Prebena 1GP-A16 User manual

PREBENA Wilfried Bornemann GmbH & Co. KG

Seestraße 20 –26, 63679 Schotten, Germany

Tel.: +49 (0) 60 44 / 96 01 –0, Fax: +49 (0) 60 44 / 96 01 –820

E-mail: info@prebena.com

www.prebena.de, www.kartuschen-tausch.de

Original Operating Instructions for

Pneumatically-Driven Tackers

1GP-A16

1GP-D16

1GP-V16

1GP-XA16

1GP-A16LN50

1GP-V16LN50

97510801

Preface

2

Preface

These operating instructions will help you with the

proper use as intended,

safe and

cost-effective

use of the following pneumatically-driven tackers:

1GP-A16

1GP-D16

1GP-V16

1GP-XA16

1GP-A16LN50

1GP-V16LN50

In the operating Instructions, these compressed air-driven staplers

and nail guns are referred to as tackers.

We assume that every person using the tacker has knowledge of

how to handle pneumatic equipment and the applied materials.

People who do not have this knowledge must be instructed by an

experienced user about how to use the tacker.

These operating instructions are directed at the following persons:

Persons who operate this tacker

Persons who clean this tacker or

Persons who dispose of this tacker.

All of these persons must read and understand these operating

instructions.

These operating instructions are considered a part of the product.

Always keep them with the tacker. Pass on the operating instructions

if you sell the tacker or hand it on in any other manner.

Table of contents

3

Table of contents

Preface...............................................................................................2

Table of contents..............................................................................3

Layout characteristics .....................................................................5

General layout characteristics............................................................5

Features of the danger warnings........................................................5

Features of the notes on property or environmental damage............6

Safety.................................................................................................7

Proper, intended use..........................................................................7

Improper use ......................................................................................7

Avoid the risk of fatal injuries..............................................................8

Avoid explosion hazards.....................................................................8

Avoid risk of injury ..............................................................................8

Avoid damage to the tacker................................................................9

Description......................................................................................10

Device overview ...............................................................................10

Scope of supply................................................................................11

Function............................................................................................11

Product features ...............................................................................11

Accessories ......................................................................................11

Information on the rating plate..........................................................12

Preparing the tacker.......................................................................13

Unpacking the tacker........................................................................13

Check condition................................................................................13

Connecting tacker to compressed air supply ...................................14

Opening magazine ...........................................................................16

Inserting fastener..............................................................................17

Closing magazine.............................................................................17

Checking function.............................................................................18

Operating the tacker.......................................................................19

Regulating the driving depth via operating pressure........................19

Check driving depth..........................................................................19

Table of contents

4

Driving in fasteners.......................................................................... 20

Triggering the tacker........................................................................ 21

After operation............................................................................... 22

Disconnect the compressed air supply............................................ 22

Emptying magazine......................................................................... 22

Transporting and storing the tacker............................................ 23

Packing............................................................................................ 23

Transportation.................................................................................. 23

Transport over short distances........................................................ 23

Transport over long distances ......................................................... 24

Storage ............................................................................................ 24

Servicing the tacker....................................................................... 25

Cleaning housing and external surfaces ......................................... 25

Slight contamination ........................................................................ 25

Serious contamination..................................................................... 25

Oil the tacker.................................................................................... 26

Malfunctions................................................................................... 27

Malfunction overview ....................................................................... 28

Ordering accessories.................................................................... 30

Reordering fasteners....................................................................... 30

1GP-A16 / 1GP-A16LN50................................................................ 30

1GP-D16.......................................................................................... 30

1GP-V16 / 1GP-V16LN50................................................................ 31

1GP-XA16........................................................................................ 31

Ordering other accessories ............................................................. 31

All types ........................................................................................... 31

Disposing of tacker ....................................................................... 32

Technical data................................................................................ 33

Manufacturer's address ................................................................ 34

Guarantee....................................................................................... 35

Index................................................................................................ 36

Layout characteristics

5

Layout characteristics

General layout characteristics

Various elements in the operating instructions are marked with

specific layout characteristics. This allows you to easily distinguish

whether it is normal text,

lists or

process steps

that you are reading about.

