17-584-01 rev. 02 07/24/18

Surface Mount: Analog

Temperature Sensor

Model: T80

Patent http://www.airmar.com/patent.html

Applications

• Measures air or water temperature.

• Stainless steel sensor is compatible with all hull materials.

Recommended for aluminum hulls to prevent electrolytic

corrosion, provided the stainless steel sensor is isolated from

the metal hull by using marine sealant.

Mounting Location

The sensor can be mounted anywhere that you want to know the

temperature. For example, you can mount the sensor on the

transom, in the live well, or in the engine compartment.

If you are measuring water temperature, choose a location where

the sensor will be in contact with the water at all times.

Installation

Mounting on the transom

CAUTION: Mount the sensor as close to the centerline (keel) of

the boat as possible to ensure the sensor remains in the water

when the boat is turning (Figure1).

CAUTION: Fiberglass hull—Minimize surface cracking by

running the drill in reverse until the gelcoat is penetrated.

CAUTION: If the sensor came with a connector, do not remove it

to ease cable routing. If the cable must be cut and spliced, use

Airmar’s splash-proof Junction Box No. 33-035 and follow the

instructions provided. Removing the waterproof connector or

cutting the cable, except when using a water-tight junction box,

will void the sensor warranty.

Record the information found on the cable tag for future reference.

Part No._________________Date___________

Follow the precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING: Always wear safety glasses, a dust mask,

and ear protection when installing.

WARNING: Below the waterline mount—When the

boat is placed in the water, immediately check for

leaks around the screws and any other holes drilled in

the hull.

CAUTION: Installation on a metal hull—The

stainless steel housing must be isolated from a metal

hull to prevent electrolytic corrosion. Use marine

sealant.

CAUTION: Never install a metal sensor on a vessel

with a positive ground system.

IMPORTANT:Read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

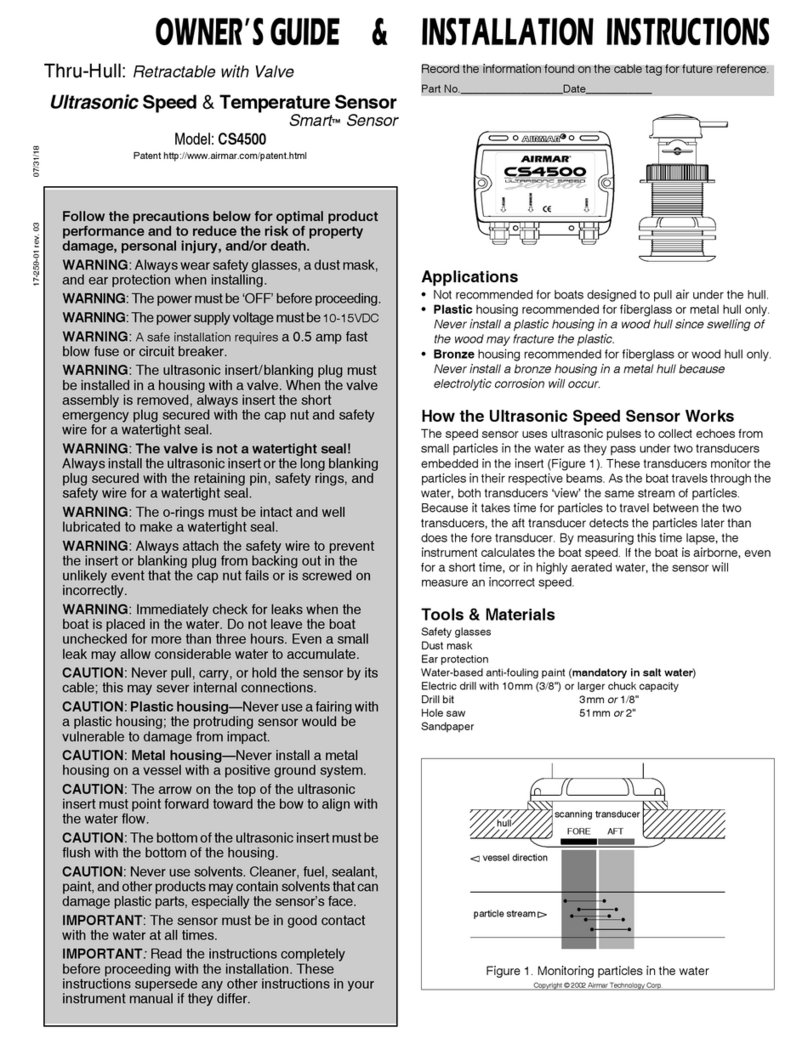

T80

Figure 1. Mounting on the transom

Copyright © 2014 Airmar Technology Corp.

transom hole

sensor cable

T80 sensor

Tools & Materials

Safety glasses

Dust mask

Ear protection

Pencil

Electric drill

Drill bit/hole saw/spade bit:

Pilot holes 3mm or 1/8"

Transom hole (some installations) 18mm or 3/4"

2 Stainless steel, self-tapping screws 4 x 18mm or #8 x 3/4"

Marine sealant (suitable for below waterline)

Screwdriver(s)

Cable clamp(s) (some installations)

Grommet(s) (some installations)

Cable ties

OWNER’ S GUIDE & INSTALLATION INSTRUCTIONS