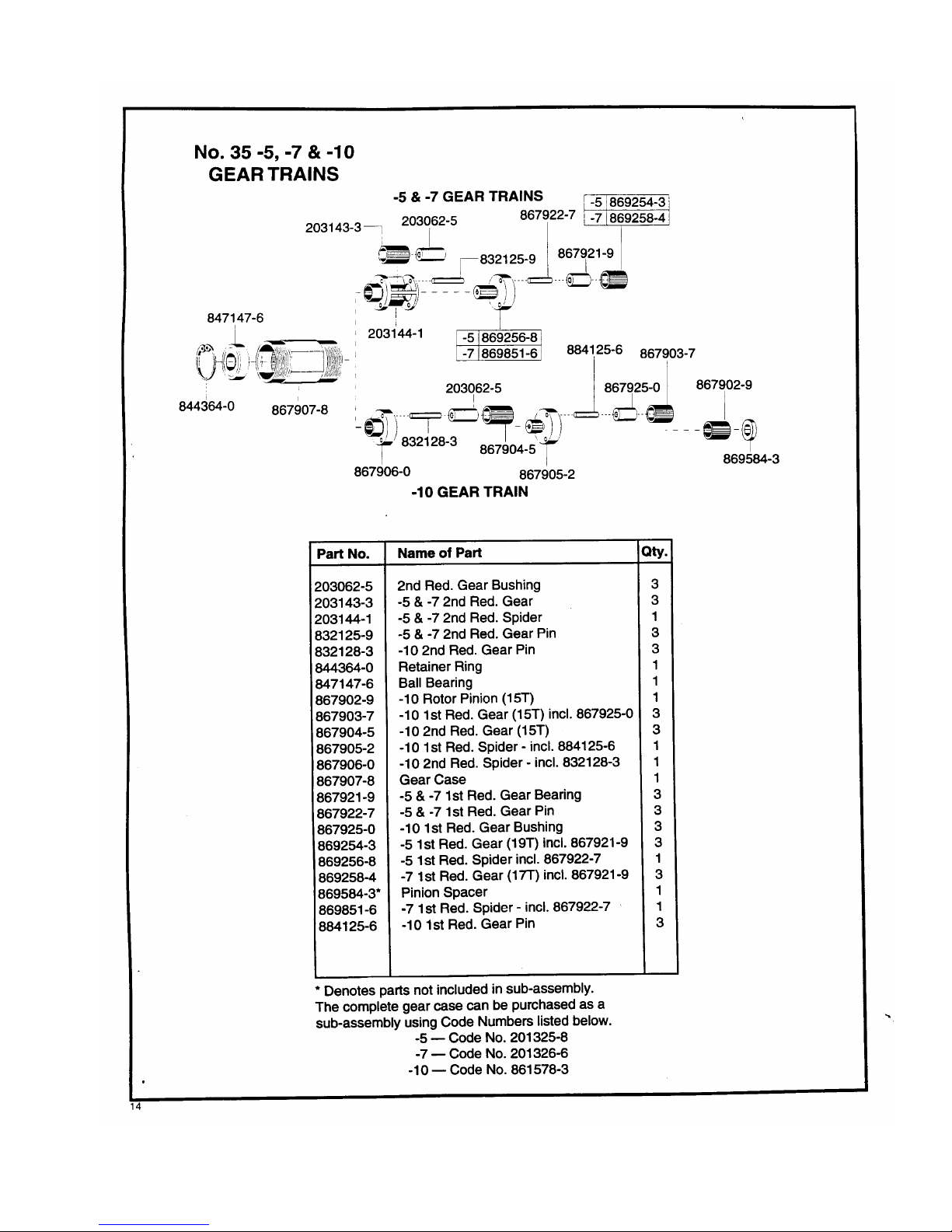

Page 11

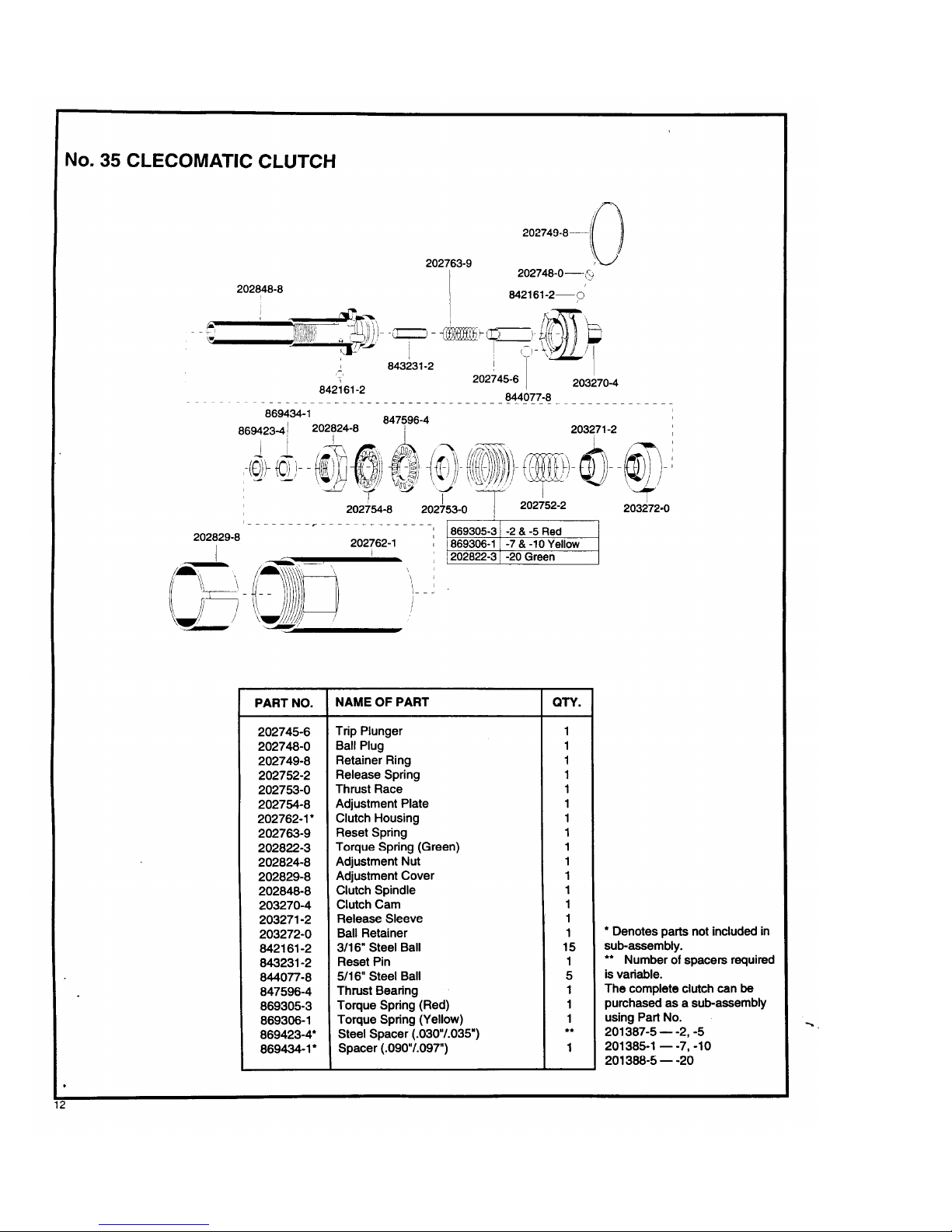

Page 12

Page 13

Page 14

Sales & Service Centers

Note: All locations may not service all products. Please contact the nearest Sales & Service Center for

the appropriate facility to handle your service requirements.

Dallas, TX Detroit, MI Houston, TX Lexington, SC

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center Sales & Service Center 670 Industrial Drive

1470 Post & Paddock 2630 Superior Court 6550 West Sam Houston Lexington, SC 29072

Grand Prairie, TX 75050 Auburn Hills, MI 48326 Parkway North, Suite 200 Tel: 800-845-5629

Tel: 972-641-9563 Tel: 248-391-3700 Houston, TX 77041 Tel: 803-951-7544

Fax: 972-641-9674 Fax: 248-391-7824 Tel: 713-849-2364 Fax: 803-358-7681

Fax: 713-849-2047

Los Angeles, CA Seattle, WA York, PA Canada

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center Sales & Service Center Sales & Service Center

15503 Blackburn Avenue 2865 152nd Avenue N.E. 3990 East Market Street 5925 McLaughlin Road

Norwalk, CA 90650 Redmond, WA 98052 York, PA 17402 Mississauga, Ont. L5R 1B8

Tel: 562-623-4457 Tel: 425-497-0476 Tel: 717-755-2933 Canada

Fax: 562-802-1718 Fax: 425-497-0496 Fax: 717-757-5063 Tel: 905-501-4785

Fax: 905-501-4786

Germany England France China

Cooper Power Tools Cooper Power Tools Cooper Power Tools SAS Cooper (China) Co., Ltd.

GmbH & Co. OHG GmbH & Co. OHG a company of a company of

a company of a company of Apex Tool Group, LLC Apex Tool Group, LLC

Apex Tool Group, LLC Apex Tool Group, LLC 25 rue Maurice Chevalier 955 Sheng Li Road,