These instructions contain additional information such as

specific information on the cost-effective use of the tacker.

Features of the danger warnings

All danger warnings in these operating instructions are based on the

same pattern. On the left you will find a symbol indicating the type of

danger. To the right of that you will see a signal word which identifies

the severity of the danger. Under that you will find a description of

the source of danger and instructions on how to avoid this danger.

DANGER

Warnings with the word DANGER indicate

hazards with an immediate impending risk of

serious or even fatal injuries.

WARNING

Warnings with the word WARNING warn of

hazards that can lead to potentially serious or

even fatal injuries.

Layout characteristics

6

CAUTION

Warnings with the word CAUTION warn of

hazards that can lead to minor or moderate

injuries.

Features of the notes on property or environmental

damage

CAUTION

These notes warn about dangers that can lead to property or

environmental damage.

Safety

7

Safety

Read the operating instructions prior to initial operation.

Observe and follow all the warnings and instructions in these

operating instructions and those on the pressure equipment when

using the tacker. The enclosed spare parts list is an element of these

operating instructions.

Proper, intended use

The tackers are used to fasten film, padding, leather, insulation mats,

paper and cardboard materials on wood. Use of the tacker on other

materials is only permissible after consultation with the manufacturer.

Proper intended use also includes compliance with the accident

prevent regulations and the statutory regulations and standards in

force at the place of use. Use in any other way is not considered

proper intended use and can result in material damage or even

personal injury.

Improper use

Improper use refers, in particular, to operation

by persons without the necessary knowledge in the use of tackers

and the materials used,

of tackers modified without the authorisation of the manufacturer,

with accessories other than those stipulated in these operating

instructions,

connected to compressed air sources not listed in these operating

instructions.

PREBENA WILFRIED BORNEMANN GMBH & CO. KG accepts no

liability for any damage resulting from any such improper or

unspecified use.

Safety

8

Avoid the risk of fatal injuries

During the triggering sequence and whenever the tacker is

connected to the air supply, ensure that body parts are not near

the opening.

Only trigger the tacker when the tool lug is pressed onto the

workpiece.

Do not allow children to play with packaging films - risk of

suffocation.

Avoid explosion hazards

Do not use the tacker in areas with an explosion hazard.

Never operate the tacker with oxygen or other explosive gases or

gas mixtures.

Avoid risk of injury

Wear hearing protection when operating the tacker.

Wear safety goggles when operating the tacker.

Store the tacker out of the reach of children and other

unauthorised persons.

Always disconnect the tacker from the compressed-air supply

before transporting.

When operating the tacker, always wear safety goggles, hearing

protection and sturdy working clothes.

Hold the tacker such that the possibility of injury caused by

kickback is excluded.

Only use the tacker if your are standing in a safe position.

Safety

9

Avoid damage to the tacker

Never open the tacker. Always leave repairs to qualified

specialists.

Do not use the tacker if it has been dropped or is damaged. Have

it inspected by qualified specialists before putting it into use

again.

Do not connect the tacker to a compressed air supply where the

maximum operating pressure of 7 bar is exceeded.

Install permanently mounted tackers only in safely anchored

mounts. It must not be possible to rotate or shift the tacker. The

mount must not cause damage to the tacker and its accessories.

