AeroPlus Corvus Racer 540 User manual

Table of contents

Other AeroPlus Toy manuals

AeroPlus

AeroPlus Extra 330LT User manual

AeroPlus

AeroPlus A?G030010A User manual

AeroPlus

AeroPlus Edge 540 V3 35CC User manual

AeroPlus

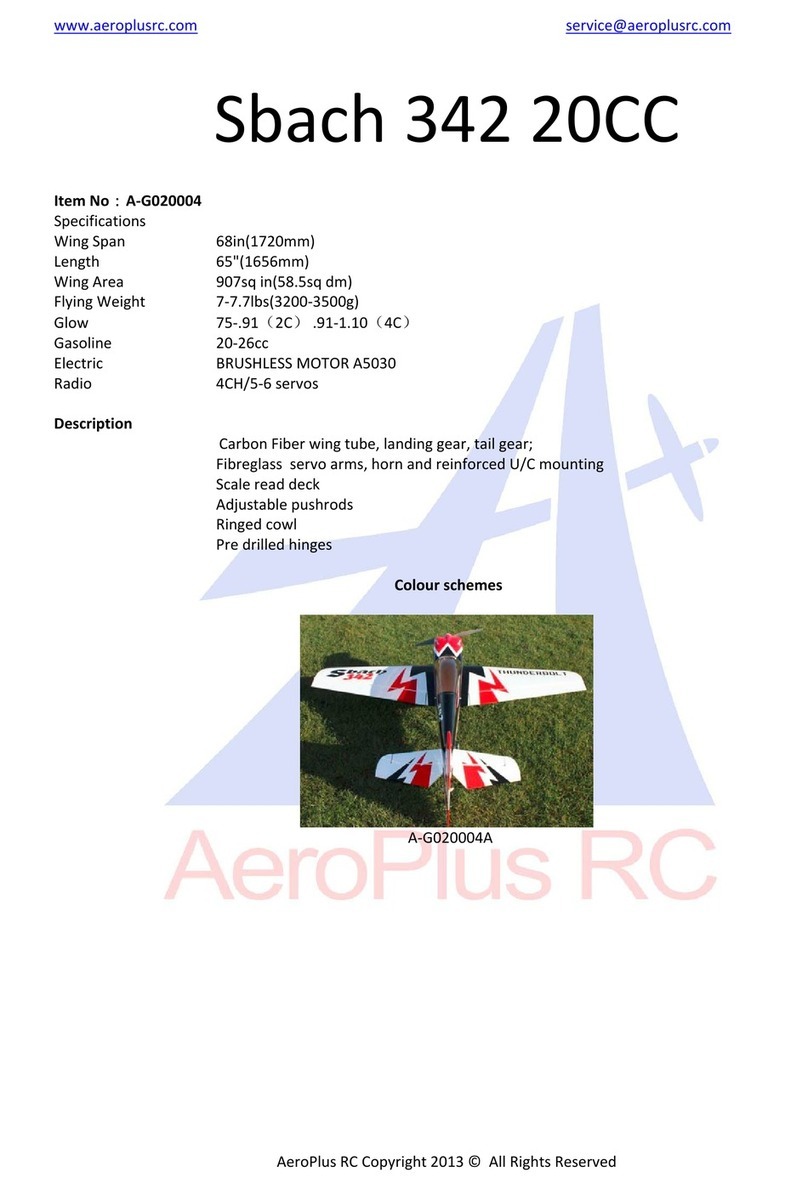

AeroPlus Sbach 342 20CC User manual

AeroPlus

AeroPlus YAK 55M User manual

AeroPlus

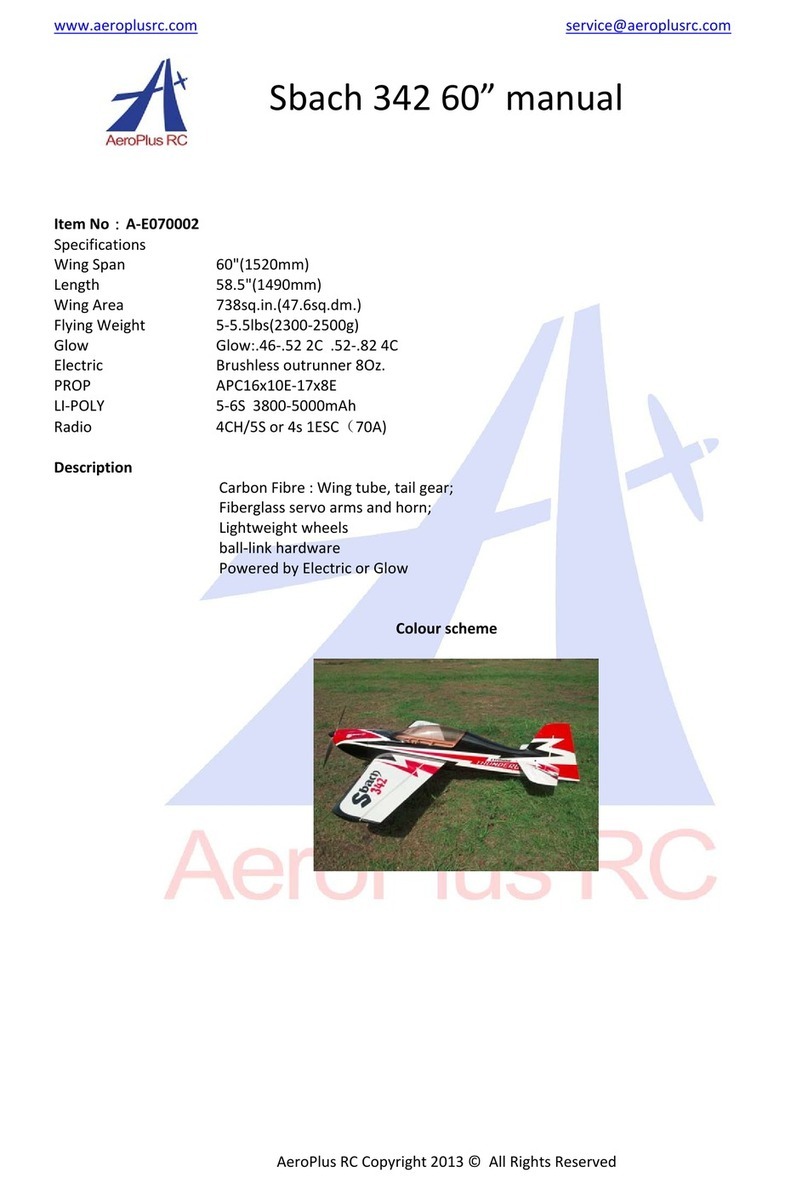

AeroPlus Sbach 342 User manual

AeroPlus

AeroPlus MXS-R 30CC User manual

AeroPlus

AeroPlus Corvus Racer 540 59 User manual

AeroPlus

AeroPlus EXTRA 330SC 60CC User manual