Industriestraße 1 C/O Spline Gauges 77330 Ozoir-La-Ferrière Heqing Pudong, Shanghai

73463 Westhausen Piccadilly, Tamworth France China 201201

Germany Staffordshire B78 2ER Tel: +33 1 6443 2200 Tel: +86-21-28994176

Tel: +49 (0) 73 63 81 0 United Kingdom Fax: +33 1 6443 1717 Fax: +86-21-51118446

Fax: +49 (0) 73 63 81 222 Tel: +44 1827 8741 28

Fax: +44 1827 8741 28

Mexico Brazil Hungary

Cooper Tools Cooper Tools Industrial Ltda. Cooper Tools Hungaria Kft.

de México S.A. de C.V. a company of a company of

a company of Apex Tool Group, LLC Apex Tool Group, LLC

Apex Tool Group, LLC Av. Liberdade, 4055 Berkenyefa sor 7

Vialidad El Pueblito #103 Zona Industrial - Iporanga Pf: 640

Parque Industrial Querétaro 18087-170 Sorocaba 9027 Györ

Querétaro, QRO 76220 SP Brazil Hungary

Mexico Tel: +55 15 2383929 Tel: +36 96 66 1383

Tel: +52 (442) 211-3800 Fax: +55 15 2383260 Fax: +36 96 66 1135

Fax: +52 (442) 103-0443

90109-IM/Printed in USA 05/2011/Copyright © Apex Tool Group, LLC

Apex Tool Group, LLC

1000 Lufkin Road

Apex, NC 27539

Phone: 919-387-0099

Fax: 919-387-2614

www.apextoolgroup.com

Airetool®

This manual suits for next models

16

Table of contents

Popular Nail Gun manuals by other brands

Parkside

Parkside PDT 40 H6 Translation of the original instructions

Makita

Makita AF353 instruction manual

Hitachi

Hitachi NV65AC - 2-1/2" Full Head Pallet Coil Nailer Instruction and safety manual

Senco

Senco FramePro 600 FRH Specifications

Senco

Senco SN325+ operating instructions

Numax

Numax SST9032 user manual