Description

10

Description

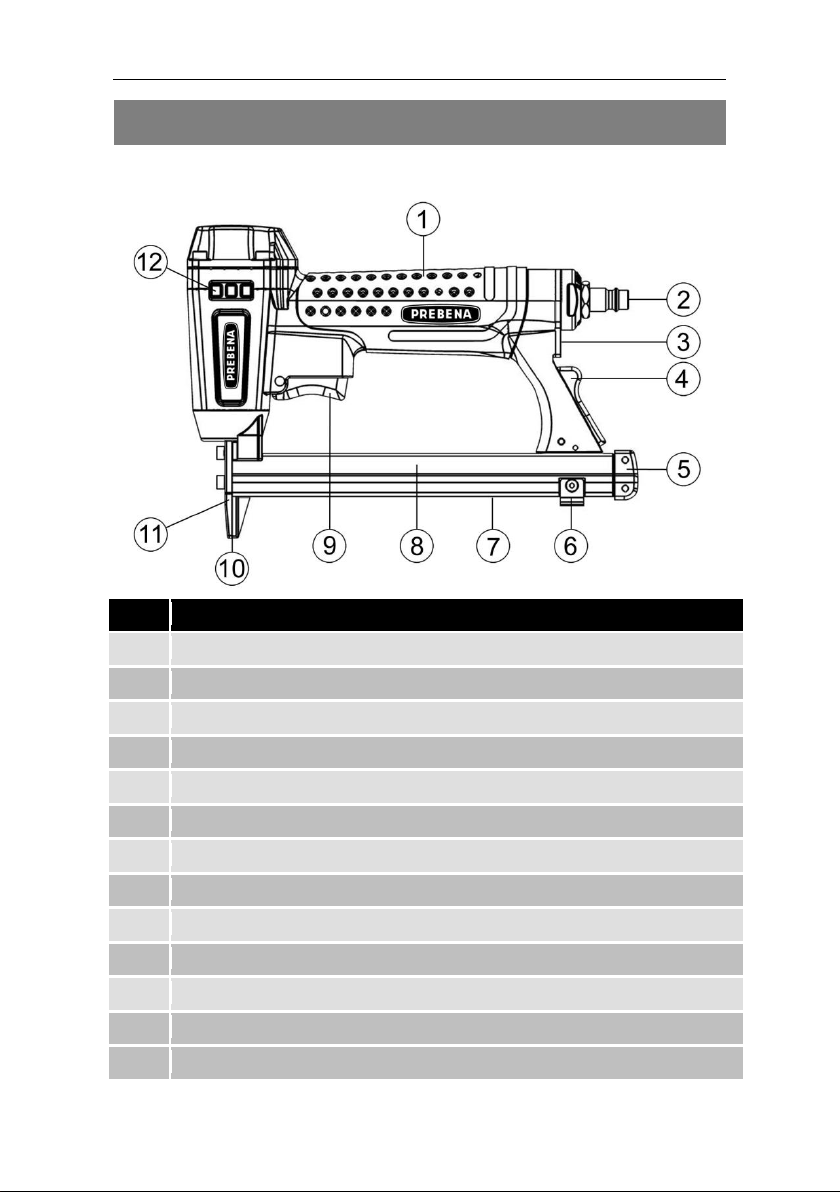

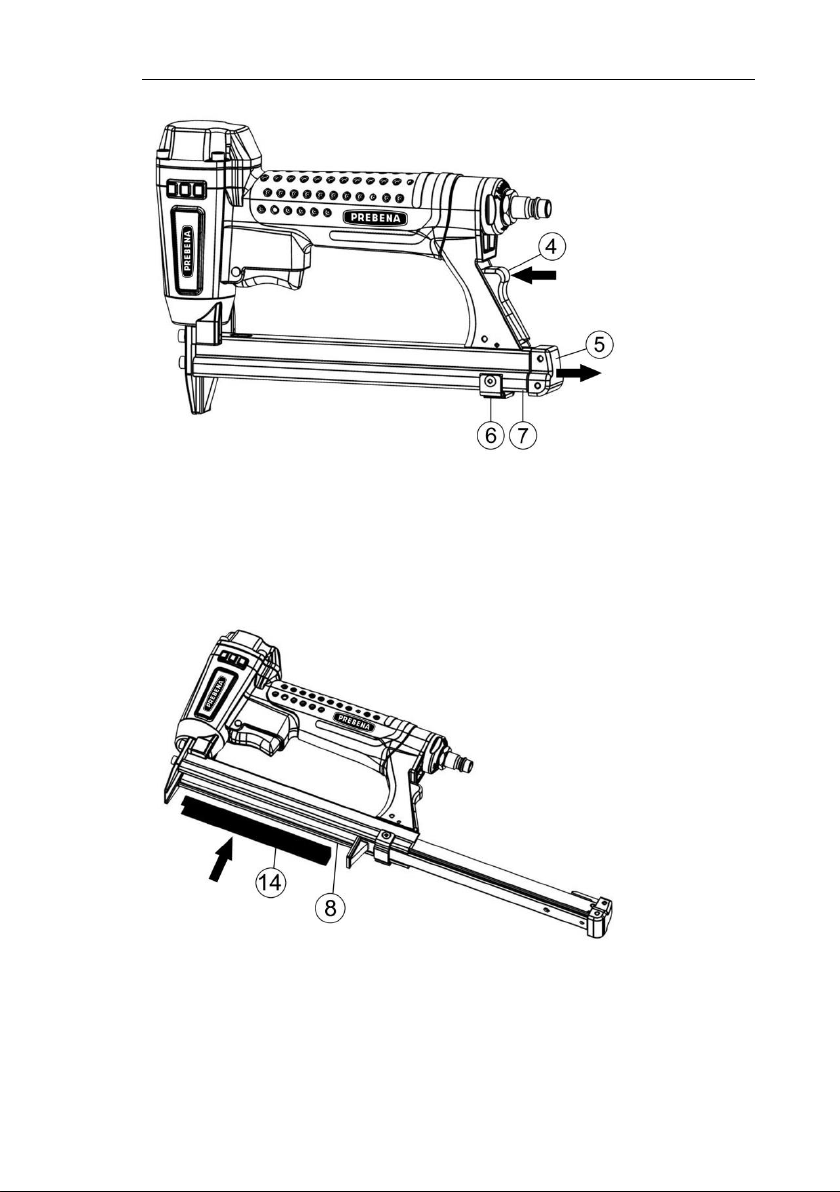

Device overview

No.

Explanation

1

Handle

2

Compressed air supply, ID 7.2

3

Ventilation

4

Lock for lower pusher

5

Closure for lower pusher

6

Stop for lower pusher

7

Lower pusher

8

Magazine

9

Trigger lever

10

Opening

11

Tool plate

12

Lateral contact protection

-

Rating plate on the magazine (without illustration)

Description

11

Scope of supply

Tacker

Packaging board

Operating instructions

Declaration of Conformity

Function

The tackers drive individual PREBENA fasteners by means of

compressed air into wooden or textile materials. All tackers work with

compressed air that corresponds at least to quality class 4 according

to DIN ISO 8573-1. The compressed air source is PREBENA

compressors or the PREBENA PKT compressed air cartridge

technology. They can be ordered from the accessories range from

the manufacturer (see page 30).

Product features

The tackers have the following common features:

Sound absorbers

Individual triggering

Ergonomic handle design

Lateral resting surface protection

Accessories

Compressors for compressed

air supply (see Manufacturer,

page 34)

PKT compressed air cartridge

technology for compressed air

supply (see Manufacturer,

page 34)

Fasteners (see Overview,

page 30 ff)

