Airglas, Inc.

Manual # LH4000-106

6 | P a g e

MANUAL REVISION B December 3, 2012

THIS MANUAL INCLUDES INFORMATION PROPRIETARY TO

Airglas, Inc.

AND SHALL NOT BE USED TO MANUFACTURE OR REPRODUCE ANY PART OR

ASSEMBLY WITHOUT THE PRIOR WRITTEN PERMISSION OF

Airglas, Inc.

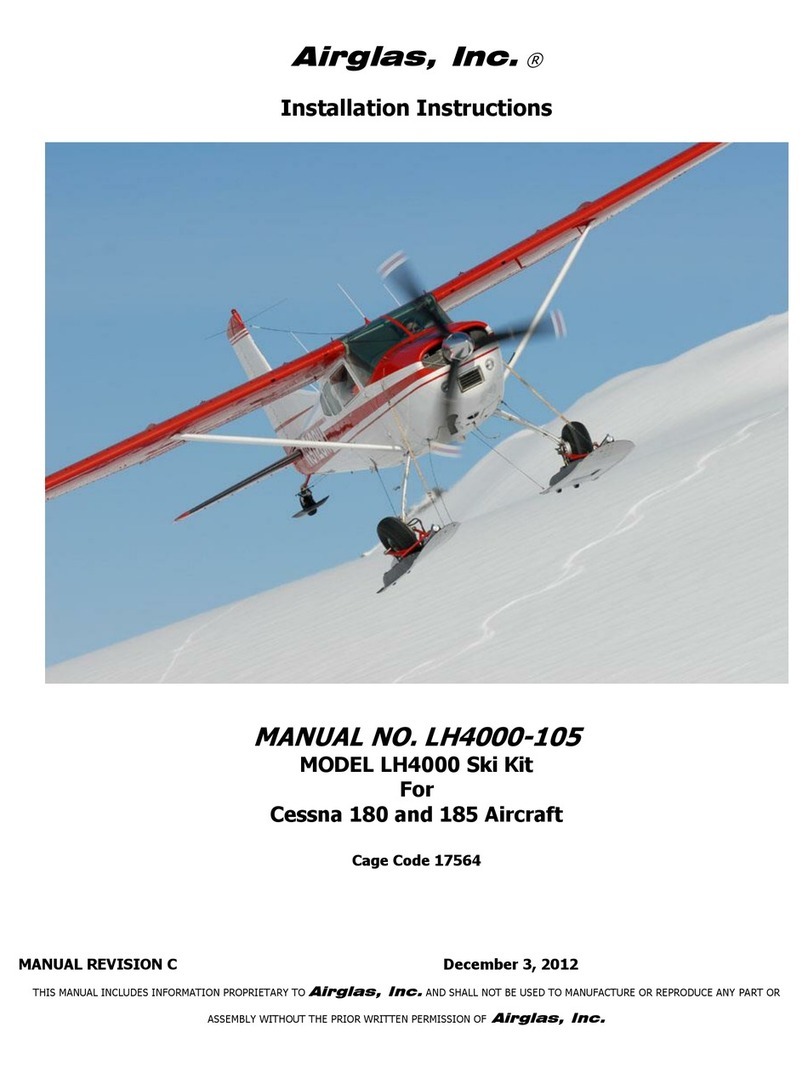

1.0 INTRODUCTION AND DESCRIPTION

Introduction: Since1955

Airglas, Inc.

has designed and manufactured a full line of composite

skis that dramatically increase the usefulness of the aircraft by allowing it to operate on snow or

frozen surfaces. The installation of the LH4000 hydraulic wheel ski kit allows the aircraft to operate

on paved or hard surfaces, and snow. The skis are actuated by a hydraulic cylinder on each ski with

an electric/hydraulic or hand pump to provide operating pressure. The ski is pushed down as a sliding

door closes the opening in the ski and causes the tire to ride up on top of the door. The door closes

off the wheel opening, thus creating the performance characteristics of a “straight ski”. When the

airplane is on snow, deploying to the ski position dramatically improves the takeoff performance

(compared to wheel penetration skis). The simplicity of this design allows for a low maintenance high

performance ski kit.

Description: The LH4000 ski kit consists of essentially 4 systems;

1. The Mechanical System –This includes the ski with all attaching hardware (interface to the

gear leg) and the rigging components.

2. The Hydraulic System –This includes hydraulic lines (both onboard and external), hydraulic

actuating cylinders (on the skis), all the hydraulic fittings on the skis, and the hydraulic pump.

3. The Electrical System –This includes pressure switches, a circuit breaker, wiring, a control

switch and indicator lights (the electric pump is covered under the hydraulic system).

4. Placards and Markings- This includes the flight manual supplement, placards, and instrument

markings.

Instructions for initial installation of this kit are detailed within manual LH4000-105.

Notes:

1.

All hardware in this kit shall be installed and torqued IAW AC 43.13-1B Chapter 7, Par 7-40,

Table 7-1 and table 7-2, unless otherwise specified.

2. Aircraft must be equipped with 8.50x6 main tires for ski operations.

1.1 SKI RIGGING BRACKETS AND ATTACH FITTINGS

The aircraft must have the brackets and attach fittings installed on the fuselage for the rigging to

attach.