AeroPlus

AeroPlus Edge 540 V3 20CC User manual

Popular Toy manuals by other brands

LEGO

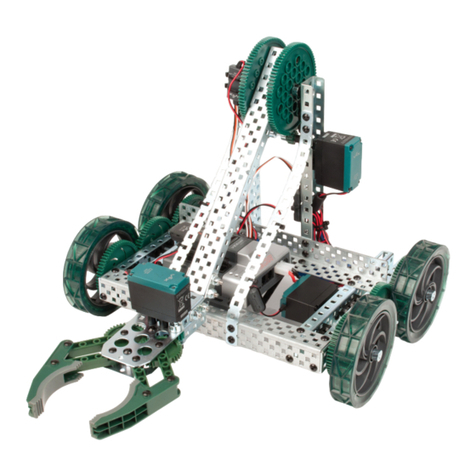

LEGO Mindstorms education 9797 Assembly manual

Enabling Devices

Enabling Devices Rusty user guide

Harbor Freight Tools

Harbor Freight Tools 62578 Owner's manual & safety instructions

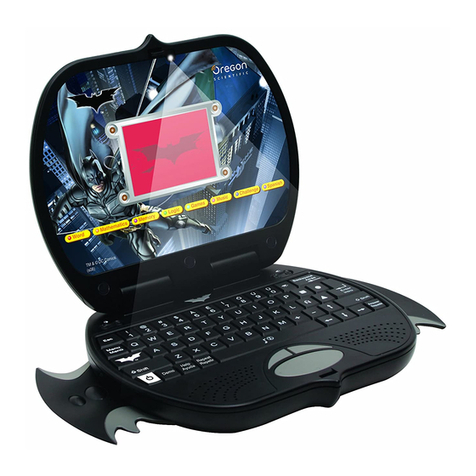

Oregon Scientific

Oregon Scientific Batman Power Wing Laptop manual

Canon

Canon CREATIVE PARK Shoebill Assembly instructions

Elves & Angels

Elves & Angels Anna's Dollhouse Assembly instructions