PREBENA special nailer oil

Z 200.10

Micro-mist oiler Z 200.00

Air hose set 9 mm Z 200.20

Spiral hose Z 160.12

Hose drum Z 180.00

Description

12

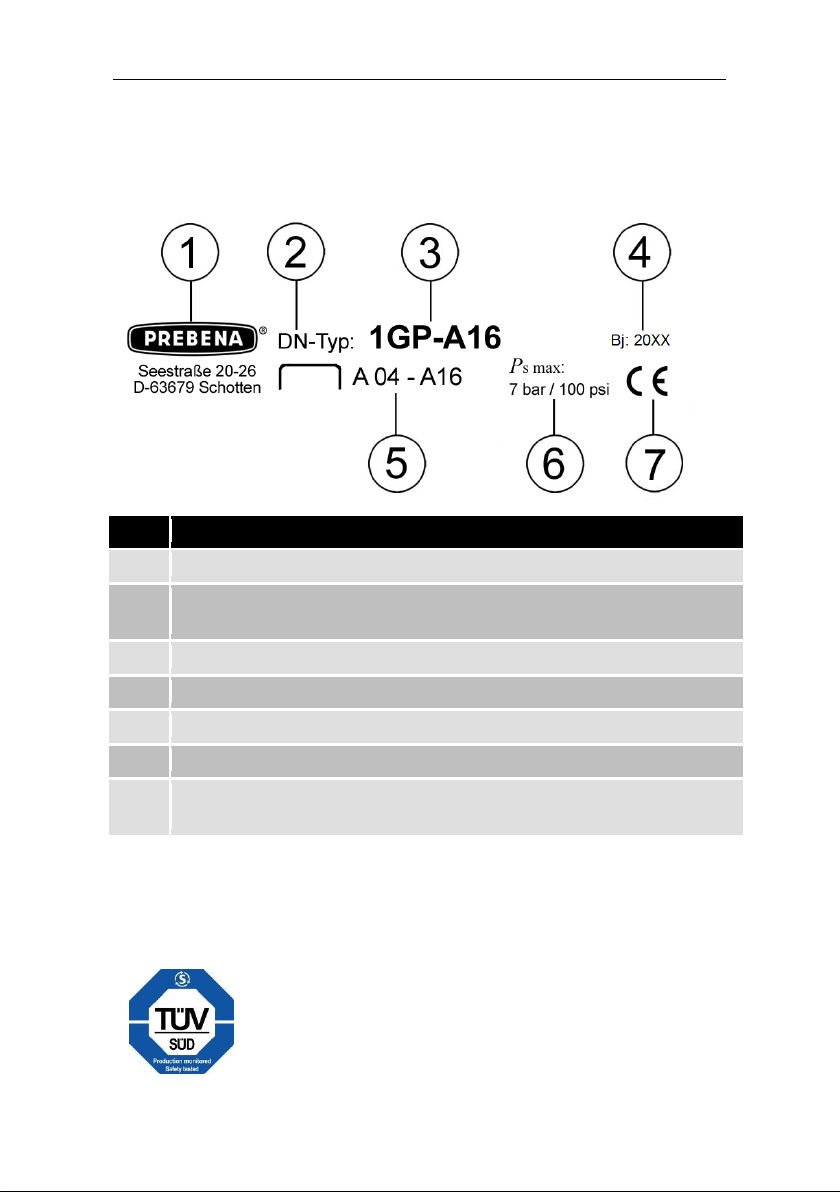

Information on the rating plate

The rating plate is glued to the top side of the magazine. It contains

the following information:

One further sticker is attached alongside the rating plate. This has

the following meaning:

Sticker

Meaning

The product was tested on a voluntary basis by TÜV SÜD to

ensure compliance with the essential requirements.

No.

Explanation

1

Company name and full address of the manufacturer

2

Designation of machine - DN = Druckluftbetriebenes Eintreibgerät

(Pneumatically-driven tacker)

3

Model designation

4

Year of manufacture

5

Model designation of fasteners used

6

Maximum permissible operating pressure

7

CE symbol (the product conforms to the standards listed in the included

Declaration of Conformity)

Preparing the tacker

13

Preparing the tacker

Unpacking the tacker

Remove the tacker from the packaging.

Remove all packaging materials, such as plastic films, filler

material and the cardboard box.

WARNING

Do not allow children to play with plastic

packaging films. Risk of suffocation!

Do not allow children to play with plastic packaging films.

Keep the packaging material out of reach of children.

Save the packaging material for later use.

Store the cardboard box for transporting the tacker.

The tacker must only be transported in the cardboard box.

Check condition

WARNING

There is a risk of injury when using a

damaged tacker and if the accessories are

not correctly fastened.

Check the condition of the tacker before each use.

Ensure that the tacker is in perfect condition.

Check the following points in particular:

-The hose line must not be damaged.

-All parts of the tacker and all accessories must be securely

attached.

-The safety devices must not be blocked or otherwise impaired

in their function.

Preparing the tacker

14

-No parts of the tacker or the accessories may show visible

signs of damage, such as scratches or dents.

Scratches on the housing paint or the magazine do not

constitute damage.

