1 Use

1.1 Intended use

TopVent® DGV units are heaters intended for heating high

spaces operating with air recirculation.

Intended use also includes compliance with the operating

instructions. Any use beyond this is considered improper

use. The manufacturer can accept no liability for damage

resulting from improper use.

1.2 User group

The units are only allowed to be installed, operated and

maintained by authorised and instructed personnel who

are well acquainted with the units and are informed about

possible dangers.

The operating instructions are for operating engineers and

technicians as well as specialists in building, heating and

ventilation technology.

1.3 Hazards

TopVent® DGV units are state-of-the-art and safe to operate.

Despite every precaution being taken, potential and not

immediately obvious risks always remain, for example:

■Dangers when working with the electrical system

■Dangers when working with components of the gas circuit

■When working on the unit, objects (e.g. tools) could be

dropped.

■Malfunctions as a result of defective parts

■Danger caused by coming in contact with hot components

when carrying out work inside the unit or on the ue gas

system

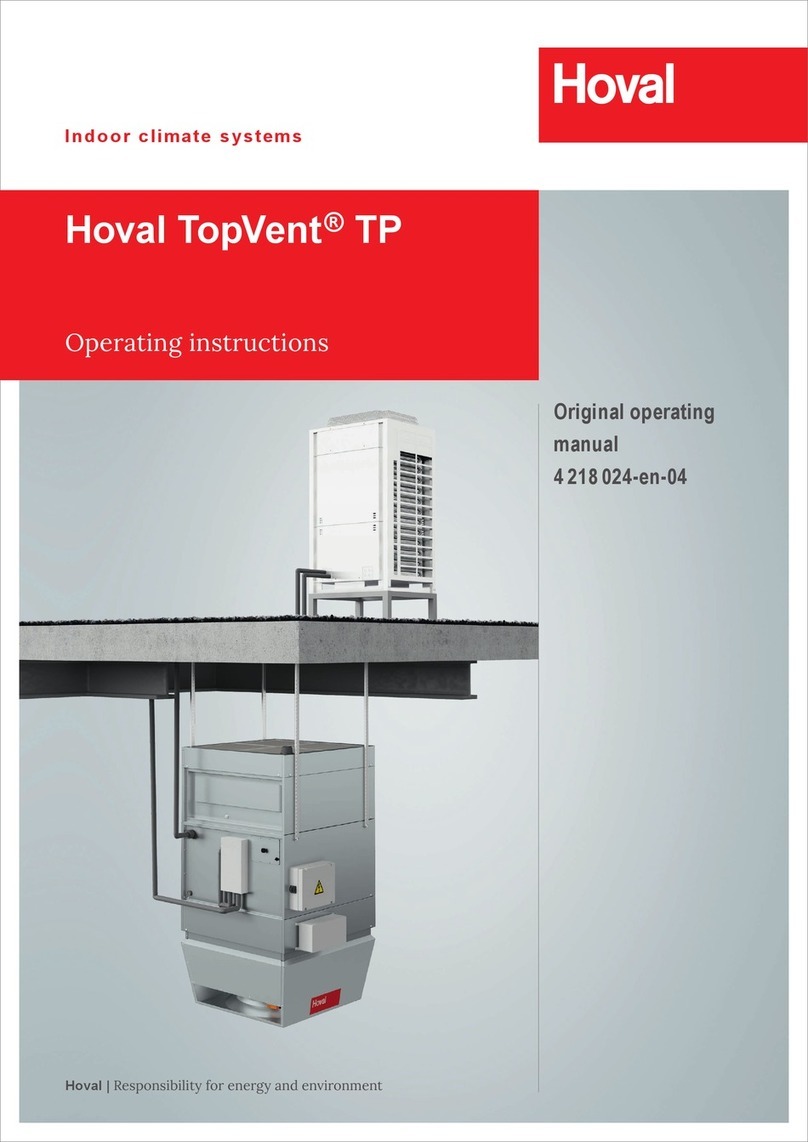

2 Construction and operation

TopVent® DGV has been specially developed for use in high

spaces. It fulls the following functions:

■Heating (with gas-red heat exchanger)

■Recirculation operation

■Air distribution with Air-Injector

■Air ltration (optional)

The unit is mounted under the ceiling and draws in interior

air. The air is heated in a gas-red heat exchanger and

injected back into the room through the Air-Injector.

Thanks to its high performance and ecient air distribution

the TopVent® DGV covers a large area. Therefore, compared

to other systems, fewer units are needed to achieve the

required conditions.

2 dierent unit sizes and diverse output levels, as well as a

broad range of accessories make possible solutions tailored

to the requirements of each individual hall.

2.1 Unit construction

TopVent® DGV consists of the heater unit and the air injector.

Both components are bolted together, but can be dismantled

separately again.

2.2 Air distribution with the Air-Injector

The patented air distributor – called the Air-Injector – is the

core element. The air discharge angle is set by means of the

adjustable guide vanes. It depends on the air ow rate, the

mounting height and the temperature dierence between

the supply air and room air. The air is therefore blown into

the room vertically downward, conically or horizontally. This

ensures that:

■with each unit a large area of the hall can be covered,

■the occupied area is draught-free,

■the temperature stratication in the room is reduced, thus

saving energy.

6

TopVent ®DGV Use