D-17-623-01 rev.7 17-623-01-rev.7 05/11/20

NMEA 2000®Network

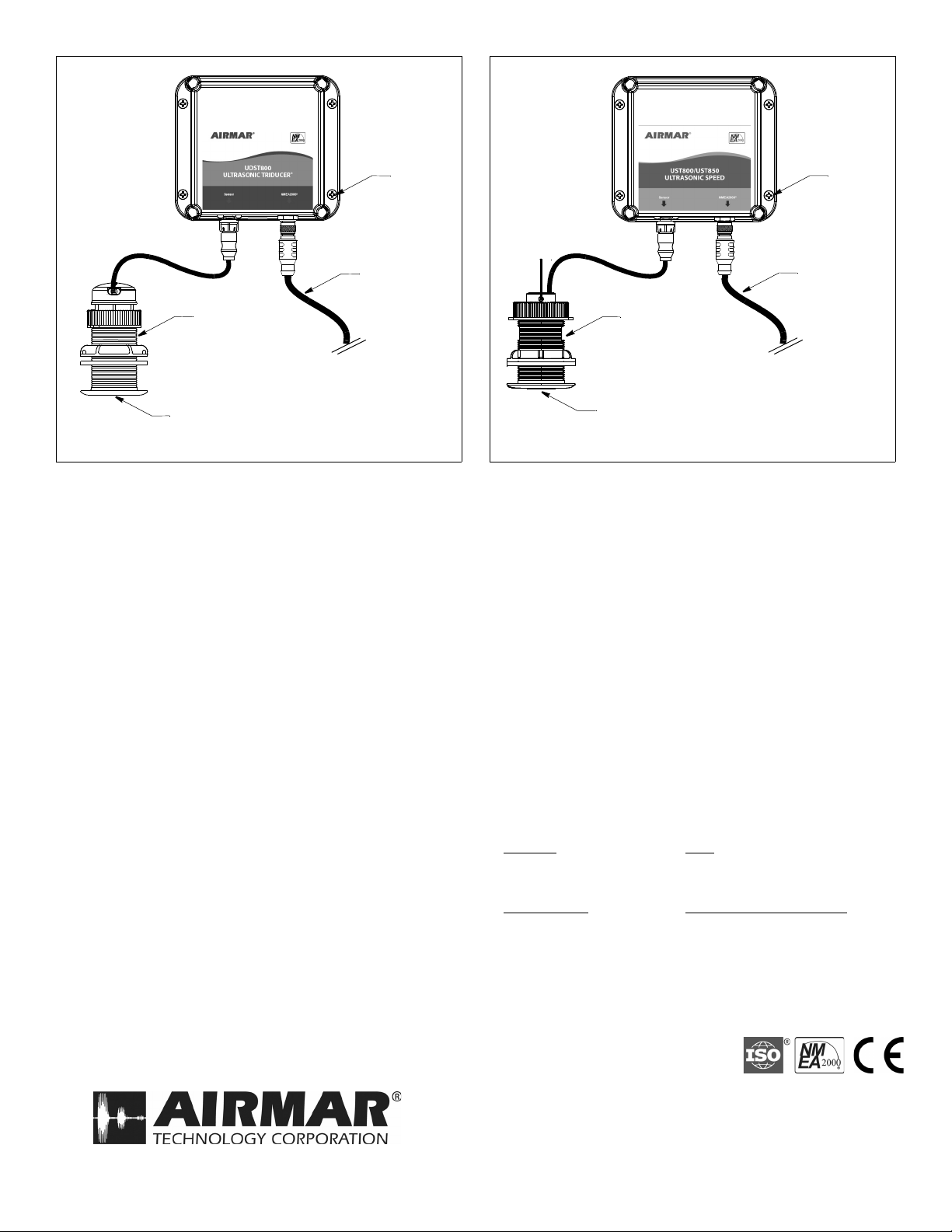

Ultrasonic Processor

for Models: UDST800, UST800, UST850

Patent http://www.airmar.com/patent.html

Applications

Connect to an NMEA 2000 network.

Installation

Locating the Ultrasonic Processor

CAUTION: If the processor will be mounted on a vertical surface,

face the connectors downward to avoid water seeping into the box.

1. Select a convenient, dry, mounting location for the water-

resistant Ultrasonic Processor a minimum of 1m (3') from other

cables and electronic equipment.

2. Hold the processor at the selected location and mark the

position of the four screw holes with a pencil.

3. At the marked locations, drill a 3mm or 1/8" hole to a depth of

10mm (3/8").

4. Fasten the processor to the selected mounting surface, using

the screws supplied.

Routing the Cables & Connecting

CAUTION: Do not remove connectors to ease cable routing. If the

cable must be cut and spliced, use Airmar’s splash-proof Junction

Box No. 33-035 and follow the instructions supplied. Removing

the waterproof connector or cutting the cable, except when using

a watertight junction box, will void the sensor’s warranty.

1. Route the cables to the Ultrasonic Processor. Be careful not to

tear the cable jacket when passing it through the bulkhead(s)

and other parts of the boat. Use grommets to prevent chafing. To

reduce electrical interference, separate the sensor cable from

other electrical wiring and the engine. Do not fasten the cables

in place at this time.

2. Connect the cables to the Ultrasonic Processor (Figure 1 or 2).

3. Fasten all the cables in place. Coil any excess cable and

secure it with cable-ties to prevent damage.

Record the information found on the cable tag for future reference.

Part No._________________Date___________

Follow the precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING: Always wear safety glasses, a dust mask,

and ear protection when installing.

WARNING: The power must be OFF before proceeding.

WARNING: The power supply voltage must be

9 – 16VDC.

WARNING: A safe installation requires a 0.5 amp fast-

blow fuse or circuit breaker.

CAUTION: To reduce electrical interference from

other electrical wiring and any on-board equipment with

strong magnetic fields such as radar equipment, radio

transmitters, boat engines, generators, etc., separate

the Ultrasonic Processor and cables by at least 1m (3').

CAUTION: Never use solvents. Cleaner, fuel, sealant,

paint, and other products may contain solvents that

can damage plastic parts.

IMPORTANT:Read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

OWNER’ S GUIDE & INSTALLATION INSTRUCTIONS

Tools & Materials

Safety glasses

Dust mask

Ear protection

Pencil

Electric drill

Drill bit 3mm or 1/8"

Phillips screwdriver

Grommet(s) (some installations)

Cable ties