Do not connect a damaged tacker to a compressed air supply.

Have a damaged tacker repaired by qualified specialists before

putting it into operation.

Connecting tacker to compressed air supply

You can connect the tacker to a compressor or a compressed air

system.

Operation with a compressor or a compressed air system is only

permitted if the following preconditions are met:

The operating pressure of the compressor or compressed air

system must not be more than 10% above the maximum

operating pressure of the tacker. Specifications on the operating

pressure of the tackers are provided in this chapter on page 14.

On compressed air systems with higher pressure, a pressure

regulating valve (pressure reducer) with a downstream pressure

relief valve must be installed in the compressed air line.

The compressed air must be filtered, dry and lubricated with

PREBENA special nailer oil.

At the outlets for the compressed air line to the tacker, a

compressed air maintenance unit must be installed on the

coupling side. It should contain

-a filter,

-a water separator and

-an oiler.

If no oiler is installed, the length of the air line to the tacker must

not exceed 10 m. Otherwise three to five drops of PREBENA

special nailer oil must be filled directly into the air inlet of the

tacker every day prior to use.

The compressed air system must be able to maintain operating

pressure even during the desired air removal.

The inside diameter of the air line must be at least 6 mm.

The connection for the tacker must be fitted with a quick-action

coupling, ID 7.2 and have an inside diameter of at least 6.5 mm.

Preparing the tacker

15

CAUTION

Operation on compressed air systems that do not

meet the above-mentioned preconditions can lead

to damage to the tacker.

Only operate the tacker on suitable compressed air systems.

Only use the tacker if it is in perfect working order.

Check the condition of the tacker (see page 13).

Check the connection for the air hose for foreign bodies and

contamination and clean it if necessary.

Set the operating pressure at the pressure regulator of the

compressor to 4.0 –7.0 bar.

WARNING

Accidental triggering when connecting to the

compressed air supply can result in serious or

fatal injury.

Never direct the tacker at people or animals.

Empty the magazine prior to connection.

CAUTION

Damaged hose lines can burst and cause

injury.

Check the compressed air system and tacker for damage

before connecting them.

Only connect the tacker to a functioning compressed air

system.

CAUTION

Damaged hose lines can burst and cause damage when

compressed air escapes.

Check the compressed air system and tacker for damage

before connecting them.

Only connect the tacker to a functioning compressed air

system.

Preparing the tacker

16

Push the quick coupler (1) of the air hose onto the connection (2)

until it engages audibly.

Check the operating pressure at the pressure display of the

compressor.

The maximum permissible operating pressure of the tackers is

7.0 bar.

WARNING

Risk of explosion if the maximum operating

pressure is exceeded.

In this case, immediately disconnect the compressed air

hose from the tacker.

Opening magazine

To open the magazine (7), press the lock (4) forwards in the

direction of the arrow.

Pull out the lower pusher at the closure (5) to the rear.

Preparing the tacker

17

Inserting fastener

To insert the fastener (14) in the magazine, turn the tacker upside

down and place the staple bars with the back downwards in the

magazine.

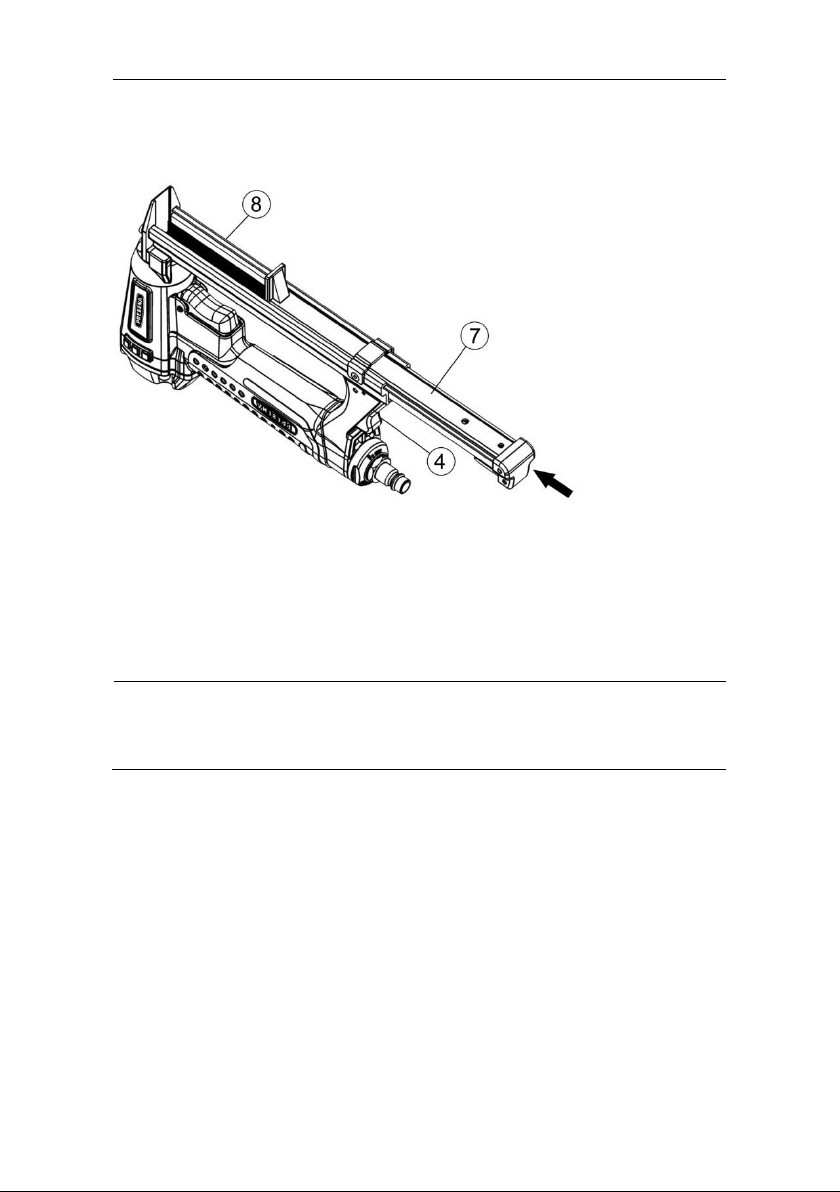

Closing magazine

To close the magazine (8), press the lower pusher (7) forwards

again.

Preparing the tacker

18

Ensure that the lower pusher (7) engages at the lock (4).

Push the lock (4) forwards if necessary.

The magazine is closed.

Checking function

To check correct operation of the tacker, proceed as follows:

CAUTION

Observe the danger notes in the chapter on 'Safety' from page

7 ff.

Set the tool lug of the tacker on a piece of wood with a minimum

thickness of 20 mm.

Trigger the tacker (see chapter "Triggering device" on page 21).

Check the following properties:

-Every time the device is triggered, a fastener must be driven

into the piece of wood.

-To achieve the desired driving depth, alter the operating

pressure of the compressor (see page 15).

Repeat these steps if necessary.

The tacker is not ready for operation.

Operating the tacker

19

Operating the tacker

Regulating the driving depth via operating pressure

The driving depth of the fastener in the material can be set by

regulating the operating pressure. At a high operating pressure, the

fasteners are driven in deeper and not so deep at a lower operating

pressure.

Adjust the operating pressure so that the desired driving depth

is just reached. This offers the following advantages:

You save energy (compressed air),

You reduce the noise level, and

You reduce the wear on the tacker.

To adjust the operating pressure, proceed as follows:

Hold the tacker so that the tool lug faces down.

Adjust the pressure at the pressure regulator of the compressor.

Observe the pressure display of the compressor.

Check driving depth

Press the tool lug onto a sample wooden workpiece with the

same properties as the material to be worked on.

Check the setting by triggering once on the sample material.

Repeat these steps until the desired driving depth is set.

Operating the tacker

20

Driving in fasteners

WARNING

Risk of injury due to electric shock.

Before triggering the tacker, always ensure

that a power supply line cannot be struck.

WARNING

During operation, injuries to the eyes and other

body parts are possible due to flying splinters.

Always wear safety goggles during operation and suitable

protective clothing.

Observe the valid work protection regulations.

WARNING

Loud operating noises can cause damage to

hearing.

Wear suitable ear protection.

Observe the valid noise protection regulations.

Select the lowest possible operating pressure.

When fasteners are driven into workpieces that are too hard, or into

other fasteners, a powerful kickback is generated. This can cause

the tacker to slip off.

WARNING

Risk of injury when nails slide off or are driven in

too far or due to kickback.

Only use the tacker for wooden objects.

Ensure that the driving depth is not set deeper than the

thickness of the piece of wood.

When triggering, press the tacker firmly against the wood

Other manuals for 1GP-A16

1

This manual suits for next models

5

Table of contents

Other Prebena Nail Gun manuals

Popular Nail Gun manuals by other brands

Cleco

Cleco 15ML-1.6B- 837 Operating instructions and service manual

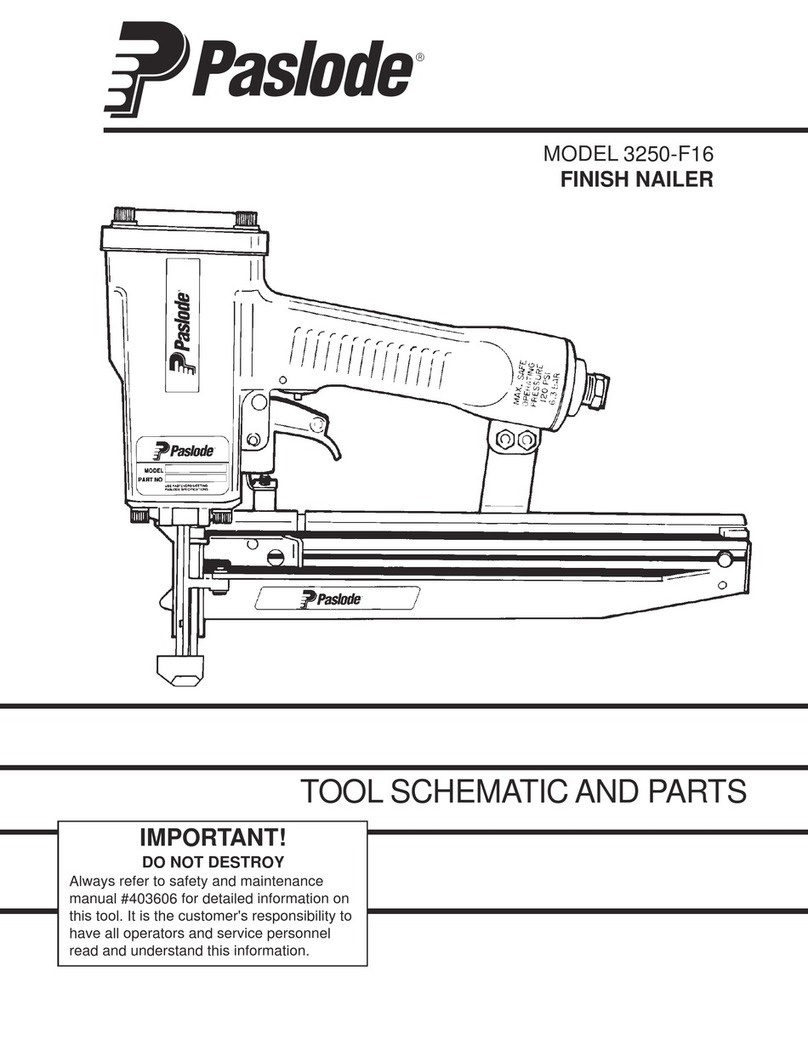

Paslode

Paslode PS225C Operating manual and schematic

Everwin

Everwin PN70CL Operation and maintenance manual

Makita

Makita DPT350 instruction manual

Paslode

Paslode 3250-F16 TOOL SCHEMATIC AND PARTS

Bostitch

Bostitch N95162 Operation and maintenance manual